turn signal INFINITI QX56 2008 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: QX56, Model: INFINITI QX56 2008Pages: 4083, PDF Size: 81.73 MB

Page 1726 of 4083

![INFINITI QX56 2008 Factory Service Manual ECM

EC-427

< ECU DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

LOAD SIGNAL • Ignition switch: ON

Rear window defogger switch is ON

and/or lighting switch is in 2nd.

ON

Rear window defogger s INFINITI QX56 2008 Factory Service Manual ECM

EC-427

< ECU DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

LOAD SIGNAL • Ignition switch: ON

Rear window defogger switch is ON

and/or lighting switch is in 2nd.

ON

Rear window defogger s](/img/42/57030/w960_57030-1725.png)

ECM

EC-427

< ECU DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

LOAD SIGNAL • Ignition switch: ON

Rear window defogger switch is ON

and/or lighting switch is in 2nd.

ON

Rear window defogger switch is OFF

and lighting switch is OFF. OFF

IGNITION SW • Ignition switch: ON → OFF → ON ON → OFF → ON

HEATER FAN SW • Engine: After warming up, idle the

engine Heater fan control switch: ON ON

Heater fan control switch: OFF OFF

BRAKE SW • Ignition switch: ON Brake pedal: Fully released

OFF

Brake pedal: Slightly depressed ON

INJ PULSE-B1

INJ PULSE-B2 • Engine: After warming up

• Selector lever: P or N

• Air conditioner switch: OFF

• No load Idle

2.0 - 2.8 msec

2,000 rpm 1.9 - 2.9 msec

IGN TIMING • Engine: After warming up

• Selector lever: P or N

• Air conditioner switch: OFF

• No load Idle

10° - 20 ° BTDC

2,000 rpm 25° - 45 ° BTDC

CAL/LD VALUE • Engine: After warming up

• Selector lever: P or N

• Air conditioner switch: OFF

• No load Idle

14% - 33%

2,500 rpm 12% - 25%

MASS AIRFLOW • Engine: After warming up

• Selector lever: P or N

• Air conditioner switch: OFF

• No load Idle

3.0 - 9.0 g·m/s

2,500 rpm 9.0 - 28.0 g·m/s

PURG VOL C/V • Engine: After warming up

• Selector lever: P or N

• Air conditioner switch: OFF

• No load Idle

(Accelerator pedal: Not depressed

even slightly, after engine starting.)

0%

2,000 rpm —

INT/V TIM (B1)

INT/V TIM (B2) • Engine: After warming up

• Selector lever: P or N

• Air conditioner switch: OFF

• No load Idle

−5° - 5 °CA

2,000 rpm Approx. 0° - 20°CA

INT/V SOL (B1)

INT/V SOL (B2) • Engine: After warming up

• Selector lever: P or N

• Air conditioner switch: OFF

• No load Idle

0% - 2%

2,000 rpm Approx. 25% - 50%

AIR COND RLY • Engine: After warming up, idle the

engine Air conditioner switch: OFF

OFF

Air conditioner switch: ON

(Compressor: Operates) ON

FUEL PUMP RLY • For 1 second after turning ignition switch ON

•

En

g

ine running or cranking ON

• Except above conditions OFF

VENT CONT/V • Ignition switch: ON OFF

THRTL RELAY • Ignition switch: ON ON

COOLING FAN • Engine: After warming up, idle the

engine

• Air conditioner switch: OFF Engine coolant temperature: 99

°C

(210 °F) or less OFF

Engine coolant temperature: 100 °C

(212 °F) or more HI

HO2S2 HTR (B1)

HO2S2 HTR (B2) • Engine speed: Below 3,600 rpm after the following conditions are met.

- Engine: After warming up

- Keeping the engine speed between 3,500 and 4,000 rpm for 1 minute and

at idle for 1 minute under no load ON

• Engine speed: Above 3,600 rpm OFF

MONITOR ITEM

CONDITION SPECIFICATION

Revision: March 2010 2008 QX56

Page 1727 of 4083

![INFINITI QX56 2008 Factory Service Manual EC-428

< ECU DIAGNOSIS >[VK56DE]

ECM

*1: Accelerator pedal position sensor 2 signal and throttle position sensor 2 signal are converted by ECM internally. Thus, the

y differ

from ECM terminals voltage INFINITI QX56 2008 Factory Service Manual EC-428

< ECU DIAGNOSIS >[VK56DE]

ECM

*1: Accelerator pedal position sensor 2 signal and throttle position sensor 2 signal are converted by ECM internally. Thus, the

y differ

from ECM terminals voltage](/img/42/57030/w960_57030-1726.png)

EC-428

< ECU DIAGNOSIS >[VK56DE]

ECM

*1: Accelerator pedal position sensor 2 signal and throttle position sensor 2 signal are converted by ECM internally. Thus, the

y differ

from ECM terminals voltage signal.

