battery INFINITI QX56 2008 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: QX56, Model: INFINITI QX56 2008Pages: 4083, PDF Size: 81.73 MB

Page 2219 of 4083

HA-14

< PREPARATION >

PREPARATION

Tool number

(Kent-Moore No.)

Tool nameDescription

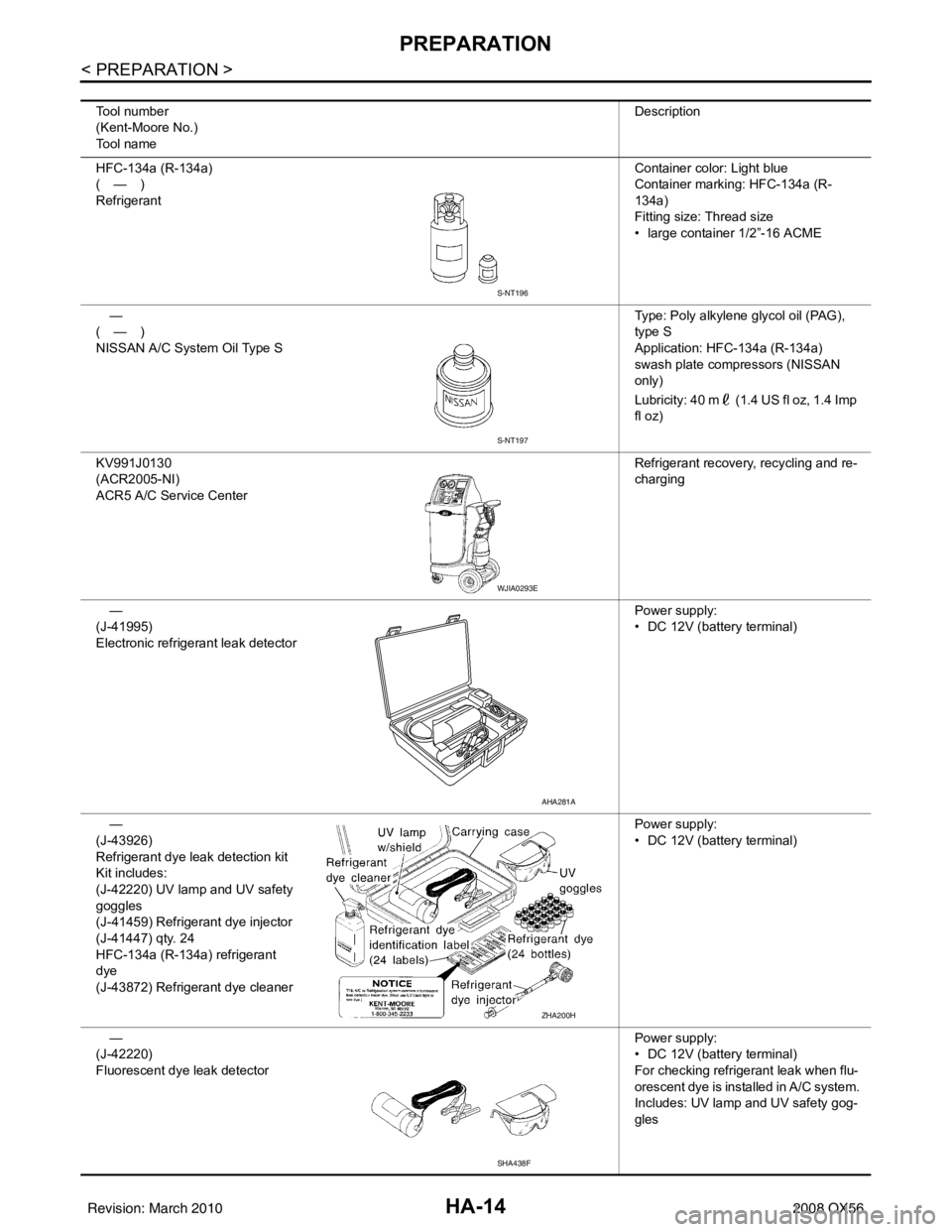

HFC-134a (R-134a)

(—)

Refrigerant Container color: Light blue

Container marking: HFC-134a (R-

134a)

Fitting size: Thread size

• large container 1/2”-16 ACME

—

(—)

NISSAN A/C System Oil Type S Type: Poly alkylene glycol oil (PAG),

type S

Application: HFC-134a (R-134a)

swash plate compressors (NISSAN

only)

Lubricity: 40 m (1.4 US fl oz, 1.4 Imp

fl oz)

KV991J0130

(ACR2005-NI)

ACR5 A/C Service Center Refrigerant recovery, recycling and re-

charging

—

(J-41995)

Electronic refrigerant leak detector Power supply:

• DC 12V (battery terminal)

—

(J-43926)

Refrigerant dye leak detection kit

Kit includes:

(J-42220) UV lamp and UV safety

goggles

(J-41459) Refrigerant dye injector

(J-41447) qty. 24

HFC-134a (R-134a) refrigerant

dye

(J-43872) Refrigerant dye cleaner Power supply:

• DC 12V (battery terminal)

—

(J-42220)

Fluorescent dye leak detector Power supply:

• DC 12V (battery terminal)

For checking refrigerant leak when flu-

orescent dye is installed in A/C system.

