differential INFINITI QX56 2008 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: QX56, Model: INFINITI QX56 2008Pages: 4083, PDF Size: 81.73 MB

Page 4 of 4083

2008

QUICK REFERENCE CHART: QX56

QUICK REFERENCE CHART: QX56

Engine Tune-up DataINFOID:0000000006237760

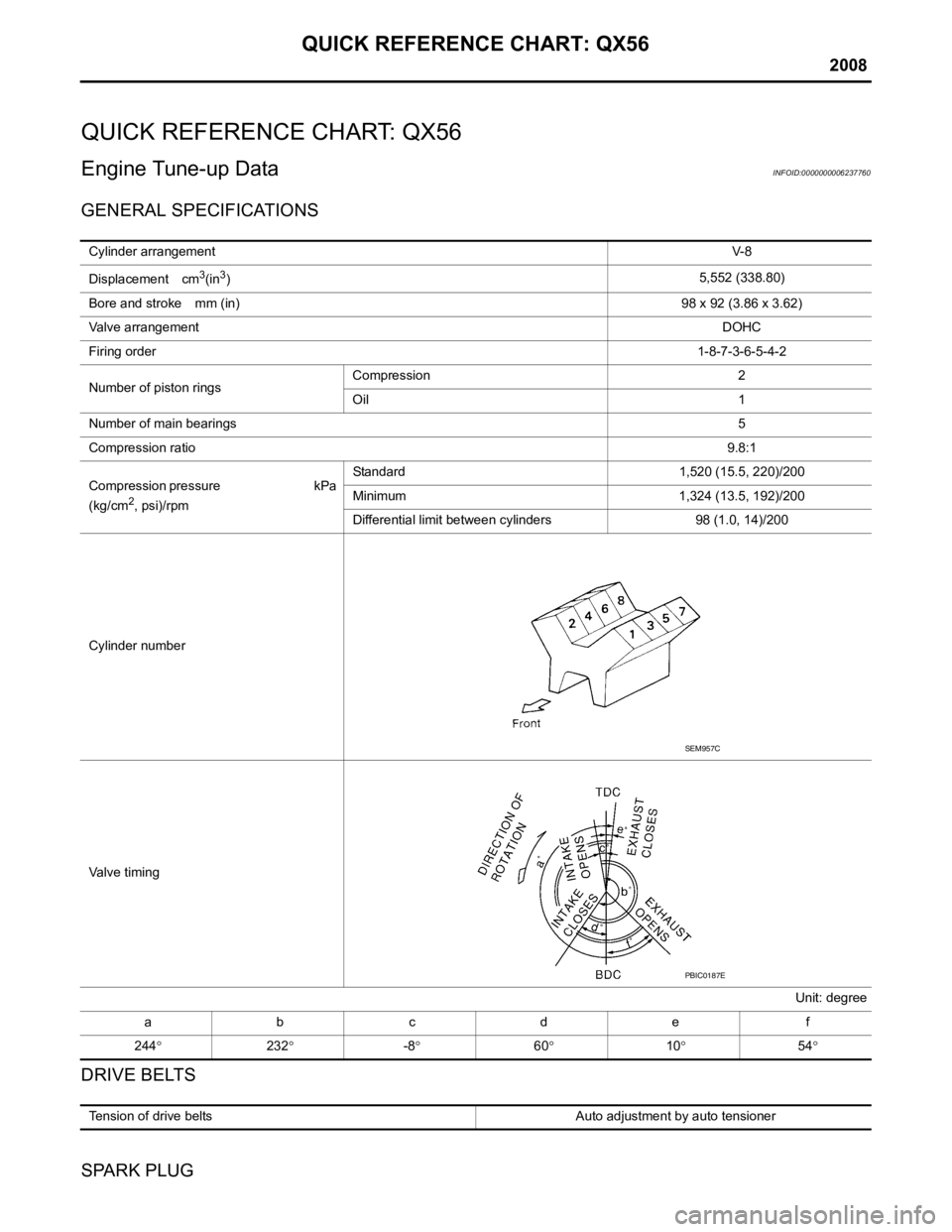

GENERAL SPECIFICATIONS

DRIVE BELTS

SPARK PLUG

Cylinder arrangementV- 8

Displacement cm

3(in3) 5,552 (338.80)