*2: Before measuring the terminal voltage, confirm the battery is fully charged. Refer to PG-73

.

I/P PULLY SPD • Vehicle speed: More than 20 km/h (12 MPH)

Almost the same speed as the

tachometer indication

VEHICLE SPEED • Turn drive wheels and compare CONSULT-IIl value with the speedometer

indication. Almost the same speed as the

speedometer indication

TRVL AFTER MIL • Ignition switch: ON Vehicle has traveled after MIL has

turned ON.0 - 65,535 km

(0 - 40,723 mile)

A/F S1 HTR (B1)

A/F S1 HTR (B2) • Engine: After warming up, idle the engine

4 - 100%

AC PRESS SEN • Engine: Idle

• Both A/C switch and blower fan switch: ON (Compressor operates.)

1.0 - 4.0V

VHCL SPEED SE • Turn drive wheels and compare CONSULT-IIl value with the speedometer

indication. Almost the same speed as the

speedometer indication

SET VHCL SPD • Engine: Running ASCD: Operating.The preset vehicle speed is dis-

played.

MAIN SW • Ignition switch: ON MAIN switch: Pressed

ON

MAIN switch: Released OFF

CANCEL SW • Ignition switch: ON CANCEL switch: Pressed

ON

CANCEL switch: Released OFF

RESUME/ACC SW • Ignition switch: ON RESUME/ACCELERATE switch:

Pressed

ON

RESUME/ACCELERATE switch: Re-

leased OFF

SET SW • Ignition switch: ON SET/COAST switch: Pressed

ON

SET/COAST switch: Released OFF

DIST SW • Ignition switch: ON DISTANCE switch: Pressed

ON

DISTANCE switch: Released OFF

BRAKE SW1 • Ignition switch: ON Brake pedal: Fully released

ON

Brake pedal: Slightly depressed OFF

BRAKE SW2 • Ignition switch: ON Brake pedal: Fully released

OFF

Brake pedal: Slightly depressed ON

CRUISE LAMP • Ignition switch: ON MAIN switch: Pressed at the 1st time

→ at the 2nd timeON

→ OFF

SET LAMP • MAIN switch: ON

• Vehicle speed: Between 40 km/h

(25 MPH) and 144 km/h (89

MPH) ASCD: Operating

ON

ASCD: Not operating OFF

ALT DUTY • Engine: Idle 0 - 80%

BAT CUR SEN • Engine speed: Idle

• Battery: Fully charged*

2

• Selector lever: P or N

• Air conditioner switch: OFF

•No load Approx. 2,600 - 3,500mV

ALT DUTY SIG • Power generation voltage variable control: Operating

ON

• Power generation voltage variable control: Not operating OFF

MONITOR ITEM

CONDITION SPECIFICATION

Revision: March 2010 2008 QX56

Page 1736 of 4083

![INFINITI QX56 2008 Factory Service Manual ECM

EC-437

< ECU DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

99 G/R

ASCD steering switch

(Models with ASCD system) [Ignition switch: ON]

• ASCD steering switch: OFF

Approximately 4V

[Igniti INFINITI QX56 2008 Factory Service Manual ECM

EC-437

< ECU DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

99 G/R

ASCD steering switch

(Models with ASCD system) [Ignition switch: ON]

• ASCD steering switch: OFF

Approximately 4V

[Igniti](/img/42/57030/w960_57030-1735.png)

ECM

EC-437

< ECU DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

99 G/R

ASCD steering switch

(Models with ASCD system) [Ignition switch: ON]

• ASCD steering switch: OFF

Approximately 4V

[Ignition switch: ON]

• MAIN switch: Pressed Approximately 0V

[Ignition switch: ON]

• CANCEL switch: Pressed Approximately 1V

[Ignition switch: ON]

• RESUME/ACCELERATE switch: Pressed Approximately 3V

[Ignition switch: ON]

• SET/COAST switch: Pressed Approximately 2V

101 R/W Stop lamp switch [Ignition switch: OFF]

• Brake pedal: Fully released

Approximately 0V

[Ignition switch: OFF]

