fl sensor INFINITI QX56 2008 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: QX56, Model: INFINITI QX56 2008Pages: 4083, PDF Size: 81.73 MB

Page 3548 of 4083

TM-1

TRANSMISSION & DRIVELINE

CEF

G H

I

J

K L

M

SECTION TM

A

B

TM

N

O P

CONTENTS

TRANSAXLE & TRANSMISSION

BASIC INSPECTION ....... .............................5

DIAGNOSIS AND REPAIR WORKFLOW ..... .....5

Work Flow ........................................................... ......5

Diagnostic Work Sheet ..............................................6

FUNCTION DIAGNOSIS ...............................8

A/T CONTROL SYSTEM ................................ .....8

Cross-Sectional View (2WD models) .................. ......8

Cross-Sectional View (4WD models) ........................9

Shift Mechanism ........................................................9

TCM Function ..........................................................20

CAN Communication ...............................................21

Input/Output Signal of TCM .....................................22

Line Pressure Control .............................................22

Shift Control ........................................................ ....24

Lock-up Control .......................................................25

Engine Brake Control ..............................................26

Control Valve ...........................................................26

Component Parts Location ......................................28

A/T SHIFT LOCK SYSTEM ............................ ....29

System Description ............................................. ....29

Component Parts Location ......................................29

ON BOARD DIAGNOSTIC (OBD) SYSTEM ......30

Introduction ......................................................... ....30

OBD-II Function for A/T System ..............................30

One or Two Trip Detection Logic of OBD-II ............30

OBD-II Diagnostic Trouble Code (DTC) ..................30

Malfunction Indicator Lamp (MIL) ............................31

DIAGNOSIS SYSTEM (TCM) .............................32

CONSULT-III Function (TRANSMISSION) ......... ....32

COMPONENT DIAGNOSIS .........................38

U1000 CAN COMM CI RCUIT .............................38

Description .......................................................... ....38

On Board Diagnosis Logic ......................................38

Possible Cause .......................................................38

DTC Confirmation Procedure .............................. ....38

Diagnosis Procedure ...............................................38

P0615 STARTER RELAY .................................39

Description ...............................................................39

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... ....

39

On Board Diagnosis Logic .......................................39

Possible Cause ........................................................39

DTC Confirmation Procedure ..................................39

Diagnosis Procedure ...............................................39

P0700 TRANSMISSION CONTROL .................42

Description ...............................................................42

On Board Diagnosis Logic .......................................42

Possible Cause ........................................................42

DTC Confirmation Procedure ..................................42

Diagnosis Procedure ...............................................42

P0705 TRANSMISSION RANGE SWITCH A ...43

Description ...............................................................43

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... ....

43

On Board Diagnosis Logic .......................................43

Possible Cause ........................................................43

DTC Confirmation Procedure ..................................43

Diagnosis Procedure ...............................................43

P0717 INPUT SPEED SENSOR A ....................46

Description ...............................................................46

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... ....

46

On Board Diagnosis Logic .......................................46

Possible Cause ........................................................46

DTC Confirmation Procedure ..................................46

Diagnosis Procedure ...............................................46

P0720 OUTPUT SPEED SENSOR ...................48

Description ...............................................................48

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... ....

48

On Board Diagnosis Logic .......................................48

Revision: March 2010 2008 QX56

Page 3549 of 4083

TM-2

Possible Cause .......................................................48

DTC Confirmation Procedure .................................48

Diagnosis Procedure ..............................................49

P0725 ENGINE SPEED .....................................51

Description ........................................................... ...51

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... ...