Bore and stroke mm (in) 98 x 92 (3.86 x 3.62)

Valve arrangement DOHC

Firing order 1-8-7-3-6-5-4-2

Number of piston rings Compression 2

Oil 1

Number of main bearings 5

Compression ratio 9.8:1

C o m p r e s s i o n p r e s s u r e k P a

(kg/cm

2, psi)/rpm Standard 1,520 (15.5, 220)/200

Minimum 1,324 (13.5, 192)/200

Differential limit between cylinders 98 (1.0, 14)/200

Cylinder number

Valve timing Unit: degree

abcde f

244 ° 232° -8° 60° 10° 54°

SEM957C

PBIC0187E

Tension of drive belts Auto adjustment by auto tensioner

Page 426 of 4083

BR-6

< FUNCTION DIAGNOSIS >

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

FUNCTION DIAGNOSIS

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NVH Troubleshooting ChartINFOID:0000000004894481

Use the chart below to help you find the cause of the sy mptom. If necessary, repair or replace these parts.

×: ApplicableReference page

BR-7

, BR-9

BR-7

, BR-9

BR-7

, BR-9

BR-7

, BR-9

BR-7

, BR-9

BR-7

, BR-9

BR-7

, BR-9

BR-7

, BR-9

BR-7

, BR-9

BR-7

, BR-9

DLN-182, "

NVH Troubleshooting Chart

" (2F1310),

DLN-192, "

NVH Troubleshooting Chart

" (2S1410)

DLN-206, "

NVH Troubleshooting Chart

" (FFD),

DLN-240, "

NVH Troubleshooting Chart

" (RFD)

FAX-5, "

NVH Troubleshooting Chart

" (FAX),

RAX-5, "

NVH Troubleshooting Chart

" (RAX)

FSU-6, "

NVH Troubleshooting Chart

" (FSU),

RSU-5, "

NVH Troubleshooting Chart

" (RSU)

WT-41, "

NVH Troubleshooting Chart

"

ST-12, "

NVH Troubleshooting Chart

"

Possible cause and

SUSPECTED PARTS

Pads - damaged

Pads - uneven wear

Shims damaged

Rotor imbalance

Rotor damage

Rotor runout

Rotor deformation

Rotor deflection

Rotor rust

Rotor thickness variation

PROPELLER SHAFT

DIFFERENTIAL

DRIVESHAFT

SUSPENSION

TIRES AND ROAD WHEEL

STEERING

Symptom Noise

××× × × × × ××

Shake ×× ××××

Shimmy, Shudder ××××××× × × ××

Revision: March 2010 2008 QX56

Page 594 of 4083

BRM-8

< SERVICE INFORMATION >

BODY REPAIR

FRAME COMPONENT PARTS

1. Front shock absorber bracket RH/LH

2. Front differential mounting bracket RH/LH

3. 1st cab mounting bracket RH/LH

4. Front side member extension assembly RH/LH

5. 1st crossmember assembly

LIIA1594E

Revision: March 20102008 QX56

Page 1034 of 4083

DLN-4

Commercial Service Tool ......................................191

SYMPTOM DIAGNOSIS ............................192

NOISE, VIBRATION, AND HARSHNESS

(NVH) TROUBLESHOOTING ......................... .

192

NVH Troubleshooting Chart ................................ ..192

ON-VEHICLE REPAIR ...............................193

PROPELLER SHAFT ..................................... .193

On-Vehicle Service .............................................. ..193

REMOVAL AND INSTALLATION ..............194

PROPELLER SHAFT ..................................... .194

Removal and Installation ..................................... ..194

DISASSEMBLY AND ASSEMBLY ............197

PROPELLER SHAFT ..................................... .197

Disassembly and Assembly ................................. ..197

SERVICE DATA AND SPECIFICATIONS

(SDS) ........................................................ ..

199

SERVICE DATA AND SPECIFICATIONS

(SDS) ............................................................... .

199

General Specification .......................................... ..199

Snap Ring ..............................................................200

FRONT FINAL DRIVE: M205

PRECAUTION .............. ..............................

