check engine INFINITI QX56 2008 Factory Owner's Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: QX56, Model: INFINITI QX56 2008Pages: 4083, PDF Size: 81.73 MB

Page 578 of 4083

![INFINITI QX56 2008 Factory Owners Manual PRECAUTIONSBRC-111

< PRECAUTION > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

5. When the repair work is completed, return the ignition switch to the ″LOCK ″ position before connecting

the ba INFINITI QX56 2008 Factory Owners Manual PRECAUTIONSBRC-111

< PRECAUTION > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

5. When the repair work is completed, return the ignition switch to the ″LOCK ″ position before connecting

the ba](/img/42/57030/w960_57030-577.png)

PRECAUTIONSBRC-111

< PRECAUTION > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

5. When the repair work is completed, return the ignition switch to the ″LOCK ″ position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of al l control units using CONSULT-III.

Precaution for Brake SystemINFOID:0000000001604543

CAUTION:

• Always use recommended brake fluid. Refer to MA-12, "

Fluids and Lubricants".

• Never reuse drained brake fluid.

• Be careful not to splash brake fluid on painted areas; it may cause paint damage. If brake fluid is

splashed on painted areas, wash it away with water immediately.

• To clean or wash all parts of master cylin der and disc brake caliper, use clean brake fluid.

• Never use mineral oils such as gasoline or kerosen e. They will ruin rubber parts of the hydraulic sys-

tem.

• Use flare nut wrench when removing and installing brake

tube.

• If a brake fluid leak is found, the part must be disassembled

without fail. Then it has to be replaced with a new one if a

defect exists.

• Turn the ignition switch OFF and remove the connector of the ABS actuator and electric unit (con trol unit) or the battery ter-

minal before performing the work.

• Always torque brake lines when installing.

• Burnish the brake contact surf aces after refinishing or replac-

ing rotors, after replacing pads, or if a soft pedal occurs at

very low mileage.

Refer to BR-30, "

Brake Burnishing Procedure" (front disc brake) or BR-35, "Brake Burnishing Proce-

dure" (rear disc brake).

WARNING:

• Clean brake pads and shoes with a waste cl oth, then wipe with a dust collector.

Precaution for Brake ControlINFOID:0000000001604544

• During ABS operation, the brake pedal may vibrate lightly and a mechanical noise may be heard. This is

normal.

• Just after starting vehicle, the brake pedal may vibrate or a motor operating noise may be heard from engine

compartment. This is a normal status of operation check.

• Stopping distance may be longer than that of vehicles without ABS when vehicle drives on rough, gravel, or snow-covered (fresh, deep snow) roads.

• When an error is indicated by ABS or another warning lamp, collect all necessary information from customer (what symptoms are present under what conditions) and check for simple causes before starting diagnosis.

Besides electrical system inspection, check boos ter operation, brake fluid level, and fluid leaks.

• If incorrect tire sizes or types are installed on the vehicle or brake pads are not Genuine NISSAN parts, stop-

ping distance or steering stability may deteriorate.

• If there is a radio, antenna or related wiring near control module, ABS function may have a malfunction or

error.

• If aftermarket parts (car stereo, CD player, etc.) have been installed, check for incidents such as harness pinches, open circuits or improper wiring.

• If the following components are replaced with non-genuine components or modified, the VDC OFF indicator lamp and SLIP indicator lamp may turn on or the VDC system may not operate properly. Components

related to suspension (shock absorbers, struts, springs , bushings, etc.), tires, wheels (exclude specified

size), components related to brake system (pads, roto rs, calipers, etc.), components related to engine (muf-

fler, ECM, etc.), components related to body reinforcement (roll bar, tower bar, etc.).

• Driving with broken or excessively worn suspensi on components, tires or brake system components may

cause the VDC OFF indicator lamp and the SLIP indicator lamp to turn on, and the VDC system may not

operate properly.

• When the TCS or VDC is activated by sudden acceleration or sudden turn, some noise may occur. The noise is a result of the normal operation of the TCS and VDC.

• When driving on roads which have extreme slopes (such as mountainous roads) or high banks (such as sharp curves on a freeway), the VDC may not operate no rmally, or the VDC warning lamp and the SLIP indi-

cator lamp may turn on. This is not a problem if normal operation can be resumed after restarting the engine.

