ECU INFINITI QX56 2009 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2009, Model line: QX56, Model: INFINITI QX56 2009Pages: 4171, PDF Size: 84.65 MB

Page 460 of 4171

BR-30

< ON-VEHICLE REPAIR >

FRONT DISC BRAKE

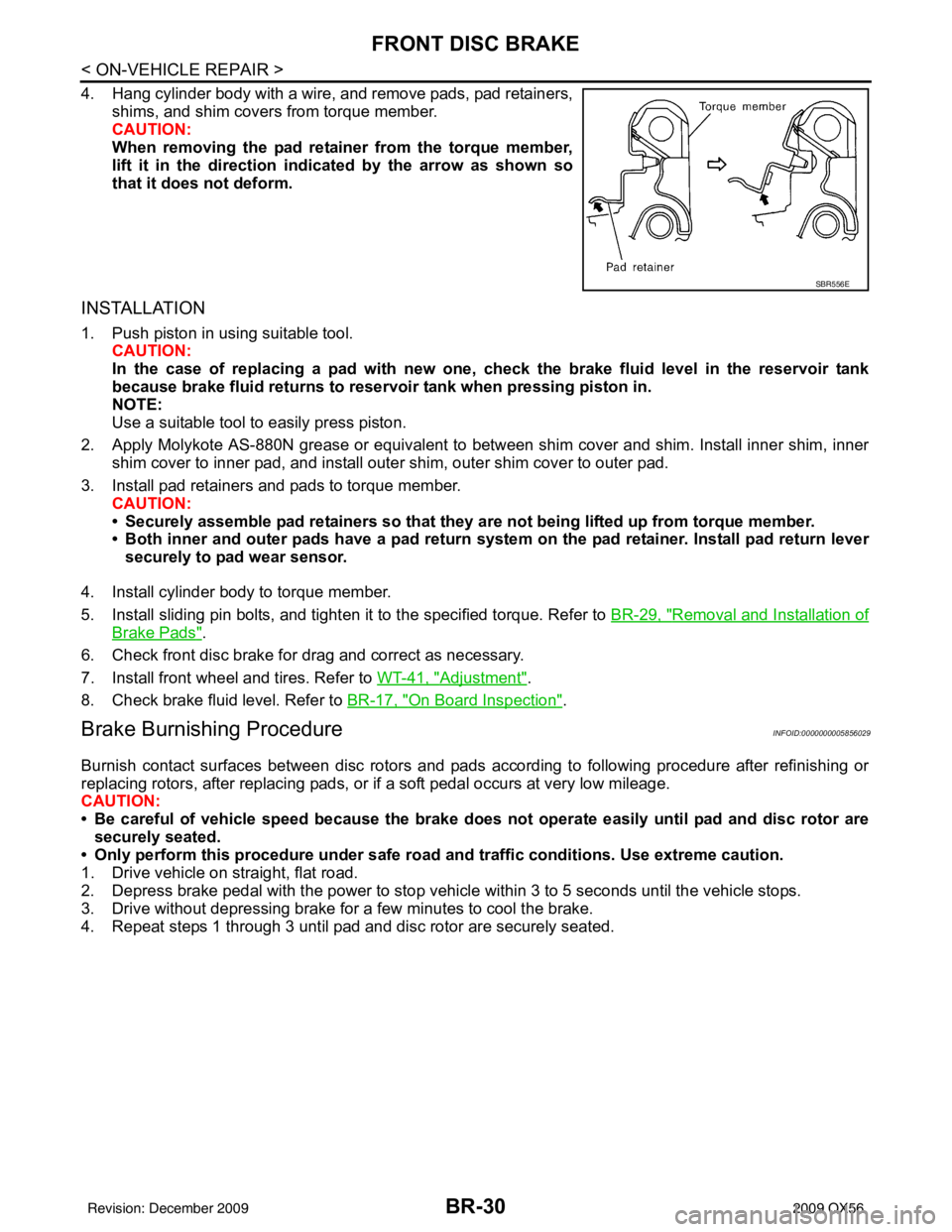

4. Hang cylinder body with a wire, and remove pads, pad retainers,shims, and shim covers from torque member.

CAUTION:

When removing the pad retainer from the torque member,

lift it in the direction indi cated by the arrow as shown so

that it does not deform.