201

PRECAUTIONS .............................................. .201

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" .............................................................. ..

201

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect .................................

201

Precaution for Servicing Front Final Drive .............202

PREPARATION ..........................................203

PREPARATION .............................................. .203

Special Service Tool ............................................ ..203

Commercial Service Tool ......................................205

SYMPTOM DIAGNOSIS ............................206

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING ......................... .

206

NVH Troubleshooting Chart ................................ ..206

ON-VEHICLE MAINTENANCE ..................207

DIFFERENTIAL GEAR OIL ............................ .207

Changing Differential Gear Oil ...............................207

Checking Differential Gear Oil ............................. ..207

ON-VEHICLE REPAIR ...............................208

SIDE OIL SEAL .............................................. ..208

Removal and Installation .......................................208

FRONT OIL SEAL ............................................209

Removal and Installation .......................................209

CARRIER COVER .......................................... ..211

Removal and Installation .......................................211

REMOVAL AND INSTALLA TION .............212

FRONT FINAL DRIVE .................................... ..212

Removal and Installation .......................................212

DISASSEMBLY AND ASSEMBLY ...........214

FRONT FINAL DRIVE .................................... ..214

Disassembly and Assembly ................................. .214

SERVICE DATA AND SPECIFICATIONS

(SDS) ........ .................................................

231

SERVICE DATA AND SPECIFICATIONS

(SDS) .............................................................. ..

231

General Specification ........................................... .231

Inspection and Adjustment ....................................231

REAR FINAL DRIVE: R230

PRECAUTION ............... ............................

233

PRECAUTIONS .............................................. ..233

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" .............................................................. .

233

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ................................

233

Precaution for Servicing Rear Final Drive .............234

PREPARATION .........................................235

PREPARATION .............................................. ..235

Special Service Tool ............................................ .235

Commercial Service Tool ......................................239

SYMPTOM DIAGNOSIS ...........................240

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING ......................... ..

240

NVH Troubleshooting Chart ..................................240

DESCRIPTION ................................................ ..241

Cross-Sectional View ........................................... .241

ON-VEHICLE MAINTENANCE .................242

DIFFERENTIAL GEAR OIL ..............................242

Changing Differential Gear Oil ............................. .242

Checking Differential Gear Oil ..............................242

ON-VEHICLE REPAIR ..............................243

FRONT OIL SEAL ............................................243

Revision: March 2010 2008 QX56

Page 1212 of 4083

![INFINITI QX56 2008 Factory Service Manual DLN-182

< SYMPTOM DIAGNOSIS >[PROPELLER SHAFT: 2F1310]

NOISE, VIBRATION, AND HARSHNESS

(NVH) TROUBLESHOOTING

SYMPTOM DIAGNOSIS

NOISE, VIBRATION, AND HARSHNESS (NVH) TROUBLESHOOTING

NVH Troubleshootin INFINITI QX56 2008 Factory Service Manual DLN-182

< SYMPTOM DIAGNOSIS >[PROPELLER SHAFT: 2F1310]

NOISE, VIBRATION, AND HARSHNESS

(NVH) TROUBLESHOOTING

SYMPTOM DIAGNOSIS

NOISE, VIBRATION, AND HARSHNESS (NVH) TROUBLESHOOTING

NVH Troubleshootin](/img/42/57030/w960_57030-1211.png)

DLN-182

< SYMPTOM DIAGNOSIS >[PROPELLER SHAFT: 2F1310]

NOISE, VIBRATION, AND HARSHNESS

(NVH) TROUBLESHOOTING

SYMPTOM DIAGNOSIS

NOISE, VIBRATION, AND HARSHNESS (NVH) TROUBLESHOOTING

NVH Troubleshooting ChartINFOID:0000000001604426

Use the chart below to help you find the cause of the sy mptom. If necessary, repair or replace these parts.