51

On Board Diagnosis Logic ......................................51

Possible Cause .......................................................51

DTC Confirmation Procedure .................................51

Diagnosis Procedure ..............................................51

P0731 1GR INCORRECT RATIO ......................53

Description ........................................................... ...53

On Board Diagnosis Logic ......................................53

Possible Cause .......................................................53

DTC Confirmation Procedure .................................53

Diagnosis Procedure ..............................................54

P0732 2GR INCORRECT RATIO ......................55

Description ........................................................... ...55

On Board Diagnosis Logic ......................................55

Possible Cause .......................................................55

DTC Confirmation Procedure .................................55

Diagnosis Procedure ..............................................56

P0733 3GR INCORRECT RATIO ......................57

Description ........................................................... ...57

On Board Diagnosis Logic ......................................57

Possible Cause .......................................................57

DTC Confirmation Procedure .................................57

Diagnosis Procedure ..............................................58

P0734 4GR INCORRECT RATIO ......................59

Description ........................................................... ...59

On Board Diagnosis Logic ......................................59

Possible Cause .......................................................59

DTC Confirmation Procedure .................................59

Diagnosis Procedure ..............................................60

P0735 5GR INCORRECT RATIO ......................61

Description ........................................................... ...61

On Board Diagnosis Logic ......................................61

Possible Cause .......................................................61

DTC Confirmation Procedure .................................61

Diagnosis Procedure ..............................................62

P0740 TORQUE CONVERTER .........................63

Description ........................................................... ...63

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... ...

63

On Board Diagnosis Logic ......................................63

Possible Cause .......................................................63

DTC Confirmation Procedure .................................63

Diagnosis Procedure ..............................................63

P0744 TORQUE CONVERTER .........................65

Description ........................................................... ...65

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... ...

65

On Board Diagnosis Logic ................................... ...65

Possible Cause .......................................................65

DTC Confirmation Procedure ..................................65

Diagnosis Procedure ...............................................66

P0745 PRESSURE CONTROL SOLENOID A ...67

Description ........................................................... ...67

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... ...

67

On Board Diagnosis Logic ......................................67

Possible Cause .......................................................67

DTC Confirmation Procedure ..................................67

Diagnosis Procedure ...............................................67

P1705 TP SENSOR ...........................................69

Description ..............................................................69

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... ...

69

On Board Diagnosis Logic ......................................69

Possible Cause .......................................................69

DTC Confirmation Procedure ..................................69

Diagnosis Procedure ...............................................69

P1710 TRANSMISSION FLUID TEMPERA-

TURE SENSOR .................................................

71

Description ........................................................... ...71

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... ...

71

On Board Diagnosis Logic ......................................71

Possible Cause .......................................................71

DTC Confirmation Procedure ..................................71

Diagnosis Procedure ...............................................71

Component Inspection ............................................73

P1721 VEHICLE SPEED SIGNAL ....................74

Description ..............................................................74

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... ...

74

On Board Diagnosis Logic ......................................74

Possible Cause .......................................................74

DTC Confirmation Procedure ..................................74

Diagnosis Procedure ...............................................74

P1730 INTERLOCK ...........................................76

Description ..............................................................76

On Board Diagnosis Logic ......................................76

Possible Cause .......................................................76

DTC Confirmation Procedure ..................................76

Judgement of Interlock ............................................76

Diagnosis Procedure ............................................ ...76

P1731 1ST ENGINE BRAKING .........................78

Description ........................................................... ...78

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... ...