SBR686C

Revision: March 2010 2008 QX56

Page 579 of 4083

![INFINITI QX56 2008 Factory Owners Manual BRC-112

< PRECAUTION >[VDC/TCS/ABS]

PRECAUTIONS

• Sudden turns (such as spin turns, acceleration turns), drifting, etc. with VDC turned off may cause the yaw

rate/side/decel G sensor to indicate a p INFINITI QX56 2008 Factory Owners Manual BRC-112

< PRECAUTION >[VDC/TCS/ABS]

PRECAUTIONS

• Sudden turns (such as spin turns, acceleration turns), drifting, etc. with VDC turned off may cause the yaw

rate/side/decel G sensor to indicate a p](/img/42/57030/w960_57030-578.png)

BRC-112

< PRECAUTION >[VDC/TCS/ABS]

PRECAUTIONS

• Sudden turns (such as spin turns, acceleration turns), drifting, etc. with VDC turned off may cause the yaw

rate/side/decel G sensor to indicate a problem. This is not a problem if normal operation can be resumed

after restarting the engine.

Precaution for CAN SystemINFOID:0000000001604545

• Do not apply voltage of 7.0V or higher to terminal to be measured.

• Maximum open terminal voltage of test er in use must be less than 7.0V.

• Before checking harnesses, turn ignition sw itch OFF and disconnect battery negative cable.

• Area to be repaired must be soldered and wrapped with tape. Make sure that fraying of twisted wire is within 110 mm (4.33 in).

• Do not make a bypass connection to repaired area. (If the circuit is bypassed, characteristics of twisted wire will be lost.)

PKIA0306E

PKIA0307E

Revision: March 2010 2008 QX56

Page 645 of 4083

CCS

INSPECTION AND ADJUSTMENTCCS-5

< BASIC INSPECTION >

C

DE

F

G H

I

J

K L

M B

N P A

INSPECTION AND ADJUSTMENT

ADDITIONAL SERVICE WHEN REPLACING CONTROL UNIT

ADDITIONAL SERVICE WHEN REPL ACING CONTROL UNIT : Description

INFOID:0000000001731800

Always perform the laser beam aiming adjustment after repl acing the ICC unit. In addition, test the ICC sys-

tem operations to see if it functions normally.

ADDITIONAL SERVICE WHEN REPLACING CONTROL UNIT : Special Repair Re-

quirement

INFOID:0000000001731801

1.LASER BEAM AIMING ADJUSTMENT

Adjust laser beam aiming. Refer to CCS-5, "

LASER BEAM AIMING ADJUSTMENT : Outline of Laser Beam

Aiming Adjustment Procedure".

>> GO TO 2

2.ICC SYSTEM ACTION TEST

1. Perform the ICC system operation test. Refer to CCS-8, "

ACTION TEST : ICC System Running Test".

2. Check that the ICC system operates normally.

>> INSPECTION END.

LASER BEAM AIMI NG ADJUSTMENT

LASER BEAM AIMING ADJUSTMENT : Outlin e of Laser Beam Aiming Adjustment

Procedure

INFOID:0000000001756724

CAUTION:

• The laser beam aiming adjustment can not be performed without CONSULT-III.

• The laser beam aiming adjustment must be performed every time the ICC sensor is removed,

installed or has been moved as a result of a collision.

