INFINITI QX56 2008 Factory Service Manual

Manufacturer: INFINITI, Model Year: 2008, Model line: QX56, Model: INFINITI QX56 2008Pages: 4083, PDF Size: 81.73 MB

Page 2591 of 4083

LU-10

< ON-VEHICLE MAINTENANCE >

ENGINE OIL

Unit: (US qt, Imp qt)

CAUTION:

• The refill capacity depends on the engine oil temperature and drain time. Use these specifica-

tions for reference only.

• Always use the oil level gauge to determine when the proper amount of engine oil is in the engine.

8. Warm up engine and check area around drain plug and oil filter for oil leakage.

9. Stop engine and wait for 10 minutes.

10. Check engine oil level. Refer to LU-8, "

Inspection".

Drain and refill With oil filter change

6.5 (6 7/8, 5-3/4)

Without oil filter change 6.2 (6-1/2, 5-1/2)

Dry engine (engine overhaul) 7.6 (8, 6-3/4)

Revision: March 2010 2008 QX56

Page 2592 of 4083

OIL FILTERLU-11

< ON-VEHICLE MAINTENANCE >

C

DE

F

G H

I

J

K L

M A

LU

NP

O

OIL FILTER

Removal and InstallationINFOID:0000000001538846

REMOVAL

1. Remove the engine front undercover using power tool.

2. Remove the oil filter using Tool.

CAUTION:

• The oil filter is provided with a relief valve.Use Genuine NISSAN oil filter or equivalent.

• Be careful not to get burned when the engine and engine

oil are hot.

• When removing, prepare a s hop cloth to absorb any

engine oil leakage or spillage.

• Do not allow engine oil to adhere to the drive belts.

• Completely wipe off any engine oil that adheres to the engine and the vehicle.

INSTALLATION

1. Remove foreign materials adhering to the oil filter installation surface.

2. Apply engine oil to the oil seal circumference of the new oil filter.

3. Screw the oil filter manually until it touches the installation sur-

face, then tighten it by 2/3 turn. Or tighten to specification.

4. Inspect the engine for oil leakage. Follow the "INSPECTION AFTER INSTALLATION" procedure.

5. Install the engine front undercover using power tool.

INSPECTION AFTER INSTALLATION

1. Check the engine oil level. Refer to LU-8, "Inspection".

2. Start the engine and check for engine oil leakage.

3. Stop the engine and wait for 10 minutes.

4. Check the engine oil level and add engine oil as required. Tool number : KV10115801 (J-38956)

WBIA0388E

SMA010

Oil filter : 17.7 N·m (1.8 kg-m, 13 ft-lb)

SMA229B

Revision: March 2010

2008 QX56

Page 2593 of 4083

LU-12

< ON-VEHICLE REPAIR >

OIL COOLER

ON-VEHICLE REPAIR

OIL COOLER

Removal and InstallationINFOID:0000000001538847

WARNING:

Be careful not to burn yourself, as the engine oil and engine coolant are hot.

REMOVAL

1. Remove engine front undercover using power tool.

2. Disconnect water hoses, pinching hoses near oil cooler to prevent engine coolant from spilling.

CAUTION:

Do not spill engine coolant on the drive belt.

3. Remove oil filter. Refer to LU-11, "

Removal and Installation".

CAUTION:

Do not spill engine oi l on the drive belts.

4. Remove connector bolt, and remove oil cooler.

INSPECTION AFTER REMOVAL

Oil Cooler

Check oil cooler for cracks. Check oil cooler for clogging by blowing compressed air through engine coolant

inlet. If necessary, replace oil cooler assembly.

Relief Valve

Inspect relief valve for movement, cracks and breaks by pushing the ball. If replacement is necessary, remove

the valve by prying it out using a suitable tool. Install a new valve in place by tapping it.

INSTALLATION

WBIA0790E

1. Oil pan 2. Water hose 3. Water pipe

4. Water hose 5. Connector bolt 6. Oil filter

7. Oil cooler 8. O-ring 9. Relief valve

10. Water hose 11. Connector pipe 12. Gasket

A. To thermostat housing B. Refer to LU-11

C. To cylinder block

Revision: March 2010 2008 QX56

Page 2594 of 4083

OIL COOLERLU-13

< ON-VEHICLE REPAIR >

C

DE

F

G H

I

J

K L

M A

LU

NP

O

Installation is in the reverse order of removal, paying attention to the following:

• Confirm that no foreign objects are adhering to the sealing sur-

faces of the oil cooler or oil pan.