Includes: UV lamp and UV safety gog-

gles

S-NT196

S-NT197

WJIA0293E

AHA281A

ZHA200H

SHA438F

Revision: March 2010

2008 QX56

Page 2243 of 4083

HA-38

< ON-VEHICLE REPAIR >

LOW-PRESSURE PIPE

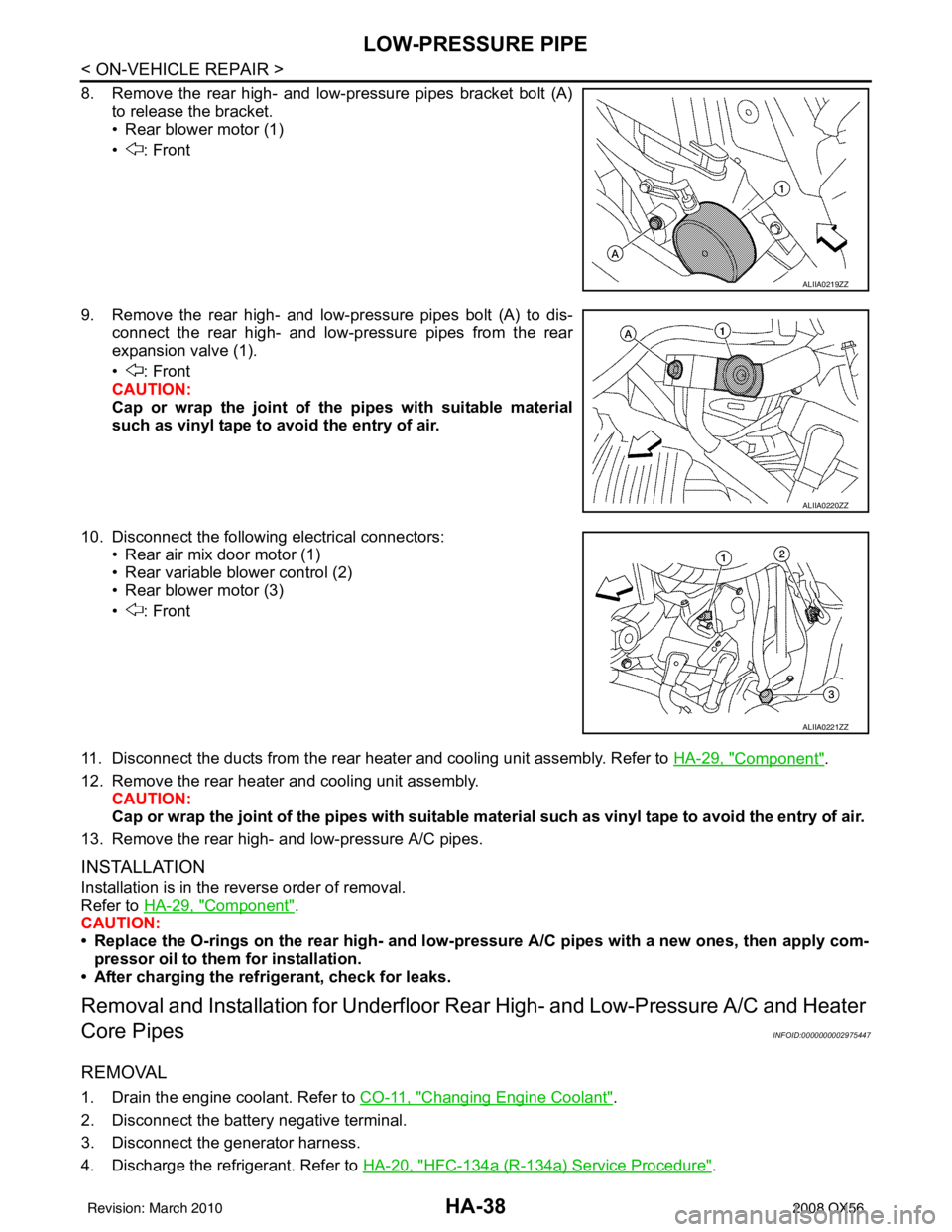

8. Remove the rear high- and low-pressure pipes bracket bolt (A)to release the bracket.

• Rear blower motor (1)

• : Front

9. Remove the rear high- and low-pressure pipes bolt (A) to dis- connect the rear high- and low-pressure pipes from the rear

expansion valve (1).