×: ApplicableReference page

DLN-183, "

On-Vehicle Service

"

DLN-183, "

On-Vehicle Service

"

DLN-183, "

On-Vehicle Service

"

DLN-240, "

NVH Troubleshooting Chart

"

RAX-5, "

NVH Troubleshooting Chart

"

RSU-5, "

NVH Troubleshooting Chart

"

WT-41, "

NVH Troubleshooting Chart

"

WT-41, "

NVH Troubleshooting Chart

"

RAX-10, "

Removal and Installation

"

BR-6, "

NVH Troubleshooting Chart

"

ST-12, "

NVH Troubleshooting Chart

"

Possible cause and suspected parts

Uneven rotation torque

Rotation imbalance

Excessive run out

Differential

Axle

Suspension

Tires

Road wheel

Drive shaft

Brakes

Steering

Symptom Noise

×××××××××××

Shake ×××××××

Vibration ××××××××

Revision: March 2010 2008 QX56

Page 1222 of 4083

![INFINITI QX56 2008 Factory Service Manual DLN-192

< SYMPTOM DIAGNOSIS >[PROPELLER SHAFT: 2S1410]

NOISE, VIBRATION, AND HARSHNESS

(NVH) TROUBLESHOOTING

SYMPTOM DIAGNOSIS

NOISE, VIBRATION, AND HARSHNESS (NVH) TROUBLESHOOTING

NVH Troubleshootin INFINITI QX56 2008 Factory Service Manual DLN-192

< SYMPTOM DIAGNOSIS >[PROPELLER SHAFT: 2S1410]

NOISE, VIBRATION, AND HARSHNESS

(NVH) TROUBLESHOOTING

SYMPTOM DIAGNOSIS

NOISE, VIBRATION, AND HARSHNESS (NVH) TROUBLESHOOTING

NVH Troubleshootin](/img/42/57030/w960_57030-1221.png)

DLN-192

< SYMPTOM DIAGNOSIS >[PROPELLER SHAFT: 2S1410]

NOISE, VIBRATION, AND HARSHNESS

(NVH) TROUBLESHOOTING

SYMPTOM DIAGNOSIS

NOISE, VIBRATION, AND HARSHNESS (NVH) TROUBLESHOOTING

NVH Troubleshooting ChartINFOID:0000000001604433

Use the chart below to help you find the cause of the sy mptom. If necessary, repair or replace these parts.

×: ApplicableReference page

DLN-193, "

On-Vehicle Service

"

DLN-193, "

On-Vehicle Service

"

DLN-193, "

On-Vehicle Service

"

DLN-240, "

NVH Troubleshooting Chart

"

RAX-5, "

NVH Troubleshooting Chart

"

RSU-5, "

NVH Troubleshooting Chart

"

WT-41, "

NVH Troubleshooting Chart

"

WT-41, "

NVH Troubleshooting Chart

"

RAX-5, "

NVH Troubleshooting Chart

"

BR-6, "

NVH Troubleshooting Chart

"

ST-12, "

NVH Troubleshooting Chart

"

Possible cause and suspected parts

Uneven rotation torque

Rotation imbalance

Excessive run out

Differential

Axle

Suspension

Tires

Road wheel

Drive shaft

Brakes

Steering

Symptom Noise

×××××××××××

Shake ×××××××

Vibration ××××××××

Revision: March 2010 2008 QX56

Page 1232 of 4083

![INFINITI QX56 2008 Factory Service Manual DLN-202

< PRECAUTION >[FRONT FINAL DRIVE: M205]

PRECAUTIONS

5. When the repair work is completed, return the ignition switch to the

″LOCK ″ position before connecting

the battery cables. (At this INFINITI QX56 2008 Factory Service Manual DLN-202

< PRECAUTION >[FRONT FINAL DRIVE: M205]

PRECAUTIONS

5. When the repair work is completed, return the ignition switch to the

″LOCK ″ position before connecting

the battery cables. (At this](/img/42/57030/w960_57030-1231.png)

DLN-202

< PRECAUTION >[FRONT FINAL DRIVE: M205]

PRECAUTIONS

5. When the repair work is completed, return the ignition switch to the

″LOCK ″ position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of a ll control units using CONSULT-III.

Precaution for Servicing Front Final DriveINFOID:0000000001604439

• Before starting diagnosis of the vehicle, understand the symptoms well. Perform correct and systematic

operations.

