Stop INFINITI QX56 2008 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: QX56, Model: INFINITI QX56 2008Pages: 4083, PDF Size: 81.73 MB

Page 2848 of 4083

POWER WINDOW SYSTEMPWC-7

< FUNCTION DIAGNOSIS >

C

DE

F

G H

I

J

L

M A

B

PWC

N

O P

ANTI-PINCH OPERATION

• Pinch foreign material in the door glass during AUTO-U P operation, and it is the anti-pinch function that low-

ers the door glass 150 mm (5.91 in) or 2 seconds when detected.

• Encoder continues detecting the movement of power window motor and transmits to power window switch

as the encoder pulse signal while power window motor is operating.

• Resistance is applied to the power window motor rotation that changes the frequency of encoder pulse sig-

nal if foreign material is trapped in the door glass.

• Front power window switch LH/RH and rear power window control unit LH/RH controls to lower the window glass for 150 mm (5.91 in) or 2 seconds after it detects encoder pulse signal frequency change.

OPERATION CONDITION

• When all door glass AUTO-UP operation is performed ( anti-pinch function does not operate just before the

door glass closes and is fully closed)

NOTE:

Depending on environment and driving conditions, if a similar impact or load is applied to the door glass, it

may lower.

KEY CYLINDER SWITCH OPERATION

Hold the door key cylinder to the LOCK or UNLOCK dire ction for more than 1 second to OPEN or CLOSE front

power windows when ignition switch is OFF. In addition, it stops when key position is moved to NEUTRAL

when operating.

OPERATION CONDITION

• Ignition switch OFF

• Hold door key cylinder to LOCK position for more than 1 second to perform CLOSE operation of the door glass.

• Hold door key cylinder to UNLOCK position for more than 1 second to perform OPEN operation of the door glass.

KEYLESS POWER WINDOW DOWN OPERATION

Front power windows open when the unlock button on Intelligent Key is activated and kept pressed for more

than 3

(NOTE) seconds with the ignition switch OFF. The windows keep opening if the unlock button is continu-

ously pressed.

The power window opening stops when the following operations are performed:

• When the unlock button is kept pressed more than 15 seconds.

• When the ignition switch is turned ON while the power window opening is operated.

• When the unlock button is released.

While retained power operation is activated, ke yless power window down function cannot be operated.

NOTE:

Keyless power window down operation mode can be changed by “PW DOWN SET” mode in “WORK SUP-

PORT”. Refer to SEC-22, "

CONSULT-III Function (INTELLIGENT KEY)".

NOTE:

Use CONSULT-III to change settings.

MODE1 (3sec)/MODE2 (OFF)/MODE3 (5sec)