INSTALLATION

1. Push piston in using suitable tool.

CAUTION:

In the case of replacing a pad with new one, ch eck the brake fluid level in the reservoir tank

because brake fluid returns to reservoir tank when pressing piston in.

NOTE:

Use a suitable tool to easily press piston.

2. Apply Molykote AS-880N grease or equivalent to between shim cover and shim. Install inner shim, inner shim cover to inner pad, and install outer shim, outer shim cover to outer pad.

3. Install pad retainers and pads to torque member. CAUTION:

• Securely assemble pad retainers so that they ar e not being lifted up from torque member.

• Both inner and outer pads have a pad return system on the pad retainer. Install pad return lever

securely to pad wear sensor.

4. Install cylinder body to torque member.

5. Install sliding pin bolts, and tighten it to the specified torque. Refer to BR-29, "

Removal and Installation of

Brake Pads".

6. Check front disc brake for drag and correct as necessary.

7. Install front wheel and tires. Refer to WT-41, "

Adjustment".

8. Check brake fluid level. Refer to BR-17, "

On Board Inspection".

Brake Burnishing ProcedureINFOID:0000000005856029

Burnish contact surfaces between disc rotors and pads according to following procedure after refinishing or

replacing rotors, after replacing pads, or if a soft pedal occurs at very low mileage.

CAUTION:

• Be careful of vehicle speed because the brake does not operate easily until pad and disc rotor are securely seated.

• Only perform this procedure under safe road and traffic conditions. Use extreme caution.

1. Drive vehicle on straight, flat road.

2. Depress brake pedal with the power to stop vehicle within 3 to 5 seconds until the vehicle stops.

3. Drive without depressing brake for a few minutes to cool the brake.

4. Repeat steps 1 through 3 until pad and disc rotor are securely seated.

SBR556E

Revision: December 20092009 QX56

Page 464 of 4171

BR-34

< ON-VEHICLE REPAIR >

REAR DISC BRAKE

REAR DISC BRAKE

Exploded View of Brake PadsINFOID:0000000004057217

Removal and Installation of Brake PadINFOID:0000000004057218

WARNING:

Clean dust on caliper and brake pad with a vacuum dust collector to minimize the hazard of air borne

particles or other materials.

CAUTION:

• While removing cylinder body, do not depress brake pedal because piston will pop out.

• It is not necessary to disconnect brake hose connection except for disassembly or replacement of caliper assembly. In this case, ha ng cylinder body with a wire so as not to stretch brake hose.

• Do not damage piston boot.

• If any shim is subject to serious corrosion, replace it with a new one.

• Always replace shim and shim cover as a set when replacing brake pads.

• Keep rotor free from brake fluid.

• Burnish the brake pads and disc rotor mutually contacting surfaces, after refinishing or replacing

rotors, after replacing pads, or if a soft pedal occurs at very low mileage.

REMOVAL

1. Partially drain brake fluid. Refer to BR-17, "Drain and Refill".

2. Remove rear wheel and tires using power tools. Refer to WT-41, "

Adjustment".

3. Remove the sliding pin bolt from the cylinder body. Refer to BR-35, "

Exploded View of Brake Caliper".

4. Remove the cylinder body secure with wire and remove pads.

INSTALLATION

1. Push piston in using suitable tool. CAUTION:

1. Outer pad 2. Inner pad

AWFIA0676ZZ

Revision: December 20092009 QX56

Page 465 of 4171

REAR DISC BRAKEBR-35

< ON-VEHICLE REPAIR >

C

DE

G H

I

J

K L

M A

B

BR

N

O P

By pushing in piston, br ake fluid returns to master cylinder reservoir tank. Watch the brake fluid

level in the reservoir tank.

NOTE:

Using a suitable tool, makes it easier to push in the piston.

2. Apply Molykote M-77 grease to knuckle slide where brake pad contacts. CAUTION:

Do not get grease on the brake pads or brake rotor friction surfaces.

3. Install pads to cylinder body.

4. Install cylinder body to torque member

5. Install sliding pin bolt and tighten to specification. Refer to BR-35, "

Exploded View of Brake Caliper"

6. Check rear disc brake for drag and correct as necessary.

7. Install rear wheel and tires. Refer to WT-41, "

Adjustment".