• Brake pedal: Slightly depressed BATTERY VOLTAGE

(11 - 14V)

102 GR/R PNP signal [Ignition switch: ON]

• Selector lever: P or N

Approximately 0V

[Ignition switch: ON]

• Except the above gear position BATTERY VOLTAGE

(11 - 14V)

104 O Throttle cont rol motor relay[Ignition switch: OFF]

BATTERY VOLTAGE

(11 - 14V)

[Ignition switch: ON] 0 - 1.0V

106 BR/W Accelerator pedal position

sensor 1 [Ignition switch: ON]

• Engine: Stopped

• Accelerator pedal: Fully released

0.5 - 1.0V

[Ignition switch: ON]

• Engine: Stopped

• Accelerator pedal: Fully depressed 4.2 - 4.8V

107 V/R Fuel tank temperature sensor [Engine is running]Approximately 0 - 4.8V

Output voltage varies with fuel

tank temperature.

108 BR/W ICC brake switch

(Models with ICC system)

ASCD brake switch

(Models with ASCD system) [Ignition switch: ON]

• Brake pedal: Slightly depressed

Approximately 0V

[Ignition switch: ON]

• Brake pedal: Fully released BATTERY VOLTAGE

(11 - 14V)

109 L/W Ignition switch [Ignition switch: OFF]

0V

[Ignition switch: ON] BATTERY VOLTAGE

(11 - 14V)

111 W / B ECM relay

(Self shut-off) [Engine is running]

[Ignition switch: OFF]

• For a few seconds after turning ignition

switch OFF 0 - 1.5V

[Ignition switch: OFF]

• More than a few seconds after turning igni- tion switch OFF BATTERY VOLTAGE

(11 - 14V)

11 3 G R F u e l p u m p r e l a y [Ignition switch: ON]

• For 1 second after turning ignition switch

ON

[Engine is running] 0 - 1.5V

[Ignition switch: ON]

• More than 1 second after turning ignition switch ON BATTERY VOLTAGE

(11 - 14V)

TER-

MI-

NAL NO. WIRE

COLOR ITEM

CO

NDITION DA

TA (DC Voltage)

Revision: March 2010 2008 QX56

Page 1781 of 4083

![INFINITI QX56 2008 Factory Service Manual EC-482

< SYMPTOM DIAGNOSIS >[VK56DE]

ENGINE CONTROL SYSTEM SYMPTOMS

1 - 6: The numbers refer to the order of inspection.

(continued on next page)

SYSTEM — ENGINE MECHANICAL & OTHER

Mass air flow sen INFINITI QX56 2008 Factory Service Manual EC-482

< SYMPTOM DIAGNOSIS >[VK56DE]

ENGINE CONTROL SYSTEM SYMPTOMS

1 - 6: The numbers refer to the order of inspection.

(continued on next page)

SYSTEM — ENGINE MECHANICAL & OTHER

Mass air flow sen](/img/42/57030/w960_57030-1780.png)

EC-482

< SYMPTOM DIAGNOSIS >[VK56DE]

ENGINE CONTROL SYSTEM SYMPTOMS

1 - 6: The numbers refer to the order of inspection.

(continued on next page)

SYSTEM — ENGINE MECHANICAL & OTHER

Mass air flow sensor circuit

1

12 2

222 2 EC-106,

EC-113

Engine coolant temperature sensor circuit

333

EC-124,

EC-132

Air fuel ratio (A/F ) sensor 1 circuit EC-141

,

EC-145

,

EC-149

,

EC-153

,

EC-385

Throttle position sensor circuit

22EC-128

,

EC-194

,

EC-310

,

EC-312

,

EC-377

Accelerator pedal position sensor circuit 3 2 1EC-289

,

EC-370

,

EC-373

,

EC-381

Knock sensor circuit 23EC-204

Crankshaft position sensor (POS) circuit 2 2 EC-207

Camshaft position sensor (PHASE) circuit 3 2 EC-211

Vehicle speed signal circuit2 3 33EC-280

Power steering pressu re sensor circuit 23 3 EC-286

ECM 22333333333 EC-289,

EC-291

Intake valve timing control solenoid valve cir-

cuit 32 13223 3

EC-103

Park/Neutral position (PNP) signal circuit3 3 3 33EC-296

Refrigerant pressure sensor circuit 233 4 EC-423

Electrical load signal circuit 3EC-397

Air conditioner circuit 223333333 3 2 HAC-24

ABS actuator and electric unit (control unit) 4 BRC-37

SYMPTOM

Refer-

ence page

HARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

SPARK KNOCK/DETONATION

LACK OF POWER/POOR ACCELERATION

HIGH IDLE/LOW IDLE

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEATS/WATER TEMPERATURE HIGH

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

BATTERY DEAD (UNDER CHARGE)

