4WD INFINITI QX56 2009 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2009, Model line: QX56, Model: INFINITI QX56 2009Pages: 4171, PDF Size: 84.65 MB

Page 5 of 4171

QUICK REFERNCE CHART: QX56

2010

Unit: mm (in)

*: Always check with the Parts Department for the latest parts information

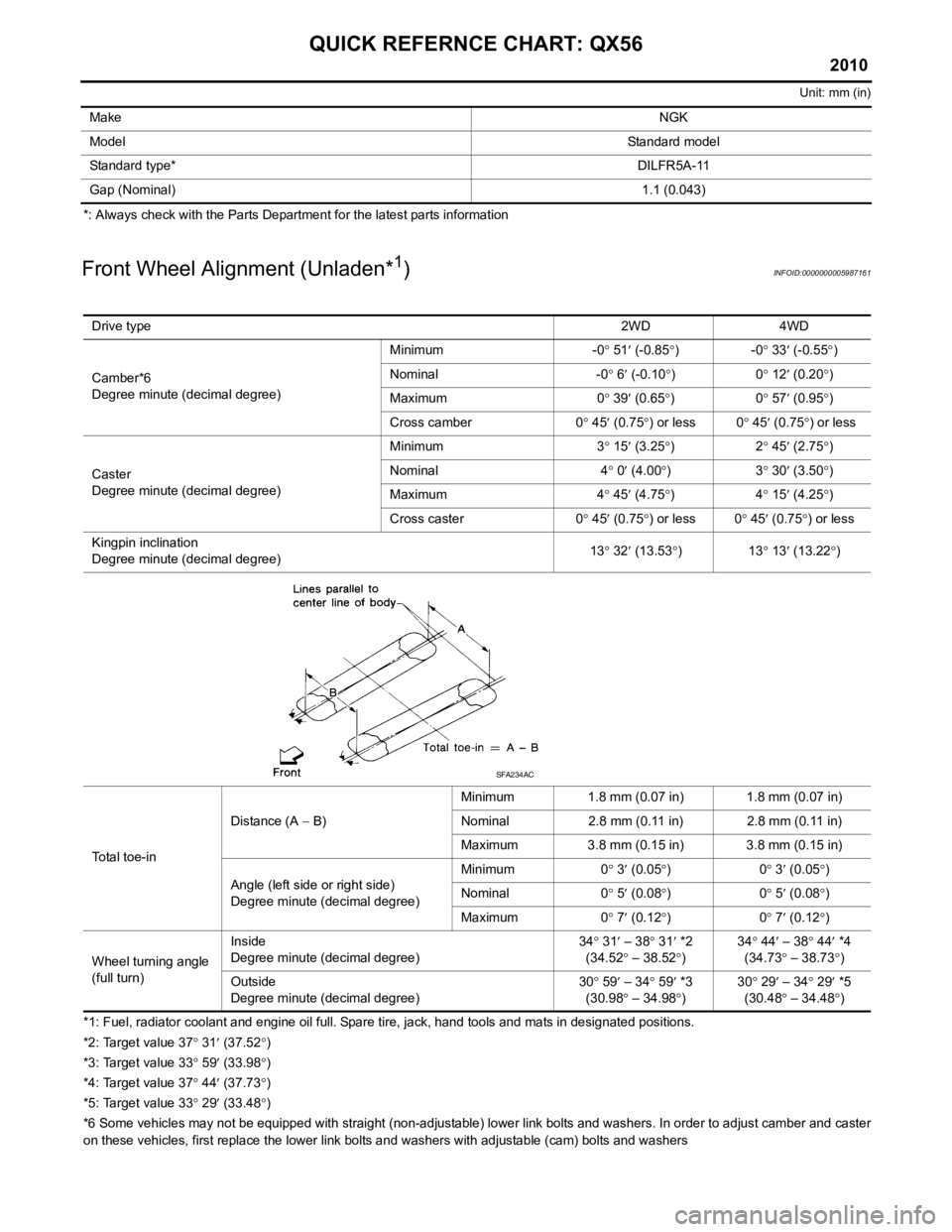

Front Wheel Alignment (Unladen*1)INFOID:0000000005987161

*1: Fuel, radiator coolant and engine oil full. Spare tire, jack, hand tools and mats in designated positions.