8. Check brake fluid level. Refer to BR-17, "

On Board Inspection".

Brake Burnishing ProcedureINFOID:0000000004057219

Burnish contact surfaces between disc rotors and pads according to following procedure after refinishing or

replacing rotors, after replacing pads, or if a soft pedal occurs at very low mileage.

CAUTION:

• Be careful of vehicle speed because the brake does not operate easily until pad and disc rotor are securely seated.

• Only perform this procedure under safe road and traffic conditions. Use extreme caution.

1. Drive vehicle on straight, flat road.

2. Depress brake pedal with the power to stop vehicle within 3 to 5 seconds until the vehicle stops.

3. Drive without depressing brake for a few minutes to cool the brake.

4. Repeat steps 1 through 3 until pad and disc rotor are securely seated.

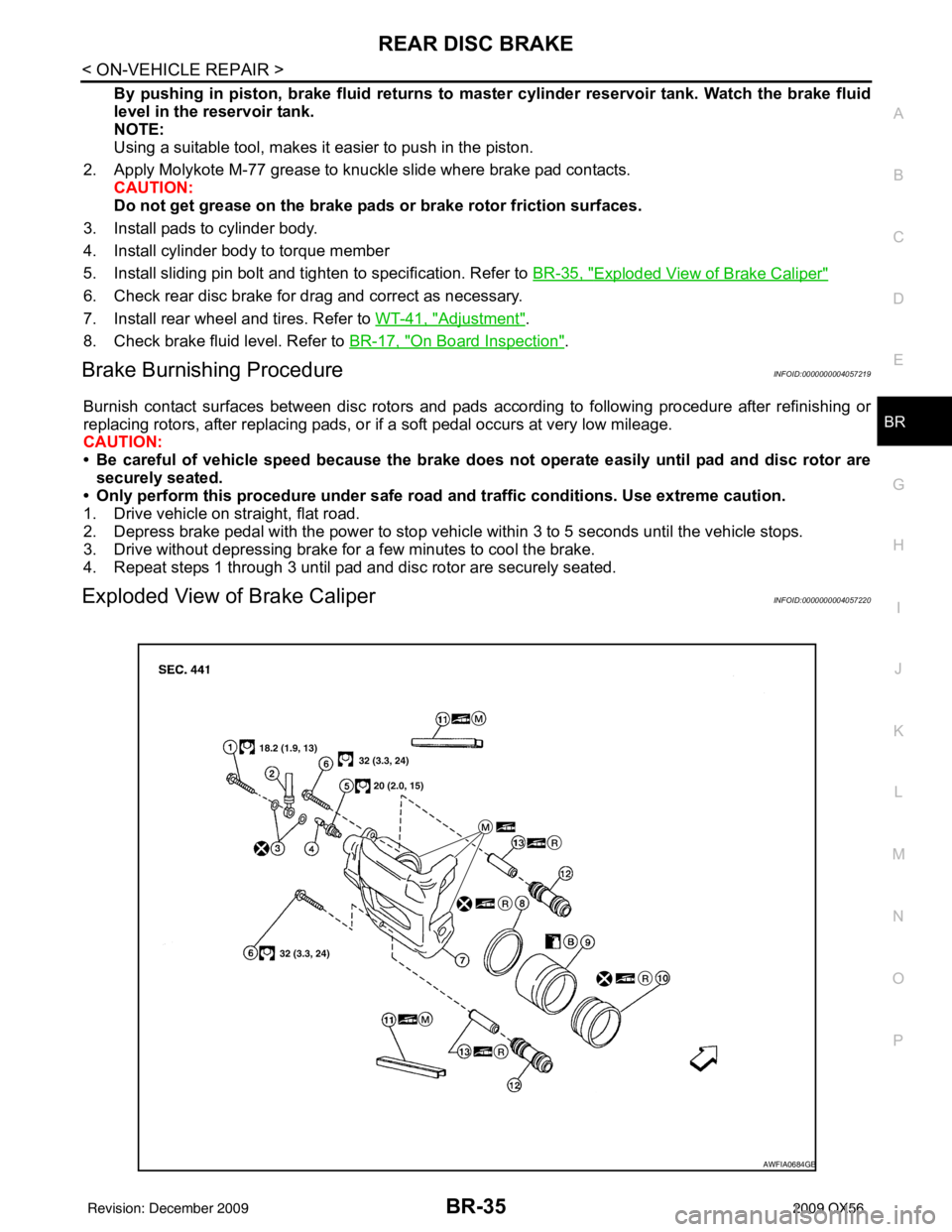

Exploded View of Brake CaliperINFOID:0000000004057220

AWFIA0684GB

Revision: December 20092009 QX56

Page 466 of 4171

BR-36

< ON-VEHICLE REPAIR >

REAR DISC BRAKE

Removal and Installation of Brake Caliper and Disc Rotor

INFOID:0000000004057221

WARNING:

Clean dust on caliper and brake pad with a vacuum dust collector to minimize the hazard of air borne

particles or other materials.

CAUTION:

• While removing cylinder body, do not depress brake pedal because piston will pop out.

• Do not damage piston boot.

• Keep rotor free from brake fluid.

• Refill with new specified brake fluid.

• Burnish brake contact surface after refinishing or re placing rotors, after replacing pads, or it a soft

pedal occurs at very low mileage. Refer to BR-35, "

Brake Burnishing Procedure".

REMOVAL

1. Remove rear wheel and tires using power tools. Refer to WT-41, "Adjustment".

2. Fasten disc rotor using wheel nut.

3. Drain brake fluid as necessary. Refer to BR-17, "

Drain and Refill".

4. Remove union bolt and cylinder body bolts, then remove cylin- der body.

NOTE:

Discard the copper washers, do not reuse.

5. Apply matching marks to disc rotor and wheel hub assembly if the disc rotor is to be reused, then remove disc rotor.

CAUTION:

Put matching marks on wheel hub assembly and disc rotor

if the disc rotor is to be reused.

INSTALLATION

1. If reusing the disc rotor, use the matching marks to align disc rotor on the wheel hub assembly, then install

disc rotor using a wheel nut to hold it in place.

CAUTION:

Use matching marks on wheel hub assembly and di sc rotor if the disc rotor is to be reused.

2. Install cylinder body and tighten cylinder body bolts to specification. CAUTION:

Before installing cylinder body to the vehic le, wipe off mating surface of cylinder body.

3. Install brake hose to cylinder body with new copper washers and tighten union bolt to specification.

CAUTION:

• Do not reuse copper washers.

• Securely attach brake hose to projection on cylinderbody.

4. Refill with new brake fluid and bleed. Refer to BR-17, "

Bleeding

Brake System".

5. Check rear disc brake for drag and correct as necessary.

6. Install rear wheel and tires. Refer to WT-41, "

Adjustment".

1. Union bolt2. Brake hose 3. Copper washer

4. Cap 5. Bleed valve 6. Sliding pin bolt

7. Cylinder body 8. Piston seal 9. Piston

10. Piston boot 11. Knuckle slide 12. Sliding sleeve boot

13. Sliding sleeve B: Brake fluidR: Rubber grease

M: Molykote 7439 grease Front

LFIA0211E

SFIA1137E

Revision: December 20092009 QX56

Page 471 of 4171

FRONT DISC BRAKEBR-41

< DISASSEMBLY AND ASSEMBLY >

C

DE

G H

I

J

K L

M A

B

BR

N

O P

3. Apply rubber grease to piston boots. Cover the piston ends with piston boots, and then install cylinder side lip on piston boots

securely into the grooves on cylinder body.

CAUTION:

Do not reuse piston boots.

4. Apply clean brake fluid to pistons (1), then install pistons into cyl- inder body and insert piston boot (2) side lip into groove of pis-

tons as shown.

CAUTION:

Press the pistons evenly to prevent damage to cylinder

wall.

5. Apply rubber grease and install sliding pins, bushing and sliding pin boots to torque member.

6. Install cylinder body. Tighten sliding pin bolts to the specified torque.

SFIA2432E

JPFIA0041ZZ

Revision: December 20092009 QX56

Page 473 of 4171

REAR DISC BRAKEBR-43

< DISASSEMBLY AND ASSEMBLY >

C

DE

G H

I

J

K L

M A

B

BR

N

O P

4. Using a suitable tool, remove piston seal from cylinder body as shown.

CAUTION:

Be careful not to damage cylinder body inner wall.

