weight INFINITI QX56 2008 Factory Owner's Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: QX56, Model: INFINITI QX56 2008Pages: 4083, PDF Size: 81.73 MB

Page 2163 of 4083

IDENTIFICATION INFORMATIONGI-21

< FEATURES OF NEW MODEL >

C

DE

F

G H

I

J

K L

M B

GI

N

O P

Identification NumberINFOID:0000000001559940

VEHICLE IDENTIFICATION NUMBER ARRANGEMENT

1. Emission control information label/ vacuum hose diagram 2. Tire placard 3. F.M.V.S.S./C.M.V.S.S. certification

label

4. Vehicle identification number plate 5. Air conditioner specification label

AWAIA0026GB

Position Character Qualifier Definition

1 5N3 Manufacturer 5N3: USA produced multi-purpose vehicle

2

3

4 A Engine type A: VK56DE

5 A0 Model code A0: Infiniti QX56

6

7 8 Body type 8: 4 door wagon

8D Gross vehicle

weight ratingD: 2WD, 4-wheel ABS, Class F

C: 4WD, 4-wheel ABS, Class F

9 * Check digit (0 to 9 or X) The code for the check digit is determined by a mathematical com-

putation.

10 8 Model year 2008

11 NManufacturing

plant

N: Canton Mississippi

12

XXXXXX Vehicle serial num-

ber Chassis number

13

14

15

16

17

Revision: March 2010

2008 QX56

Page 2167 of 4083

PRECAUTIONSGI-25

< PRECAUTION >

C

DE

F

G H

I

J

K L

M B

GI

N

O P

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be

rotated.

4. Perform the necessary repair operation.

5. When the repair work is completed, return the ignition switch to the ″LOCK ″ position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of al l control units using CONSULT-III.

Procedures without Cowl Top CoverINFOID:0000000001539208

When performing the procedure after removing cowl top cover, cover

the lower end of windshield with urethane, etc.

General PrecautionsINFOID:0000000001539209

• Do not operate the engine for an extended period of time without

proper exhaust ventilation.

Keep the work area well ventilated and free of any inflammable

materials. Special care should be taken when handling any inflam-

mable or poisonous materials, such as gasoline, refrigerant gas,

etc. When working in a pit or ot her enclosed area, be sure to prop-

erly ventilate the area before working with hazardous materials.

Do not smoke while working on the vehicle.

• Before jacking up the vehicle, apply wheel chocks or other tire blocks to the wheels to prevent t he vehicle from moving. After jack-

ing up the vehicle, support the vehicle weight with safety stands at

the points designated for proper lifting before working on the vehi-

cle.

These operations should be done on a level surface.

• When removing a heavy component such as the engine or tran-

saxle/transmission, be careful not to lose your balance and drop

them. Also, do not allow them to strike adjacent parts, especially

the brake tubes and master cylinder.