• Tighten the connecting bolt after aligning the stopper on the oil pan side with protrusion of the oil cooler.

INSPECTION AFTER INSTALLATION

1. Check levels and add engine oil and engine coolant. Refer to LU-8, "Inspection" and CO-10, "Inspection".

2. Start the engine, and check for leaks of engine oil and engine coolant.

3. Stop the engine and wait for 10 minutes.

4. Check engine oil level and engine coolant level again.

KBIA2500E

Revision: March 2010 2008 QX56

Page 2595 of 4083

LU-14

< ON-VEHICLE REPAIR >

OIL PUMP

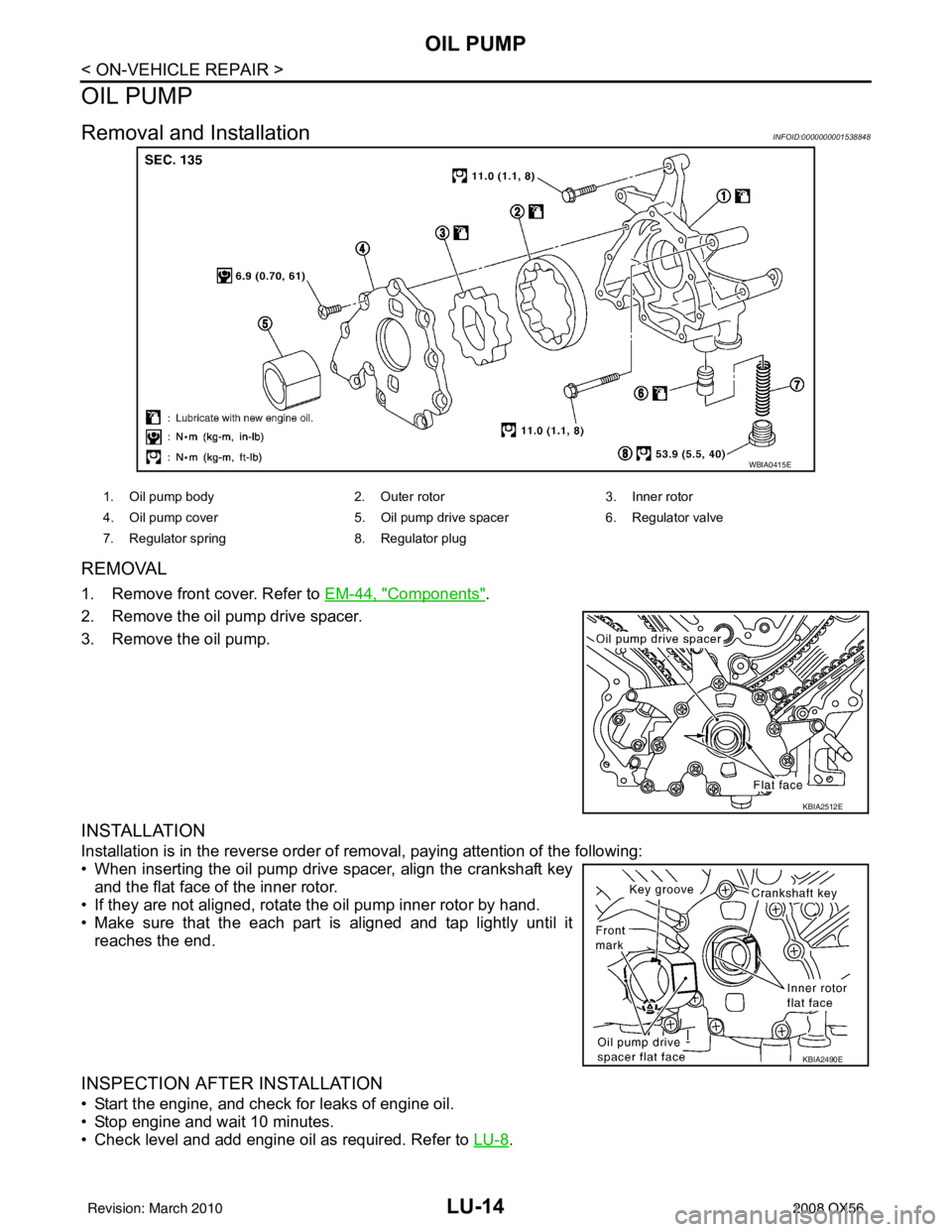

OIL PUMP

Removal and InstallationINFOID:0000000001538848

REMOVAL

1. Remove front cover. Refer to EM-44, "Components".

2. Remove the oil pump drive spacer.

3. Remove the oil pump.

INSTALLATION

Installation is in the reverse order of removal, paying attention of the following:

• When inserting the oil pump drive spacer, align the crankshaft key and the flat face of the inner rotor.

• If they are not aligned, rotate the oil pump inner rotor by hand.

• Make sure that the each part is aligned and tap lightly until it

reaches the end.

INSPECTION AFTER INSTALLATION

• Start the engine, and check for leaks of engine oil.

• Stop engine and wait 10 minutes.

• Check level and add engine oil as required. Refer to LU-8

.

WBIA0415E

1. Oil pump body2. Outer rotor 3. Inner rotor

4. Oil pump cover 5. Oil pump drive spacer 6. Regulator valve

7. Regulator spring 8. Regulator plug

KBIA2512E

KBIA2490E

Revision: March 2010 2008 QX56

Page 2596 of 4083

OIL PUMPLU-15

< DISASSEMBLY AND ASSEMBLY >

C

DE

F

G H

I

J

K L

M A

LU

NP

O

DISASSEMBLY AND ASSEMBLY

OIL PUMP

