key INFINITI QX56 2008 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: QX56, Model: INFINITI QX56 2008Pages: 4083, PDF Size: 81.73 MB

Page 2396 of 4083

DIAGNOSIS SYSTEM (BCM)INL-13

< FUNCTION DIAGNOSIS >

C

DE

F

G H

I

J

K

M A

B

INL

N

O P

BATTERY SAVER

BATTERY SAVER : CONSULT-III FunctionINFOID:0000000001601385

WORK SUPPORT

DATA MONITOR

ACTIVE TEST

LUGGAGE LAMP TEST ON Outputs the cargo lamp control signal to turn cargo lamp ON.

OFF Stops the cargo lamp control signal to turn cargo lamp OFF.

Test item

Operation Description

Service itemSetting item Setting

ROOM LAMP TIMER SET MODE 1

(ON)

Interior room lamp timer activates with synchronizing all doors.

MODE 2

(OFF) Interior room lamp timer activates with synchronizing the front door LH

only.

Monitor item

[Unit] Description

IGN ON SW

[ON/OFF] The switch status input from ignition switch

KEY ON SW

[ON/OFF] Key switch status input from key slot

DOOR SW-DR

[ON/OFF] The switch status input from front door switch LH

DOOR SW-AS

[ON/OFF] The switch status input from front door switch RH

DOOR SW-RR

[ON/OFF] The switch status input from rear door switch RH

DOOR SW- RL

[ON/OFF] The switch status input from rear door switch LH

BACK DOOR SW

[ON/OFF] The switch status input from back door switch

KEY CYL LK-SW

[ON/OFF] Lock switch status received from key cylinder switch by power window serial link

KEY CYL UN-SW

[ON/OFF] Unlock switch status received from key cylinder switch by power window serial link

CDL LOCK SW

[ON/OFF] Lock switch status received from door lock/unlock switch by power window serial link

CDL UNLOCK SW

[ON/OFF] Unlock switch status received from door lock/unlock switch by power window serial

link

I-KEY LOCK

[ON/OFF] Lock signal status received from remote keyless entry receiver

I-KEY UNLOCK

[ON/OFF] Unlock signal status received from remote keyless entry receiver

Test item

Operation Description

BATTERY SAVER ON Outputs the battery saver output/power supply to turn the interior lamps ON.

OFF Stops the battery saver output/power supply to turn the interior lamps OFF.

Revision: March 2010 2008 QX56

Page 2398 of 4083

INTERIOR ROOM LAMP POWER SUPPLY CIRCUIT

INL-15

< COMPONENT DIAGNOSIS >

C

D E

F

G H

I

J

K

M A

B

INL

N

O P

INTERIOR ROOM LAMP POWER SUPPLY CIRCUIT

DescriptionINFOID:0000000001601387

Provides the battery saver output/power supply. Also cu ts the power supply when the interior room lamp bat-

tery saver is activating.

Component Function CheckINFOID:0000000001601388

1.CHECK BATTERY SAVER OUTPUT /POWER SUPPLY FUNCTION

CONSULT-III

1. Turn ignition switch ON.

2. Turn each interior room lamp ON.

- Front room/map lamp assembly

- Vanity lamps

- Personal lamp 2nd row

- Personal lamp 3rd row

- Cargo lamp

3. Open the driver door to turn ON the step lamps, foot lamps and puddle lamps.

- Front step lamps

- Rear step lamps

- Foot lamps

- Puddle lamps

- Ignition keyhole Illumination

4. Select “BATTERY SAVER” of BCM (BATTERY SAVER) active test item.

5. While operating the test item, check that each interior room lamp turns ON/OFF.

Is the inspection result normal?

YES >> Battery saver output/power supply circuit is normal.

NO >> Refer to INL-15, "

Diagnosis Procedure".

Diagnosis ProcedureINFOID:0000000001601389

1.CHECK BATTERY SAVER OUTPUT/POWER SUPPLY OUTPUT

CONSULT-III

1. Turn ignition switch ON.

2. Select “BATTERY SAVER” of BCM (BATTERY SAVER) active

test item.