Warranty symptom code AA AB AC AD AE AF AG AH AJ AK AL AM HA

Revision: March 2010 2008 QX56

Page 1782 of 4083

![INFINITI QX56 2008 Factory Service Manual ENGINE CONTROL SYSTEM SYMPTOMSEC-483

< SYMPTOM DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

SYMPTOM

Reference

page

HARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

S INFINITI QX56 2008 Factory Service Manual ENGINE CONTROL SYSTEM SYMPTOMSEC-483

< SYMPTOM DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

SYMPTOM

Reference

page

HARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

S](/img/42/57030/w960_57030-1781.png)

ENGINE CONTROL SYSTEM SYMPTOMSEC-483

< SYMPTOM DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

SYMPTOM

Reference

page

HARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

SPARK KNOCK/DETONATION

LACK OF POWER/POOR ACCELERATION

HIGH IDLE/LOW IDLE

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEATS/WATER TEMPERATURE HIGH

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

BATTERY DEAD (UNDER CHARGE)

Warranty symptom code AA AB AC AD AE AF AG AH AJ AK AL AM HA

Fuel Fuel tank 5

5 FL-11

Fuel piping

5 5 5 5 55FL-6

Va p o r l o c k —

Valve deposit 5 555 55 5—

Poor fuel (Heavy weight gasoline,

Low octane) —

Air Air duct

55555 5 EM-25

Air cleaner

EM-25

Air leakage from air duct

(Mass air flow sensor — electric

throttle control actuator)