*2: Target value 37° 31 ′ (37.52 °)

*3: Target value 33 ° 59 ′ (33.98 °)

*4: Target value 37 ° 44 ′ (37.73 °)

*5: Target value 33 ° 29 ′ (33.48 °)

*6 Some vehicles may not be equipped with straight (non-adjustable) lower link bolts and washers. In order to adjust camber and caster

on these vehicles, first replace the lower link bolts and washers with adjustable (cam) bolts and washers Make

NGK

Model Standard model

Standard type* DILFR5A-11

Gap (Nominal) 1.1 (0.043)

Drive type2WD 4WD

Camber*6

Degree minute (decimal degree) Minimum -0

° 51 ′ (-0.85 °)-0 ° 33 ′ (-0.55 °)

Nominal -0 ° 6 ′ (-0.10 °)0 ° 12 ′ (0.20 °)

Maximum 0 ° 39 ′ (0.65 °)0 ° 57 ′ (0.95 °)

Cross camber 0 ° 45 ′ (0.75 °) or less 0 ° 45 ′ (0.75 °) or less

Caster

Degree minute (decimal degree) Minimum 3

° 15 ′ (3.25 °)2 ° 45 ′ (2.75 °)

Nominal 4 ° 0 ′ (4.00 °)3 ° 30 ′ (3.50 °)

Maximum 4 ° 45 ′ (4.75 °)4 ° 15 ′ (4.25 °)

Cross caster 0 ° 45 ′

(0.75 °) or less 0 ° 45 ′ (0.75 °) or less

Kingpin inclination

Degree minute (decimal degree) 13

° 32 ′ (13.53 °)13 ° 13 ′ (13.22 °)

Total toe-in Distance (A

− B) Minimum 1.8 mm (0.07 in) 1.8 mm (0.07 in)

Nominal 2.8 mm (0.11 in) 2.8 mm (0.11 in)

Maximum 3.8 mm (0.15 in) 3.8 mm (0.15 in)

Angle (left side or right side)

Degree minute (decimal degree) Minimum 0

° 3 ′ (0.05 °)0 ° 3 ′ (0.05 °)

Nominal 0 ° 5 ′ (0.08 °)0 ° 5 ′ (0.08 °)

Maximum 0 ° 7 ′ (0.12 °)0 ° 7 ′ (0.12 °)

Wheel turning angle

(full turn) Inside

Degree minute (decimal degree)

34

° 31 ′ – 38 ° 31 ′ *2

(34.52 ° – 38.52 °) 34

° 44 ′ – 38 ° 44 ′ *4

(34.73 ° – 38.73

° )

Outside

Degree minute (decimal degree) 30

° 59 ′ – 34 ° 59 ′ *3

(30.98 ° – 34.98 °) 30

° 29 ′ – 34 ° 29 ′ *5

(30.48 ° – 34.48 °)

SFA234AC

Page 6 of 4171

2009

QUICK REFERNCE CHART: QX56

Rear Wheel Alignment (Unladen

*1)INFOID:0000000005987159

*1: Fuel tank, engine coolant and engine oil full. Spare tire, jack, hand tools and mats in designated positions.

Wheelarch Height (Unladen*1)INFOID:0000000005987160

Unit: mm (in)

*1: Fuel, radiator coolant and engine oil full. Spare tire, jack, hand tools and mats in designated positions. Applied model

Without air leveling With air leveling

Camber

Degree minute (decimal degree) Minimum - 0

° 25 ′ (- 0.4 °)- 1 ° 0 ′ (- 1 °)

Nominal 0 ° 5 ′ (0.1 °)- 0 ° 30 ′ (- 0.5 °)

Maximum 0 ° 35 ′ (0.6 °)0 ° 0 ′ (0 °)

Cross camber 0 ° 45' (0.75 °) or less

To e - i n Distance

Toe-in (left side or right side)

AL - BL or AR - BR

mm (in)

:Front Minimum - 2.4 mm (- 0.094 in) 0 mm (0 in)

Nominal 0.9 mm (0.035 in) 3.3 mm (0.130 in)

