ignition INFINITI QX56 2009 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2009, Model line: QX56, Model: INFINITI QX56 2009Pages: 4171, PDF Size: 84.65 MB

Page 3594 of 4171

PRECAUTIONSST-3

< PRECAUTION >

C

DE

F

H I

J

K L

M A

B

ST

N

O P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005867894

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SR and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the SR section.

Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

When working near the Airbag Diagnosis Sensor Un it or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or el ectric power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minutes before performing any service.

Precaution Necessary for Steering Wh eel Rotation After Battery Disconnect

INFOID:0000000005867895

NOTE:

This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

Remove and install all control units after disconnecti ng both battery cables with the ignition knob in the

″ LOCK ″ position.

Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS , an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be

rotated.

4. Perform the necessary repair operation.

Revision: December 20092009 QX56

Page 3595 of 4171

ST-4

< PRECAUTION >

PRECAUTIONS

5. When the repair work is completed, return the ignition switch to the ″LOCK ″ position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of a ll control units using CONSULT-III.

Precaution for Steering SystemINFOID:0000000003775116

Before disassembly, thoroughly clean the outside of the unit.

Disassembly should be done in a clean work area. It is im portant to prevent the internal parts from becoming

contaminated by dirt or other foreign matter.

For easier and proper assembly, place disassembled parts in order on a parts rack.

Use nylon cloth or paper towels to clean the parts; co mmon shop rags can leave lint that might interfere with

their operation.

Before inspection or reassembly, carefully clean all parts with a general purpose, non-flammable solvent.

Before assembly, apply a coat of recommended Genuine NISSAN PSF or equivalent to hydraulic parts.

Petroleum jelly may be applied to O-rings and seals. Do not use any grease.

Replace all gaskets, seals and O-rings. Avoid damaging O-rings, seals and gaskets during installation. Per-

form functional tests whenever designated.