• : Front

CAUTION:

Cap or wrap the joint of the pipes with suitable material

such as vinyl tape to avoid the entry of air.

10. Disconnect the following electrical connectors: • Rear air mix door motor (1)

• Rear variable blower control (2)

• Rear blower motor (3)

• : Front

11. Disconnect the ducts from the rear heater and cooling unit assembly. Refer to HA-29, "

Component".

12. Remove the rear heater and cooling unit assembly. CAUTION:

Cap or wrap the joint of the pipes with suitable material such as viny l tape to avoid the entry of air.

13. Remove the rear high- and low-pressure A/C pipes.

INSTALLATION

Installation is in the reverse order of removal.

Refer to HA-29, "

Component".

CAUTION:

• Replace the O-rings on the rear high- and low-pr essure A/C pipes with a new ones, then apply com-

pressor oil to them for installation.

• After charging the refrigerant, check for leaks.

Removal and Installati on for Underfloor Rear High- and Low-Pressure A/C and Heater

Core Pipes

INFOID:0000000002975447

REMOVAL

1. Drain the engine coolant. Refer to CO-11, "Changing Engine Coolant".

2. Disconnect the battery negative terminal.

3. Disconnect the generator harness.

4. Discharge the refrigerant. Refer to HA-20, "

HFC-134a (R-134a) Service Procedure".

ALIIA0219ZZ

ALIIA0220ZZ

ALIIA0221ZZ

Revision: March 2010 2008 QX56

Page 2246 of 4083

HIGH-PRESSURE PIPEHA-41

< ON-VEHICLE REPAIR >

C

DE

F

G H

J

K L

M A

B

HA

N

O P

HIGH-PRESSURE PIPE

Removal and Installation for High-Pressure PipeINFOID:0000000001516657

REMOVAL

1. Remove the cowl top extension. Refer to EXT-18, "Removal and Installation".

2. Disconnect the battery negative terminal and positive battery terminal.

3. Reposition the IPDM E/R aside.

4. Remove the front right wheel and tire assembly. Refer to WT-48, "

Rotation".

5. Remove front right fender protector. Refer to EXT-23, "

Removal and Installation"

6. Position aside the front floor insulator.

7. Discharge the refrigerant. Refer to HA-20, "

HFC-134a (R-134a) Service Procedure".

8. Remove the low pressure pipe. Refer to HA-37, "

Removal and Installation for Low-Pressure Pipe".

9. Remove the high-pressure pipe. CAUTION:

Cap or wrap the joint of the pipe with suitable mate rial such as vinyl tape to avoid the entry of air.

INSTALLATION

Installation is in the reverse order of removal.

Refer to HA-29, "

Component".

CAUTION:

• Replace the O-ring of the high-pressure pipe with a new one, then apply compressor oil to it when

installing it.

• After charging refrigerant, check for leaks.

Removal and Installation for Rear High- and Low-Pressure A/C and Heater Core Pipes

INFOID:0000000002975448

REMOVAL

1. Discharge the refrigerant from the A/C system. Refer to HA-20, "HFC-134a (R-134a) Service Procedure".

2. Drain the coolant from the engine cooling system. Refer to CO-11, "

Changing Engine Coolant".