Maximum 4.2 mm (0.165 in) 6.6 mm (0.260 in)

Cross toe

(AL - BL) - (AR - BR)

mm (in) 2 mm (0.079 in) or less

Angle Toe angle (left side or right side)

Degree minute

(Decimal degree) Minimum - 0

° 5' (- 0.08 °)0 ° 0' (0 °)

Nominal 0 ° 2' (0.03 °)0 ° 7' (0.11 °)

Maximum 0 ° 9' (0.14 °)0 ° 14' (0.22 °)

Cross toe

Degree minute (Decimal degree) 0

° 8' (0.14 °) or less

ALEIA0059ZZ

Suspension type

Air leveling*2

Applied model 2WD 4WD

Front wheelarch height (Hf)920

(36.22) 937

(36.89)

Rear wheelarch height (Hr) 917

(36.10) 937

(36.89)

LEIA0085E

Page 503 of 4171

![INFINITI QX56 2009 Factory Service Manual BRC-26

< FUNCTION DIAGNOSIS >[VDC/TCS/ABS]

DIAGNOSIS SYSTEM [

ABS ACTUATOR AND ELECTRIC UNIT (CONTROL

UNIT)]

CV1

(ON/OFF) ––× Front side switch-over solenoid

valve (cut valve) (ON/OFF) status i INFINITI QX56 2009 Factory Service Manual BRC-26

< FUNCTION DIAGNOSIS >[VDC/TCS/ABS]

DIAGNOSIS SYSTEM [

ABS ACTUATOR AND ELECTRIC UNIT (CONTROL

UNIT)]

CV1

(ON/OFF) ––× Front side switch-over solenoid

valve (cut valve) (ON/OFF) status i](/img/42/57031/w960_57031-502.png)

BRC-26

< FUNCTION DIAGNOSIS >[VDC/TCS/ABS]

DIAGNOSIS SYSTEM [

ABS ACTUATOR AND ELECTRIC UNIT (CONTROL

UNIT)]

CV1

(ON/OFF) ––× Front side switch-over solenoid

valve (cut valve) (ON/OFF) status is

displayed.

CV2

(ON/OFF) ––× Rear side switch-over solenoid

valve (cut-valve) (O

N/OFF) status is

displayed.

SV1

(ON/OFF) ––× Front side switch-over solenoid

valve (suction valve) (ON/OFF) sta-

tus is displayed.

SV2

(ON/OFF) ––× Rear side switch-over solenoid

valve (suction valve) (ON/OFF) sta-

tus is displayed.

VDC FAIL SIG

(ON/OFF) ––× VDC fail signal (ON/OFF) status is

displayed.

TCS FAIL SIG

(ON/OFF) ––× TCS fail signal (ON/OFF) status is

displayed.

ABS FAIL SIG

(ON/OFF) ––×

ABS fail signal (ON/OFF) status is

displayed.

EBD FAIL SIG

(ON/OFF) ––× EBD fail signal (ON/OFF) status is

displayed.

FLUID LEV SW

(ON/OFF) ×

– ×Brake fluid level switch (ON/OFF)

status is displayed.

EBD SIGNAL

(ON/OFF) ––×

EBD operation (ON/OFF) status is

displayed.

ABS SIGNAL

(ON/OFF) ––× ABS operation (ON/OFF) status is

displayed.

TCS SIGNAL

(ON/OFF) ––× TCS operation (ON/OFF) status is

displayed.

VDC SIGNAL

(ON/OFF) ––×

VDC operation (ON/OFF) status is

displayed.

EBD WARN LAMP

(ON/OFF) ––× Brake warning lamp (ON/OFF) sta-

tus is displayed.

SLCT LVR POSI

(P, R, N, D, 4, 3, 2, 1) ××× Selector lever position judged by

transmission range switch signal.

R POSI SIG

(ON/OFF) ––× Shift position (ON/OFF) judged by

transmission range switch signal.

2WD/4WD

(2WD/4WD) ––× It

re

cognizes on software whether it

is 2WD and whether it is in 4WD

state.

BST OPER SIG

(ON/OFF) ––× Active booster operation (ON/OFF)

status is displayed.