1. Prepare the vehicle and the work area.

2. Set up the ICC target board. For details, refer to Technical Service Bulletin.

3. Adjust the sensor following the procedure on CONSULT-III.

4. Check system operation after the adjustment.

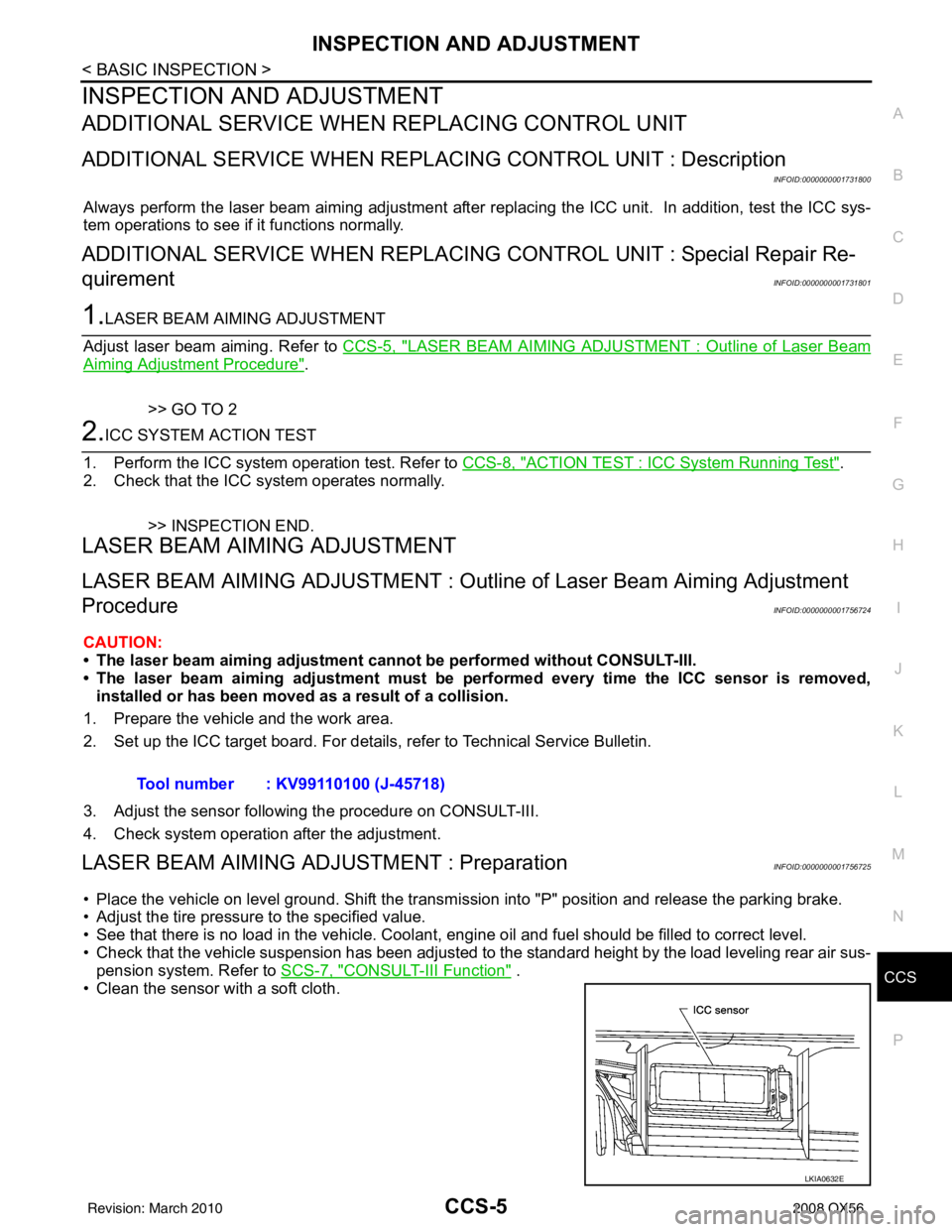

LASER BEAM AIMING ADJU STMENT : PreparationINFOID:0000000001756725

• Place the vehicle on level ground. Shift the transmi ssion into "P" position and release the parking brake.

• Adjust the tire pressure to the specified value.

• See that there is no load in the vehicle. Coolant , engine oil and fuel should be filled to correct level.

• Check that the vehicle suspension has been adjusted to the standard height by the load leveling rear air sus-

pension system. Refer to SCS-7, "

CONSULT-III Function" .

• Clean the sensor with a soft cloth. Tool number : KV99110100 (J-45718)

LKIA0632E

Revision: March 2010

2008 QX56

Page 649 of 4083

CCS

INSPECTION AND ADJUSTMENTCCS-9

< BASIC INSPECTION >

C

DE

F

G H

I

J

K L

M B

N P A

• When there is no vehicle ahead, drive at the set speed steadily.

• When there is a vehicle ahead, control to maintain distance from the vehicle ahead, watching its speed.

• The set vehicle speed is displayed on the ICC system indicator in the combination meter.

CHECK FOR INCREASE OF THE CRUISING SPEED

1. Set vehicle-to-vehicle distance control mode at desired speed.

2. Check if the set speed increases by 1.6 km /h (1 MPH) as ACCEL/RES switch is pushed.

NOTE:

The maximum set speed of the vehicle-to-vehicl e distance control mode is 144 km/h (89 MPH).

CHECK FOR DECREASE OF THE CRUISING SPEED

1. Set vehicle-to-vehicle distance control mode at desired speed.

2. Check if the set speed decreases by 1.6 km /h (1 MPH) as COAST/SET switch is pushed.

NOTE:

• Vehicle-to-vehicle distance control mode is automatica lly turned off when the driving speed lowers to 32 km/

h (20 MPH) due to the deceleration of the vehicle ahead.

• The minimum set speed of the vehicle-to-vehicle distance control mode is 40 km/h (25 MPH).