3. While operating the test item, check voltage between BCM con-

nector M20 terminal 56 and ground.

Is the inspection result normal?

YES >> GO TO 2

NO >> Replace BCM. Refer to BCS-55, "

Removal and Installation".

2.CHECK BATTERY SAVER OUTPUT/P OWER SUPPLY OPEN CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect the following connectors.

-BCM M20

- Ignition keyhole illumination OFF : Interior room lamps OFF

ON : Interior room lamps ON

(+)

(-)Te s t i t e m

Voltag e

Connector Terminal BATTERY SAVER

M20 56 Ground OFF

0V

ON Battery voltage

ALLIA0408GB

Revision: March 2010 2008 QX56

Page 2399 of 4083

INL-16

< COMPONENT DIAGNOSIS >

INTERIOR ROOM LAMP POWER SUPPLY CIRCUIT

- Front step lamp LH

- Front step lamp RH

- Door mirror LH

- Door mirror RH

- Rear step lamp LH

- Rear step lamp RH

- Foot lamp LH

- Foot lamp RH

- Front room/map lamp assembly

- Vanity lamp LH

- Vanity lamp RH

- Cargo lamp

- Personal lamp 2nd row

- Personal lamp 3rd row

3. Check continuity between BCM connector M20 term inal 56 and each interior room lamp connector.

Is the inspection result normal?

YES >> GO TO 3

NO >> Repair the harness or connectors.

3.CHECK BATTERY SAVER OUTPUT/P OWER SUPPLY SHORT CIRCUIT

Check continuity between BCM connector M20 terminal 56 and

ground.

Is the inspection result normal?

YES >> Check that each interior room lamp has no internal short circuit.

NO >> Repair the harness or connectors.

BCM Interior room lamp

Continuity

Connector Terminal ConnectorTerminal

M20 56 Ignition keyhole illumination

M1501

Ye s

Front step lamp LH

D111

Front step lamp RH D1091

Door mirror LH D412

Door mirror RH D10712

Rear step lamp LH D2061

Rear step lamp RH D3061

Foot lamp LH M991

Foot lamp RH M1001

Front room/map lamp assembly R1026

Vanity lamp LH R31

Vanity lamp RH R81

Cargo lamp B1532

Personal lamp 2nd row R2033

Personal lamp 3rd row R2053

Connector Terminal —Continuity

M20 56Ground No

ALLIA0409GB

Revision: March 2010 2008 QX56

Page 2406 of 4083

IGNITION KEYHOLE ILLUMINATION CONTROL CIRCUIT

INL-23

< COMPONENT DIAGNOSIS >

C

D E

F

G H

I

J

K

M A

B

INL

N

O P

IGNITION KEYHOLE ILLUMI NATION CONTROL CIRCUIT

DescriptionINFOID:0000000001601399

Controls the ignition keyhole illumination (ground side) to turn the ignition keyhole illumination ON and OFF.

Component Function CheckINFOID:0000000001601400

CAUTION:

Before performing the diagnosis, check that the following is normal.

• Battery saver output/power supply circuit

• Ignition keyhole il lumination bulb

1.CHECK IGNITION KEYHOLE ILLUMINATION OPERATION

CONSULT-III

1. Turn the ignition switch ON.

2. Select “IGN ILLUM” of BCM (INT LAMP) active test item.

3. While operating the test item, check that the ignition keyhole illumination turns ON/OFF

Is the inspection result normal?

YES >> Ignition keyhole illumination circuit is normal.

NO >> Refer to INL-23, "

Diagnosis Procedure".

Diagnosis ProcedureINFOID:0000000001601401

1.CHECK IGNITION KEYHOLE OUTPUT

CONSULT-III

1. Turn ignition switch ON.

2. Select “IGN ILLUM” of BCM (INT LAMP) active test item.

3. While operating the test item, check voltage between BCM con- nector M18 terminal 1 and ground.

Is the inspection result normal?