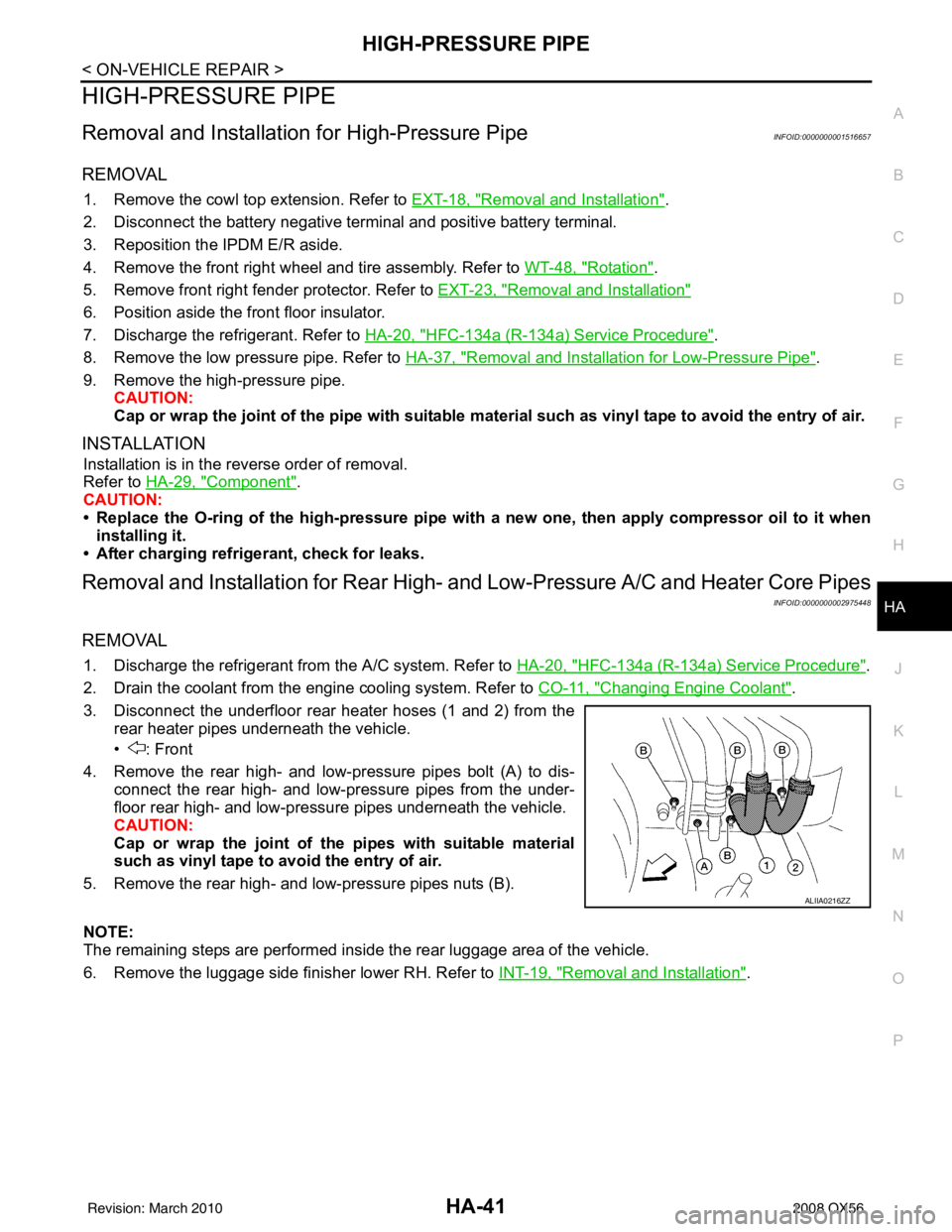

3. Disconnect the underfloor rear heater hoses (1 and 2) from the rear heater pipes underneath the vehicle.

• : Front

4. Remove the rear high- and low-pressure pipes bolt (A) to dis- connect the rear high- and low-pressure pipes from the under-

floor rear high- and low-pressure pipes underneath the vehicle.

CAUTION:

Cap or wrap the joint of the pipes with suitable material

such as vinyl tape to avo id the entry of air.

5. Remove the rear high- and low-pressure pipes nuts (B).

NOTE:

The remaining steps are performed inside the rear luggage area of the vehicle.

6. Remove the luggage side finisher lower RH. Refer to INT-19, "

Removal and Installation".

ALIIA0216ZZ

Revision: March 2010 2008 QX56

Page 2248 of 4083

HIGH-PRESSURE PIPEHA-43

< ON-VEHICLE REPAIR >

C

DE

F

G H

J

K L

M A

B

HA

N

O P

• Replace the O-rings on the rear high- and low-pr essure A/C pipes with a new ones, then apply com-

pressor oil to them for installation.

• After charging the refrigerant, check for leaks.

Removal and Installation for Underfloor Rear High- and Lo w-Pressure A/C and Heater

Core Pipes

INFOID:0000000002975449

REMOVAL

1. Drain the engine coolant. Refer to CO-11, "Changing Engine Coolant".

2. Disconnect the battery negative terminal.

3. Disconnect the generator harness.

4. Discharge the refrigerant. Refer to HA-20, "

HFC-134a (R-134a) Service Procedure".

5. Remove the front and rear bumper fascia. Refer to EXT-13, "

Removal and Installation" (front), EXT-15,

"Removal and Installation" (rear).

6. Reposition the front fender protector out of the way. Refer to EXT-23, "

Removal and Installation".

7. Disconnect the chassis harness connector.

8. Remove the spare wheel and tire.

9. Remove the tailpipe and tailpipe hanger bracket. Refer to EX-6, "

Removal and Installation".

10. Remove the seatbelt latch anchor. Refer to EX-6, "

Removal and Installation".

11. Remove the front floor heat shield.

12. Disconnect each end of the underfloor rear high- and low-pressure A/C and heater core pipes. Refer to HA-29, "

Component".

CAUTION:

Cap or wrap the joint of the pipes with suitable material such as viny l tape to avoid the entry of air.

13. Set two suitable jacks at the RH body mount points to support the vehicle body when it is separated from the RH side of the frame.

14. Remove the RH body mount bolts. Refer to BRM-2, "

Body Mounting".