PIIB3706J

SGI285

SGI231

Revision: March 2010 2008 QX56

Page 2217 of 4083

HA-12

< PRECAUTION >

PRECAUTIONS

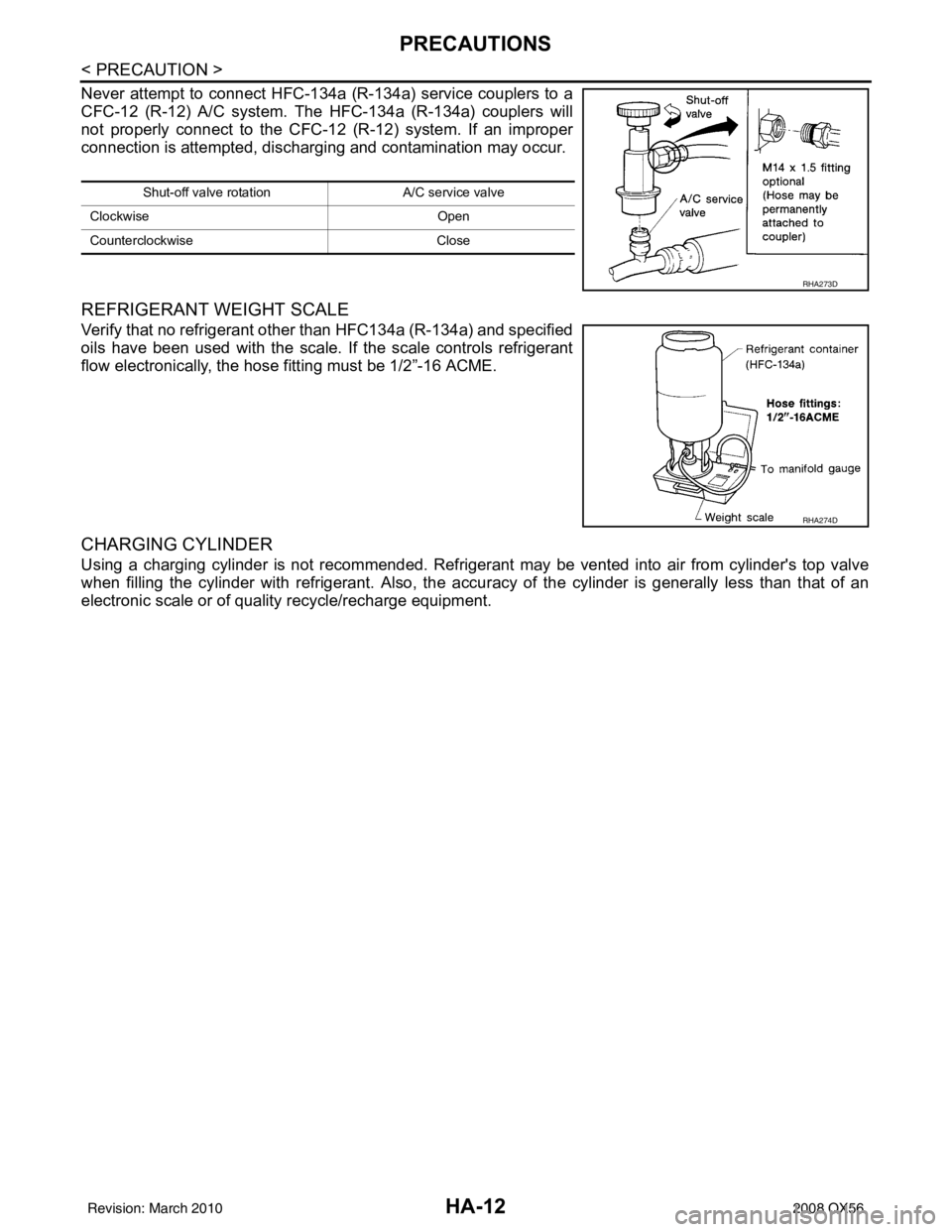

Never attempt to connect HFC-134a (R-134a) service couplers to a

CFC-12 (R-12) A/C system. The HFC-134a (R-134a) couplers will

not properly connect to the CFC-12 (R-12) system. If an improper

connection is attempted, discharging and contamination may occur.

REFRIGERANT WEIGHT SCALE

Verify that no refrigerant other than HFC134a (R-134a) and specified

oils have been used with the scale. If the scale controls refrigerant

flow electronically, the hose fitting must be 1/2”-16 ACME.

CHARGING CYLINDER

Using a charging cylinder is not recommended. Refrigerant may be vented into air from cylinder's top valve

when filling the cylinder with refrigerant. Also, the accu racy of the cylinder is generally less than that of an

electronic scale or of quality recycle/recharge equipment.

Shut-off valve rotati on A/C service valve

Clockwise Open

Counterclockwise Close

RHA273D

RHA274D

Revision: March 2010 2008 QX56

Page 2221 of 4083

HA-16

< PREPARATION >

PREPARATION

Commercial Service Tool

INFOID:0000000001516640

—

(J-39699)

Refrigerant weight scale For measuring of refrigerant

Fitting size-Thread size

• 1/2”-16 ACME

—

(J-39649)

Vacuum pump

(Including the isolator valve) Capacity:

• Air displacement: 4 CFM

• Micron rating: 20 microns

• Oil capacity: 482 g (17 oz)

Fitting size-Thread size

• 1/2”-16 ACME

Tool number

(Kent-Moore No.)