CHECK FOR THE CANCELLATION OF VEHICLE-TO-VEHICLE DISTANCE CONTROL MODE (NORMAL DRIV-

ING CONDITION) IN THE FOLLOWING CASES:

1. When the brake pedal is depressed after the system is turned on.

2. When the selector lever is shifted to the "N" (Neutral) position.

3. When the system is turned off.

4. When CANCEL switch is operated.

CHECK FOR RESTORING THE SPEED THAT IS SET BY VEHICLE-TO-VEHICLE DI STANCE CONTROL MODE

BEFORE CANCELLATION

1. Cancel the system by depressing the brake. Then, check that the speed before cancellation is restored

when pressing ACCEL/RES switch with vehi cle speed at 40 km/h (25 MPH) or above.

2. Cancel the system by shifting the selector lever to “N”. Then, check if the speed set before the cancella-

tion is restored when ACCEL/RES switch is pressed.

3. Check if the speed previously set is restored w hen ACCEL/RES switch is operated when driving 40 km/h

(25 MPH) or above, after canceling vehicle-to-v ehicle distance control mode by operating the CANCEL

switch.

CHECK ON/OFF SWITCH OPERATION

1. Start the engine. Then, check that the following operations are performed correctly.

2. Vehicle-to-vehicle distance control mode is displayed when ON/ OFF switch is pressed ON. Vehicle-to-vehicle distance control

mode goes off when ON/OFF switch is turned to OFF.

3. Turn off the ignition switch while ON/OFF switch is ON. Turn the ignition switch back to ON and confirm that CRUISE lamp and

ICC system display are OFF.

CHECK FOR ACCEL/RES, COAST/SET, CANCEL SWITCHES

1. Check if ACCEL/RES, COAST/SET, CANCEL sw itches operate smoothly.

2. Check if switch buttons r ebound as the buttons are released.

CHECK FOR DISTANCE SWITCH

1. Start the engine.

2. Press the ON/OFF switch for less than 1.5 seconds.

3. Press the DISTANCE switch.

4. Check if the set distance indicator changes display in order of:

(long) →(middle)→ (short).

NOTE:

ALOIA0012ZZ

Revision: March 2010 2008 QX56

Page 650 of 4083

CCS-10

< BASIC INSPECTION >

INSPECTION AND ADJUSTMENT

The set distance indicator shows long immediately after the engine starts.

CONVENTIONAL (FIXED SPEED) CRUISE CONTROL MODE

SET CHECKING

1. Press the ON/OFF switch for more than 1.5 seconds.

2. Drive the vehicle between 40 km/h (25 MPH) and 144 km/h (89 MPH).

3. Push the COAST/SET switch.

4. Confirm that the desired speed is set when the COAST/SET switch is released.

NOTE:

• ICC system display in the combination meter shows nothing.

CHECK FOR INCREASE OF THE CRUISING SPEED

1. Set the conventional (fixed speed) cruise control mode at desired speed.

2. Check if the set speed increases by 1.6 km /h (1 MPH) as ACCEL/RES switch is pushed.

NOTE:

• If the ACCEL/RES switch is held, the vehicl e speed increases until the switch is released.

• The maximum set speed is 144 km/h (89 MPH).

CHECK FOR DECREASE OF THE CRUISING SPEED

1. Set the conventional (fixed speed) cruise control mode at desired speed.

2. Check if the set speed decreases by 1.6 km /h (1 MPH) as COAST/SET switch is pushed.

NOTE:

• Conventional (fixed speed) cruise control mode is autom atically turned off when the driving speed lowers to

32 km/h (20 MPH).

• The lowest set speed is 40 km/h (25 MPH).

CHECK FOR THE CANCELLATION OF CONVENTIONAL (FIXED SPEED) CRUISE CO NTROL MODE (NORMAL

DRIVING CONDITION) IN THE FOLLOWING CASES:

Refer to "CHECK FOR THE CANCELLATION OF VEHICLE-TO-VEHICLE DISTANCE CONTROL MODE

(NORMAL DRIVING CONDITION) IN THE FOLLOWING CASES:" .

CHECK FOR RESTORING THE SPEED TH AT IS SET BY CONVENTIONAL (FIXED SPEED) CRUISE CONTROL

MODE BEFORE ICC CANCELLATION

Refer to "CHECK FOR RESTORING THE SPEED THAT IS SET BY VEHICLE-TO-VEHICLE DISTANCE

CONTROL MODE BEFORE CANCELLATION" .