15. Use the vehicle hoist to lower the RH side of the frame from the RH side of the body [approximately 305 mm (12 in)] until there is sufficient clearance to remove the underfloor rear high- and low-pressure A/C

and heater core pipes from between the body and the frame.

16. Remove the underfloor rear high- and low-pressure A/C and heater core pipes from the back of the vehi- cle.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• Replace the O-rings of the underfloor rear high - and low-pressure A/C and heater core pipes with

new ones, then apply compressor oil to them for installation.

• After charging refrigerant, check for leaks.

Revision: March 2010 2008 QX56

Page 2273 of 4083

![INFINITI QX56 2008 Factory Service Manual HAC-20

< FUNCTION DIAGNOSIS >[AUTOMATIC AIR CONDITIONER]

DIAGNOSIS SYSTEM (HVAC)

DIAGNOSIS SYSTEM (HVAC)

CONSULT-III Function (HVAC)INFOID:0000000001679777

CONSULT-III can display each diagnostic item INFINITI QX56 2008 Factory Service Manual HAC-20

< FUNCTION DIAGNOSIS >[AUTOMATIC AIR CONDITIONER]

DIAGNOSIS SYSTEM (HVAC)

DIAGNOSIS SYSTEM (HVAC)

CONSULT-III Function (HVAC)INFOID:0000000001679777

CONSULT-III can display each diagnostic item](/img/42/57030/w960_57030-2272.png)

HAC-20

< FUNCTION DIAGNOSIS >[AUTOMATIC AIR CONDITIONER]

DIAGNOSIS SYSTEM (HVAC)

DIAGNOSIS SYSTEM (HVAC)

CONSULT-III Function (HVAC)INFOID:0000000001679777

CONSULT-III can display each diagnostic item using the diagnostic test modes shown following.

SELF-DIAGNOSIS

Display Item List

DATA MONITOR

Display Item List

Diagnostic mode

Description

SELF-DIAG RESULTS Displays A/C au to amp. self-diagnosis results.

DATA MONITOR Displays A/C auto amp. input/output data in real time.

CAN DIAG SUPPORT MNTR The result of transmit/receive diagnosis of CAN communication can be read. ECU PART NUMBER A/C auto amp. part number can be read.

DTC Description

Reference page

B2573 Battery voltage out of range CHG-10, "

Inspection Procedure"

B2578 In-vehicle sensor circuit out of range (low)

HAC-81, "In-Vehicle Sensor Diagnosis Procedure"B2579 In-vehicle sensor circuit out of range (high)

B257B Ambient sensor circuit short HAC-78, "

Ambient Sensor Diagnosis Procedure"B257C Ambient sensor circuit open

B257F Optical sensor (Driver) circuit open or short HAC-84, "

Optical Sensor Diagnosis Procedure".

B2580 Optical sensor (Passenger) circuit open or short

B2581 Intake sensor circuit short HAC-86, "

Intake Sensor Diagnosis Procedure"B2582 Intake sensor circuit open

U1000 CAN bus fault LAN-14, "

Trouble Diagnosis Flow Chart"

Monitor itemValue Contents

BATT VIA CAN "V" Displays battery voltage signal.

IGN VIA CAN "ON/OFF" Displays ignition switch signal.

DVR SUNLD SEN "w/m2" Displays optical sensor (driver) signal.

PAS SUNLD SEN "w/m2" Displays optical sensor (passenger) signal.

AMB TEMP SEN "° C" Displays ambient sensor signal.

EVAP TEMP SEN "° C" Displays intake sensor signal.

INCAR TMP SEN "° C" Displays in-vehicle sensor signal.

RR TEMPSET FR "V" Displays air mix door (front) set point signal.

RR TEMPSET RR "V" Displays air mix door (rear) set point signal.

MODE FDBCK "V" Displays mode door motor feedback signal.

DVR MIX FDBCK "V" Displays air mix door motor (driver) feedback signal.

PAS MIX FDBCK "V" Displays air mix door motor (passenger) feedback signal.

RR FDBCK "V" Displays air mix door motor (rear) feedback signal.

DEF FDBCK "V" Displays defroster door motor feedback signal.

Revision: March 2010 2008 QX56

Page 2275 of 4083

![INFINITI QX56 2008 Factory Service Manual HAC-22

< FUNCTION DIAGNOSIS >[AUTOMATIC AIR CONDITIONER]

SELF-DIAGNOSIS FUNCTION

SELF-DIAGNOSIS FUNCTION

A/C Auto Amp. Self-DiagnosisINFOID:0000000001679779

A/C SYSTEM SELF-DIAGNOSIS FUNCTION

The self INFINITI QX56 2008 Factory Service Manual HAC-22

< FUNCTION DIAGNOSIS >[AUTOMATIC AIR CONDITIONER]

SELF-DIAGNOSIS FUNCTION

SELF-DIAGNOSIS FUNCTION

A/C Auto Amp. Self-DiagnosisINFOID:0000000001679779

A/C SYSTEM SELF-DIAGNOSIS FUNCTION

The self](/img/42/57030/w960_57030-2274.png)

HAC-22

< FUNCTION DIAGNOSIS >[AUTOMATIC AIR CONDITIONER]

SELF-DIAGNOSIS FUNCTION

SELF-DIAGNOSIS FUNCTION

A/C Auto Amp. Self-DiagnosisINFOID:0000000001679779

A/C SYSTEM SELF-DIAGNOSIS FUNCTION

The self-diagnosis function is built into the A/C aut

o amp. to quickly locate the cause of malfunctions.