PRESS SENSOR

(bar) ×

– ×Brake pressure detected by pres-

sure sensor is displayed (bar).

CRANKING SIG

(ON/OFF) ––× The input state of the key SW

START position signal (ON/OFF) is

displayed.

PRESS SEN 2

(bar) ––×

Brake pressure detected by pres-

sure sensor is displayed (bar).

DELTA S SEN

(mm) ––× The amount of stroke sensor move-

ments in the active booster detected

by DELTA S SEN is displayed (mm).

Item

(Unit) Data monitor item selection

Remarks

ECU INPUT

SIGNALS MAIN

SIGNALS SELECTION

FROM MENU

Revision: December 20092009 QX56

Page 566 of 4171

![INFINITI QX56 2009 Factory Service Manual ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT)BRC-89

< ECU DIAGNOSIS > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

RR RH OUT SOL Operation status of each solenoid valve Actuator (solenoid valve) i INFINITI QX56 2009 Factory Service Manual ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT)BRC-89

< ECU DIAGNOSIS > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

RR RH OUT SOL Operation status of each solenoid valve Actuator (solenoid valve) i](/img/42/57031/w960_57031-565.png)

ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT)BRC-89

< ECU DIAGNOSIS > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

RR RH OUT SOL Operation status of each solenoid valve Actuator (solenoid valve) is active (“AC-

TIVE TEST” with CONSULT-III) or actua-

tor relay is inactive

(in fail-safe mode) ON

When the actuator (solenoid valve) is not

active and actuator relay is active (igni-

tion switch ON) OFF

RR LH IN SOL Operation status of each solenoid valve Actuator (solenoid valve) is active (“AC-

TIVE TEST” with CONSULT-III) or actua-

tor relay is inactive

(in fail-safe mode) ON

When the actuator (solenoid valve) is not

active and actuator relay is active (igni-

tion switch ON) OFF

RR LH OUT SOL Operation status of each solenoid valve Actuator (solenoid valve) is active (“AC-

TIVE TEST” with CONSULT-III) or actua-

tor relay is inactive

(in fail-safe mode) ON

When the actuator (solenoid valve) is not

active and actuator relay is active (igni-

tion switch ON) OFF

MOTOR RELAY Motor and motor relay operation When the motor relay and motor are op-

erating

ON

When the motor relay and motor are not

operating OFF

ACTUATOR RLY Actuator relay operation When the actuator relay is operating

ON

When the actuator relay is not operating OFF

ABS WARN LAMP ABS warning lamp

(Note 3) When ABS warning lamp is ON

ON

When ABS warning lamp is OFF OFF

OFF LAMP VDC OFF indicator lamp

(Note 3) When VDC OFF indicator lamp is ON

ON

When VDC OFF indicator lamp is OFF OFF

SLIP LAMP SLIP indicator lamp

(Note 3) When SLIP indicator lamp is ON

ON

When SLIP indicator lamp is OFF OFF

4WD FAIL REQ

(Note 2) Transfer control unit fail-safe signal When transfer control unit is in fail-safe

mode

ON

When transfer control unit is normal OFF

BST OPER SIG Active booster operation Active booster is active

ON

Active booster is inactive OFF

EBD SIGNAL EBD operation EBD is active

ON

EBD is inactive OFF

ABS SIGNAL ABS operation ABS is active

ON

ABS is inactive OFF

TCS SIGNAL TCS operation TCS is active

ON

TCS is inactive OFF

VDC SIGNAL VDC operation VDC is active

ON

VDC is inactive OFF

EBD FAIL SIG EBD fail-safe signal In EBD fail-safe

ON

EBD is normal OFF

ABS FAIL SIG ABS fail-safe signal In ABS fail-safe

ON

ABS is normal OFF

Monitor item

Display content Data monitor

Condition Reference value in

normal operation

Revision: December 20092009 QX56

Page 567 of 4171

![INFINITI QX56 2009 Factory Service Manual BRC-90

< ECU DIAGNOSIS >[VDC/TCS/ABS]

ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT)

TCS FAIL SIG TCS fail-safe signalIn TCS fail-safe ON

TCS is normal

OFF

VDC FAIL SIG VDC fail-safe signal In VDC fail INFINITI QX56 2009 Factory Service Manual BRC-90