Tool name

Description

S-NT200

S-NT203

Tool name

Description

(J-41810-NI)

Refrigerant identifier equipment (R-

134a) For checking refrigerant purity and

system contamination

Power tool Loosening bolts and nuts

RJIA0197E

PBIC0190E

Revision: March 2010 2008 QX56

Page 2226 of 4083

REFRIGERATION SYSTEMHA-21

< ON-VEHICLE MAINTENANCE >

C

DE

F

G H

J

K L

M A

B

HA

N

O P

1. Shut-off valve 2. A/C service valve3. Recovery/recycling equipment

4. Refrigerant container (HFC-134a) 5. Weight scale (J-39650) 6. Evacuating vacuum pump (J-39699)

7. Manifold gauge set (J-39183)

*1 HA-22, "

Maintenance of Oil Quantity

in Compressor"

*3HAC-113, "Performance Chart"*5 HA-4, "Contaminated Refrigerant"

*2HAC-109, "Component Function

Check"

*4HAC-110, "Diagnostic Work Flow"

WJIA1923E

Revision: March 2010 2008 QX56

Page 2597 of 4083

LU-16

< DISASSEMBLY AND ASSEMBLY >

OIL PUMP

2. Measure the inner diameter of oil pump body to brazed portion(position 6) using suitable tool.

3. Calculate the clearance using the following formula. • (Clearance) = (Inner diameter of oil pump body) - (Outer diameter of inner rotor)

Regulator Valve Clearance

Check regulator valve to oil pump cover clearance using the following formula.

• (Clearance) = D

1 (Valve hole diameter) - D2 (Outer Diameter of

valve)

CAUTION:

• Coat regulator valve with engine oil.

• Check that it falls smoothly into the regulator valve hole by its own weight.

ASSEMBLY

Installation is in the reverse order of removal.

NOTE:

Install the inner rotor and outer rotor with the punched marks on the

oil pump cover side.

PBIC0142E

Inner rotor to brazed portion of housing

clearance

: 0.045 - 0.091 mm (0.0018 - 0.0036 in)

Regulator valve to oil pump cover

: 0.040 - 0.097 mm (0.0016 - 0.0038 in)

PBIC0143E

PBIC0144E

Revision: March 2010 2008 QX56

Page 2625 of 4083

CHASSIS AND BODY MAINTENANCEMA-27

< ON-VEHICLE MAINTENANCE >

C

DE

F

G H

I

J

K L

M B

MA

N

O A

2. Check the oil level as shown. A

dd the specified oil as necessary.

NOTE:

Rear final drive shown, front final drive similar

3. Install the filler plug and tighten to specification.

Changing Final Drive OilINFOID:0000000001606187

1. Remove the filler plug.

2. Remove the drain plug and drain the final drive oil.

3. Apply sealant to the drain plug threads. • Use High Performance Thread Sealant or equivalent. Refer to GI-15, "

Recommended Chemical Prod-

ucts and Sealants" .

4. Install the drain plug and tighten to specification.

5. Refill the rear final drive with new specified oil.

6. Check the oil level. NOTE:

Rear final drive shown, front final drive similar

7. Install the filler plug and tighten to specification.

AdjustmentINFOID:0000000006059786

BALANCING WHEELS (ADH ESIVE WEIGHT TYPE)

Preparation Before Adjustment

Remove inner and outer balance weights from the r oad wheel using releasing agent, remove double-faced

adhesive tape from the road wheel.

CAUTION:

• Be careful not scratch the road wheel during removal. Oil grade and viscosity : Refer to

MA-12, "

Fluids and

Lubricants" .

LLIA0068E

Filler plug : Refer to DLN-214, "Disassembly and Assembly" (FFD), DLN-251, "Disassem-

bly and Assembly" (RFD).

Drain plug : Refer to DLN-214, "

Disassembly and Assembly" (FFD), DLN-251, "Dis-

assembly and Assembly" (RFD).

Oil grade and capacity : Refer to MA-12, "

Fluids and Lubricants" .

LLIA0068E

Filler plug : Refer to DLN-214, "Disassembly and Assembly" (FFD), DLN-251, "Disassem-

bly and Assembly" (RFD).

Revision: March 2010 2008 QX56

Page 2626 of 4083

MA-28

< ON-VEHICLE MAINTENANCE >

CHASSIS AND BODY MAINTENANCE

• After removing double-faced adhesive tape, wipe clean traces of releasing agent from the roadwheel.

Wheel Balance Adjustment

• If a balancer machine has an adhesive weight mode se tting, select the adhesive weight mode setting and

skip Step 2. below. If a balancer machine only has the clip-on (rim flange) weight mode setting, follow Step 2.

to calculate the correct size adhesive weight.