CALIPER INSPECTION

Cylinder Body

Check inside surface of cylinder body for score, rust wear, damage or foreign materials. If any of the above

conditions are observed, replace cylinder body.

Minor damage from rust or foreign materials may be eliminated by polishing surface with a fine emery paper.

Replace cylinder body if necessary.

CAUTION:

• Use new brake fluid to clean. Do not use mi neral oils such as gasoline or kerosene.

Torque Member

Check for wear, cracks, and damage. If damage or deformation is present, replace the affected part.

Piston

Check piston for score, rust, wear, damage or presence of foreign materials. Replace if any of the above con-

ditions are observed.

CAUTION:

• Piston sliding surface is plated, do not polish with emery paper even if rust of foreign materials are

stuck to sliding surface.

Sliding Pin Bolts and Sliding Pin Boots

Make sure there is no wear, damage, or cracks in sliding sleeve and sliding sleeve boots, and if there are,

replace them.

ASSEMBLY

1. Install the bleed valve and cap.

2. Apply rubber grease to the new piston seal (1) and insert the new piston seal (1) into the groove on the cylinder body.

CAUTION:

Do not reuse piston seal.

3. Apply rubber grease to the new piston boot (1). Cover the piston end (2) with the piston boot (1), and then install the cylinder side

lip on the piston boot (1) securely into the groove on the cylinder

body.

CAUTION:

• Do not reuse piston boot.

• Press pistons in evenly and vary the pressing points toprevent the cylinder inner wall from being damaged.

PFIA0269E

JPFIA0039ZZ

JPFIA0040ZZ

Revision: December 20092009 QX56

Page 480 of 4171

BRC-3

C

DE

G H

I

J

K L

M A

B

BRC

N

O P

C1185 ICC UNIT .................................................78

Description .......................................................... ....78

DTC Logic ...............................................................78

Diagnosis Procedure ...............................................78

Special Repair Requirement ...................................79

U1000 CAN COMM CIRCUIT .............................80

Description .......................................................... ....80

DTC Logic ...............................................................80

Diagnosis Procedure ...............................................80

Special Repair Requirement ...................................80

VDC OFF SWITCH ......................................... ....81

Description .......................................................... ....81

Component Function Check ....................................81

Diagnosis Procedure ...............................................81

Component Inspection ............................................82

ABS WARNING LAMP ................................... ....83

Description .......................................................... ....83

Component Function Check ....................................83

Diagnosis Procedure ...............................................83

BRAKE WARNING LAMP ............................. ....84

Description .......................................................... ....84

Component Function Check ....................................84

Diagnosis Procedure ...............................................84

VDC OFF INDICATOR LAMP ............................85

Description .......................................................... ....85

Component Function Check ....................................85

Diagnosis Procedure ...............................................85

SLIP INDICATOR LAMP ....................................86

Description .......................................................... ....86

Component Function Check ....................................86

Diagnosis Procedure ...............................................86

ECU DIAGNOSIS .........................................87

ABS ACTUATOR AND ELECTRIC UNIT

(CONTROL UNIT) .......................................... ....

87

Reference Value ................................................. ....87

Wiring Diagram .......................................................92

Fail-Safe ..................................................................99

DTC No. Index ......................................................100

SYMPTOM DIAGNOSIS ............................102

VDC/TCS/ABS ................................................ ..102

Symptom Table ................................................... ..102

EXCESSIVE ABS FUNCTION OPERATION

FREQUENCY ...................................................

103

Diagnosis Procedure ........................................... ..103

UNEXPECTED PEDAL REACTION ...............104

Diagnosis Procedure ........................................... ..104

THE BRAKING DISTANCE IS LONG .............105

Diagnosis Procedure .............................................105

ABS FUNCTION DOES NOT OPERATE .......106

Diagnosis Procedure .............................................106

PEDAL VIBRATION OR ABS OPERATION

SOUND OCCURS ...........................................

107

Diagnosis Procedure ........................................... ..107

VEHICLE JERKS DURING VDC/TCS/ABS

CONTROL .......................................................

108

Diagnosis Procedure .............................................108

NORMAL OPERATING CONDITION .............109

Description .............................................................109

PRECAUTION ............................................110

PRECAUTIONS ...............................................110

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ..

110

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect .................................