Revision: March 2010 2008 QX56

Page 2892 of 4083

BCM (BODY CONTROL MODULE)PWC-51

< ECU DIAGNOSIS >

C

DE

F

G H

I

J

L

M A

B

PWC

N

O P

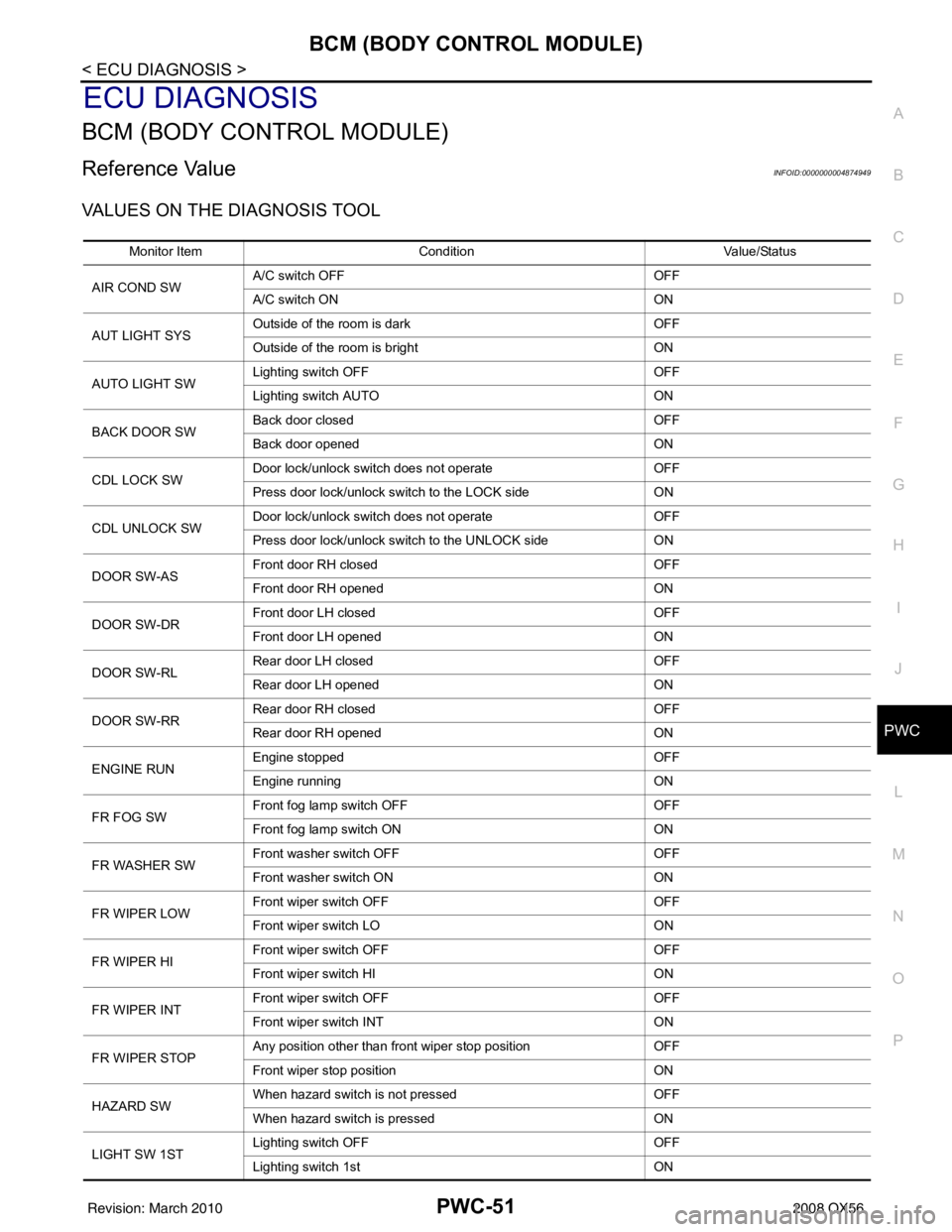

ECU DIAGNOSIS

BCM (BODY CONTROL MODULE)