5555 EM-25

Electric throttle control actuator

EM-26

Air leakage from intake manifold/

Collector/GasketEM-26

Cranking Battery

111111

11

PG-73

Generator circuit

CHG-8

Starter circuit3 STR-8

Signal plate6 EM-45

Park/Neutral position (PNP) sig-

nal4

TM-43

Engine Cylinder head

55555 55 5 EM-68

Cylinder head gasket 4 3

Cylinder block

66666 66 64

EM-82

Piston

Piston ring

Connecting rod

Bearing

Crankshaft

Va l v e

mecha-

nism Timing chain

55555 55 5EM-45

Camshaft

EM-53

Intake valve timing controlEM-53

Intake valve

3EM-68

Exhaust valve

Revision: March 2010 2008 QX56

Page 1883 of 4083

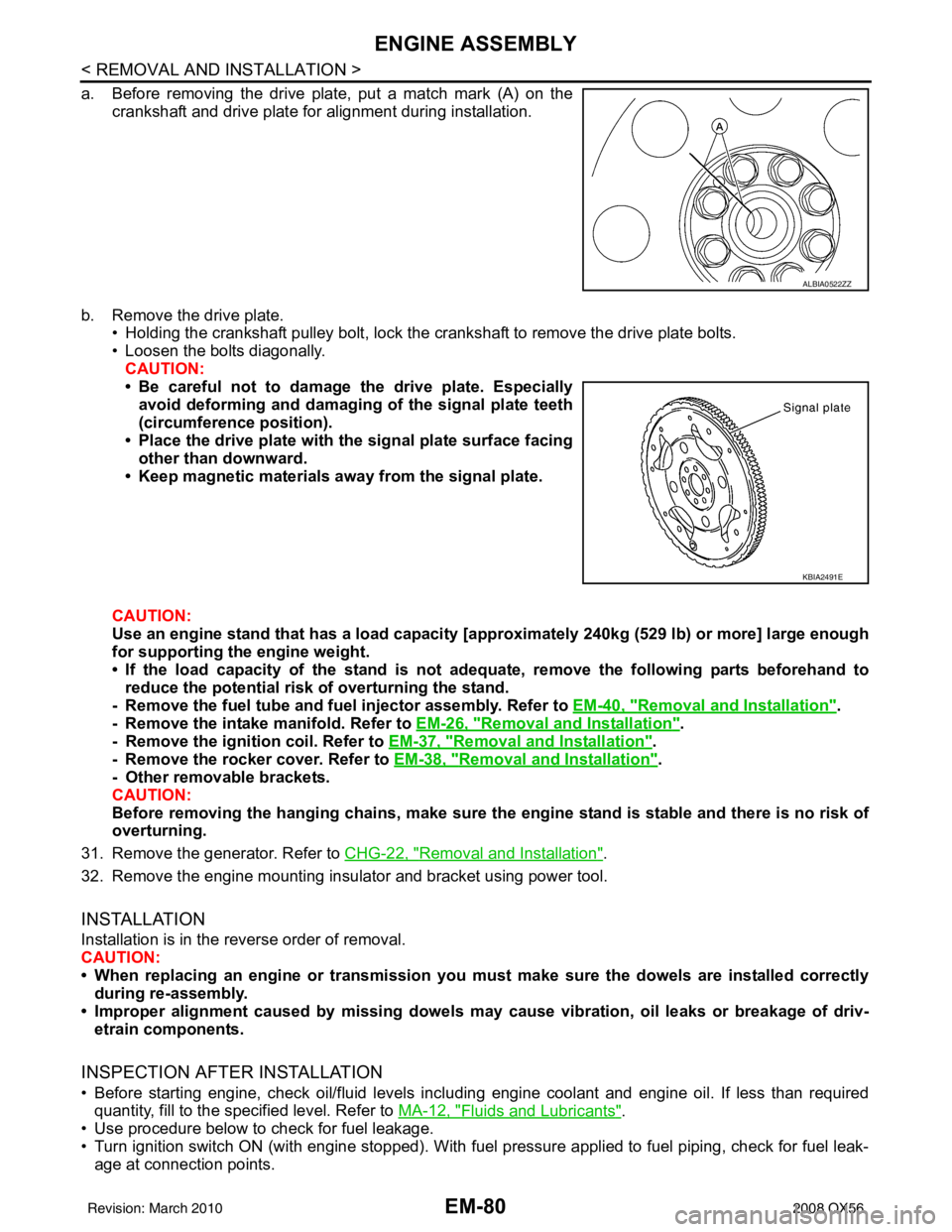

EM-80

< REMOVAL AND INSTALLATION >

ENGINE ASSEMBLY

a. Before removing the drive plate, put a match mark (A) on thecrankshaft and drive plate for alignment during installation.

b. Remove the drive plate. • Holding the crankshaft pulley bolt, lock the crankshaft to remove the drive plate bolts.

• Loosen the bolts diagonally.

CAUTION:

• Be careful not to damage the drive plate. Especiallyavoid deforming and damaging of the signal plate teeth

(circumference position).

• Place the drive plate with th e signal plate surface facing

other than downward.

• Keep magnetic materials away from the signal plate.

CAUTION:

Use an engine stand that has a load capacity [a pproximately 240kg (529 lb) or more] large enough

for supporting the engine weight.

• If the load capacity of the stand is not adeq uate, remove the following parts beforehand to

reduce the potential risk of overturning the stand.

- Remove the fuel tube and fuel injector assembly. Refer to EM-40, "

Removal and Installation".

- Remove the intake manifold. Refer to EM-26, "

Removal and Installation".

- Remove the ignition coil. Refer to EM-37, "

Removal and Installation".

- Remove the rocker cover. Refer to EM-38, "

Removal and Installation".

- Other removable brackets.

CAUTION:

Before removing the hanging chains, make sure th e engine stand is stable and there is no risk of

overturning.

31. Remove the generator. Refer to CHG-22, "

Removal and Installation".

32. Remove the engine mounting insulator and bracket using power tool.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• When replacing an engine or transmission you mu st make sure the dowels are installed correctly

during re-assembly.

• Improper alignment caused by mi ssing dowels may cause vibration, oil leaks or breakage of driv-

etrain components.

INSPECTION AFTER INSTALLATION

• Before starting engine, check oil/fluid levels incl uding engine coolant and engine oil. If less than required

quantity, fill to the specified level. Refer to MA-12, "

Fluids and Lubricants".

• Use procedure below to check for fuel leakage.

• Turn ignition switch ON (with engine stopped). With fuel pressure applied to fuel piping, check for fuel leak- age at connection points.