YES >> Ignition keyhole illumination control circuit is operating normally.

Fixed ON>>GO TO 3

Fixed OFF>>GO TO 2

2.CHECK IGNITION KEYHOLE I LLUMINATION OPEN CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect BCM connector M18 and ignition keyhole illumina- tion connector.

3. Check continuity between BCM connector M18 (A) terminal 1 and ignition keyhole illumination connector M150 (B) terminal 2.

Is the inspection result normal?

ON : Ignition keyhole illumination ON

OFF : Ignition keyhole illumination OFF

Connector Terminal — IGN ILLUM Voltage

M18 1 Ground ON

0V

OFF Battery voltage

ALLIA0420GB

BCM Ignition keyhole illumination

Continuity

Connector Terminal Connector Terminal

M18 (A) 1 M150 (B) 2 Yes

ALLIA0421GB

Revision: March 2010 2008 QX56

Page 2407 of 4083

INL-24

< COMPONENT DIAGNOSIS >

IGNITION KEYHOLE ILLUMINATION CONTROL CIRCUIT

YES >> Check ignition keyhole illumination for an open. If OK, replace BCM. Refer to BCS-55, "Removal

and Installation". If NG, replace ignition keyhole illumination.

NO >> Repair harness or connectors.

3.CHECK IGNITION KEYHOLE ILLUMINATION SHORT CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect BCM connector M18 and ignition keyhole illumina- tion connector.

3. Check continuity between BCM connector M18 terminal 1 and ground.

Is the inspection result normal?

YES >> Check ignition keyhole illumination for a short circuit. If OK, replace BCM. Refer to BCS-55, "

Removal and

Installation". If NG, replace ignition keyhole illumination.

NO >> Repair harness or connectors.

