turn signal INFINITI QX56 2009 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2009, Model line: QX56, Model: INFINITI QX56 2009Pages: 4171, PDF Size: 84.65 MB

Page 670 of 4171

CCS

DIAGNOSIS SYSTEM (ICC SENSOR INTEGRATED UNIT)

CCS-19

< FUNCTION DIAGNOSIS >

C

D E

F

G H

I

J

K L

M B

N P A

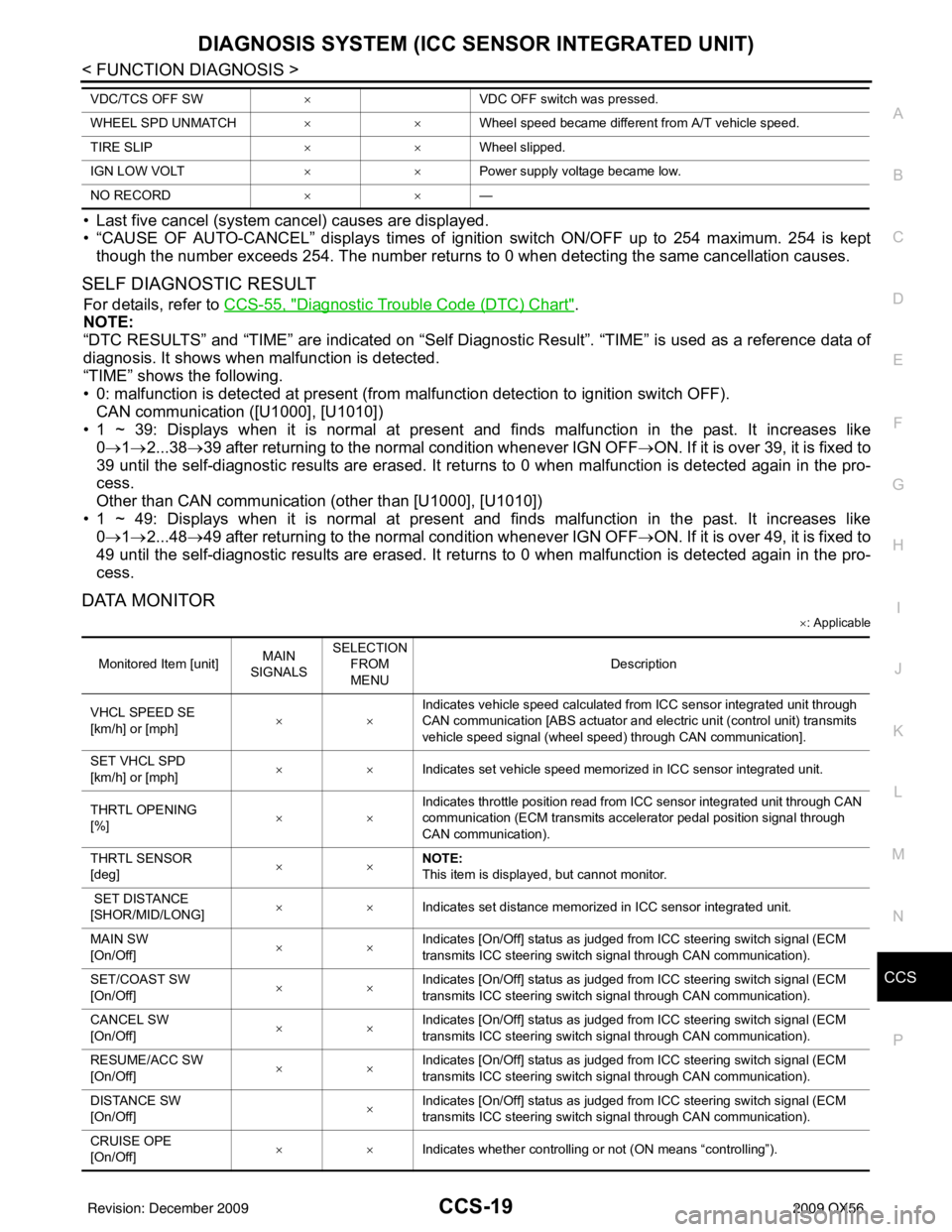

• Last five cancel (system cancel) causes are displayed.

• “CAUSE OF AUTO-CANCEL” displays times of ignition switch ON/OFF up to 254 maximum. 254 is kept though the number exceeds 254. The num ber returns to 0 when detecting the same cancellation causes.