Disassembly and AssemblyINFOID:0000000001538849

DISASSEMBLY

1. Remove oil pump cover.

2. Remove inner rotor and outer rotor from oil pump body.

3. Remove the regulator plug, regulator spring and regulator valve.

INSPECTION AFTER DISASSEMBLY

Clearance of Oil Pump Parts

• Measure radial clearance using a suitable tool.

• Measure side clearance using suitable tools.

• Calculate the clearance between inner rotor and oil pump body as

follows.

1. Measure the outer diameter of protruded portion of inner rotor

(position 5) using suitable tool. Body to outer rotor (position 1)

: 0.114 - 0.200 mm (0.0045 - 0.0079 in)

Inner rotor to outer rotor tip (position 2)

: Below 0.180 mm (0.0071 in)

PBIC0139E

Body to inner rotor (position 3)

: 0.030 - 0.070 mm (0.0012 - 0.0028 in)

Body to outer rotor (position 4)

: 0.030 - 0.090 mm (0.0012 - 0.0035 in)

PBIC0140E

PBIC0141E

Revision: March 2010

2008 QX56

Page 2597 of 4083

LU-16

< DISASSEMBLY AND ASSEMBLY >

OIL PUMP

2. Measure the inner diameter of oil pump body to brazed portion(position 6) using suitable tool.

3. Calculate the clearance using the following formula. • (Clearance) = (Inner diameter of oil pump body) - (Outer diameter of inner rotor)

Regulator Valve Clearance

Check regulator valve to oil pump cover clearance using the following formula.

• (Clearance) = D

1 (Valve hole diameter) - D2 (Outer Diameter of

valve)

CAUTION:

• Coat regulator valve with engine oil.

• Check that it falls smoothly into the regulator valve hole by its own weight.

ASSEMBLY

Installation is in the reverse order of removal.

NOTE:

Install the inner rotor and outer rotor with the punched marks on the

oil pump cover side.