Connector Terminal —Continuity

M18 1Ground No

ALLIA0422GB

Revision: March 2010 2008 QX56

Page 2439 of 4083

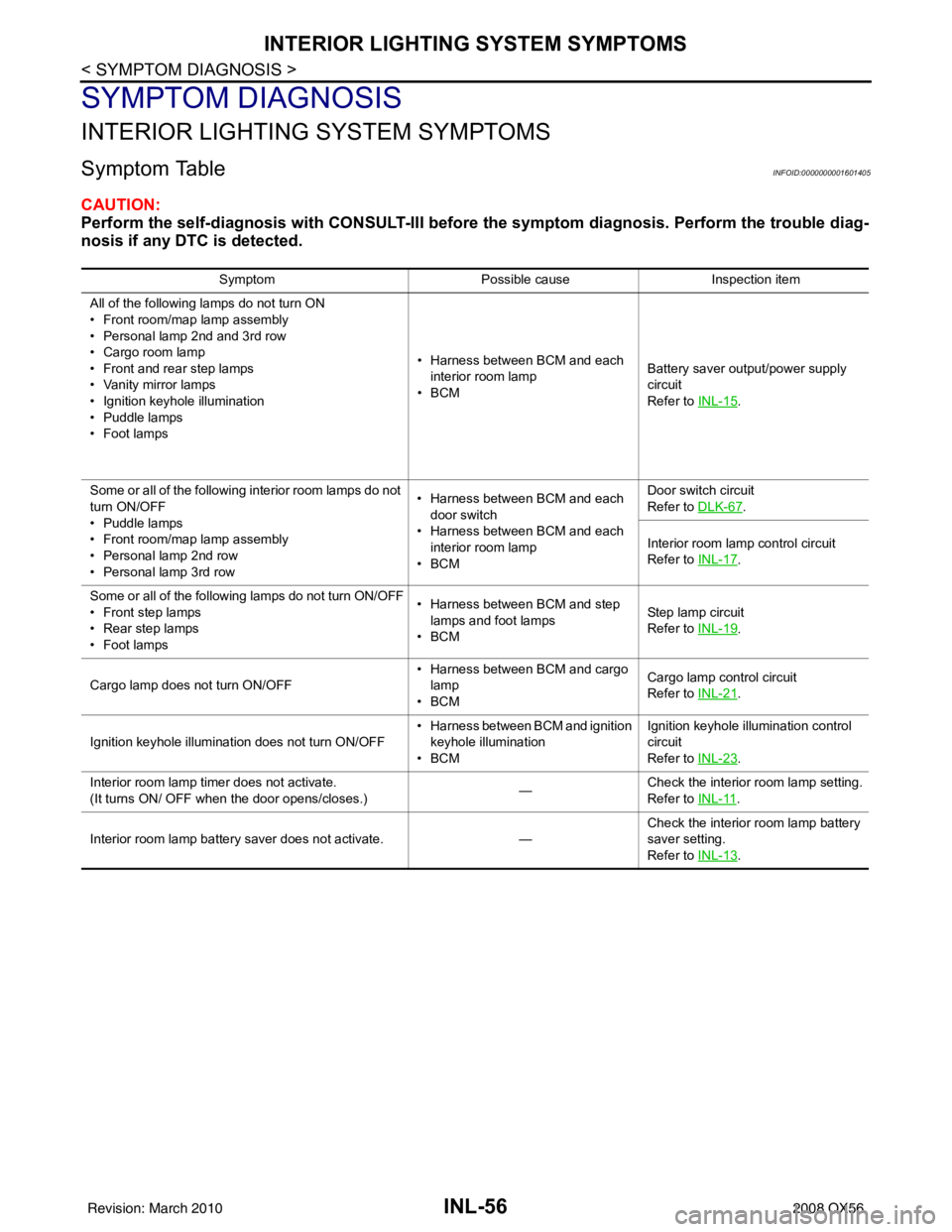

INL-56

< SYMPTOM DIAGNOSIS >

INTERIOR LIGHTING SYSTEM SYMPTOMS

SYMPTOM DIAGNOSIS

INTERIOR LIGHTING SYSTEM SYMPTOMS

Symptom TableINFOID:0000000001601405

CAUTION:

Perform the self-diagnosis with CONSULT-III before the symptom diagnosis. Perform the trouble diag-

nosis if any DTC is detected.

Symptom Possible causeInspection item

All of the following lamps do not turn ON

• Front room/map lamp assembly

• Personal lamp 2nd and 3rd row

• Cargo room lamp

• Front and rear step lamps

• Vanity mirror lamps

• Ignition keyhole illumination

• Puddle lamps

•Foot lamps • Harness between BCM and each

interior room lamp

•BCM Battery saver output/power supply

circuit

Refer to

INL-15

.

Some or all of the following interior room lamps do not

turn ON/OFF

• Puddle lamps

• Front room/map lamp assembly

• Personal lamp 2nd row

• Personal lamp 3rd row • Harness between BCM and each

door switch

• Harness between BCM and each interior room lamp

•BCM Door switch circuit

Refer to

DLK-67

.

Interior room lamp control circuit

Refer to INL-17

.

Some or all of the following lamps do not turn ON/OFF

• Front step lamps

• Rear step lamps

•Foot lamps • Harness between BCM and step

lamps and foot lamps

•BCM Step lamp circuit

Refer to

INL-19

.

Cargo lamp does not turn ON/OFF • Harness between BCM and cargo

lamp

•BCM Cargo lamp co

ntrol circuit

Refer to INL-21

.

Ignition keyhole illumination does not turn ON/OFF • Harness between BCM and ignition

keyhole illumination

•BCM Ignition keyhole illumination control

circuit

Refer to

INL-23

.

Interior room lamp timer does not activate.

(It turns ON/ OFF when the door opens/closes.) —Check the interior room lamp setting.

Refer to

INL-11

.

Interior room lamp battery saver does not activate. —Check the interior room lamp battery

saver setting.