Reference ValueINFOID:0000000004874949

VALUES ON THE DIAGNOSIS TOOL

Monitor Item Condition Value/Status

AIR COND SW A/C switch OFF

OFF

A/C switch ON ON

AUT LIGHT SYS Outside of the room is dark

OFF

Outside of the room is bright ON

AUTO LIGHT SW Lighting switch OFF

OFF

Lighting switch AUTO ON

BACK DOOR SW Back door closed

OFF

Back door opened ON

CDL LOCK SW Door lock/unlock switch does not operate

OFF

Press door lock/unlock switch to the LOCK side ON

CDL UNLOCK SW Door lock/unlock switch does not operate

OFF

Press door lock/unlock switch to the UNLOCK side ON

DOOR SW-AS Front door RH closed

OFF

Front door RH opened ON

DOOR SW-DR Front door LH closed

OFF

Front door LH opened ON

DOOR SW-RL Rear door LH closed

OFF

Rear door LH opened ON

DOOR SW-RR Rear door RH closed

OFF

Rear door RH opened ON

ENGINE RUN Engine stopped

OFF

Engine running ON

FR FOG SW Front fog lamp switch OFF

OFF

Front fog lamp switch ON ON

FR WASHER SW Front washer switch OFF

OFF

Front washer switch ON ON

FR WIPER LOW Front wiper switch OFF

OFF

Front wiper switch LO ON

FR WIPER HI Front wiper switch OFF

OFF

Front wiper switch HI ON

FR WIPER INT Front wiper switch OFF

OFF

Front wiper switch INT ON

FR WIPER STOP Any position other than front wiper stop position

OFF

Front wiper stop position ON

HAZARD SW When hazard switch is not pressed

OFF

When hazard switch is pressed ON

LIGHT SW 1ST Lighting switch OFF

OFF

Lighting switch 1st ON

Revision: March 2010 2008 QX56

Page 2893 of 4083

PWC-52

< ECU DIAGNOSIS >

BCM (BODY CONTROL MODULE)