CHECK ON/OFF SWITCH OPERATION

SKIA6178E

Revision: March 2010 2008 QX56

Page 651 of 4083

CCS

INSPECTION AND ADJUSTMENTCCS-11

< BASIC INSPECTION >

C

DE

F

G H

I

J

K L

M B

N P A

1. Start the engine. Then, check that the following operations are performed correctly.

2. CRUISE lamp illuminates and ICC system indicator goes off when ON/OFF switch is pressed ON for more than 1.5 seconds.

The CRUISE lamp goes off when ON/OFF switch is turned to

OFF.

3. Turn off the ignition switch while ON/OFF switch is ON. Turn the ignition switch back to ON and confirm that CRUISE lamp is

OFF.

CHECK FOR ACCEL/RES, COAST/SET, CANCEL SWITCHES

1. Check if ACCEL/RES, COAST/SET, CANCEL sw itches operate smoothly.

2. Check if switch buttons r ebound as the buttons are released.

ALOIA0012ZZ

Revision: March 2010 2008 QX56

Page 657 of 4083

CCS

DIAGNOSIS SYSTEM (ICC SENSOR INTEGRATED UNIT)

CCS-17

< FUNCTION DIAGNOSIS >

C

D E

F

G H

I

J

K L

M B

N P A

DIAGNOSIS SYSTEM (ICC SENSOR INTEGRATED UNIT)

Diagnosis DescriptionINFOID:0000000001731813

The ICC system includes the on board self-diagnosis functi on that allows the technician to check for any trou-

ble codes on the ICC system display by operating the ICC steering switch.

ON BOARD SELF-DIAGNOSIS OPERETION PROCEDURE

1. Turn ignition switch OFF.

2. Start engine.

3. From 5 seconds through 15 seconds after start engine, press

RESUME/ACCELERATE switch 5 times, and SET/COAST

switch 5 times.

NOTE:

• Never turn the MAIN switch ON.

• When operation above is not completed from 5 secondsthrough 15 seconds, start again from above go to 1.

4. When the on board self-diagnosis starts up, the ICC system display shows DTC No. (1) at the set vehicle speed indicator. Refer to CCS-55, "

Diagnostic Trouble Code (DTC) Chart".

NOTE:

• DTC will disappear after 5 minutes.

• When more than one malfunction is detected, a maxi mum of 3 code numbers can be stored; the latest

malfunction will be displayed first.

WHEN ON BOARD SELF-DIAGNOSIS WILL NOT START UP

If the on board self-diagnosis does not start up, check the following items.

PKIB8371E

JSOIA0008GB

Assumed abnormal point Inspection item

ICC steering switch malfunction. Perform the inspection for DTC 46 OPERATION SW CIRC. Refer to CCS-30, "

DTC

46 OPERATION SW CIRC" .

Harness malfunction between ICC

steering switch and ECM.

ECM malfunction.

ICC unit malfunction. • Inspect the ICC sensor power and ground circuits. Refer to

CCS-25, "

DTC 31

POWER SUPPLY CIR1, DTC 34 POWER SUPPLY CIR2"

• Perform the self-diagnosis for the ICC unit with CONSULT-III, and check the diag-

nosis results. Refer to CCS-55, "

Diagnostic Trouble Code (DTC) Chart".

Revision: March 2010 2008 QX56

Page 658 of 4083

CCS-18

< FUNCTION DIAGNOSIS >

DIAGNOSIS SYSTEM (ICC SENSOR INTEGRATED UNIT)

ERASING ON BOARD SELF-DIAGNOSIS

1. Stop the vehicle and turn ignition switch OFF.

2. Start engine and start on board self-diagnosis.

3. During on board self-diagnosis, press CANCEL switch 5 times,

and DISTANCE switch 5 times in this order.

NOTE:

• Press them within 10 seconds after pressing CANCEL switch

at first.

• When operation is not completed within 10 seconds, start again from step 2 above.

4. DTC 55 will be shown. NOTE:

DTC of an existing malfunction will not be erased.

5. Turn ignition switch OFF to exit the diagnosis.

CONSULT-III Function (ICC)INFOID:0000000001731814

DESCRIPTION

CONSULT-III can display each diagnostic item us ing the diagnostic test modes shown following.

WORK SUPPORT

Cause of Auto-Cancel Display Item List

×: Applicable

PKIB8373E

Test mode Function

Work Support • Monitors aiming direction to facilitate laser beam aiming operation.

• Indicates causes of automatic cancellation of the ICC system.