< ECU DIAGNOSIS >[VDC/TCS/ABS]

ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT)

TCS FAIL SIG TCS fail-safe signalIn TCS fail-safe ON

TCS is normal

OFF

VDC FAIL SIG VDC fail-safe signal In VDC fail](/img/42/57031/w960_57031-566.png)

BRC-90

< ECU DIAGNOSIS >[VDC/TCS/ABS]

ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT)

TCS FAIL SIG TCS fail-safe signalIn TCS fail-safe ON

TCS is normal

OFF

VDC FAIL SIG VDC fail-safe signal In VDC fail-safe

ON

VDC is normal OFF

CRANKING SIG Crank operation Crank is active

ON

Crank is inactive OFF

CV1 VDC switch-over valve When actuator (switch-over valve) is ac-

tive (“ACTIVE TEST” with CONSULT-III)

or actuator relay is inactive (when in fail-

safe mode)

ON

When actuator (switch-over valve) is not

active and actuator relay is active (igni-

tion switch ON) OFF

CV2 VDC switch-over valve When actuator (switch-over valve) is ac-

tive (“ACTIVE TEST” with CONSULT-III)

or actuator relay is inactive (when in fail-

safe mode)

ON

When actuator (switch-over valve) is not

active and actuator relay is active (igni-

tion switch ON) OFF

SV1 VDC switch-over valve When actuator (switch-over valve) is ac-

tive (“ACTIVE TEST” with CONSULT-III)

or actuator relay is inactive (when in fail-

safe mode)

ON

When actuator (switch-over valve) is not

active and actuator relay is active (igni-

tion switch ON) OFF

SV2 VDC switch-over valve When actuator (switch-over valve) is ac-

tive (“ACTIVE TEST” with CONSULT-III)

or actuator relay is inactive (when in fail-

safe mode)

ON

When actuator (switch-over valve) is not

active and actuator relay is active (igni-

tion switch ON) OFF

DECEL G-SEN Longitudinal acceleration detected by Decel

G-Sensor Vehicle stopped

Approx. 0 G

Vehicle running -1.7 to 1.7 G

EBD WARN LAMP EBD warning lamp

(Note 3) When EBD warning lamp is ON

ON

When EBD warning lamp is OFF OFF

N POSI SIG Transmission range switch signal ON/OFF

condition A/T shift position = N position

ON

A/T shift position = other than N position OFF

P POSI SIG Transmission range switch signal ON/OFF

condition A/T shift position = P position

ON

A/T shift position = other than P position OFF

R POSI SIG Transmission range switch signal ON/OFF

condition A/T shift position = R position

ON

A/T shift position = other than R position OFF

2WD/4WD Drive axle 2WD model

2WD

4WD model 4WD

PRESS SEN2 Brake fluid pressure detected by rear pres-

sure sensor With ignition switch turned ON and brake

pedal released

Approx. 0 bar

With ignition switch turned ON and brake

pedal depressed –40 to 300 bar

Monitor item

Display content Data monitor

Condition Reference value in

normal operation

Revision: December 20092009 QX56

Page 568 of 4171

![INFINITI QX56 2009 Factory Service Manual ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT)BRC-91

< ECU DIAGNOSIS > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

NOTE:

• 1: Confirm tire pr essure is normal.

• 2: Only 4WD models.

• 3: On a INFINITI QX56 2009 Factory Service Manual ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT)BRC-91

< ECU DIAGNOSIS > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

NOTE:

• 1: Confirm tire pr essure is normal.

• 2: Only 4WD models.

• 3: On a](/img/42/57031/w960_57031-567.png)

ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT)BRC-91

< ECU DIAGNOSIS > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

NOTE:

• 1: Confirm tire pr essure is normal.

• 2: Only 4WD models.

• 3: On and off timing for warning lamp and indicator lamp.

- ABS warning lamp: Refer to BRC-83, "

Description".

- Brake warning lamp: Refer to BRC-84, "

Description".

- VDC OFF indicator lamp: Refer to BRC-85, "

Description".

- SLIP indicator lamp: Refer to BRC-86, "

Description".