SELF DIAGNOSTIC RESULT

For details, refer to CCS-55, "Diagnostic Trouble Code (DTC) Chart".

NOTE:

“DTC RESULTS” and “TIME” are indicated on “Self Diagnostic Result”. “TIME” is used as a reference data of

diagnosis. It shows when malfunction is detected.

“TIME” shows the following.

• 0: malfunction is detected at present (from malfunction detection to ignition switch OFF).

CAN communication ([U1000], [U1010])

• 1 ~ 39: Displays when it is normal at present and finds malfunction in the past. It increases like

0→ 1→ 2...38→ 39 after returning to the normal condition whenever IGN OFF→ ON. If it is over 39, it is fixed to

39 until the self-diagnostic results are erased. It retu rns to 0 when malfunction is detected again in the pro-

cess.

Other than CAN communication (other than [U1000], [U1010])

• 1 ~ 49: Displays when it is normal at present and finds malfunction in the past. It increases like 0→ 1→ 2...48→ 49 after returning to the normal condition whenever IGN OFF→ ON. If it is over 49, it is fixed to

49 until the self-diagnostic results are erased. It retu rns to 0 when malfunction is detected again in the pro-

cess.

DATA MONITOR

× : Applicable

VDC/TCS OFF SW ×VDC OFF switch was pressed.

WHEEL SPD UNMATCH ××Wheel speed became different from A/T vehicle speed.

TIRE SLIP ××Wheel slipped.

IGN LOW VOLT ××Power supply voltage became low.

NO RECORD ××—

Monitored Item [unit]MAIN

SIGNALS SELECTION

FROM

MENU Description

VHCL SPEED SE

[km/h] or [mph] ××Indicates vehicle speed calculated from ICC sensor integrated unit through

CAN communication [ABS actuator and electric unit (control unit) transmits

vehicle speed signal (wheel speed) through CAN communication].

SET VHCL SPD

[km/h] or [mph] ××

Indicates set vehicle speed memorized in ICC sensor integrated unit.

THRTL OPENING

[%] ××Indicates throttle position read from ICC sensor integrated unit through CAN

communication (ECM transmits accelerator pedal position signal through

CAN communication).

THRTL SENSOR

[deg] ××NOTE:

This item is displayed, but cannot monitor.

SET DISTANCE

[SHOR/MID/LONG] ××

Indicates set distance memorized in ICC sensor integrated unit.

MAIN SW

[On/Off] ××

Indicates [On/Off] status as judged from ICC steering switch signal (ECM

transmits ICC steering switch signal through CAN communication).

SET/COAST SW

[On/Off] ××Indicates [On/Off] status as judged from ICC steering switch signal (ECM

transmits ICC steering switch signal through CAN communication).

CANCEL SW

[On/Off] ××Indicates [On/Off] status as judged from ICC steering switch signal (ECM

transmits ICC steering switch signal through CAN communication).

RESUME/ACC SW

[On/Off] ××

Indicates [On/Off] status as judged from ICC steering switch signal (ECM

transmits ICC steering switch signal through CAN communication).

DISTANCE SW

[On/Off] ×Indicates [On/Off] status as judged from ICC steering switch signal (ECM

transmits ICC steering switch signal through CAN communication).

CRUISE OPE

[On/Off] ××

Indicates whether controlling or not (ON means “controlling”).

Revision: December 20092009 QX56

Page 681 of 4171

CCS-30

< COMPONENT DIAGNOSIS >

DTC 46 OPERATION SW CIRC

DTC 46 OPERATION SW CIRC

DTC 46 OPERATION SW CIRCINFOID:0000000003776944

1.CHECK ECM CONNECTOR

1. Turn ignition switch OFF.

2. Disconnect ECM connector and connect it securely again. Erase DTC, then perform self-diagnosis of ICC

system again.

Does the DTC reset?

YES >> • Poor connector connection. • Check connector. Check connector housing for disconnected, loose, bent, and collapsed termi-nals. If any malfunction is detected, repair as as necessary. Erase DTC and perform ICC system

running test. Refer to CCS-8, "

ACTION TEST : ICC System Running Test".

NO >> GO TO 2

2.CHECK ICC STEERING SWITCH

Check ICC steering switch.

Does the ICC steeri ng switch check OK?