78

On Board Diagnosis Logic ......................................78

Possible Cause .......................................................78

DTC Confirmation Procedure ..................................78

Diagnosis Procedure ...............................................78

Revision: March 2010 2008 QX56

Page 3551 of 4083

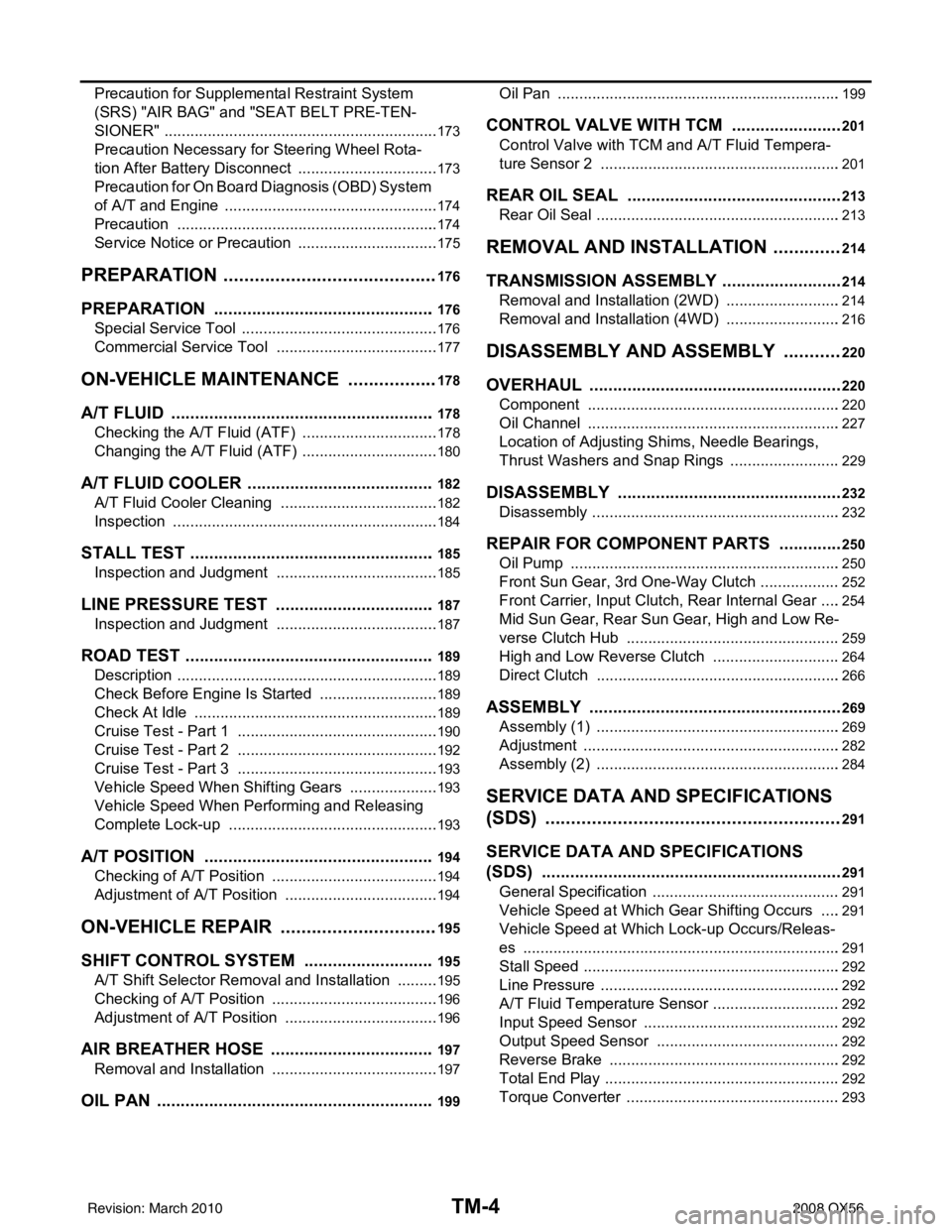

TM-4

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ................................................................

173

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect .................................

173

Precaution for On Board Diagnosis (OBD) System

of A/T and Engine ..................................................

174

Precaution .............................................................174

Service Notice or Precaution .................................175

PREPARATION ..........................................176

PREPARATION .............................................. .176

Special Service Tool ............................................ ..176

Commercial Service Tool ......................................177

ON-VEHICLE MAINTENANCE ..................178

A/T FLUID ....................................................... .178

Checking the A/T Fluid (ATF) .............................. ..178

Changing the A/T Fluid (ATF) ................................180

A/T FLUID COOLER ........................................182

A/T Fluid Cooler Cleaning ................................... ..182

Inspection ..............................................................184

STALL TEST ....................................................185

Inspection and Judgment .................................... ..185

LINE PRESSURE TEST ..................................187

Inspection and Judgment .................................... ..187

ROAD TEST .....................................................189

Description ........................................................... ..189

Check Before Engine Is Started ............................189

Check At Idle ....................................................... ..189

Cruise Test - Part 1 ...............................................190

Cruise Test - Part 2 ...............................................192

Cruise Test - Part 3 ...............................................193

Vehicle Speed When Shifting Gears .....................193

Vehicle Speed When Performing and Releasing

Complete Lock-up .................................................

193

A/T POSITION .................................................194

Checking of A/T Position ..................................... ..194

Adjustment of A/T Position ....................................194

ON-VEHICLE REPAIR ...............................195

SHIFT CONTROL SYSTEM ........................... .195

A/T Shift Selector Removal and Installation ..........195

Checking of A/T Position ..................................... ..196

Adjustment of A/T Position ....................................196

AIR BREATHER HOSE ...................................197

Removal and Installation ..................................... ..197

OIL PAN ...........................................................199

Oil Pan ................................................................. .199

CONTROL VALVE WITH TCM ........................201

Control Valve with TCM and A/T Fluid Tempera-

ture Sensor 2 ....................................................... .