1. Set road wheel on balancer machine using the center hole as a guide. Start the balancer machine.

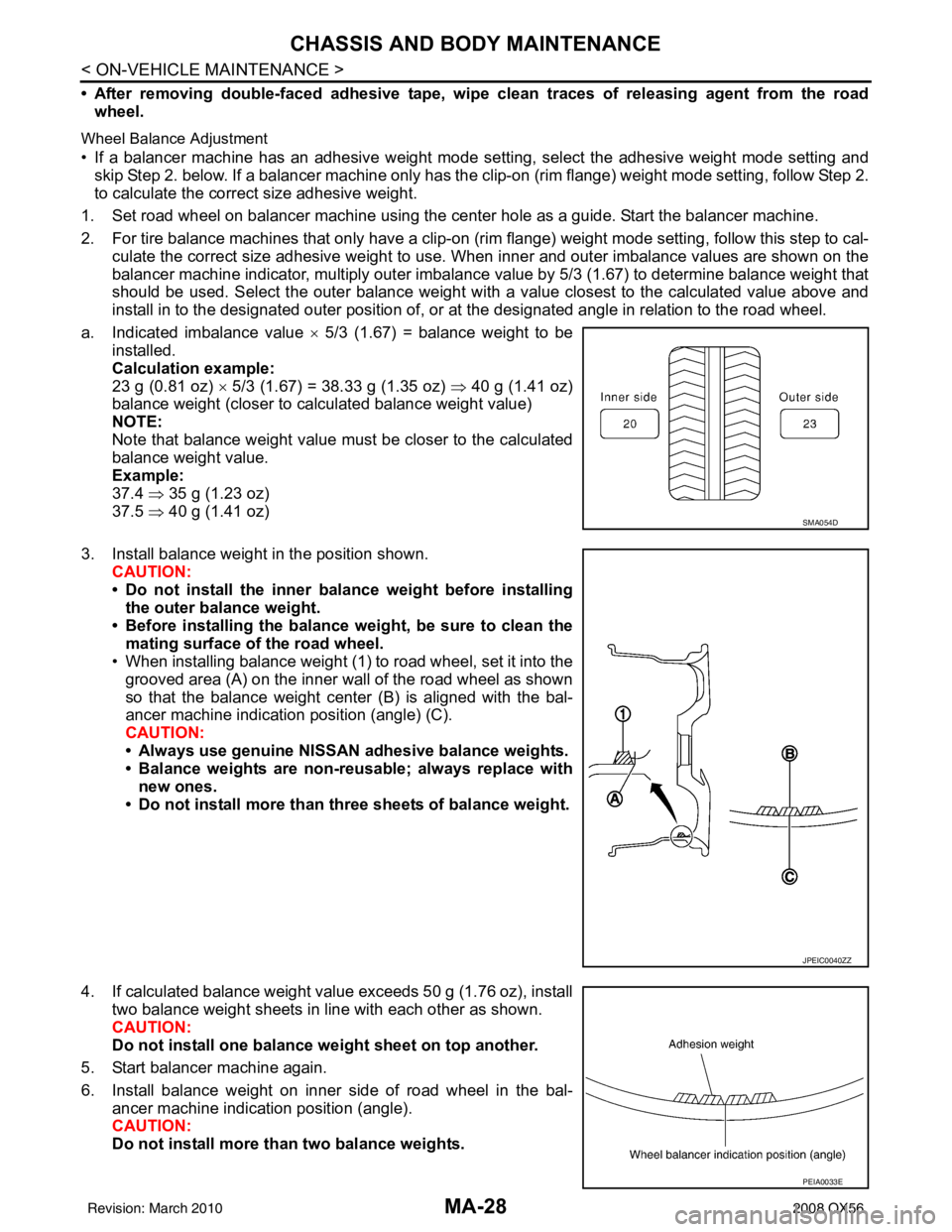

2. For tire balance machines that only have a clip-on (rim flange) weight mode setting, follow this step to cal- culate the correct size adhesive weight to use. When inner and outer imbalance values are shown on the

balancer machine indicator, multiply outer imbalance value by 5/3 (1.67) to determine balance weight that

should be used. Select the outer balance weight with a value closest to the calculated value above and

install in to the designated outer position of, or at the designated angle in relation to the road wheel.

a. Indicated imbalance value × 5/3 (1.67) = balance weight to be

installed.