Revision: December 20092009 QX56

Page 3611 of 4171

ST-20

< REMOVAL AND INSTALLATION >

STEERING COLUMN

STEERING COLUMN

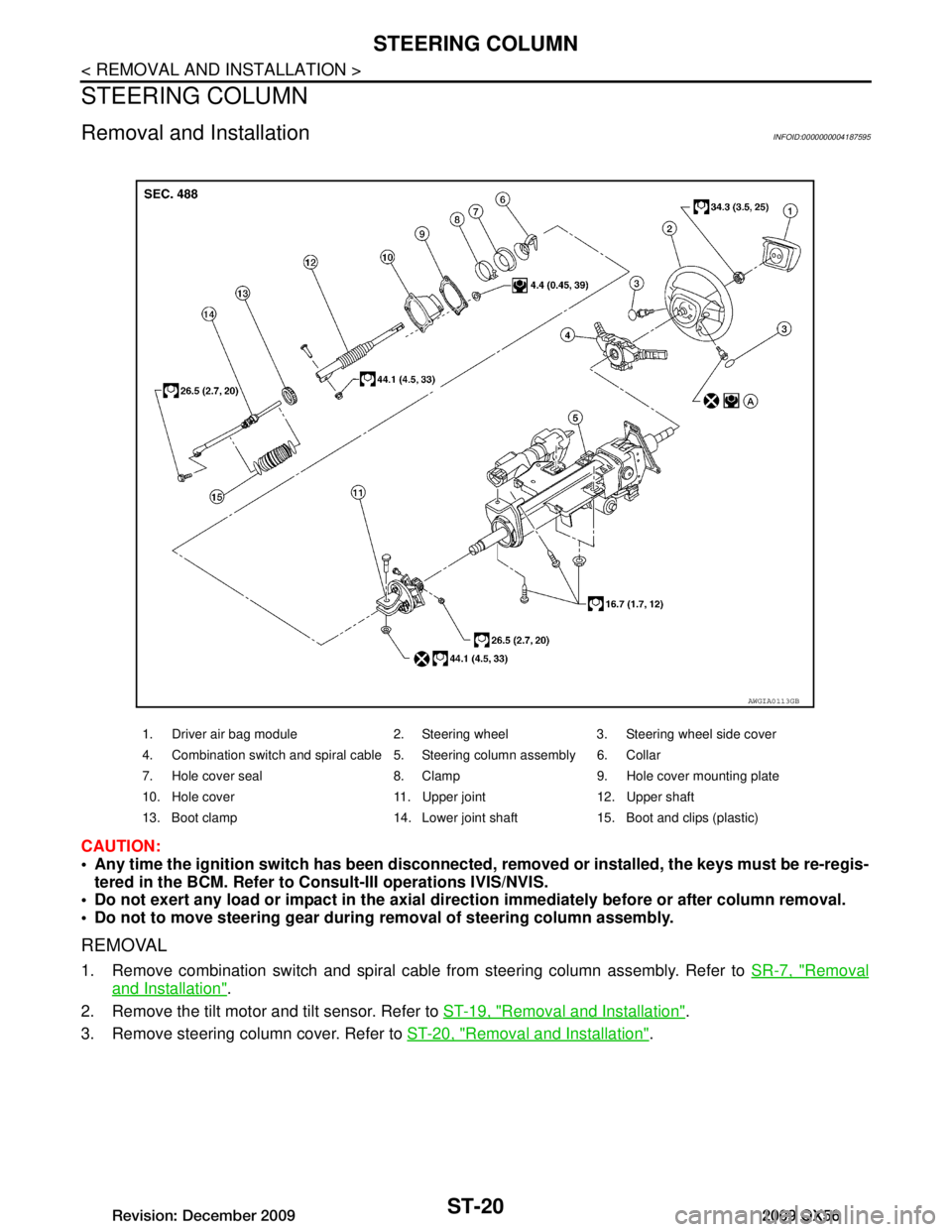

Removal and InstallationINFOID:0000000004187595

CAUTION:

Any time the ignition switch has been disconnected, removed or inst alled, the keys must be re-regis-

tered in the BCM. Refer to Consult-III operations IVIS/NVIS.

Do not exert any load or impact in the axial dir ection immediately before or after column removal.

Do not to move steering gear during removal of steering column assembly.

REMOVAL

1. Remove combination switch and spiral cable from steering column assembly. Refer to SR-7, "Removal

and Installation".

2. Remove the tilt motor and tilt sensor. Refer to ST-19, "Removal and Installation"

.

3. Remove steering column cover. Refer to ST-20, "Removal and Installation"

.

1. Driver air bag module 2. Steering wheel 3. Steering wheel side cover

4. Combination switch and spiral cable 5. Steering column assembly 6. Collar

7. Hole cover seal 8. Clamp 9. Hole cover mounting plate

10. Hole cover 11. Upper joint 12. Upper shaft

13. Boot clamp 14. Lower joint shaft 15. Boot and clips (plastic)

AWGIA0113GB

Revision: December 20092009 QX56

Page 3620 of 4171

STEERING COLUMNST-29

< DISASSEMBLY AND ASSEMBLY >

C

DE

F

H I

J

K L

M A

B

ST

N

O P

DISASSEMBLY AND ASSEMBLY

STEERING COLUMN

Disassembly and AssemblyINFOID:0000000004187599

DISASSEMBLY

1. Remove bolt from upper joint, then remove upper joint from steering column assembly.

2. Remove ignition switch tamper resistant self-s hear screws with a drill or other suitable tool.

ASSEMBLY

Assembly is in the reverse order of disassembly.

Install new tamper resistant self-shear screws.

CAUTION:

Any time the ignition switch has been disconnected, removed

or installed, the keys must be re -registered in the BCM. Refer to

CONSULT-III operation manual IVIS/NVIS.

INSPECTION AFTER ASSEMBLY

When the steering wheel does not turn smoothl y, check the steering column as follows:

1. Steering column assembly 2. Upper joint 3. Ignition switch

4. Tamper resistant self-shear screw

WGIA0091E

WGIA0009E

Revision: December 20092009 QX56

Page 3631 of 4171

STR-2

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005856238

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SR and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution Necessary for Steering W heel Rotation After Battery Disconnect

INFOID:0000000005856245

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecting both battery cables with the ignition knob in the

″LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS, an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be rotated.

4. Perform the necessary repair operation.

Revision: December 20092009 QX56

Page 3632 of 4171

PRECAUTIONSSTR-3

< PRECAUTION >

C

DE

F

G H

I

J

K L

M A

STR

NP

O

5. When the repair work is completed, return the ignition switch to the

″LOCK ″ position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of al l control units using CONSULT-III.