201

REAR OIL SEAL ..............................................213

Rear Oil Seal ........................................................ .213

REMOVAL AND INSTALLATION .............214

TRANSMISSION ASSEMBLY ........................ ..214

Removal and Installation (2WD) .......................... .214

Removal and Installation (4WD) ...........................216

DISASSEMBLY AND ASSEMBLY ...........220

OVERHAUL ......................................................220

Component .......................................................... .220

Oil Channel ...........................................................227

Location of Adjusting Shims, Needle Bearings,

Thrust Washers and Snap Rings ......................... .

229

DISASSEMBLY .............................................. ..232

Disassembly ......................................................... .232

REPAIR FOR COMPONENT PARTS ..............250

Oil Pump .............................................................. .250

Front Sun Gear, 3rd One-Way Clutch ...................252

Front Carrier, Input Clutch, Rear Internal Gear .....254

Mid Sun Gear, Rear Sun Gear, High and Low Re-

verse Clutch Hub ................................................. .

259

High and Low Reverse Clutch ..............................264

Direct Clutch .........................................................266

ASSEMBLY .................................................... ..269

Assembly (1) ........................................................ .269

Adjustment ............................................................282

Assembly (2) .........................................................284

SERVICE DATA AND SPECIFICATIONS

(SDS) ........ .................................................

291

SERVICE DATA AND SPECIFICATIONS

(SDS) .............................................................. ..

291

General Specification ........................................... .291

Vehicle Speed at Which Gear Shifting Occurs .....291

Vehicle Speed at Which Lock-up Occurs/Releas-

es ......................................................................... .

291

Stall Speed ............................................................292

Line Pressure ........................................................292

A/T Fluid Temperature Sensor ..............................292

Input Speed Sensor ..............................................292

Output Speed Sensor ...........................................292

Reverse Brake ......................................................292

Total End Play .......................................................292

Torque Converter ..................................................293

Revision: March 2010 2008 QX56

Page 3552 of 4083

DIAGNOSIS AND REPAIR WORKFLOWTM-5

< BASIC INSPECTION >

CEF

G H

I

J

K L

M A

B

TM

N

O P

BASIC INSPECTION

DIAGNOSIS AND REPAIR WORKFLOW

Work FlowINFOID:0000000001603985

INTRODUCTION

The TCM receives a signal from the output speed sensor, accelera-

tor pedal position sensor (throttle position sensor) or transmission

range switch. Then provides shift c ontrol or lock-up control via A/T

solenoid valves.

The TCM also communicates with the ECM by means of a signal

sent from sensing elements used wit h the OBD-related parts of the

A/T system for malfunction-diagnostic purposes. The TCM is capa-

ble of diagnosing malfunctioning parts while the ECM can store mal-

functions in its memory.

Input and output signals must always be correct and stable in the

operation of the A/T system. T he A/T system must be in good oper-

ating condition and be free of valve seizure, solenoid valve malfunc-

tion, etc.

It is much more difficult to diagnose an error that occurs intermit-

tently rather than continuously. Most intermittent errors are caused

by poor electric connections or impr oper wiring. In this case, careful

checking of suspected circuits may help prevent the replacement of

good parts.

A visual check only may not find t he cause of the errors. A road test

with CONSULT-III (or GST) or a circuit tester connected should be

performed. Follow the “DETAILED FLOW”.

Before undertaking actual checks, take a few minutes to talk with a

customer who approaches with a driveability complaint. The cus-

tomer can supply good information about such errors, especially

intermittent ones. Find out what symptoms are present and under

what conditions they occur. A “Diagnostic work sheet” as shown on

the example (Refer to TM-6

) should be used.

Start your diagnosis by looking for “conventional” errors first. This will

help troubleshoot driveability errors on an electronically controlled

engine vehicle.

Also check related Service bulletins.

DETAILED FLOW

1.COLLECT THE INFORMATION FROM THE CUSTOMER

Get the detailed information from the customer about the symptom (the condition and the environment when

the incident/malfunction occurred) us ing diagnosis worksheet. Refer to TM-6, "

Diagnostic Work Sheet".

>> GO TO 2.

2.CHECK SYMPTOM 1

Check the following items based on the in formation obtained from the customer.

• Fail-safe. Refer to TM-114, "

Fail-Safe".

• A/T fluid inspection. Refer to TM-178, "

Checking the A/T Fluid (ATF)".

• Stall test. Refer to TM-185, "

Inspection and Judgment".

• Line pressure test. Refer to TM-187, "

Inspection and Judgment".