Calculation example:

23 g (0.81 oz) × 5/3 (1.67) = 38.33 g (1.35 oz) ⇒ 40 g (1.41 oz)

balance weight (closer to calculated balance weight value)

NOTE:

Note that balance weight value must be closer to the calculated

balance weight value.

Example:

37.4 ⇒ 35 g (1.23 oz)

37.5 ⇒ 40 g (1.41 oz)

3. Install balance weight in the position shown. CAUTION:

• Do not install the inner bala nce weight before installing

the outer balance weight.

• Before installing the balance weight, be sure to clean the mating surface of the road wheel.

• When installing balance weight (1) to road wheel, set it into the

grooved area (A) on the inner wall of the road wheel as shown

so that the balance weight center (B) is aligned with the bal-

ancer machine indication position (angle) (C).

CAUTION:

• Always use genuine NISSAN adhesive balance weights.

• Balance weights are non-reusable; always replace withnew ones.

• Do not install more than three sheets of balance weight.

4. If calculated balance weight value exceeds 50 g (1.76 oz), install two balance weight sheets in line with each other as shown.

CAUTION:

Do not install one balance weight sheet on top another.

5. Start balancer machine again.

6. Install balance weight on inner side of road wheel in the bal- ancer machine indication position (angle).

CAUTION:

Do not install more than two balance weights.

SMA054D

JPEIC0040ZZ

PEIA0033E

Revision: March 2010 2008 QX56

Page 3105 of 4083

SCS-22

< COMPONENT DIAGNOSIS >

HEIGHT SENSOR SIGNAL CIRCUIT

HEIGHT SENSOR SIGNAL CIRCUIT

DescriptionINFOID:0000000001731990

Supplies vehicle height input to the suspension control unit.

Component Function CheckINFOID:0000000001731991

1.CHECK HEIGHT SENSOR OPERATION

CONSULT-III

1. Select "HEIGT SEN" of AIR LEVELIZER data monitor test item.

2. While monitoring test item, add or take away weight from the rear of the vehi cle. Check that the voltage

value changes with vehicle height.

Is the HEIGHT SEN data monitor responding normally?

YES >> Height sensor is operating normally.

NO >> Refer to SCS-22, "

Diagnosis Procedure".

Diagnosis ProcedureINFOID:0000000001731992

1.CHECK HEIGHT SENSOR POWER AND GROUND SUPPLY

Check height sensor power and ground supply. Refer to SCS-18, "

HEIGHT SENSOR : Diagnosis Procedure"

Are the inspection results normal?

YES >> GO TO 2.

NO >> Repair harness or connector.

2.CHECK HEIGHT SENSOR SIGNAL CIRCUIT

1. Disconnect suspension control unit connector B3 and height sensor connector C8.

2. Check continuity between suspension control unit connector B3 (A) terminal 3 and height sensor connector C8 (B) terminal 2.

3. Check continuity between display unit harness connector B3 (A) terminal 3 and ground.

Are the continuity results as specified?

YES >> Replace the height sensor. Refer to RSU-26, "Removal and Installation"

NO >> Repair harness or connector.HEIGHT SEN : Voltage changes with vehicle height

AB

Continuity

Connector Terminal Connector Terminal

B33C82 Yes

A —Continuity

Connector Terminal

B3 3Ground No

ALEIA0035GB

Revision: March 2010 2008 QX56

Page 3556 of 4083

A/T CONTROL SYSTEMTM-9

< FUNCTION DIAGNOSIS >

CEF

G H

I

J

K L

M A

B

TM

N

O P

Cross-Sectional View (4WD models)INFOID:0000000001603988

Shift MechanismINFOID:0000000001603989

The automatic transmission uses compact triple planet ary gear systems to improve power-transmission effi-

ciency, simplify construction and reduce weight.

It also employs an optimum shift control and super wide gear ratios. They improve starting performance and

acceleration during medium and high-speed operation.

CONSTRUCTION

1. Front planetary gear 2. Mid planetary gear 3. Rear planetary gear

4. Direct clutch 5. High and low reverse clutch 6. Reverse brake

7. Drum support 8. Forward brake 9. Low coast brake

10. Input shaft 11. Torque converter 12. Oil pump

13. Front brake 14. 3rd one-way clutch 15. Input clutch

16. 1st one-way clutch 17. Control valve with TCM 18. Forward one-way clutch

19. Adapter case 20. Output shaft

SCIA5268E

Revision: March 2010 2008 QX56