Precaution for Power Generation Variable Voltage Control SystemINFOID:0000000003771784

CAUTION:

For this model, the battery current sensor that is installed to the negative battery cable measures the

charging/discharging current of the battery and performs various engine controls. If an electrical com-

ponent is connected directly to the negative battery terminal, the current flowing through that compo-

nent will not be measured by the battery current sensor. This condition may cause a malfunction of

the engine control system and battery discharge m ay occur. Do not connect an electrical component

or ground wire directly to the battery terminal.

Revision: December 20092009 QX56

Page 3639 of 4171

STR-10

< COMPONENT DIAGNOSIS >

B TERMINAL CIRCUIT

COMPONENT DIAGNOSIS

B TERMINAL CIRCUIT

DescriptionINFOID:0000000003771792

Terminal "2" (B) is constantly supplied with battery power.

Diagnosis ProcedureINFOID:0000000003771793

CAUTION:

Perform diagnosis under the condition that the engine cannot start by the following procedure.

1. Remove fuel pump fuse.

2. Crank or start the engine (where possible) until the fuel pressure is depleted.

1.CHECK TERMINAL 2 POWER SUPPLY VOLTAGE

1. Turn ignition switch OFF.

2. Make sure that starter motor connector F27 terminal 2 connection is clean and tight.

3. Check voltage between starter motor connector F27 terminal 2

and ground.

Is there battery voltage present?

YES >> GO TO 2

NO >> Check harness between battery and starter motor for open circuit.

2.CHECK BATTERY CABLE (VOLTAGE DROP TEST)

1. Shift the transmission into park or neutral.

2. Check voltage between battery positive terminal and starter motor connector F27 terminal 2 while cranking the engine.

Is the voltage drop less than 0.2V?

YES >> GO TO 3

NO >> Check harness between the battery and the starter motor for high resistance.

3.CHECK GROUND CIRCUIT STATUS (VOLTAGE DROP TEST)

Check voltage between starter motor case and battery negative ter-

minal while cranking the engine.

Is the voltage drop less than 0.2V?

YES >> Terminal 2 circuit is OK. Further inspection necessary. Refer to STR-5, "

Work Flow".

NO >> Check the starter motor case to engine mounting for high resistance.

(+) (-)Condition Voltage

Connector Terminal

F27 2 Ground While cranking the

engine Battery voltage

AWBIA0122GB

(+)

(-)Condition Voltage

Connector Terminal

F27 2 Battery (+)

terminal While cranking the

engine Less than 0.2V

AWBIA0123GB

(+)

(-)Condition Voltage

Starter motor case Battery (-) terminal

While cranking the

engine Less than 0.2V

AWBIA0124GB

Revision: December 20092009 QX56

Page 3640 of 4171

S CONNECTOR CIRCUITSTR-11

< COMPONENT DIAGNOSIS >

C

DE

F

G H

I

J

K L

M A

STR

NP

O

S CONNECTOR CIRCUIT

DescriptionINFOID:0000000003771794

Terminal "1" (S) is the power supply for the starter mo

tor magnetic switch. Terminal 1 is supplied with power

when the ignition switch is turned to the START position while the selector lever is in the P or N position.

Diagnosis ProcedureINFOID:0000000003771795

CAUTION:

Perform diagnosis under the cond ition that engine cannot start by the following procedure.

1. Remove fuel pump fuse.

2. Crank or start the engine (where possi ble) until the fuel pressure is released.

1.CHECK STARTER MOTOR MAGNETIC SWITCH CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect starter motor connector F28.

3. Shift transmission into park or neutral.

4. Check voltage between starter motor harness connector F28 terminal 1 and ground with the ignition switch in START.

Is battery voltage present?

YES >> Magnetic switch circuit is OK. Further inspection necessary. Refer to STR-5, "Work Flow".

NO >> GO TO 2

2.CHECK CONNECTOR

1. Turn ignition switch OFF.

2. Check the IPDM E/R harness connector E120 and starter motor harness connector F28 for damage, bent pins and loose connections.

Is the inspection result normal?

YES >> GO TO 3

NO >> Repair the terminal and connector.

3.CHECK HARNESS CONTI NUITY (OPEN CIRCUIT)

1. Disconnect IPDM E/R connector E120 and starter motor con- nector F28.

2. Check continuity between starter motor harness connector F28 (A) terminal 1 and IPDM E/R harness connector E120 (B) termi-

nal 19.