SAT631IB

SAT632I

SEF234G

Revision: March 2010 2008 QX56

Page 3567 of 4083

TM-20

< FUNCTION DIAGNOSIS >

A/T CONTROL SYSTEM

TCM Function

INFOID:0000000001603990

The function of the TCM is to:

• Receive input signals sent from various switches and sensors.

• Determine required line pressure, shifting poi nt, lock-up operation, and engine brake operation.

• Send required output signals to the respective solenoids.

CONTROL SYSTEM OUTLINE

The automatic transmission senses vehicle operating conditions through vari ous sensors or signals. It always

controls the optimum shift position and reduces shifting and lock-up shocks.

1. Front brake 2. Input clutch3. Direct clutch

4. High and low reverse clutch 5. Reverse brake 6. Forward brake

7. Low coast brake 8. 1st one-way clutch 9. Forward one-way clutch

10. 3rd one-way clutch 11. Front sun gear12. Input shaft

13. Mid internal gear 14. Front internal gear15. Rear carrier

16. Rear sun gear 17. Mid sun gear18. Front carrier

19. Mid carrier 20. Rear internal gear21. Output shaft

22. Parking gear 23. Parking pawl

SCIA1519E

Revision: March 2010 2008 QX56

Page 3568 of 4083

A/T CONTROL SYSTEMTM-21

< FUNCTION DIAGNOSIS >

CEF

G H

I

J

K L

M A

B

TM

N

O P

CONTROL SYSTEM DIAGRAM

CAN CommunicationINFOID:0000000001603991

SYSTEM DESCRIPTION

CAN (Controller Area Network) is a serial communication line for real time application. It is an on-vehicle mul-

tiplex communication line with high data communication speed and excellent error detection ability. Many elec-

tronic control units are equipped onto a vehicle, and each control unit shares information and links with other

control units during operation (not independent). In CAN communication, control units are connected with 2

communication lines (CAN H line, CAN L line) allowing a high rate of information transmission with less wiring.

Each control unit transmits/receives data but selectively reads required data only. For details, refer to LAN-4,

"System Description".

SENSORS (or SIGNALS)

⇒TCM

⇒ACTUATORS

Transmission range switch

Accelerator pedal position sensor

Closed throttle position signal

Wide open throttle position signal

Engine speed signal

A/T fluid temperature sensor

Output speed sensor

Vehicle speed signal

Stop lamp switch signal

Input speed sensor

1st position switch signal

4th position switch signal

ATF pressure switch 2 signal

Tow mode switch signal Shift control

Line pressure control

Lock-up control

Engine brake control

Timing control

Fail-safe control

Self-diagnosis

CONSULT-III co

mmunication

line

Duet-EA control

CAN system Input clutch solenoid valve

Direct clutch solenoid valve

Front brake solenoid valve

High and low reverse clutch sole-

noid valve

Low coast brake solenoid valve

Torque converter clutch solenoid

valve

Line pressure solenoid valve

A/T CHECK indicator lamp

Starter relay

Back-up lamp relay

JSDIA1315GB

Revision: March 2010

2008 QX56

Page 3569 of 4083

TM-22

< FUNCTION DIAGNOSIS >

A/T CONTROL SYSTEM

Input/Output Signal of TCM

INFOID:0000000001603992

*1: Spare for output speed sensor

*2: Spare for accelerator pedal position signal

*3: If these input and output signals are different, the TCM triggers the fail-safe function.

*4: CAN comm unications

Line Pressure ControlINFOID:0000000001603993

• When an input torque signal equivalent to the engine drive force is sent from the ECM to the TCM, the TCM

controls the line pressure solenoid.