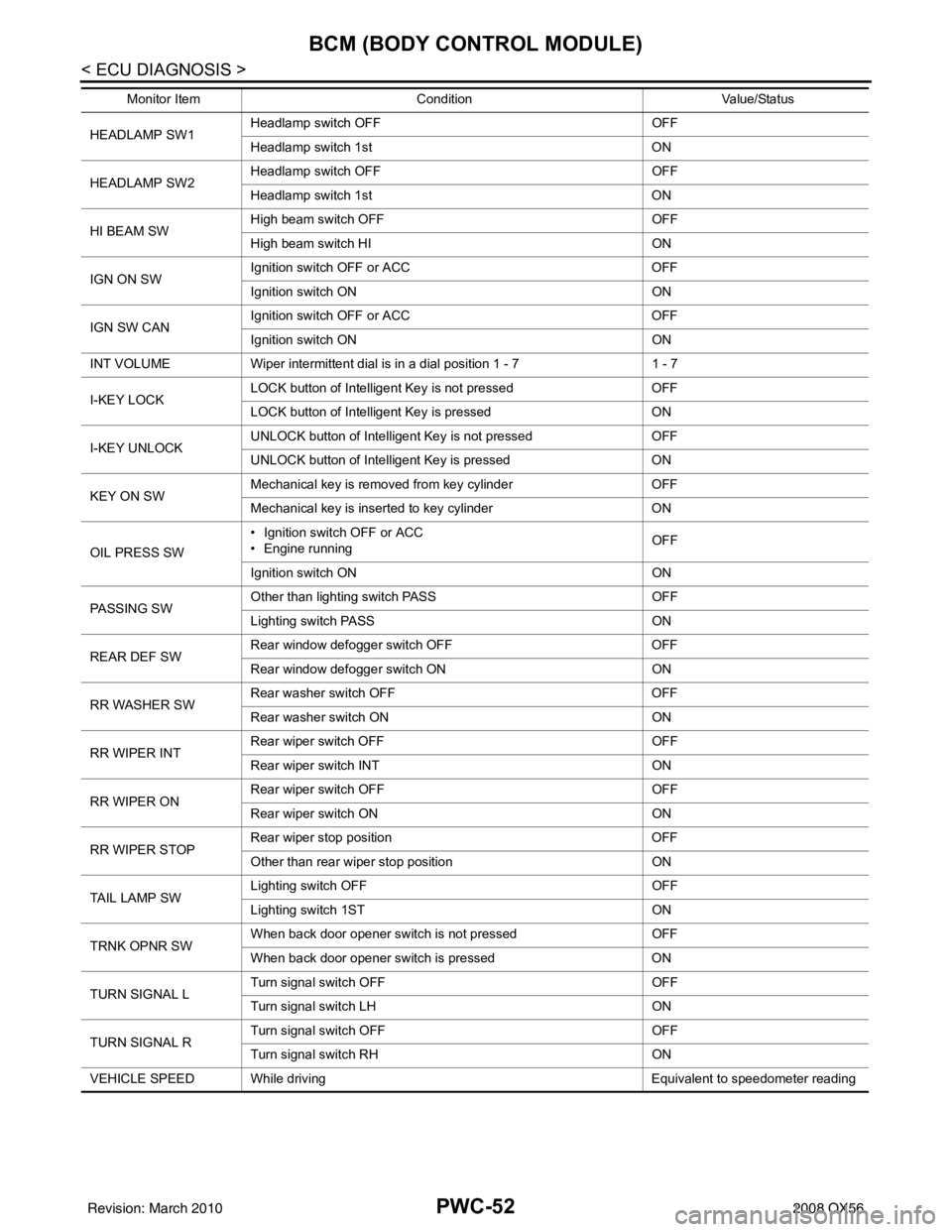

HEADLAMP SW1Headlamp switch OFF OFF

Headlamp switch 1st

ON

HEADLAMP SW2 Headlamp switch OFF

OFF

Headlamp switch 1st ON

HI BEAM SW High beam switch OFF

OFF

High beam switch HI ON

IGN ON SW Ignition switch OFF or ACC

OFF

Ignition switch ON ON

IGN SW CAN Ignition switch OFF or ACC

OFF

Ignition switch ON ON

INT VOLUME Wiper intermittent dial is in a dial position 1 - 7 1 - 7

I-KEY LOCK LOCK button of Intelligent Key is not pressed

OFF

LOCK button of Intelligent Key is pressed ON

I-KEY UNLOCK UNLOCK button of Intelligent Key is not pressed

OFF

UNLOCK button of Intelligent Key is pressed ON

KEY ON SW Mechanical key is removed from key cylinder

OFF

Mechanical key is inserted to key cylinder ON

OIL PRESS SW • Ignition switch OFF or ACC

• Engine running

OFF

Ignition switch ON ON

PASSING SW Other than lighting switch PASS

OFF

Lighting switch PASS ON

REAR DEF SW Rear window defogger switch OFF

OFF

Rear window defogger switch ON ON

RR WASHER SW Rear washer switch OFF

OFF

Rear washer switch ON ON

RR WIPER INT Rear wiper switch OFF

OFF

Rear wiper switch INT ON

RR WIPER ON Rear wiper switch OFF

OFF

Rear wiper switch ON ON

RR WIPER STOP Rear wiper stop position

OFF

Other than rear wiper stop position ON

TAIL LAMP SW Lighting switch OFF

OFF

Lighting switch 1ST ON

TRNK OPNR SW When back door opener switch is not pressed

OFF

When back door opener switch is pressed ON

TURN SIGNAL L Turn signal switch OFF

OFF

Turn signal switch LH ON

TURN SIGNAL R Turn signal switch OFF

OFF

Turn signal switch RH ON

VEHICLE SPEED While driving Equivalent to speedometer reading

Monitor Item

Condition Value/Status

Revision: March 2010 2008 QX56

Page 2896 of 4083

BCM (BODY CONTROL MODULE)PWC-55

< ECU DIAGNOSIS >

C

DE

F

G H

I

J

L

M A

B

PWC

N

O P

19 V/W Remote keyless entry

receiver (power sup-

ply) Output OFF Ignition switch OFF

20 G/W Remote keyless entry

receiver (signal) Input OFFStand-by (keyfob buttons re-

leased)

When remote keyless entry

receiver receives signal from

keyfob (keyfob buttons

pressed)

21 G NATS antenna amp. Input OFF

→

ON Ignition switch (OFF → ON) Just after turning ignition switch

ON: Pointer of tester should

move for approx. 1 second, then return to battery voltage.

22 W/V BUS — —Ignition switch ON or power

window timer operates

23 G/O Security indicator

lamp Output OFF

Goes OFF

→ illuminates (Ev-

ery 2.4 seconds) Battery voltage

→ 0V

25 BR NATS antenna amp. Input OFF

→

ON Ignition switch (OFF → ON) Just after turning ignition switch

ON: Pointer of tester should

move for approx. 1 second, then return to battery voltage.