Self Diagnostic Result Displays malfunctioning system memorized in ICC sensor integrated unit.

Data Monitor Displays real-time input/output data of ICC sensor integrated unit.

Active Test Enables operation check of electrical loads by sending driving signal to them.

ECU Identification Displays part number of ICC sensor integrated unit.

Work support item Function

CAUSE OF AUTO-CANCEL Indicates causes of automatic cancellation of the ICC system.

LASER BEAM ADJUST Outputs laser beam, calculates dislocation of the beam, and indicates adjustment direction.

For the adjustment procedure, refer to

CCS-5, "

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT : Special Repair Requirement".

Cause of cancellationVehicle-to-vehi-

cle distance

control modeConventional

(fixed speed)

cruise control

mode

Description

OPERATING WIPER ×Windshield wipers were operated at HI or LO speed operation.

OPERATING ABS ×ABS function was operated.

OPERATING TCS ××TCS function was operated.

OPERATING VDC ××VDC function was operated.

OPE SW VOLT CIRC ××Outside the standard control switch input voltage was detected.

ECM CIRCUIT ××ECM did not permit ICC operation.

LASER SUN BEAM ×Intense light such as sunlight entered ICC sensor integrated unit

light sensing part.

LASER TEMP ×Temperature around ICC sensor integrated unit became low.

OP SW DOUBLE TOUCH ××ICC steering switches were pressed at the same time.

WHL SPD ELEC NOISE ××Wheel speed sensor signal caught electromagnetic noise.

Revision: March 2010 2008 QX56

Page 685 of 4083

CCS

DTC109 LASER HIGH TEMPCCS-45

< COMPONENT DIAGNOSIS >

C

DE

F

G H

I

J

K L

M B

N P A

DTC109 LASER HIGH TEMP

DTC 109 LASER HIGH TEMPINFOID:0000000001744720

1.CHECK SYMPTOM

Inspect engine cooling system.

Did the engine overheat?

YES >> • Repair cooling system. • Erase DTC and perform ICC system running test. Refer to CCS-8, "

ACTION TEST : ICC Sys-

tem Running Test". Then perform self-diagnosis of ICC system again.

NO >> • Replace ICC sensor and adjust laser beam aiming. Refer to CCS-71, "

ICC Sensor".

• Erase DTC, then perform ICC system running test. Refer to CCS-8, "

ACTION TEST : ICC Sys-

tem Running Test". Then perform self-diagnosis of ICC system again.

Revision: March 2010 2008 QX56

Page 705 of 4083

CCS

THE SYSTEM DOES NOT DETECT THE VEHICLE AHEAD AT ALL

CCS-65

< SYMPTOM DIAGNOSIS >

C

D E

F

G H

I

J

K L

M B

N P A

THE SYSTEM DOES NOT DETECT THE VEHICLE AHEAD AT ALL

Diagnosis ProcedureINFOID:0000000001744729

1.VISUAL CHECK

With ignition switch turned ON (engine not started), che ck that all indicator lamps in ICC system display are

continuously lit. (Check for a missing segment in preceding vehicle detection display.)

Does the display operate normally?

YES >> GO TO 2

NO >> Check combination meter. Refer to MWI-24, "

Diagnosis Description".

2. VISUAL CHECK

Check ICC sensor window for contamination and foreign materials.

Is the ICC sensor window clean and free of obstruction?

YES >> If any contamination or foreign materials are found, remove them. Perform ICC system running

test. Refer to CCS-8, "

ACTION TEST : ICC System Running Test".

NO >> GO TO 3

3.VISUAL CHECK

Check ICC sensor window for cracks and scratches.

Is the ICC sensor window intact?

YES >> GO TO 4

NO >> • Replace ICC sensor and perform laser beam aiming adjustment. Refer to CCS-71, "

ICC Sen-

sor".

• Perform ICC system running test. Refer to CCS-8, "

ACTION TEST : ICC System Running Test".

4.ADJUST ICC SENSOR

• After performing laser beam aiming adjustment, perform ICC system running test. Refer to CCS-8, "

ACTION

TEST : ICC System Running Test". Check that preceding vehicle detection performance has been improved.

Is the ICC system operating normally?

YES >> INSPECTION END.

NO >> • Replace ICC sensor and perform laser beam aiming adjustment. Refer to CCS-71, "

ICC Sen-

sor".

• Perform ICC system running test. Refer to CCS-8, "

ACTION TEST : ICC System Running Test".

Revision: March 2010 2008 QX56