Control item Line

pressure control Ve h i c l e

speed

control Shift

control Lock-up

control Engine

brake

control Fail-safe

function (*3) Self-diag-

nostics

function

Input Accelerator pedal position signal

(*4)XXXXXXX

Output speed sensor A/T X X X X X X

Output speed sensor MTR

(*1) (*4)XXXX X

Closed throttle position signal

(*4)(*2) X (*2) X X (*2) XX

Wide open throttle position signal

(*4)(*2) X (*2) X (*2) XX

Input speed sensor 1 X XXX X

Input speed sensor 2

(for 4th speed only) X

XXX X

Engine speed signals

(*4)XX

Transmission range switch XXXXXXX

A/T fluid temperature sensors 1, 2 X X X X X X X

ASCD Operation signal

(*4)XXXX

Overdrive cancel sig-

nal

(*4)XX X

TCM power supply voltage signal X X X X X X

Out-

put Direct clutch solenoid

X XX X

Input clutch solenoid X XX X

High and low reverse clutch sole-

noid XX

XX

Front brake solenoid X XX X

Low coast brake solenoid (ATF

pressure switch 2) XX

XXX

Line pressure solenoid XXXXXXX

TCC solenoid XX X

Starter relay XX

Revision: March 2010 2008 QX56

Page 3571 of 4083

TM-24

< FUNCTION DIAGNOSIS >

A/T CONTROL SYSTEM

The necessary and adequate line pressure for shift change is set.

For this reason, line pressure pattern setting corresponds to input

torque and gearshift selection. Also, line pressure characteristic is

set according to engine speed, during engine brake operation.

At Low Fluid Temperature

When the A/T fluid temperature drops below the prescribed tempera-

ture, in order to speed up the action of each friction element, the line

pressure is set higher than the normal line pressure characteristic.

Shift ControlINFOID:0000000001603994

The clutch pressure control solenoid is controlled by the signals from the switches and sensors. Thus, the

clutch pressure is adjusted to be appropriate to the engine load state and vehicle driving state. It becomes

possible to finely control the clutch hydraulic pressure with high precision and a smoother shift change charac-

teristic is attained.

SHIFT CHANGE

The clutch is controlled with the optimum timing and oil pressure by the engine speed, engine torque informa-

tion, etc.

Shift Change System Diagram

PCIA0010E

PCIA0011E

PCIA0012E

Revision: March 2010 2008 QX56

Page 3577 of 4083

TM-30

< FUNCTION DIAGNOSIS >

ON BOARD DIAGNOSTIC (OBD) SYSTEM

ON BOARD DIAGNOSTIC (OBD) SYSTEM

IntroductionINFOID:0000000001604002

The A/T system has two self-diagnostic systems.

The first is the emission-related on board diagnostic syst em (OBD-II) performed by the TCM in combination

with the ECM. The malfunction is indicated by the MI L (malfunction indicator lamp) and is stored as a DTC in

the ECM memory but not the TCM memory.

The second is the TCM original self-diagnosis indicated by the A/T CHECK indicator lamp. The malfunction is

stored in the TCM memory. The detected items are ov erlapped with OBD-II self-diagnostic items. For detail,

refer to TM-32, "

CONSULT-III Function (TRANSMISSION)".

OBD-II Function for A/T SystemINFOID:0000000001604003

The ECM provides emission-related on board diagnostic (O BD-II) functions for the A/T system. One function

is to receive a signal from the TCM used with OBD-relat ed parts of the A/T system. The signal is sent to the

ECM when a malfunction occurs in the corresponding OBD-re lated part. The other function is to indicate a

diagnostic result by means of the MIL (malfunction indi cator lamp) on the instrument panel. Sensors, switches

and solenoid valves are used as sensing elements.

The MIL automatically illuminates in One or Two Trip Detection Logic when a malfunction is sensed in relation

to A/T system parts.

One or Two Trip Detection Logic of OBD-IIINFOID:0000000001604004

ONE TRIP DETECTION LOGIC

If a malfunction is sensed during the first test drive, the MIL will illuminate and the malfunction will be stored in

the ECM memory as a DTC. The TCM is not provided with such a memory function.

TWO TRIP DETECTION LOGIC

When a malfunction is sensed during the first test drive, it is stored in the ECM memory as a 1st trip DTC

(diagnostic trouble code) or 1st trip freeze frame data. At this point, the MIL will not illuminate. — 1st Trip

If the same malfunction as that experienced during the fi rst test drive is sensed during the second test drive,

the MIL will illuminate. — 2nd Trip

The “Trip” in the “One or Two Trip Detection Logic” means a driving mode in which self-diagnosis is performed

during vehicle operation.

OBD-II Diagnostic Trouble Code (DTC)INFOID:0000000001604005

HOW TO READ DTC AND 1ST TRIP DTC

DTC and 1st trip DTC can be read by the following methods.

( with CONSULT-III or GST) CONSULT-III or GST (Generic Scan Tool) Examples: P0705, P0720 etc.

These DTC are prescribed by SAE J2012.

(CONSULT-III also displays the malfunctioning component or system.)

• 1st trip DTC No. is the same as DTC No.