26 Y/L Rear wiper auto stop

switch 2 Input ONRise up position (rear wiper

arm on stopper)

0V

A Position (full clockwise stop

position) 0V

Forward sweep (counterclock-

wise direction) Fluctuating

B Position (full counterclock-

wise stop position) Battery voltage

Reverse sweep (clockwise di-

rection) Fluctuating

27 W/R Compressor ON sig-

nal Input ONA/C switch OFF

5V

A/C switch ON 0V

Te r m i n a l

Wire

color Signal name Signal

input/

output Measuring condition

Reference value or waveform

(Approx.)

Ignition

switch Operation or condition

LIIA1893E

LIIA1894E

LIIA1895E

PIIA2344E

Revision: March 2010

2008 QX56

Page 2898 of 4083

BCM (BODY CONTROL MODULE)PWC-57

< ECU DIAGNOSIS >

C

DE

F

G H

I

J

L

M A

B

PWC

N

O P

44 O Rear wiper auto stop

switch 1 Input ONRise up position (rear wiper

arm on stopper)

0V

A Position (full clockwise stop

position) Battery voltage

Forward sweep (counterclock-

wise direction) Fluctuating

B Position (full counterclock-

wise stop position) 0V

Reverse sweep (clockwise di-

rection) Fluctuating

47 SB Front door switch LH Input OFF ON (open)

0V

OFF (closed) Battery voltage

48 R/Y Rear door switch LH Input OFF ON (open)

0V

OFF (closed) Battery voltage

49 R Cargo lamp Output OFFAny door open (ON)

0V

All doors closed (OFF) Battery voltage

51 G/Y Trailer turn signal

(right) Output ON Turn right ON

52 G/B Trailer turn signal (left) Output ON Turn left ON

53 L/W Glass hatch lock actu-

ator

Output OFFGlass hatch switch released

0

Glass hatch switch pressed Battery

54 Y Rear wiper output cir-

cuit 2 Input ONRise up position (rear wiper

arm on stopper)

0V

A Position (full clockwise stop

position) 0V

Forward sweep (counterclock-

wise direction) 0V

B Position (full counterclock-

wise stop position) Battery voltage

Reverse sweep (clockwise di-

rection) Battery voltage

55 SB Rear wiper output cir-

cuit 1 Output ONOFF

0

ON Battery voltage

56 R/G Battery saver output Output OFF

30 minutes after ignition

switch is turned OFF 0V

ON — Battery voltage

57 Y/R Battery power supply Input OFF —Battery voltage

Te r m i n a l

Wire

color Signal name Signal

input/

output Measuring condition

Reference value or waveform

(Approx.)

Ignition

switch Operation or condition

SKIA3009J

SKIA3009J

Revision: March 2010

2008 QX56

Page 2979 of 4083

REAR DRIVE SHAFTRAX-11

< DISASSEMBLY AND ASSEMBLY >

CEF

G H

I

J

K L

M A

B

RAX

N

O P

DISASSEMBLY AND ASSEMBLY

REAR DRIVE SHAFT

Disassembly and AssemblyINFOID:0000000004886837

DISASSEMBLY

Final Drive Side

1. Mount the drive shaft in a vise. CAUTION:

When mounting the drive shaft in a vise, use co pper or aluminum plates between the vise and the

drive shaft.

2. Remove the boot bands.

3. If the plug needs to be removed, move the boot to t he wheel side, then drive the plug out using a suitable

plastic hammer.

4. Remove the stopper ring with a flat-bladed screwdriver as shown, and pull the housing out.

1. Plug 2. Housing3. Snap ring

4. Ball cage, steel ball, liner race assembly 5. Stopper ring 6. Boot band

7. Boot 8. Shaft9. Circlip

10. Joint sub-assembly

SDIA1488E

SRA249A

Revision: March 2010 2008 QX56

Page 2981 of 4083

REAR DRIVE SHAFTRAX-13

< DISASSEMBLY AND ASSEMBLY >

CEF

G H

I

J

K L

M A

B

RAX

N

O P

• Check the ball sliding surface for any co mpression scars, cracks, or fractures.