PBIC0142E

Inner rotor to brazed portion of housing

clearance

: 0.045 - 0.091 mm (0.0018 - 0.0036 in)

Regulator valve to oil pump cover

: 0.040 - 0.097 mm (0.0016 - 0.0038 in)

PBIC0143E

PBIC0144E

Revision: March 2010 2008 QX56

Page 2598 of 4083

SERVICE DATA AND SPECIFICATIONS (SDS)LU-17

< SERVICE DATA AND SPECIFICATIONS (SDS)

C

DE

F

G H

I

J

K L

M A

LU

NP

O

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

Standard and LimitINFOID:0000000001538850

OIL PRESSURE

Unit: kPa (kg/cm2

, psi)

OIL PUMP

Unit: mm (in)

REGULATOR VALVE

Unit: mm (in)

ENGINE OIL CAPACITY (APPROXIMATE)

Unit: (US qt, Imp qt)

Engine speed

rpm Approximate discharge oil pressure

Idle speed 2,000 More than 98 (1.0, 14)

More than 294 (3.0, 43)

Body to outer rotor ra dial clearance 0.114 - 0.200 (0.0045 - 0.0079)

Inner rotor to outer rotor tip clearance Below 0.180 (0.0071)

Body to inner rotor side clearance 0.030 - 0.070 (0.0012 - 0.0028)

Body to outer rotor side clearance 0.030 - 0.090 (0.0012 - 0.0035)

Inner rotor to brazed portion of housing clearance 0.045 - 0.091 (0.0018 - 0.0036)

Regulator valve to oil pump cover clearance0.040 - 0.097 (0.0016 - 0.0038)

Drain and refillWith oil filter change 6.5 (6 7/8, 5 3/4)

Without oil filter change

6.2 (6 1/2, 5 1/2)

Dry engine (engine overhaul) 7.6 (8, 6-3/4)

Revision: March 2010 2008 QX56

Page 2599 of 4083

MA-1

MAINTENANCE

C

DE

F

G H

I

J

K L

M B

MA

SECTION MA

N

O A

CONTENTS

MAINTENANCE

PREPARATION ....

........................................2

PRECAUTIONS .............................................. .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

2

PREPARATION ...................................................4

Special Service Tool ........................................... ......4

Commercial Service Tool ..........................................4

ON-VEHICLE MAINTENANCE .....................6

GENERAL MAINTE NANCE ........................... .....6

General Maintenance .......................................... ......6

PERIODIC MAINTENANCE ................................8

Introduction of Periodic Maintenance .................. ......8

Maintenance for Off-road Driving (4WD only) ...........8

Schedule 1 ................................................................8

Schedule 2 ..............................................................10

RECOMMENDED FLUIDS AND LUBRI-

CANTS ................................................................

12

Fluids and Lubricants .......................................... ....12

Engine Oil Recommendation ..................................12

Anti-Freeze Coolant Mixture Ratio ..........................13

ENGINE MAINTENANCE ...................................14

Checking Drive Belts ........................................... ....14

Changing Engine Coolant .................................... ....14

Checking Fuel Line ..................................................17

Changing Fuel Filter ................................................17

Changing Engine Air Cleaner Filter .........................17

Changing Engine Oil ................................................18

Changing Oil Filter ...................................................18

Changing Spark Plugs .............................................20

Checking EVAP Vapor Line .....................................21

CHASSIS AND BODY MAINTENANCE ...........22

Changing In-cabin Microfilter ............................... ....22

Checking Exhaust System .......................................23

Checking Automatic Transmission Fluid (ATF) .......23

Changing Automatic Transmission Fluid (ATF) .......25

Changing Transfer Fluid ..........................................25

Checking Transfer Fluid ..........................................26

Checking Propeller Shaft .........................................26

Checking Final Drive Oil ..........................................26

Changing Final Drive Oil ..........................................27

Adjustment ...............................................................27

Tire Rotation ............................................................29

Checking Brake Fluid Level and Leaks ...................29

CheckingBrake Line and Cables .............................30

Checking Disc Brake ...............................................30

Checking Steering Gear and Linkage ......................30

Checking Power Steering Fluid and Line ................31

Checking Axle and Suspension Parts .....................31

Lubricating Locks, Hinges and Hood Latches .........33

Checking Seat Belts, Buckles, Retractors, An-

chors and Adjusters ............................................. ....

33

Revision: March 2010 2008 QX56

Page 2600 of 4083

MA-2

< PREPARATION >

PRECAUTIONS

PREPARATION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000006054111

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SR and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution Necessary for Steering W heel Rotation After Battery Disconnect

INFOID:0000000004900832

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecting both battery cables with the ignition knob in the

″LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS, an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be rotated.

4. Perform the necessary repair operation.

Revision: March 2010 2008 QX56