• Check for the correct installation status prior to re moval or disassembly. When matching marks are required,

be certain they do not interfere with the function of the parts they are applied to.

• Overhaul should be done in a clean work area, a dust proof area is recommended.

• Before disassembly, completely remove sand and mud from the exterior of the unit, preventing them from

entering into the unit during disassembly or assembly.

• Always use shop paper for cleaning the inside of components.

• Avoid using cotton gloves or a shop cloth to prevent the entering of lint.

• Check appearance of the disassembled parts for dam age, deformation, and abnormal wear. Replace them

with new ones if necessary.

• Gaskets, seals and O-rings should be replaced any time the unit is disassembled.

• Clean and flush the parts sufficiently and blow them dry.

• Be careful not to damage sliding surfaces and mating surfaces.

• When applying sealant, remove the old sealant from the mating surface; then remove any moisture, oil, and

foreign materials from the application and mating surfaces.

• In principle, tighten nuts or bolts gradually in severa l steps working diagonally from inside to outside. If a

tightening sequence is specified, observe it.

• During assembly, observe the specified tightening torque.

• Add new differential gear oil, petroleum jelly, or multi-purpose grease, as specified.

Revision: March 2010 2008 QX56

Page 1236 of 4083

![INFINITI QX56 2008 Factory Service Manual DLN-206

< SYMPTOM DIAGNOSIS >[FRONT FINAL DRIVE: M205]

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING

SYMPTOM DIAGNOSIS

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NVH Troubleshooting INFINITI QX56 2008 Factory Service Manual DLN-206

< SYMPTOM DIAGNOSIS >[FRONT FINAL DRIVE: M205]

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING

SYMPTOM DIAGNOSIS

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NVH Troubleshooting](/img/42/57030/w960_57030-1235.png)

DLN-206

< SYMPTOM DIAGNOSIS >[FRONT FINAL DRIVE: M205]

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING

SYMPTOM DIAGNOSIS

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NVH Troubleshooting ChartINFOID:0000000001604442

Use the chart below to help you find the cause of the sy mptom. If necessary, repair or replace these parts.

×: ApplicableReference page

DLN-214, "

Disassembly and Assembly

"

DLN-214, "

Disassembly and Assembly

"

DLN-214, "

Disassembly and Assembly

"

DLN-214, "

Disassembly and Assembly

"

DLN-214, "

Disassembly and Assembly

"

DLN-207, "

Changing Differential Gear Oil

"

DLN-182, "

NVH Troubleshooting Chart

"

FAX-5, "

NVH Troubleshooting Chart

"

FSU-6, "

NVH Troubleshooting Chart

"

WT-41, "

NVH Troubleshooting Chart

"

WT-41, "

NVH Troubleshooting Chart

"

FAX-5, "

NVH Troubleshooting Chart

"

BR-6, "

NVH Troubleshooting Chart

"

ST-12, "

NVH Troubleshooting Chart

"

Possible cause and SUSPECTED PARTS

Gear tooth rough

Gear contact improper

Tooth surfaces worn

Incorrect backlash

Companion flange excessive runout

Gear oil improper

PROPELLER SHAFT

FRONT AXLE

FRONT SUSPENSION

TIRES

ROAD WHEEL

DRIVE SHAFT

BRAKES

STEERING

Symptom

Noise××××××××××××××

Revision: March 2010 2008 QX56

Page 1237 of 4083

![INFINITI QX56 2008 Factory Service Manual DIFFERENTIAL GEAR OILDLN-207

< ON-VEHICLE MAINTENANCE > [FRONT FINAL DRIVE: M205]

C

EF

G H

I

J

K L

M A

B

DLN

N

O P

ON-VEHICLE MAINTENANCE

DIFFERENTIAL GEAR OIL

Changing Differential Gear OilINFOID:000 INFINITI QX56 2008 Factory Service Manual DIFFERENTIAL GEAR OILDLN-207

< ON-VEHICLE MAINTENANCE > [FRONT FINAL DRIVE: M205]

C

EF

G H

I

J

K L

M A

B

DLN

N

O P

ON-VEHICLE MAINTENANCE

DIFFERENTIAL GEAR OIL

Changing Differential Gear OilINFOID:000](/img/42/57030/w960_57030-1236.png)