ALBIA0522ZZ

KBIA2491E

Revision: March 2010 2008 QX56

Page 1929 of 4083

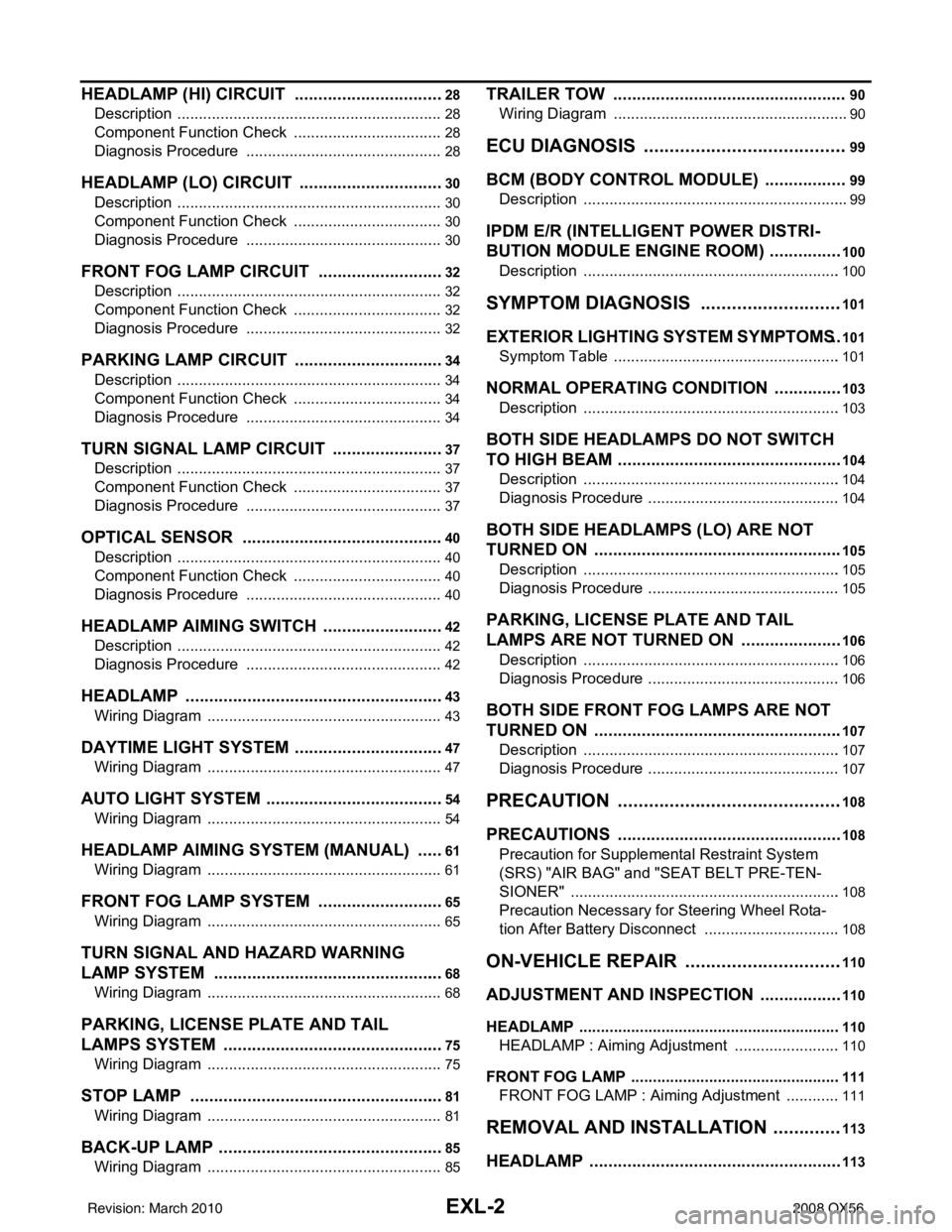

EXL-1

DRIVER CONTROLS

C

DE

F

G H

I

J

K

M

SECTION EXL

A

B

EXL

N

O P

CONTENTS

EXTERIOR LIGHTING SYSTEM

BASIC INSPECTION ....... .............................4

DIAGNOSIS AND REPAIR WORKFLOW ..... .....4

Work Flow ........................................................... ......4

FUNCTION DIAGNOSIS ...............................7

HEADLAMP .................................................... .....7

System Diagram .................................................. ......7

System Description ...................................................7

Component Parts Location ........................................7

Component Description .............................................7

DAYTIME LIGHT SYSTEM .................................9

System Diagram .................................................. ......9

System Description ...................................................9

Component Parts Location ........................................9

Component Description ...........................................10

AUTO LIGHT SYSTEM ......................................11

System Diagram ......................................................11

System Description .................................................11

Component Parts Location ......................................12

Component Description ...........................................12

HEADLAMP AIMING SYSTEM (MANUAL) .......14

System Diagram .................................................. ....14

System Description .................................................14

Component Description ...........................................14

FRONT FOG LAMP ............................................15

System Diagram .................................................. ....15

System Description .................................................15

Component Parts Location ......................................15

Component Description ...........................................15

TURN SIGNAL AND HAZARD WARNING

LAMPS ...............................................................