110

Precaution for Brake System .................................111

Precaution for Brake Control .................................111

Precaution for CAN System ...................................112

PREPARATION .........................................113

PREPARATION ...............................................113

Special Service Tool ............................................ ..113

Commercial Service Tool ......................................113

REMOVAL AND INSTALLATION .............114

WHEEL SENSORS .........................................114

Removal and Installation ..................................... ..114

SENSOR ROTOR ............................................115

Removal and Installation .......................................115

ACTUATOR AND ELECTRIC UNIT (ASSEM-

BLY) ................................................................

116

Removal and Installation .......................................116

STEERING ANGLE SENSOR .........................118

Removal and Installation .......................................118

G SENSOR ......................................................119

Removal and Installation .......................................119

Revision: December 20092009 QX56

Page 501 of 4171

![INFINITI QX56 2009 Factory Service Manual BRC-24

< FUNCTION DIAGNOSIS >[VDC/TCS/ABS]

DIAGNOSIS SYSTEM [

ABS ACTUATOR AND ELECTRIC UNIT (CONTROL

UNIT)]

DIAGNOSIS SYSTEM [ABS ACTUATOR AND ELECTRIC UNIT (CONTROL

UNIT)]

CONSULT-III Function (AB INFINITI QX56 2009 Factory Service Manual BRC-24

< FUNCTION DIAGNOSIS >[VDC/TCS/ABS]

DIAGNOSIS SYSTEM [

ABS ACTUATOR AND ELECTRIC UNIT (CONTROL

UNIT)]

DIAGNOSIS SYSTEM [ABS ACTUATOR AND ELECTRIC UNIT (CONTROL

UNIT)]

CONSULT-III Function (AB](/img/42/57031/w960_57031-500.png)

BRC-24

< FUNCTION DIAGNOSIS >[VDC/TCS/ABS]

DIAGNOSIS SYSTEM [

ABS ACTUATOR AND ELECTRIC UNIT (CONTROL

UNIT)]

DIAGNOSIS SYSTEM [ABS ACTUATOR AND ELECTRIC UNIT (CONTROL

UNIT)]

CONSULT-III Function (ABS)INFOID:0000000003772500

FUNCTION

CONSULT-III can display each diagnostic item us ing the diagnostic test modes shown following.

SELF-DIAG RESULTS MODE

Operation Procedure

1. Before performing the self-diagnosis, start engine and drive vehicle at 30 km/h (19 MPH) or more for

approximately 1 minute.

How to Erase Self-d iagnosis Results

1. After erasing DTC memory, start engine and drive vehicle at 30 km/h (19 MPH) or more for approximately

1 minute as the final inspection, and make sure that the ABS warning lamp, VDC OFF indicator lamp,

SLIP indicator lamp and brake warning lamp turn OFF.

CAUTION:

If memory cannot be erased, pe rform applicable diagnosis.

NOTE:

• When the wheel sensor malfunctions, after inspecting the wheel sensor system, the ABS warning lamp,

VDC OFF indicator lamp, SLIP indicator lamp and brake warning lamp will not turn OFF even when the

system is normal unless the vehicle is driving at approximately 30 km/h (19 MPH) or more for approxi-

mately 1 minute.

• Brake warning lamp will turn ON in case of parking brake operation (when switch is ON) or of brake fluid level switch operation (when brake fluid is insufficient).

• VDC OFF switch should not stay “ON” position.

Display Item List

Refer to BRC-100, "DTC No. Index".

DATA MONITOR MODE

Display Item List

Diagnostic test mode Function

Work support This mode enables a technician to adjust some devices faster and more accurately by following

the indications on CONSULT-III.

Self-diagnostic results Self-diagnostic results can be read and erased quickly.

Data monitor Input/Output data in the ABS actuator and electric unit (control unit) can be read.

Active test Diagnostic test mode is which CONSULT-III drives some actuators apart from the ABS actuator

and electric unit (control unit) and also shifts some parameters in a specified range.

ECU part number ABS actuator and electric unit (control unit) part number can be read.

CAN diagnostic support monitor The results of transmit/receive diagnosis of CAN communication can be read.

Item

(Unit) Data monitor item selection

Remarks

ECU INPUT

SIGNALS MAIN

SIGNALS SELECTION

FROM MENU

GEAR

(1, 2, 3, 4, R) ××× Gear position judged by transmis-

sion range switch signal is dis-

played.