• Check for any damage to the serrated part. CAUTION:

If any defective conditions are found, install a new housing, ball cage, steel ball, and inner race as a

set.

ASSEMBLY

Final Drive Side

1. If the plug has been removed, use Tool to press in a new one. NOTE:

Discard the old plug and use a new one for assembly.

2. Wrap the serrated part of the shaft with tape. Install the boot band and boot to shaft.

NOTE:

Discard the old boot band and boot and use a new one for

assembly.

3. Remove the tape wound around the serrated part of the shaft.

4. Install the ball cage, steel ball, and inner race assembly on the shaft, and secure them tightly using the snap ring.

NOTE:

Discard the old snap ring and use a new one for assembly.

5. Insert the specified quantity of Genuine NISSAN Grease or equivalent, onto the housing (indicated by * marks), and install it

onto shaft. Refer to MA-12, "

Fluids and Lubricants".

6. Install the stopper ring onto the housing. Tool number : KV38100500 ( — )

: KV38102200 ( — )

SDIA1153E

SFA800

SDIA1125E

Grease capacity : 175 − 195 g (6.17 − 6.88 oz)

RAC0678D

Revision: March 2010 2008 QX56

Page 2982 of 4083

RAX-14

< DISASSEMBLY AND ASSEMBLY >

REAR DRIVE SHAFT

7. After installation, pull on the shaft to check engagement between the joint sub-assembly and the stopper

ring.

8. Install the boot securely into the grooves (indicated by * marks) as shown.

CAUTION:

If there is grease on boot mo unting surfaces (indicated by*

marks) of shaft and housing, boot may come off. Remove

all grease from surfaces.

9. Check that the boot installation length “L” is the length indicated below. Insert a flat-bladed screwdriver or similar tool into smaller

side of boot. Bleed the air from the boot to prevent any boot

deformation.

CAUTION:

• The boot may break if the boot installation length is less than the specified value.

• Do not to touch the tip of the screw driver to the inside of the boot.

10. Secure the big and small ends of the boot with the new boot bands as shown.

NOTE:

Discard the old boot bands and use new ones for assembly.

11. After installing the housing and shaft, rotate the boot to check that the boot is positioned correctly. If the boot is not positioned correctly, reposition t he boot and secure the boot using a new boot band.

Wheel Side

1. Insert the Genuine NISSAN Grease or equivalent, into the joint

sub-assembly serration hole until the grease begins to ooze

from the ball groove and serration hole. Refer to MA-12, "

Fluids

and Lubricants". After inserting the grease, use a shop cloth to

wipe off the grease that has oozed out.

2. Wind the serrated part of the shaft with tape. Install the boot

band and boot onto the shaft. Do not damage the boot.

NOTE:

Discard the old boot band and boot and use a new one for

assembly.

3. Remove the protective tape wound around the serrated part of the shaft. Boot installation length

“L ” : 147.9 mm (5.82 in)

WDIA0045E

SFA395

SDIA1127E

SFA800

Revision: March 2010 2008 QX56

Page 2985 of 4083

RF-1

BODY EXTERIOR, DOORS, ROOF & VEHICLE SECURITY

C

DE

F

G H

I

J

L

M

SECTION RF

A

B

RF

N

O P

CONTENTS

ROOF

BASIC INSPECTION ....... .............................3

DIAGNOSIS AND REPAIR WORKFLOW ..... .....3

Work Flow ........................................................... ......3

INSPECTION AND ADJUSTMENT .....................5

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT .................................................... ......

5

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT : Description ..................................

5

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT : Special Repair Requirement .......

5

BASIC INSPECTION ...................................................5

BASIC INSPECTION : Spec ial Repair Require-

ment .................................................................... ......

5

FUNCTION DIAGNOSIS ...............................6

SUNROOF SYSTEM ...................................... .....6

System Diagram ................................................. ......6

System Description ...................................................6

Component Parts Location ......................................7

Component Description ............................................7

DIAGNOSIS SYSTEM (BCM) .............................8

COMMON ITEM ..................................................... ......8

COMMON ITEM : CONSULT-III Function (BCM -

COMMON ITEM) .......................................................