TERMINAL LAYOUT

DELTA S SEN Value detected by delta stroke sensor When brake pedal is depressed 1.05 - 1.80 mm

When brake pedal is released

0.00 mm (+0.6/-0.4)

RELEASE SWITCH

NO Active booster signal status When brake pedal is depressed

ON

When brake pedal is released OFF

RELEASE SWITCH

NC Active booster signal status When brake pedal is depressed

OFF

When brake pedal is released ON

STP OFF RLY Stop lamp relay signal When stop lamp relay is ON

ON

When stop lamp relay is OFF OFF

Monitor item

Display content Data monitor

Condition Reference value in

normal operation

AWFIA0032ZZ

Revision: December 20092009 QX56

Page 1057 of 4171

DLN-1

TRANSMISSION & DRIVELINE

CEF

G H

I

J

K L

M

SECTION DLN

A

B

DLN

N

O P

CONTENTS

DRIVELINE

ATX14B

BASIC INSPECTION ....... .............................

6

DIAGNOSIS AND REPAIR WORKFLOW ..... .....6

Work Flow ........................................................... ......6

Preliminary Check .....................................................7

FUNCTION DIAGNOSIS ..............................10

4WD SYSTEM ................................................ ....10

System Diagram .................................................. ....10

System Description .................................................11

Component Parts Location ......................................16

CAN Communication ...............................................17

DIAGNOSIS SYSTEM (TRANSFER CON-

TROL UNIT) ........................................................

18

CONSULT-III Function (ALL MODE AWD/4WD) ....18

COMPONENT DIAGNOSIS .........................22

P1811 POWER SUPPLY CIRCUIT FOR

TRANSFER CONTROL UNIT ........................ ....

22

Description .......................................................... ....22

DTC Logic ...............................................................22

Diagnosis Procedure ...............................................22

Component Inspection ............................................23

P1802 – P1804, P1809 TRANSFER CON-

TROL UNIT .........................................................

24

Description .......................................................... ....24

DTC Logic ...............................................................24

Diagnosis Procedure ...............................................24

P1807 VEHICLE SPEED SENSOR (A/T) ..........26

Description .......................................................... ....26

DTC Logic ...............................................................26

Diagnosis Procedure ...............................................26

P1808 VEHICLE SPEED SENSOR (ABS) .........27

Description .......................................................... ....27

DTC Logic ............................................................ ....27

Diagnosis Procedure ...............................................27

P1810 NEUTRAL-4LO SWITCH .......................28

Description ...............................................................28

DTC Logic ................................................................28

Diagnosis Procedure ...............................................28

Component Inspection .............................................30

P1813 4WD SHIFT SWITCH .............................31

Description ...............................................................31

DTC Logic ................................................................31

Diagnosis Procedure ...............................................31

Component Inspection .............................................33

P1814 WAIT DETECTION SWITCH .................35

Description ...............................................................35

DTC Logic ................................................................35

Diagnosis Procedure ...............................................35

Component Inspection .............................................37

P1816 TRANSMISSION RANGE SWITCH .......38

Description ...............................................................38

DTC Logic ................................................................38

Diagnosis Procedure ...............................................38

P1817 ACTUATOR MOTOR .............................39

Description ...............................................................39

DTC Logic ................................................................39

Diagnosis Procedure ...............................................39

Component Inspection .............................................43

P1818 ACTUATOR POSITION SWITCH ..........45

Description ...............................................................45

DTC Logic ................................................................45

Diagnosis Procedure ...............................................45

Component Inspection .............................................47

P1819 TRANSFER CONTROL DEVICE ...........48

Description ...............................................................48

DTC Logic ................................................................48

Diagnosis Procedure ...........................................