FR RH SENSOR

(km/h, MPH) ××× Wheel speed calculated by front RH

wheel sensor signal is displayed.

FR LH SENSOR

(km/h, MPH) ××× Wheel speed calculated by front LH

wheel sensor signal is displayed.

RR RH SENSOR

(km/h, MPH) ×××

Wheel speed calculated by rear RH

wheel sensor signal is displayed.

Revision: December 20092009 QX56

Page 502 of 4171

![INFINITI QX56 2009 Factory Service Manual DIAGNOSIS SYSTEM [ABS ACTUATOR AND ELECTRIC UNIT (CONTROL

UNIT)]

BRC-25

< FUNCTION DIAGNOSIS > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

RR LH SENSOR

(km/h, MPH) ××× Wheel speed calculated INFINITI QX56 2009 Factory Service Manual DIAGNOSIS SYSTEM [ABS ACTUATOR AND ELECTRIC UNIT (CONTROL

UNIT)]

BRC-25

< FUNCTION DIAGNOSIS > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

RR LH SENSOR

(km/h, MPH) ××× Wheel speed calculated](/img/42/57031/w960_57031-501.png)

DIAGNOSIS SYSTEM [ABS ACTUATOR AND ELECTRIC UNIT (CONTROL

UNIT)]

BRC-25

< FUNCTION DIAGNOSIS > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

RR LH SENSOR

(km/h, MPH) ××× Wheel speed calculated by rear LH

wheel sensor signal is displayed.

BATTERY VOLT

(V) ××× Voltage supplied to ABS actuator

and electric unit (control unit) is dis-

played.

N POSI SIG

(ON/OFF) ––

×Shift position (ON/OFF) judged by

transmission range switch signal.

P POSI SIG

(ON/OFF) ––

×Shift position (ON/OFF) judged by

transmission range switch signal.

ACCEL POS SIG

(%) ×

– ×Throttle valve open/close status

judged by CAN communication sig-

nal is displayed.

ENGINE SPEED

(rpm) ×××

Engine speed judged by CAN com-

munication signal is displayed.

STR ANGLE SIG

(deg) ×

– ×Steering angle detected by steering

angle sensor is displayed.

YAW RATE SEN

(d/s) ××× Yaw rate detected by yaw rate sen-

sor is displayed.

SIDE G-SENSOR

(m/s

2) ×

– ×Transverse acceleration detected

by side G-sensor is displayed.

STOP LAMP SW

(ON/OFF) ××× Stop lamp switch (ON/OFF) status

is displayed.

OFF SW

(ON/OFF) ×××

VDC OFF switch (ON/OFF) status

is displayed.

ABS WARN LAMP

(ON/OFF) –

×× ABS warning lamp (ON/OFF) status

is displayed.

SLIP LAMP

(ON/OFF) –

×× SLIP indicator lamp (ON/OFF) sta-

tus is displayed.

FR LH IN SOL

(ON/OFF) –

×× Front LH IN ABS solenoid (ON/

OFF) status is displayed.

FR LH OUT SOL

(ON/OFF) –

×× Front LH OUT ABS solenoid (ON/

OFF) status is displayed.

RR RH IN SOL

(ON/OFF) –

×× Rear RH IN ABS solenoid (ON/

OFF) status is displayed.

RR RH OUT SOL

(ON/OFF) –

×× Rear RH OUT ABS solenoid (ON/

OFF) status is displayed.

FR RH IN SOL

(ON/OFF) –

×× Front RH IN ABS solenoid (ON/

OFF) status is displayed.

FR RH OUT SOL

(ON/OFF) –

×× Front RH OUT ABS solenoid (ON/

OFF) status is displayed.

RR LH IN SOL

(ON/OFF) –

×× Rear LH IN ABS solenoid (ON/OFF)

status is displayed.

RR LH OUT SOL

(ON/OFF) –

×× Rear LH OUT ABS solenoid (ON/

OFF) status is displayed.

OFF LAMP

(ON/OFF) –

×× OFF Lamp (ON/OFF) status is dis-

played.

MOTOR RELAY

(ON/OFF) –

×× ABS motor relay signal (ON/OFF)

status is displayed.