16

System Diagram .................................................. ....16

System Description .................................................16

Component Parts Location ......................................17

Component Description ...........................................17

PARKING, LICENSE PLATE AND TAIL

LAMPS ..............................................................

18

System Diagram .................................................. ....18

System Description ..................................................18

Component Parts Location ......................................18

Component Description ...........................................19

TRAILER TOW ..................................................20

System Diagram ......................................................20

System Description ..................................................20

Component Parts Location ......................................21

Component Description ...........................................21

DIAGNOSIS SYSTEM (BCM) ...........................23

COMMON ITEM ..................................................... ....23

COMMON ITEM : Diagnosis Description ................23

COMMON ITEM : CONSULT-III Function ...............23

EXTERNAL LAMP ................................................. ....23

EXTERNAL LAMP : CONSULT-III Function ............23

FLASHER ............................................................... ....25

FLASHER : CONSULT-III Function (BCM -

FLASHER) ...............................................................

25

DIAGNOSIS SYSTEM (IPDM E/R) ...................26

CONSULT - III Function (IPDM E/R) .......................26

COMPONENT DIAGNOSIS .........................27

POWER SUPPLY AND GROUND CIRCUIT ....27

BCM (BODY CONTROL MODULE) ...................... ....27

BCM (BODY CONTROL MODULE) : Diagnosis

Procedure ............................................................ ....

27

IPDM E/R (INTELLIGENT POWER DISTRIBU-

TION MODULE ENGINE ROOM) .......................... ....

27

IPDM E/R (INTELLIGENT POWER DISTRIBU-

TION MODULE ENGINE ROOM) : Diagnosis Pro-

cedure .................................................................. ....

27

Revision: March 2010 2008 QX56

Page 1930 of 4083

EXL-2

HEADLAMP (HI) CIRCUIT ................................28

Description ........................................................... ...28

Component Function Check ...................................28

Diagnosis Procedure ..............................................28

HEADLAMP (LO) CIRCUIT ...............................30

Description ........................................................... ...30

Component Function Check ...................................30

Diagnosis Procedure ..............................................30

FRONT FOG LAMP CIRCUIT ...........................32

Description ........................................................... ...32

Component Function Check ...................................32

Diagnosis Procedure ..............................................32

PARKING LAMP CIRCUIT ................................34

Description ........................................................... ...34

Component Function Check ...................................34

Diagnosis Procedure ..............................................34

TURN SIGNAL LAMP CIRCUIT ........................37

Description ........................................................... ...37

Component Function Check ...................................37

Diagnosis Procedure ..............................................37

OPTICAL SENSOR ...........................................40

Description ..............................................................40

Component Function Check ...................................40

Diagnosis Procedure ..............................................40

HEADLAMP AIMING SWITCH ..........................42

Description ........................................................... ...42

Diagnosis Procedure ..............................................42

HEADLAMP .......................................................43

Wiring Diagram .................................................... ...43

DAYTIME LIGHT SYSTEM ................................47

Wiring Diagram .................................................... ...47

AUTO LIGHT SYSTEM ......................................54

Wiring Diagram .................................................... ...54

HEADLAMP AIMING SYSTEM (MANUAL) ......61

Wiring Diagram .................................................... ...61

FRONT FOG LAMP SYSTEM ...........................65

Wiring Diagram .................................................... ...65

TURN SIGNAL AND HAZARD WARNING

LAMP SYSTEM .............................................. ...

68

Wiring Diagram .................................................... ...68

PARKING, LICENSE PLATE AND TAIL

LAMPS SYSTEM ............................................ ...

75

Wiring Diagram .................................................... ...75

STOP LAMP ......................................................81

Wiring Diagram .................................................... ...81

BACK-UP LAMP ................................................85

Wiring Diagram .................................................... ...85

TRAILER TOW ..................................................90

Wiring Diagram .................................................... ...90

ECU DIAGNOSIS .......................................99

BCM (BODY CONTROL MODULE) ............... ...99

Description ........................................................... ...99

IPDM E/R (INTELLIGENT POWER DISTRI-

BUTION MODULE ENGINE ROOM) ................