....48

Revision: December 20092009 QX56

Page 1058 of 4171

DLN-2

P1820 ENGINE SPEED SIGNAL ......................52

Description ........................................................... ...52

DTC Logic ...............................................................52

Diagnosis Procedure ..............................................52

P1822 CLUTCH PRESSURE SOLENOID .........53

Description ........................................................... ...53

DTC Logic ...............................................................53

Diagnosis Procedure ..............................................53

Component Inspection ............................................55

P1823 2-4 SOLENOID .......................................57

Description ........................................................... ...57

DTC Logic ...............................................................57

Diagnosis Procedure ..............................................57

Component Inspection ............................................60

P1824 TRANSFER MOTOR ..............................61

Description ........................................................... ...61

DTC Logic ...............................................................61

Diagnosis Procedure ..............................................61

Component Inspection ............................................65

P1826 TRANSFER FLUID TEMPERATURE ....67

Description ........................................................... ...67

DTC Logic ...............................................................67

Diagnosis Procedure ..............................................67

Component Inspection ............................................68

P1827 CLUTCH PRESSURE SWITCH .............70

Description ........................................................... ...70

DTC Logic ...............................................................70

Diagnosis Procedure ..............................................70

Component Inspection ............................................71

P1828 LINE PRESSURE SWITCH ....................73

Description ........................................................... ...73

DTC Logic ...............................................................73

Diagnosis Procedure ..............................................73

Component Inspection ............................................75

P1829 THROTTLE POSITION SIGNAL (ECM)

...

76

Description ........................................................... ...76

DTC Logic ...............................................................76

Diagnosis Procedure ..............................................76

P1830 ABS OPERATION SIGNAL (ABS) ........77

Description ........................................................... ...77

DTC Logic ...............................................................77

Diagnosis Procedure ..............................................77

P1831 VDC OPERATION SIGNAL (ABS) ........78

Description ........................................................... ...78

DTC Logic ...............................................................78

Diagnosis Procedure ..............................................78

P1832 TCS OPERATION SIGNAL (ABS) .........79

Description ........................................................... ...79

DTC Logic ...............................................................79

Diagnosis Procedure ..............................................79

U1010 CONTROL UNIT (CAN) .........................80

Description ........................................................... ...80

DTC Logic ...............................................................80

Diagnosis Procedure ...............................................80

ECU DIAGNOSIS .......................................81

TRANSFER CONTROL UNIT ........................ ...81

Reference Value .................................................. ...81

Wiring Diagram .......................................................89

DTC Index ...............................................................97

SYMPTOM DIAGNOSIS ...........................102

4WD SYSTEM SYMPTOMS ........................... ..102

Symptom Table .................................................... .102

4WD SHIFT INDICATOR LAMP AND 4LO IN-

DICATOR LAMP DO NOT TURN ON ..............

103

Description ........................................................... .103

Diagnosis Procedure .............................................103

4WD WARNING LAMP DOES NOT TURN ON ..105

Description ........................................................... .105

Diagnosis Procedure .............................................105

4WD SHIFT INDICATOR LAMP OR 4LO INDI-

CATOR LAMP DO NOT CHANGE ...................

107

Description ........................................................... .107

Diagnosis Procedure .............................................107

ATP WARNING LAMP DOES NOT TURN ON ..109

Description ........................................................... .109

Diagnosis Procedure .............................................109

4WD SHIFT INDICATOR LAMP KEEPS

FLASHING ........................................................

111

Description ........................................................... .111

Diagnosis Procedure .............................................111

4WD WARNING LAMP FLASHES RAPIDLY ..112

Description ............................................................112

Diagnosis Procedure .............................................112

4WD WARNING LAMP FLASHES SLOWLY ..113

Description ............................................................113

Diagnosis Procedure .............................................113

HEAVY TIGHT-CORNER BRAKING SYMP-

TOM OCCURS ................................................ ..

114

Description ........................................................... .114

Diagnosis Procedure .............................................114

ATP SWITCH ....................................................116

Description ........................................................... .116

Diagnosis Procedure .............................................116

4WD SYSTEM DOES NOT OPERATE ............118

Description ........................................................... .118

Diagnosis Procedure .............................................118

Revision: December 20092009 QX56

Page 1062 of 4171

![INFINITI QX56 2009 Factory Service Manual

DLN-6

< BASIC INSPECTION >[ATX14B]

DIAGNOSIS AND REPAIR WORKFLOW

BASIC INSPECTION

DIAGNOSIS AND REPAIR WORKFLOW

Work FlowINFOID:0000000003772073

WORK FLOW

DETAILED FLOW

1.CUSTOMER INFORMATION

Intervi INFINITI QX56 2009 Factory Service Manual

DLN-6

< BASIC INSPECTION >[ATX14B]