YES >> GO TO 3

NO >> Replace ICC steering switch assembly. Refer to CCS-72, "

Removal and Installation". Erase DTC

and perform ICC system running test. Refer to CCS-8, "

ACTION TEST : ICC System Running

Te s t".

3.CHECK ICC STEERING SWITCH SIGNAL CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect ECM and spiral cable connectors.

3. Check continuity between ECM harness connectors E16 and F54 terminals 67, 99 and spiral cable harness connector M30

terminals 33, 34.

Does continuity exist?

YES >> GO TO 4

NO >> • Repair harness between ECM and spiral cable. • Erase DTC and perform ICC system running test. Refer to CCS-8, "

ACTION TEST : ICC Sys-

tem Running Test".

4.CHECK ICC STEERING SWITCH SIGNAL CIRCUIT

1. Disconnect remaining spiral cable connector.

2. Check continuity between spiral cable (A) (to vehicle) terminals 33, 34 and spiral cable (B) (to switch) terminals 14,15.

Does continuity exist?

YES >> Replace ECM. Erase DTC and perform ICC system run- ning test. Refer to CCS-8, "

ACTION TEST : ICC System

Running Test".

NO >> • Replace spiral cable. Refer to SR-7, "

Removal and

Installation".

• Erase DTC and perform ICC system running test.

Refer to CCS-8, "

ACTION TEST : ICC System Running Test".

67 - 33, 99 - 34

Continuity should exist.

WKIA1928E

34 - 14, 33 - 15Continuity should exist.

WKIA4572E

Revision: December 20092009 QX56

Page 689 of 4171

CCS-38

< COMPONENT DIAGNOSIS >

DTC 96 NP RANGE

DTC 96 NP RANGE

DTC 96 NP RANGEINFOID:0000000003776948

1.CHECK ICC UNIT CONNECTORS

1. Turn ignition switch OFF.

2. Disconnect ICC unit harness connectors and connect them securely again. Erase DTC, then perform self- diagnosis of ICC system again.

Does the DTC reset?

YES >> GO TO 2

NO >> • Poor connector connection. • Check connector. Check connector housing for disconnected, loose, bent, and collapsed termi-nals. If any malfunction is detected, repair as necessary. Erase DTC and perform ICC system

running test. Refer to CCS-8, "

ACTION TEST : ICC System Running Test".

2.CHECK NP RANGE SWITCH SIGNAL

With data monitor, check that “NP RANGE SW” operates normally.

Does the "NP RANGE SW" monitor item operate normally?

YES >> Perform TCM diagnosis. Refer to TM-30, "Introduction".

NO >> GO TO 3

3.CHECK HARNESS BETWEEN ICC UNIT AND TCM

1. Turn ignition switch OFF.

2. Disconnect ICC unit harness connectors and A/T assembly har- ness connector.

3. Check continuity between I CC unit harness connector B13 ter-

minal 7 and A/T assembly harness connector F9 terminal 9.

Does continuity exist?

YES >> Replace ICC unit. Refer to CCS-70, "ICC Unit". Erase

DTC and perform ICC system running test. Refer to

CCS-8, "

ACTION TEST : ICC System Running Test".

NO >> • Repair harness between ICC unit and TCM. • Erase DTC and perform ICC system running test. Refer to CCS-8, "

ACTION TEST : ICC Sys-

tem Running Test".

7 - 9 Continuity should exist.

SKIA5982E

Revision: December 20092009 QX56

Page 710 of 4171

CCS

ICC SYSTEM CANNOT BE SET (MAIN SWITCH TURNS ON/OFF)

CCS-59

< SYMPTOM DIAGNOSIS >

C

D E

F

G H

I

J

K L

M B

N P A

ICC SYSTEM CANNOT BE SET (M AIN SWITCH TURNS ON/OFF)

Diagnosis ProcedureINFOID:0000000003776962

The ICC cannot be set in the following cases.

• When the vehicle speed is not in range of approx. 40 km/h (25 MPH) to 144 km/h (89 MPH).

• When the selector lever is in "N".

• While the brake is in operation.

• When the windshield wipers are operating.

1.CHECK CAUSE OF AUTOMATIC CANCELLATION

1. With “CAUSE OF AUTO-CANCEL” in "WORK SUPPORT ", check if any cause of cancellation exists.

Is there a cause of cancellation stored?