3. Check continuity between starter motor harness connector F28 (A) terminal 1 and ground.

Are the continuity test results as specified?

YES >> Further inspection necessary. Refer to STR-5, "Work Flow".

NO >> Repair the harness.

(+) (-)Condition Voltage

Connector Terminal

F28 1 Ground Ignition switch in

START Battery voltage

AWBIA0125GB

AB

Continuity

Connector Terminal Connector Terminal

F28 1E120 19 Yes

A —Con tin uit y

Connector Terminal

F28 1Ground No

AWBIA0126GB

Revision: December 20092009 QX56

Page 3677 of 4171

A/T SHIFT LOCK SYSTEMTM-29

< FUNCTION DIAGNOSIS >

CEF

G H

I

J

K L

M A

B

TM

N

O P

A/T SHIFT LOCK SYSTEM

System DescriptionINFOID:0000000003771817

The electrical key interlock mechanism also operates as a shift lock: With the ignition switch turned to ON, the selector lever cannot be shifted from “P” (parking) to any other

position unless the brake pedal is depressed.

With the key removed, the selector lever c annot be shifted from “P” to any other position.

The key cannot be removed unless the selector lever is placed in “P”.

The shift lock and key interlock mechanisms are controlled by the ON-OFF operation of the shift lock sole-

noid and by the operation of the rotator and slider located inside the key cylinder, respectively.

Component Parts LocationINFOID:0000000003771818

LCIA0326E

Revision: December 20092009 QX56

Page 3679 of 4171

ON BOARD DIAGNOSTIC (OBD) SYSTEMTM-31

< FUNCTION DIAGNOSIS >

CEF

G H

I

J

K L

M A

B

TM

N

O P

longer stored. Remember, only one set of freeze frame data can be stored in the ECM. The ECM has the fol-

lowing priorities to update the data.

Both 1st trip freeze frame data and freeze frame data (along with the DTC) are cleared when the ECM mem-

ory is erased.

HOW TO ERASE DTC

The diagnostic trouble code can be erased by CONSULT- III, GST or ECM DIAGNOSTIC TEST MODE as

described following.

If the battery cable is disconnected, the diagnostic trouble code will be lost within 24 hours.

When you erase the DTC, using CONSULT-III or GS T is easier and quicker than switching the mode

selector on the ECM.

The following emission-related diagnostic information is cleared from the ECM memory when erasing DTC

related to OBD-II. For details, refer to EC-42, "Emission-related Diagnostic Information"

.

Diagnostic trouble codes (DTC)

1st trip diagnostic trouble codes (1st trip DTC)

Freeze frame data

1st trip freeze frame data

System readiness test (SRT) codes

Test values

HOW TO ERASE DTC (WITH CONSULT-III)

1. The emission related diagnostic information in the TCM and ECM can be er\

ased by selectioning "ALL

ERASE" in the "Description" of "F INAL CHECK" mode with CONSULT-III.

HOW TO ERASE DTC (WITH GST)

1. If the ignition switch stays “ON” after repair work, be sure to turn ignition switch “OFF” once. Wait at least

10 seconds and then turn it “ON” (engine stopped) again.

2. Select Mode 4 with the Generic Scan Tool (GST). For details refer to EC-72, "Generic Scan Tool (GST)

Function".

HOW TO ERASE DTC (NO TOOLS)

1. Disconnect battery for 24 hours.

2. Reconnect battery.

Malfunction Indicator Lamp (MIL)INFOID:0000000003771823

DESCRIPTION

The MIL is located on the instrument panel.

1. The MIL will light up when the ignition switch is turned “ON” with-

out the engine running. This is a bulb check.

If the MIL does not light up, refer to EC-55, "Malfunction Indicator

Lamp (MIL)".

2. When the engine is start ed, the MIL should go off.

If the MIL remains on, the on board diagnostic system has

detected an engine system malfunction.

Priority Items

1 Freeze frame data Misfire — DTC: P0300 - P0306 Fuel Injection System Function — DTC: P0171, P0172, P0174, P0175

2 Except the above items (Includes A/T related items)

3 1st trip freeze frame data

SEF217U

Revision: December 20092009 QX56