DESCRIPTION

The self-diagnostic system diagnoses sensors, CAN sys tem, and battery voltage on A/C auto amp. Refer to

applicable sections (items) for details. Fault codes (if any are present) will be displayed in the ambient temper-

ature display area. Refer to HAC-23, "

A/C System Self-Diagnosis Code Chart".

SELF-DIAGNOSTIC MODE

NOTE:

Radio must be off.

1. On the A/C and AV switch asse mbly, press the "SETTING" but-

ton and twist the volume knob clockwise and counterclockwise

until the Self-Diagnosis screen shows on the display.

2. Scroll down to "Confirmation/Adjustment" and press the "ENTER" button.

3. Scroll down to "Climate Control" and press the "ENTER" button.

4. The fan bars will flash on the display during the self-test, and then the fault codes will display in the ambient temperature area.

They will continue scrolling until diagnostic mode is exited.

5. Exit by pressing the "BACK" button on A/C and AV switch assembly until display returns to its normal operation screen.

HVAC system will be OFF.

The self-diagnostic system diagnoses sensors, CAN sys tem, and battery voltage on A/C auto amp. Refer to

applicable sections (items) for details. Fault codes (if any are present) will be displayed in the ambient temper-

ature display area. Refer to HAC-23, "

A/C System Self-Diagnosis Code Chart".

A/C and AV Switch Asse mbly Self-DiagnosisINFOID:0000000001679780

A/C and AV switch assembly self-diagnosis function

The ON/OFF operation (continuity) of each switch in the A/C and AV switch assembly can be checked.

Self-diagnosis mode

AWNIA0098ZZ

AWIIA0081ZZ

Revision: March 2010 2008 QX56

Page 2276 of 4083

![INFINITI QX56 2008 Factory Service Manual SELF-DIAGNOSIS FUNCTIONHAC-23

< FUNCTION DIAGNOSIS > [AUTOMATIC AIR CONDITIONER]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

• Press the “BACK” switch and the “UP” switch within 10 seconds after turni INFINITI QX56 2008 Factory Service Manual SELF-DIAGNOSIS FUNCTIONHAC-23

< FUNCTION DIAGNOSIS > [AUTOMATIC AIR CONDITIONER]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

• Press the “BACK” switch and the “UP” switch within 10 seconds after turni](/img/42/57030/w960_57030-2275.png)

SELF-DIAGNOSIS FUNCTIONHAC-23

< FUNCTION DIAGNOSIS > [AUTOMATIC AIR CONDITIONER]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

• Press the “BACK” switch and the “UP” switch within 10 seconds after turning the ignition switch from OFF to ACC and hold them for

3 seconds or more. Then the buzzer sounds, all indicators of the

preset switch illuminate, and the self-diagnosis mode starts.

• The continuity of each switch and control dials (A/C and AV switch assembly only) at the ON position can be checked by pressing

each switch and turning each control dial. The buzzer sounds and

LED’s will illuminate if the switch is normal.

Finishing self-diagnosis mode

Self-diagnosis mode is canceled when turning the ignition switch OFF.

A/C System Self-Diagnosis Code ChartINFOID:0000000001679781

SELF-DIAGNOSTIC CODE CHART

AWIIA0171GB

Code No. Reference page

03 Battery voltage out of range CHG-11, "

Inspection Procedure"

30 In-vehicle sensor circuit out of range (low)

HAC-81, "In-Vehicle Sensor Diagnosis Procedure"31 In-vehicle sensor circuit out of range (high)

40 Ambient sensor circuit shortHAC-78, "

Ambient Sensor Diagnosis Procedure"41 Ambient sensor circuit open

50 Optical sensor (Driver) circuit open or shortHAC-84, "

Optical Sensor Diagnosis Procedure"52 Optical sensor (Passenger) circuit open or short

56 Intake sensor circuit shortHAC-86, "

Intake Sensor Diagnosis Procedure"57 Intake sensor circuit open

80 CAN bus faultLAN-14, "

Trouble Diagnosis Flow Chart"