YES >> • Cancel with appropriate cause. • For causes A, B, or C, go to specified diagnosis.A: “OPE SW VOLT CIRC” : Refer to CCS-30, "

DTC 46 OPERATION SW CIRC".

B: “VHCL SPD UNMATCH” : Refer to CCS-26, "

DTC 41 VHCL SPEED SE CIRC".

C: “IGN LOW VOLT” : Refer to CCS-25, "

DTC 31 POWER SUPPLY CIR1, DTC 34

POWER SUPPLY CIR2".

NO >> GO TO 2

2.PERFORM SELF-DIAGNOSIS

1. Perform -self-diagnosis to check for malfunctioning items.

Does the ICC have any DTC’s stored?

YES >> Repair or replace as necessary, erase DT C. Perform ICC system running test. Refer to CCS-8,

"ACTION TEST : ICC System Running Test".

NO >> GO TO 3

3.CHECK SWITCHES AND VEHICLE SPEED SIGNAL

1. With "DATA MONITOR", check that the followi ng switches and vehicle speed signal operate normally.

A: VHCL SPEED SE B: NP RANGE SW

C: BRAKE SW D: SET/COAST SW

Do the monitor items display properly?

YES >> Replace ICC unit and erase DTC. Refer to CCS-70, "ICC Unit". Perform ICC system running test.

Refer to CCS-8, "

ACTION TEST : ICC System Running Test".

NO >> • A: Refer to CCS-26, "

DTC 41 VHCL SPEED SE CIRC".

• B: Refer to CCS-61, "

Diagnosis Procedure".

• C: Refer to CCS-28, "

DTC 45 BRAKE SW/STOP L SW".

• D: Refer to CCS-30, "

DTC 46 OPERATION SW CIRC".

Revision: December 20092009 QX56

Page 772 of 4171

DEF-4

< FUNCTION DIAGNOSIS >

REAR WINDOW DEFOGGER SYSTEM

FUNCTION DIAGNOSIS

REAR WINDOW DEFOGGER SYSTEM

System DiagramINFOID:0000000003776329

System DescriptionINFOID:0000000003776330

Operation Description

• When rear window defogger switch is turned ON, while ignition switch is ON, the A/C and AV switch assem-bly (rear window defogger switch) transmits rear window defogger switch signal to BCM.

• BCM transmits rear window defogger control signal to IPDM E/R and display unit via CAN communication when rear window defogger operates.

• IPDM E/R turns rear window defogger relay and heated mirror relay ON when rear window defogger switch

signal is received.

• Rear window defogger and door mirror defogger are supplied with power and operate when rear window defogger relay and heated mirror relay turn ON.

• Rear window defogger ON is displayed when signal is received.

Timer function

• BCM turns rear window defogger relay and heated mirror relay ON for approximately 15 minutes when rear window defogger switch is turned ON while ignition switch is ON. It makes rear window defogger and door

mirror defogger operate.

• Timer is canceled after pressing rear window defogger switch again during timer operation. Then BCM turns

rear window defogger relay and heated mirror relay OFF. The same reaction also occurs during timer opera-

tion, if the ignition switch is turned OFF.

INPUT/OUTPUT SIGNAL CHART

ALLIA0892GB

Switch Input signal to BCM BCM functionActuator

Rear window defogger switch Defogger switch signal Rear window defogger & door mirror

defogger control Rear window defogger

Door mirror defogger

Ignition switch Ignition signal

Revision: December 20092009 QX56

Page 773 of 4171

REAR WINDOW DEFOGGER SYSTEMDEF-5

< FUNCTION DIAGNOSIS >

C

DE

F

G H

I

J

K

M A

B

DEF

N

O P

Component Parts LocationINFOID:0000000003776331

Component DescriptionINFOID:0000000003776332

ALLIA0314ZZ

1. A. Steering column assembly B. BCM M18, M20 (view with instru-

ment panel removed) 2. A/C and AV switch assembly (rear

window defogger switch) M98 3. A. Rear window defogger ground

connector D604

B. Rear window defogger connector

D406

4. IPDM E/R E120, E122, E124 5. Do or mirror (door mirror defogger)

LH D4, RH D107

BCM • Operates the rear window defogger with the operation of rear window defogger switch.

• Performs the timer control of rear window defogger.

Rear window defogger relay • Operates the rear window defogger and the door mirror defogger with the control signal from

BCM.