Refer to

INL-13

.

Revision: March 2010 2008 QX56

Page 2440 of 4083

PRECAUTIONSINL-57

< PRECAUTION >

C

DE

F

G H

I

J

K

M A

B

INL

N

O P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000004900917

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SR and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Un it or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or el ectric power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers, always switch the Ignition OFF, disconnect the battery, and wait at least 3 minutes before performing any service.

Precaution Necessary for Steering Wheel Rotation After Battery Disconnect

INFOID:0000000004900918

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecti ng both battery cables with the ignition knob in the

″ LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS , an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery power is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be

rotated.

4. Perform the necessary repair operation.

Revision: March 2010 2008 QX56

Page 2457 of 4083

INT-8

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000004900856

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SR and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution Necessary for Steering W heel Rotation After Battery Disconnect

INFOID:0000000004900857

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecting both battery cables with the ignition knob in the

″LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS, an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be rotated.

4. Perform the necessary repair operation.

Revision: March 2010 2008 QX56

Page 2472 of 4083

IP-2

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000004904116

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SR and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution Necessary for Steering W heel Rotation After Battery Disconnect

INFOID:0000000004904117

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecting both battery cables with the ignition knob in the

″LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS, an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be rotated.

4. Perform the necessary repair operation.

Revision: March 2010 2008 QX56

Page 2482 of 4083

IP-12

< ON-VEHICLE REPAIR >

INSTRUMENT PANEL ASSEMBLY

Removal and Installation

INFOID:0000000001602122

REMOVAL

CAUTION:

Disconnect both the negative and po sitive battery terminals in advance.

1. Disconnect both negative and positive termi nals, then wait at least 3 minutes.

2. Remove front center console. Refer to IP-20, "

Removal and Installation".

3. Remove steering column assembly. Refer to ST-20, "

Removal and Installation".

4. Remove combination meter. Refer to MWI-76, "

Removal and Installation".

5. Remove instrument panel upper cover and disconnect rear sonar speaker (if equipped).

6. Remove cluster lid C. Refer to IP-15, "

Removal and Installation".

7. Remove display assembly. Refer to AV-164, "

Removal and Installation".

8. Remove instrument lower/upper panel RH and glove box. Refer to IP-17, "

Removal and Installation" and

IP-18, "

Removal and Installation".

9. Release the clips, disconnect the optical sensor harness and remove defroster grille.

10. Release the clips, disconnect the connecto rs and remove RH, LH, and center speakers.

11. Remove RH/LH front pillar finishers. Refer to INT-14, "

Removal and Installation".

12. Remove the passenger air bag module nuts and disconnect the connectors. Refer to SR-10, "

Removal

and Installation".

13. Disconnect remaining optional equipment connectors (if equipped).

14. Remove instrument panel and pad assembly screws.

15. Release instrument panel and pad assembly lifting rearward away from steering member, then carefully remove through front door opening.

1. Defroster grille 2. Center speaker grille3. Speaker center

4. Speaker grille outer 5. Speaker outer6. Instrument panel upper cover

7. Instrument panel and pad assembly 8. Side ventilator assembly LH 9. Combination meter

10. Instrument upper panel LH 11. Cluster lid A 12. Key cylinder escutcheon

13. Lower knee protector 14. Instrument lower panel LH 15. Steering column cover upper

16. Steering column cover lower 17. Cluster lid C lower 18. 4WD switch (if equipped)

19. Hazard switch 20. Cluster lid C21. Instrument lower cover RH

22. Fuse access cover 23. Glove box 24. Instrument lower panel RH

25. Audio switch RH 26. A/C and AV switch assembly 27. Audio unit

28. Audio switch LH 29. Center ventilator assembly LH 30. Display assembly

31. Center ventilator assembly RH 32. Side ventilator assembly RH 33. Instrument upper panel RH Metal clip Clip

ALJIA0083ZZ

Revision: March 2010 2008 QX56