100

Description ........................................................... .100

SYMPTOM DIAGNOSIS ...........................101

EXTERIOR LIGHTING SYSTEM SYMPTOMS ..101

Symptom Table .................................................... .101

NORMAL OPERATING CONDITION ...............103

Description ........................................................... .103

BOTH SIDE HEADLAMPS DO NOT SWITCH

TO HIGH BEAM ................................................

104

Description ........................................................... .104

Diagnosis Procedure .............................................104

BOTH SIDE HEADLAMPS (LO) ARE NOT

TURNED ON .....................................................

105

Description ............................................................105

Diagnosis Procedure .............................................105

PARKING, LICENSE PLATE AND TAIL

LAMPS ARE NOT TURNED ON ......................

106

Description ........................................................... .106

Diagnosis Procedure .............................................106

BOTH SIDE FRONT FOG LAMPS ARE NOT

TURNED ON .....................................................

107

Description ............................................................107

Diagnosis Procedure .............................................107

PRECAUTION ...........................................108

PRECAUTIONS .............................................. ..108

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" .............................................................. .

108

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ................................

108

ON-VEHICLE REPAIR ..............................110

ADJUSTMENT AND INSPECTION ................ ..110

HEADLAMP ............................................................ .110

HEADLAMP : Aiming Adjustment .........................110

FRONT FOG LAMP ................................................ .111

FRONT FOG LAMP : Aiming Adjustment .............111

REMOVAL AND INSTALLATION .............113

HEADLAMP .................................................... ..113

Revision: March 2010 2008 QX56

Page 1931 of 4083

EXL-3

C

DE

F

G H

I

J

K

M A

B

EXL

N

O P

Bulb Replacement ........

.........................................

113

Removal and Installation .......................................114

Disassembly and Assembly ................................ ..114

AUTO LIGHT SYSTEM ....................................116

Removal and Installation .......................................116

FRONT FOG LAMP ........................................ ..117

Bulb Replacement .................................................117

Removal and Installation .......................................117

LIGHTING & TURN SIGNAL SWITCH .......... ..119

Removal and Installation .......................................119

HAZARD SWITCH .......................................... ..120

Removal and Installation .......................................120

PUDDLE LAMP .............................................. ..121

Removal and Installation .......................................121

LICENSE PLATE LAMP .................................122

Bulb Replacement ............................................... ..122

Removal and Installation .......................................122

STOP LAMP ....................................................123

Bulb Replacement .................................................123

Removal and Installation .......................................123

REAR COMBINATION LAMP .........................124

Bulb Replacement .................................................124

Removal and Installation .......................................124

SERVICE DATA AND SPECIFICATIONS

(SDS) ............... .......................................... .

125

BULB SPECIFICATIONS ................................125

Headlamp ............................................................ ..125

Exterior Lamp ........................................................125

Revision: March 2010 2008 QX56

Page 1936 of 4083

EXL-8

< FUNCTION DIAGNOSIS >

HEADLAMP

mixtureof xenon (an inert gas) and certain other metal halides. In addition to added lighting power, electronic

controlof the power supply gives the headlamps stable quality and tone color.Following are some of the many

advantages of the xenon type headlamp.

• The light produced by the headlamps is a white color comparable to sunlight that is easy on the eyes.

• Light output is nearly double that of halogen headlamps, affording increased area of illumination.

• The light features a high relative spectral distribution at wavelengths to which the human eye is most sensi-tive. This means that even in the rain, more light is reflected back from the road surface toward the vehi-

cle,for added visibility.

• Power consumption is approximately 25 percent less than halogen headlamps, reducing battery load..

HIGH BEAM OPERATION/FLASH-TO-PASS OPERATION

With the lighting switch in the 2ND position and placed in HIGH position, the BCM receives input requesting

the headlamp high beams to illuminate. The flash to pass feature can be used any time and also sends a sig-

nal to the BCM. This input is communicated to t he IPDM E/R via the CAN communication lines. The CPU of

the combination meter controls the ON/OFF status off the HIGH BEAM indicator. The CPU of the IPDM E/R

controls the headlamp high relay coil which supplies power to the high beam headlamps.

The combination meter receives a high beam request signal (ON) via the CAN communication lines and turns

the high beam indicator lamp ON.

COMBINATION SWITCH READING FUNCTION

Refer to BCS-7, "System Description".

AUTO LIGHT OPERATION

Refer to EXL-11, "System Description".

Revision: March 2010 2008 QX56