• Output of the diagnostic troubl e code indicates that the indicated circuit has a malfunction. How-

ever, in case of the Mode II and GST, they do not indicate whether the malfunction is still occurring or

occurred in the past and returned to normal.

CONSULT-III can identify them as shown below, therefore, CONSULT-III (if available) is recom-

mended.

Freeze Frame Data and 1st Trip Freeze Frame Data

The ECM has a memory function, which stores the driv ing condition such as fuel system status, calculated

load value, engine coolant temperatur e, short term fuel trim, long term fuel trim, engine speed and vehicle

speed at the moment the ECM detects a malfunction.

Data which are stored in the ECM memory, along with the 1st trip DTC, are called 1st trip freeze frame data,

and the data, stored together with the DTC data, are called freeze frame data and displayed on CONSULT-III

or GST. The 1st trip freeze frame data can only be disp layed on the CONSULT-III screen, not on the GST. For

detail, refer to TM-30

.

Only one set of freeze frame data (either 1st trip freeze frame data of freeze frame data) can be stored in the

ECM. 1st trip freeze frame data is stored in the ECM memory along with the 1st trip DTC. There is no priority

for 1st trip freeze frame data and it is updated each time a different 1st trip DTC is detected. However, once

freeze frame data (2nd trip detection/MIL on) is stored in the ECM memory, 1st trip freeze frame data is no

Revision: March 2010 2008 QX56

Page 3579 of 4083

TM-32

< FUNCTION DIAGNOSIS >

DIAGNOSIS SYSTEM (TCM)

DIAGNOSIS SYSTEM (TCM)

CONSULT-III Function (TRANSMISSION)INFOID:0000000001604007

CONSULT-III can display each diagnostic item us ing the diagnostic test modes shown following.

SELF-DIAGNOSTIC RESULT MODE

Operation Procedure

After performing SELF-DIAGNOSTIC RESULT MO DE, place check marks for results on the TM-6, "Diagnostic

Work Sheet". Reference pages are provided following the items.

Display Items List

X: Applicable, —: Not applicable

TCM diagnostic mode Description

WORK SUPPORT Supports inspections and adjustments. Commands are transmitted to the TCM for setting the status

suitable for required operation, input/output signals are received from the TCM and received data is

displayed.

SELF-DIAG RESULTS Displays TCM self-diagnosis results.

DATA MONITOR Displays TCM input/output data in real time.

CAN DIAG SUPPORT MNTR The result of transmit/receive diagnosis of CAN communication can be read.

ACTIVE TEST Operation of electrical loads can be checked by sending drive signal to them.

FUNCTION TEST Conducted by CONSULT-III instead of a technici an to determine whether each system is “OK” or “NG”.

ECU PART NUMBER TCM part number can be read.

Items (CONSULT-III screen terms) Malfunction is detected when... TCM self-di-

agnosis OBD-II (DTC)

Reference page

“TRANSMIS-

SION” with

CONSULT-III MIL indicator

lamp*1, “EN-

GINE” with

CONSULT-III or GST

CAN COMM CIRCUIT • When a malfunction is detected in CAN communica-

tions U1000 U1000

TM-38

STARTER RELAY• If this signal is ON other than in P or N position, this is

judged to be a malfunction.

(And if it is OFF in P or N position, this too is judged to

be a malfunction.) P0615

—TM-39

TRANSMISSION

CONT • TCM is malfunctioning.

P0700 P0700TM-42

T/M RANGE SWITCH A• PNP switch 1-4 signals input with impossible pattern

• “P” position is detected from N position without any

other position being detected in between. P0705 P0705

TM-43

INPUT SPEED SEN-

SOR A• TCM does not receive the proper voltage signal from

the sensor.

• TCM detects an irregularity only at position of 4th gear

for turbine revolution sensor 2. P0717 P0717

TM-46

OUTPUT SPEED SEN-

SOR• Signal from vehicle speed sensor A/T (Revolution sen-

sor) not input due to cut line or the like

• Unexpected signal input during running

• After ignition switch is turned ON, unexpected signal

input from vehicle speed sensor MTR before the vehi-

cle starts moving P0720 P0720

TM-49

ENGINE SPEED• TCM does not receive the CAN communication signal

from the ECM. P0725

—TM-51

1GR INCORRECT RA-

TIO • A/T cannot shift to 1st gear

P0731 P0731TM-54

Revision: March 2010 2008 QX56