8

RETAINED PWR .........................................................8

RETAINED PWR : CONSULT-III Function (BCM -

RETAINED PWR) .....................................................

8

COMPONENT DIAGNOSIS .........................10

POWER SUPPLY AND GROUND CIRCUIT .. ....10

SUNROOF MOTOR ASSEMBLY .......................... ....10

SUNROOF MOTOR ASSEMBLY :

Diagnosis Procedure ..............................................

10

SUNROOF MOTOR ASSEMBLY : Special Repair

Requirement ........................................................ ....

11

SUNROOF SWITCH CIRCUIT ..........................12

Description ...............................................................12

Component Function Check ..................................12

Diagnosis Procedure ...............................................12

DOOR SWITCH .................................................14

Description ...............................................................14

Component Function Check ....................................14

Diagnosis Procedure ...............................................14

Component Inspection .............................................15

ECU DIAGNOSIS .........................................16

BCM (BODY CONTROL MODULE) .................16

Reference Value .................................................. ....16

Terminal Layout .......................................................18

Physical Values ................................................... ....18

Wiring Diagram ........................................................24

Fail Safe ..................................................................27

DTC Inspection Priority Chart ...............................28

DTC Index ...............................................................28

SUNROOF SYSTEM .........................................30

Reference Value ......................................................30

Wiring Diagram ........................................................31

SYMPTOM DIAGNOSIS ..............................35

SUNROOF DOES NOT OPERATE PROPER-

LY ......................................................................

35

Diagnosis Procedure ........................................... ....35

AUTO OPERATION DOES NOT OPERATE ....36

Diagnosis Procedure ...............................................36

DOES NOT STOP FULLY-OPEN OR FULLY-

CLOSED POSITION ..........................................

37

Diagnosis Procedure ...............................................37

Revision: March 2010 2008 QX56

Page 2989 of 4083

INSPECTION AND ADJUSTMENTRF-5

< BASIC INSPECTION >

C

DE

F

G H

I

J

L

M A

B

RF

N

O P

INSPECTION AND ADJUSTMENT

ADDITIONAL SERVICE WHEN REPLACING CONTROL UNIT

ADDITIONAL SERVICE WHEN REPL ACING CONTROL UNIT : Description

INFOID:0000000001731919

MEMORY RESET PROCEDURE

1. Please observe the following instructi ons at confirming the sunroof operation.

NOTE:

Do not disconnect the electronic power while the sunroof is operating or within 5 seconds after the sunroof

stops. (to wipe-out the memory of lid position and operating friction.)

2. Initialization of system should be conducted after the following conditions.

• When the sunroof motor is changed.

• When the sunroof does not operate normally. (Incomplete initialization conditions)

ADDITIONAL SERVICE WHEN REPLACING CONTROL UNIT : Special Repair Re-

quirement

INFOID:0000000001731920

INITIALIZATION PROCEDURE

If the sunroof does not close or open automatically, us e the following procedure to return sunroof operation to

normal.

1. Turn ignition switch ON.

2. Push and hold the sunroof tilt switch in the forw ard (DOWN) position until the sunroof is fully closed.

3. After the sunroof has closed all the way, push and hold the tilt switch forward (DOWN) again for more than 2 seconds to re-learn motor position.

4. Initialization is complete if the sunroof operates normally.

BASIC INSPECTION

BASIC INSPECTION : Special Repair RequirementINFOID:0000000001731921

BASIC INSPECTION

1.INSPECTION START

1. Check the service history.

2. Check the following parts.

• Fuse/circuit breaker blown.

• Poor connection, open or short circuit of harness connector.

• Battery voltage.

Is the inspection result normal?

YES >> Inspection End.

NO >> Repair or replace the malfunctioning parts.

Revision: March 2010 2008 QX56