ACTUATOR RLY

(ON/OFF) –

×× ABS actuator relay signal (ON/OFF)

status is displayed.

Item

(Unit) Data monitor item selection

Remarks

ECU INPUT

SIGNALS MAIN

SIGNALS SELE

C

TION

FROM MENU

Revision: December 20092009 QX56

Page 503 of 4171

![INFINITI QX56 2009 Factory Service Manual BRC-26

< FUNCTION DIAGNOSIS >[VDC/TCS/ABS]

DIAGNOSIS SYSTEM [

ABS ACTUATOR AND ELECTRIC UNIT (CONTROL

UNIT)]

CV1

(ON/OFF) ––× Front side switch-over solenoid

valve (cut valve) (ON/OFF) status i INFINITI QX56 2009 Factory Service Manual BRC-26

< FUNCTION DIAGNOSIS >[VDC/TCS/ABS]

DIAGNOSIS SYSTEM [

ABS ACTUATOR AND ELECTRIC UNIT (CONTROL

UNIT)]

CV1

(ON/OFF) ––× Front side switch-over solenoid

valve (cut valve) (ON/OFF) status i](/img/42/57031/w960_57031-502.png)

BRC-26

< FUNCTION DIAGNOSIS >[VDC/TCS/ABS]

DIAGNOSIS SYSTEM [

ABS ACTUATOR AND ELECTRIC UNIT (CONTROL

UNIT)]

CV1

(ON/OFF) ––× Front side switch-over solenoid

valve (cut valve) (ON/OFF) status is

displayed.

CV2

(ON/OFF) ––× Rear side switch-over solenoid

valve (cut-valve) (O

N/OFF) status is

displayed.

SV1

(ON/OFF) ––× Front side switch-over solenoid

valve (suction valve) (ON/OFF) sta-

tus is displayed.

SV2

(ON/OFF) ––× Rear side switch-over solenoid

valve (suction valve) (ON/OFF) sta-

tus is displayed.

VDC FAIL SIG

(ON/OFF) ––× VDC fail signal (ON/OFF) status is

displayed.

TCS FAIL SIG

(ON/OFF) ––× TCS fail signal (ON/OFF) status is

displayed.

ABS FAIL SIG

(ON/OFF) ––×

ABS fail signal (ON/OFF) status is

displayed.

EBD FAIL SIG

(ON/OFF) ––× EBD fail signal (ON/OFF) status is

displayed.

FLUID LEV SW

(ON/OFF) ×

– ×Brake fluid level switch (ON/OFF)

status is displayed.

EBD SIGNAL

(ON/OFF) ––×

EBD operation (ON/OFF) status is

displayed.

ABS SIGNAL

(ON/OFF) ––× ABS operation (ON/OFF) status is

displayed.

TCS SIGNAL

(ON/OFF) ––× TCS operation (ON/OFF) status is

displayed.

VDC SIGNAL

(ON/OFF) ––×

VDC operation (ON/OFF) status is

displayed.

EBD WARN LAMP

(ON/OFF) ––× Brake warning lamp (ON/OFF) sta-

tus is displayed.

SLCT LVR POSI

(P, R, N, D, 4, 3, 2, 1) ××× Selector lever position judged by

transmission range switch signal.

R POSI SIG

(ON/OFF) ––× Shift position (ON/OFF) judged by

transmission range switch signal.

2WD/4WD

(2WD/4WD) ––× It

re

cognizes on software whether it

is 2WD and whether it is in 4WD

state.

BST OPER SIG

(ON/OFF) ––× Active booster operation (ON/OFF)

status is displayed.

PRESS SENSOR

(bar) ×

– ×Brake pressure detected by pres-

sure sensor is displayed (bar).

CRANKING SIG

(ON/OFF) ––× The input state of the key SW

START position signal (ON/OFF) is

displayed.

PRESS SEN 2

(bar) ––×

Brake pressure detected by pres-

sure sensor is displayed (bar).

DELTA S SEN

(mm) ––× The amount of stroke sensor move-

ments in the active booster detected

by DELTA S SEN is displayed (mm).

Item

(Unit) Data monitor item selection

Remarks

ECU INPUT

SIGNALS MAIN

SIGNALS SELECTION

FROM MENU

Revision: December 20092009 QX56