Revision: March 2010 2008 QX56

Page 2279 of 4083

![INFINITI QX56 2008 Factory Service Manual HAC-26

< COMPONENT DIAGNOSIS >[AUTOMATIC AIR CONDITIONER]

MODE DOOR MOTOR

7.CHECK THE MODE DOOR MO

TOR (FRONT) PBR CIRCUIT

Perform diagnostic procedure for the mode door motor (front). Refer to HAC- INFINITI QX56 2008 Factory Service Manual HAC-26

< COMPONENT DIAGNOSIS >[AUTOMATIC AIR CONDITIONER]

MODE DOOR MOTOR

7.CHECK THE MODE DOOR MO

TOR (FRONT) PBR CIRCUIT

Perform diagnostic procedure for the mode door motor (front). Refer to HAC-](/img/42/57030/w960_57030-2278.png)

HAC-26

< COMPONENT DIAGNOSIS >[AUTOMATIC AIR CONDITIONER]

MODE DOOR MOTOR

7.CHECK THE MODE DOOR MO

TOR (FRONT) PBR CIRCUIT

Perform diagnostic procedure for the mode door motor (front). Refer to HAC-25, "

Mode Door Motor (Front)

Component Function Check".

Is the inspection result normal?

YES >> GO TO 8.

NO >> Repair PBR circuit or replace motor. Refer to HAC-26, "

Mode Door Motor (Front) Diagnosis Pro-

cedure".

8.RECHECK FOR CODES

Perform A/C auto amp. self-diagnosis. Refer to HAC-22, "

A/C Auto Amp. Self-Diagnosis".

Are any self-diagnostic codes present?

YES >> Refer to HAC-23, "A/C System Self-Diagnosis Code Chart".

NO >> GO TO 9.

9.RECHECK FOR SYMPTOMS

Perform a complete operational check and check for any symptoms. Refer to HAC-4, "

Operational Check

(Front)".

Does another symptom exist?

YES >> Repair as necessary.

NO >> Replace A/C auto amp. Refer to VTL-7, "

Removal and Installation".

Mode Door Motor (Front) Diagnosis ProcedureINFOID:0000000001679784

SYMPTOM:

• Air outlet does not change.

• Mode door motor does not operate normally.

1.CHECK A/C AUTO AMP. FOR POWER AND GROUND

1. Turn ignition switch ON.

2. Press the mode switch to the B/L ( ) mode.

3. Check voltage between A/C auto amp. harness connector M49 terminal 19 and terminal 20 while pressing the mode switch to

the floor ( ) mode.

Is the inspection result normal?

YES >> GO TO 3.

NO >> GO TO 2.

2.CHECK MODE DOOR MOTOR CIRCUITS FOR SHORT TO GROUND

1. Turn ignition switch OFF.

2. Disconnect the A/C auto amp. harness connector.

3. Check continuity between A/C auto amp. harness connector M49 terminal 19, 20 and ground.

Is the inspection result normal?

YES >> Replace A/C auto amp. Refer to VTL-7, "Removal and

Installation".

Connector Te r m i n a l s

Condition Voltage

(Approx.)

(+) (-)

A/C auto amp.: M49 20

19Press

mode

switch Battery

voltage

AWIIA0095ZZ

19 - Ground : Continuity should not exist.

20 - Ground : Continuity should not exist.

AWIIA0096ZZ

Revision: March 2010 2008 QX56

Page 2280 of 4083

![INFINITI QX56 2008 Factory Service Manual MODE DOOR MOTORHAC-27

< COMPONENT DIAGNOSIS > [AUTOMATIC AIR CONDITIONER]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

NO >> Repair or replace harness as necessary.

3.CHECK A/C AUTO AMP. FOR GROUND AND POWER

1. INFINITI QX56 2008 Factory Service Manual MODE DOOR MOTORHAC-27

< COMPONENT DIAGNOSIS > [AUTOMATIC AIR CONDITIONER]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

NO >> Repair or replace harness as necessary.

3.CHECK A/C AUTO AMP. FOR GROUND AND POWER

1.](/img/42/57030/w960_57030-2279.png)

MODE DOOR MOTORHAC-27

< COMPONENT DIAGNOSIS > [AUTOMATIC AIR CONDITIONER]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

NO >> Repair or replace harness as necessary.

3.CHECK A/C AUTO AMP. FOR GROUND AND POWER

1. Press the mode switch to the D/F ( ) mode.

2. Check voltage between A/C auto amp. harness connector M49 terminal 19 and terminal 20 while pressing the mode switch to

the vent ( ) mode.

Is the inspection result normal?

YES >> GO TO 4.

NO >> Replace A/C auto amp. Refer to VTL-7, "

Removal and Installation".

4.CHECK MODE DOOR MOTOR AND CIRCUITS FOR OPEN

1. Turn ignition switch OFF.

2. Disconnect the A/C auto amp. harness connector.

3. Check continuity between A/C auto amp. harness connector M49 terminal 19 and terminal 20.

Is the inspection result normal?