A/C and AV switch assembly

(rear window defogger switch) • The rear window defogger switch is turned ON.

• Turns the indicator lamp ON when detecting the operation of rear window defogger.

Rear window defogger • Heats the heating wire with the power supply from the rear window defogger relay to prevent

the rear window from fogging up.

Door mirror defogger • Heats the heating wire with the power supply from the heated mirror relay to prevent the door

mirror from fogging up.

Revision: December 20092009 QX56

Page 774 of 4171

DEF-6

< FUNCTION DIAGNOSIS >

DIAGNOSIS SYSTEM (BCM)

DIAGNOSIS SYSTEM (BCM)

COMMON ITEM

COMMON ITEM : CONSULT-III Function (BCM - COMMON ITEM)INFOID:0000000004223690

APPLICATION ITEM

CONSULT-III performs the following functions via CAN communication with BCM.

SYSTEM APPLICATION

BCM can perform the following functions for each system.

NOTE:

It can perform the diagnosis modes except the following for all sub system selection items.

REAR WINDOW DEFOGGER

Diagnosis mode Function Description

WORK SUPPORT Changes the setting for each system function.

SELF-DIAG RESULTS Displays the diagnosis results judged by BCM. Refer to BCS-51, "

DTCIndex".

CAN DIAG SUPPORT MNTR Monitors the reception status of CAN communication viewed from BCM.

DATA MONITOR The BCM input/output signals are displayed.

ACTIVE TEST The signals used to activate each device are forcibly supplied from BCM.

ECU IDENTIFICATION The BCM part number is displayed.

CONFIGURATION • Enables to read and save the vehicle specification.

• Enables to write the vehicle specification when replacing BCM.

System

Sub system selection item Diagnosis mode

WORK SUPPORT DATA MONITOR ACTIVE TEST

BCM BCM ×

Door lock DOOR LOCK ×××

Rear window defogger REAR DEFOGGER ×

Warning chime BUZZER ××

Interior room lamp timer INT LAMP ×××

Remote keyless entry system MULTI REMOTE ENT ××

Exterior lamp HEAD LAMP ×××

Wiper and washer WIPER ×××

Turn signal and hazard warning lamps FLASHER ××

Air conditioner AIR CONDITONER ×

Intelligent Key system INTELLIGENT KEY ×

Combination switch COMB SW ×

Immobilizer IMMU ××

Interior room lamp battery saver BATTERY SAVER ×××

Back door open TRUNK ××

RAP (retained accessory power) RETAINED PWR ×××

Signal buffer system SIGNAL BUFFER ××

TPMS (tire pressure monitoring sys-

tem) AIR PRESSURE MONITOR

×××

Vehicle security system PANIC ALARM ×

Revision: December 20092009 QX56

Page 786 of 4171

DEF-18

< ECU DIAGNOSIS >

BCM (BODY CONTROL MODULE)

HEADLAMP SW1Headlamp switch OFF OFF

Headlamp switch 1st

ON

HEADLAMP SW2 Headlamp switch OFF

OFF

Headlamp switch 1st ON

HI BEAM SW High beam switch OFF

OFF

High beam switch HI ON

H/L WASH SW NOTE:

The item is indicated, but not monitored OFF

IGN ON SW Ignition switch OFF or ACC

OFF

Ignition switch ON ON

IGN SW CAN Ignition switch OFF or ACC

OFF

Ignition switch ON ON

INT VOLUME Wiper intermittent dial is in a dial position 1 - 7 1 - 7

I-KEY LOCK LOCK button of Intelligent Key is not pressed

OFF

LOCK button of Intelligent Key is pressed ON

I-KEY UNLOCK UNLOCK button of Intelligent Key is not pressed

OFF

UNLOCK button of Intelligent Key is pressed ON

KEY ON SW Mechanical key is removed from key cylinder

OFF

Mechanical key is inserted to key cylinder ON

OIL PRESS SW • Ignition switch OFF or ACC

• Engine running

OFF

Ignition switch ON ON

PASSING SW Other than lighting switch PASS

OFF

Lighting switch PASS ON

REAR DEF SW Rear window defogger switch OFF

OFF

Rear window defogger switch ON ON

RKE LOCK AND UN-

LOCK NOTE:

The item is indicated, but not monitored OFF

ON

RR WASHER SW Rear washer switch OFF

OFF

Rear washer switch ON ON

RR WIPER INT Rear wiper switch OFF

OFF

Rear wiper switch INT ON

RR WIPER ON Rear wiper switch OFF

OFF

Rear wiper switch ON ON

RR WIPER STOP Rear wiper stop position

OFF

Other than rear wiper stop position ON

TAIL LAMP SW Lighting switch OFF

OFF

Lighting switch 1ST ON

TRNK OPNR SW When back door opener switch is not pressed

OFF

When back door opener switch is pressed ON

TURN SIGNAL L Turn signal switch OFF

OFF

Turn signal switch LH ON

TURN SIGNAL R Turn signal switch OFF

OFF

Turn signal switch RH ON

VEHICLE SPEED While driving Equivalent to speedometer reading

Monitor Item

Condition Value/Status

Revision: December 20092009 QX56

Page 788 of 4171

DEF-20

< ECU DIAGNOSIS >

BCM (BODY CONTROL MODULE)

Te r m i n a lWire

color Signal name Signal

input/

output Measuring condition

Reference value or waveform

(Approx.)

Ignition

switch Operation or condition

1BR/W Ignition keyhole illumi-

nation Output OFFDoor is locked (SW OFF)

Battery voltage

Door is unlocked (SW ON) 0V

2SB Combination switch

input 5 Input ON

Lighting, turn, wiper OFF

Wiper dial position 4

3G/Y Combination switch

input 4 Input ONLighting, turn, wiper OFF

Wiper dial position 4

4Y Combination switch

input 3 Input ON

Lighting, turn, wiper OFF

Wiper dial position 4

5G/B Combination switch

input 2

Input ONLighting, turn, wiper OFF

Wiper dial position 4

6V Combination switch

input 1

9GR/R Rear window defogger

switch

Input ONRear window defogger switch

ON

0V

Rear window defogger switch

OFF 5V

10 G Hazard lamp flash Input OFF ON (opening or closing)

0V

OFF (other than above) Battery voltage

11 O Ignition switch (ACC

or ON)

InputACC or

ON Ignition switch ACC or ON

Battery voltage

12 R/L Front door switch RH Input OFF ON (open)

0V

OFF (closed) Battery voltage

13 GR Rear door switch RH Input OFF ON (open)

0V

OFF (closed) Battery voltage

15 L/W Tire pressure warning

check connector

Input OFF

—5V

18 P Remote keyless entry

receiver and optical

sensor (ground)

Output OFF

—0V

SKIA5291E

SKIA5292E

SKIA5291E

SKIA5292E

Revision: December 20092009 QX56

Page 789 of 4171

BCM (BODY CONTROL MODULE)DEF-21

< ECU DIAGNOSIS >

C

DE

F

G H

I

J

K

M A

B

DEF

N

O P

19 V/W Remote keyless entry

receiver (power sup-

ply) Output OFF Ignition switch OFF

20 G/W Remote keyless entry

receiver (signal) Input OFFStand-by (keyfob buttons re-

leased)

When remote keyless entry

receiver receives signal from

keyfob (keyfob buttons

pressed)

21 G NATS antenna amp. Input OFF

→

ON Ignition switch (OFF → ON) Just after turning ignition switch

ON: Pointer of tester should

move for approx. 1 second, then return to battery voltage.

22 W/V BUS — —Ignition switch ON or power

window timer operates

23 G/O Security indicator

lamp Output OFF

Goes OFF

→ illuminates (Ev-

ery 2.4 seconds) Battery voltage

→ 0V

25 BR NATS antenna amp. Input OFF

→

ON Ignition switch (OFF → ON) Just after turning ignition switch

ON: Pointer of tester should

move for approx. 1 second, then return to battery voltage.

26 Y/L Rear wiper auto stop

switch 2 Input ONRise up position (rear wiper

arm on stopper)

0V

A Position (full clockwise stop

position) 0V

Forward sweep (counterclock-

wise direction) Fluctuating

B Position (full counterclock-

wise stop position) Battery voltage

Reverse sweep (clockwise di-

rection) Fluctuating

27 W/R Compressor ON sig-

nal Input ONA/C switch OFF

5V

A/C switch ON 0V

Te r m i n a l

Wire

color Signal name Signal

input/

output Measuring condition

Reference value or waveform

(Approx.)

Ignition

switch Operation or condition

LIIA1893E

LIIA1894E

LIIA1895E

PIIA2344E

Revision: December 20092009 QX56