DIFFERENTIAL GEAR OILDLN-207

< ON-VEHICLE MAINTENANCE > [FRONT FINAL DRIVE: M205]

C

EF

G H

I

J

K L

M A

B

DLN

N

O P

ON-VEHICLE MAINTENANCE

DIFFERENTIAL GEAR OIL

Changing Differential Gear OilINFOID:0000000001604443

DRAINING

1. Stop the engine.

2. Remove the drain plug from the front final drive assembly to drain the differential gear oil.

3. Install the drain plug with sealant applied on the thr eads to the front final drive assembly. Tighten to the

specified torque. Refer to DLN-214, "

Disassembly and Assembly".

• Use High Performance Thread Sealant or equivalent. Refer to GI-15, "

Recommended Chemical Prod-

ucts and Sealants".

FILLING

1. Remove the filler plug from the front final drive assembly.

2. Fill the front final drive assembly with new differential gear oil

until the level reaches the specified level near the filler plug hole.

3. Install the filler plug with sealant applied on the threads to the front final drive assembly. Tighten to the specified torque. Refer

to DLN-214, "

Disassembly and Assembly".

• Use High Performance Thread Sealant or equivalent. Refer to GI-15, "

Recommended Chemical Products and Sealants".

Checking Differential Gear OilINFOID:0000000001604444

DIFFERENTIAL GEAR OIL LEAKAGE AND LEVEL

1. Make sure that differential gear oil is not leaking from the front final drive assembly or around it.

2. Check the differential gear oil level from the filler plug hole as

shown.

CAUTION:

Do not start engine while checki ng differential gear oil level.

3. Install the filler plug with sealant applied on the threads to the front final drive assembly. Tighten to the specified torque. Refer

to DLN-214, "

Disassembly and Assembly".

• Use High Performance Thread Sealant or equivalent. Refer to GI-15, "

Recommended Chemical Products and Sealants".

Differential gear oil

grade and capacity

: Refer to

MA-12, "

Fluids

and Lubricants".

LDIA0176E

LDIA0176E

Revision: March 2010 2008 QX56

Page 1238 of 4083

![INFINITI QX56 2008 Factory Service Manual DLN-208

< ON-VEHICLE REPAIR >[FRONT FINAL DRIVE: M205]

SIDE OIL SEAL

ON-VEHICLE REPAIR

SIDE OIL SEAL

Removal and InstallationINFOID:0000000001604445

REMOVAL

1. Remove the front final drive assembly. R INFINITI QX56 2008 Factory Service Manual DLN-208

< ON-VEHICLE REPAIR >[FRONT FINAL DRIVE: M205]

SIDE OIL SEAL

ON-VEHICLE REPAIR

SIDE OIL SEAL

Removal and InstallationINFOID:0000000001604445

REMOVAL

1. Remove the front final drive assembly. R](/img/42/57030/w960_57030-1237.png)

DLN-208

< ON-VEHICLE REPAIR >[FRONT FINAL DRIVE: M205]

SIDE OIL SEAL

ON-VEHICLE REPAIR

SIDE OIL SEAL

Removal and InstallationINFOID:0000000001604445

REMOVAL

1. Remove the front final drive assembly. Refer to

DLN-212, "Removal and Installation".

2. Remove the differential side shaft and differential side flange using suitable tool.

3. Place a small hole in the side oil seal case using suitable tool.

4. Remove the side oil seal using suitable tool as shown.

INSTALLATION

1. Apply multi-purpose grease to the lips of the new side oil seal. Then drive the new side oil seal in evenly to

the gear carrier using suitable tool.

CAUTION:

• Do not reuse side oil seal.

• Do not incline the new side oil seal when installing.

• Apply multi-purpose grease to the lips of the new side oil seal.

2. Installation of the remaining components is in the reverse order of removal. CAUTION:

Check the differential gear oil level after installation. Refer to DLN-207, "

Checking Differential Gear

Oil".

BDIA0006E

LDIA0129E

LDIA0130E

Revision: March 2010 2008 QX56