YES >> GO TO 6.

NO >> GO TO 5.

5.CHECK MODE DOOR MOTOR CIRCUITS FOR OPEN

1. Disconnect the mode door motor harness connector.

2. Check continuity between A/C auto amp. harness connector M49 (A) terminal 19, 20 and the mode door motor harness con-

nector M142 (B) terminal 5, 6.

Is the inspection result normal?

YES >> Replace mode door motor. Refer to VTL-24, "Removal

and Installation".

NO >> Repair or replace harness as necessary.

6.CHECK A/C AUTO AMP. FOR PBR POWER AND GROUND

1. Reconnect A/C auto amp. harness connector.

2. Turn ignition switch ON.

3. Check voltage between A/C auto amp. harness connector M50 (A) terminal 28 and M49 (B) terminal 3.

Is the inspection result normal?

YES >> GO TO 8.

NO >> GO TO 7.

Connector Te r m i n a l s

Condition Voltage

(Approx.)

(+) (-)

A/C auto amp.: M49 19 20 Press

mode

switch Battery

voltage

AWIIA0097ZZ

Continuity should exist.

AWIIA0098ZZ

5 - 19 : Continuity should exist.

6 - 20 : Continuity should exist.

AWIIA0094ZZ

Connector Te r m i n a l s

Voltage (Ap-

prox.)

(+) (-)

A/C auto amp.: M49, M50 28 35V

AWIIA0099ZZ

Revision: March 2010 2008 QX56

Page 2286 of 4083

![INFINITI QX56 2008 Factory Service Manual AIR MIX DOOR MOTORHAC-33

< COMPONENT DIAGNOSIS > [AUTOMATIC AIR CONDITIONER]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

1. Turn ignition switch ON.

2. Rotate temperature control dial (driver) to 32 °C (90 °F INFINITI QX56 2008 Factory Service Manual AIR MIX DOOR MOTORHAC-33

< COMPONENT DIAGNOSIS > [AUTOMATIC AIR CONDITIONER]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

1. Turn ignition switch ON.

2. Rotate temperature control dial (driver) to 32 °C (90 °F](/img/42/57030/w960_57030-2285.png)

AIR MIX DOOR MOTORHAC-33

< COMPONENT DIAGNOSIS > [AUTOMATIC AIR CONDITIONER]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

1. Turn ignition switch ON.

2. Rotate temperature control dial (driver) to 32 °C (90 °F).

3. Check voltage between A/C auto amp. harness connector M49

terminal 17 and terminal 18 while rotating temperature control

dial (driver) to 18 °C (60° F).

Is the inspection result normal?

YES >> GO TO 3.

NO >> GO TO 2.

2.CHECK AIR MIX DOOR MOTOR (DRIVER) CIRCUITS FOR SHORT TO GROUND

1. Turn ignition switch OFF.

2. Disconnect the A/C auto amp. harness connector.

3. Check continuity between A/C auto amp. harness connector M49 terminal 17, 18 and ground.

Is the inspection result normal?

YES >> Replace A/C auto amp. Refer to VTL-7, "Removal and

Installation".

NO >> Repair or replace harness as necessary.

3.CHECK A/C AUTO AMP. FOR POWER AND GROUND

1. Turn ignition switch ON.

2. Rotate temperature control dial (driver) to 32 °C (90 °F).

3. Check voltage between A/C auto amp. harness connector M49

terminal 17 and terminal 18 while rotating temperature control

dial (driver) to 18 °C (60° F).

Is the inspection result normal?

YES >> GO TO 4.

NO >> Replace A/C auto amp. Refer to VTL-7, "

Removal and Installation".

4.CHECK AIR MIX DOOR MOTOR (DRIVER) CIRCUITS FOR OPEN

1. Turn ignition switch OFF.

2. Disconnect the A/C auto amp. harness connector.

3. Check continuity between A/C auto amp. harness connector M49 terminal 17 and terminal 18.

Is the inspection result normal?

YES >> GO TO 6.

NO >> GO TO 5.

5.CHECK AIR MIX DOOR MOTOR (DRIVER) CIRCUITS FOR OPEN

Connector Te r m i n a l s

Condition Voltage

(Approx.)

(+) (-)

A/C auto amp.: M49 17 18 Rotate temp

control dial Battery

voltage

AWIIA0112ZZ

17 - Ground : Continuity should not exist.

18 - Ground : Continuity should not exist.

AWIIA0114ZZ

Connector Te r m i n a l s

Condition Voltage

(Approx.)

(+) (-)

A/C auto amp.: M49 18 17

Rotate temp

control dial Battery

voltage

AWIIA0115ZZ

Continuity should exist.

AWIIA0116ZZ

Revision: March 2010 2008 QX56