DIAGNOSIS AND REPAIR WORKFLOW

BASIC INSPECTION

DIAGNOSIS AND REPAIR WORKFLOW

Work FlowINFOID:0000000003772073

WORK FLOW

DETAILED FLOW

1.CUSTOMER INFORMATION

Intervi](/img/42/57031/w960_57031-1061.png)

DLN-6

< BASIC INSPECTION >[ATX14B]

DIAGNOSIS AND REPAIR WORKFLOW

BASIC INSPECTION

DIAGNOSIS AND REPAIR WORKFLOW

Work FlowINFOID:0000000003772073

WORK FLOW

DETAILED FLOW

1.CUSTOMER INFORMATION

Interview the customer to obtain detailed information about the symptom.

>> GO TO 2

2.PRELIMINARY CHECK

Perform preliminary check. Refer to DLN-7, "Preliminary Check"

.

>> GO TO 3

3.SELF-DIAGNOSIS

Perform self-diagnosis. Refer to DLN-18, "CONSULT-III Function (ALL MODE AWD/4WD)"

.

AWNIA1592GB

Revision: December 20092009 QX56

Page 1063 of 4171

![INFINITI QX56 2009 Factory Service Manual

DIAGNOSIS AND REPAIR WORKFLOWDLN-7

< BASIC INSPECTION > [ATX14B]

C

EF

G H

I

J

K L

M A

B

DLN

N

O P

>> GO TO 4

4.SYMPTOM

Check for symptoms. Refer to DLN-102, "Symptom Table"

.

>> GO TO 5

5.MALFUNCTI INFINITI QX56 2009 Factory Service Manual

DIAGNOSIS AND REPAIR WORKFLOWDLN-7

< BASIC INSPECTION > [ATX14B]

C

EF

G H

I

J

K L

M A

B

DLN

N

O P

>> GO TO 4

4.SYMPTOM

Check for symptoms. Refer to DLN-102, "Symptom Table"

.

>> GO TO 5

5.MALFUNCTI](/img/42/57031/w960_57031-1062.png)

DIAGNOSIS AND REPAIR WORKFLOWDLN-7

< BASIC INSPECTION > [ATX14B]

C

EF

G H

I

J

K L

M A

B

DLN

N

O P

>> GO TO 4

4.SYMPTOM

Check for symptoms. Refer to DLN-102, "Symptom Table"

.

>> GO TO 5

5.MALFUNCTIONING PARTS

Repair or replace the applicable parts.

>> GO TO 6

6.SYSTEM OPERATION

Check system operation.

>> GO TO 7

7.SELF-DIAGNOSIS

Perform self-diagnosis.

Are any DTC's displayed?

YES >> GO TO 5

NO >> Inspection End

Preliminary CheckINFOID:0000000003772074

TRANSFER FLUID CHECK

Check for leaks and fluid level. Refer to DLN-129, "Inspection".

PREPARATION FOR ROAD TEST

The purpose of the test is to determine overall performance of trans-

fer case and analyze causes of malfunctions.

When a malfunction is found in any part of transfer, perform the road

test to locate the malfunction area and repair the malfunction parts.

The road test consists of the following three parts.

1. CHECK BEFORE ENGINE IS STARTED

2. CHECK AT IDLE

3. CRUISE TEST

CHECK BEFORE ENGINE IS STARTED

1.CHECK 4WD SHIFT INDICATOR LAMP

1. Park vehicle on flat surface.

2. Turn ignition switch to OFF position.

3. Move A/T selector lever to P position.

4. Set 4WD shift switch to 2WD position.

5. Turn ignition switch to ON position. (Do not start engine.)

Does 4WD shift indicator lamp turn ON for approximately 1 second?

YES >> GO TO 2.

NO >> GO TO DLN-103, "Diagnosis Procedure"

.

2.CHECK 4WD WARNING LAMP

1. Turn ignition switch to OFF position.

2. Move A/T selector lever to P position.

3. Set 4WD shift switch to 2WD position.

4. Turn ignition switch to ON position. (Do not start engine.)

SMT089D

Revision: December 20092009 QX56