ignition INFINITI QX56 2009 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2009, Model line: QX56, Model: INFINITI QX56 2009Pages: 4171, PDF Size: 84.65 MB

Page 4107 of 4171

WW-20

< COMPONENT DIAGNOSIS >

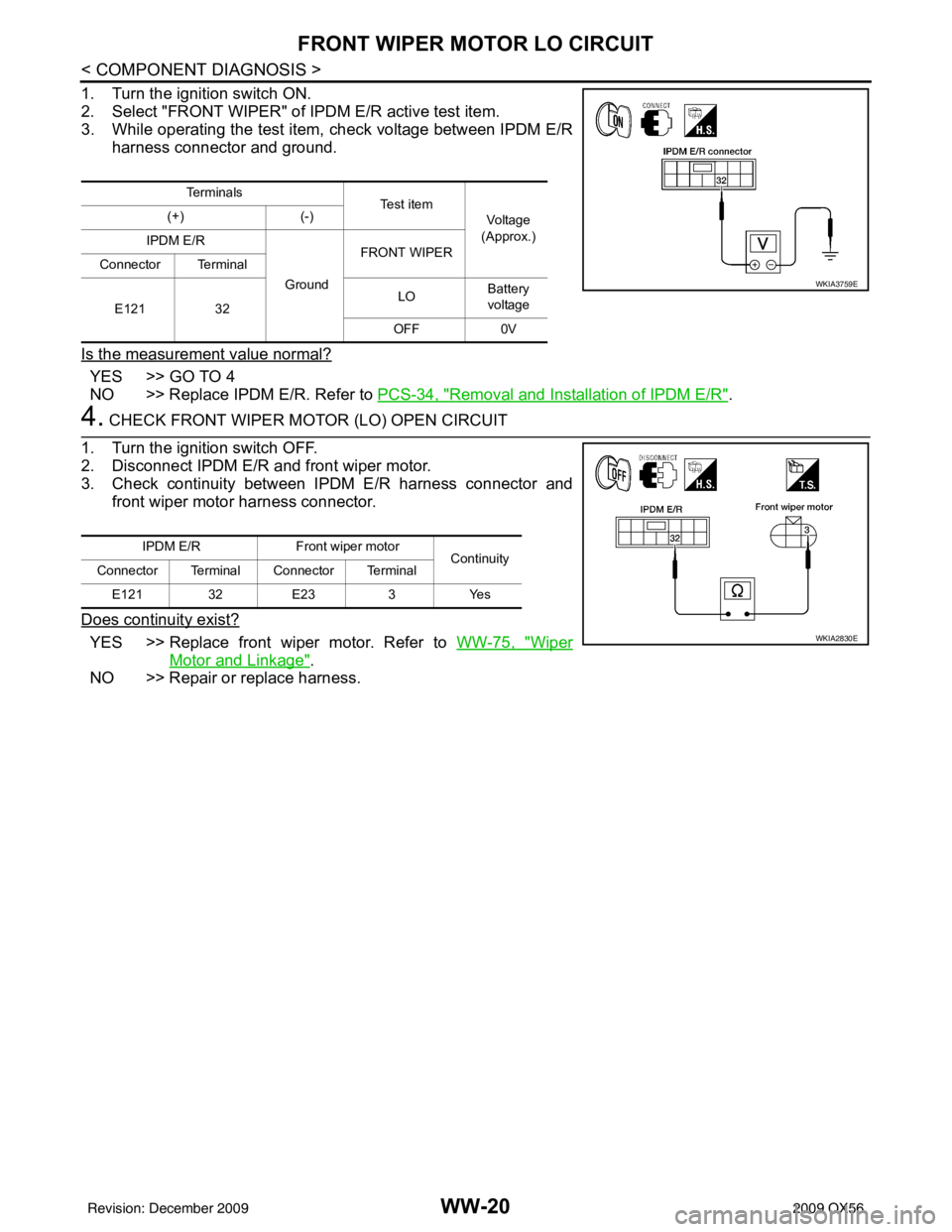

FRONT WIPER MOTOR LO CIRCUIT

1. Turn the ignition switch ON.

2. Select "FRONT WIPER" of IPDM E/R active test item.

3. While operating the test item, check voltage between IPDM E/Rharness connector and ground.

Is the measurement value normal?

YES >> GO TO 4

NO >> Replace IPDM E/R. Refer to PCS-34, "

Removal and Installation of IPDM E/R".

4. CHECK FRONT WIPER MOTOR (LO) OPEN CIRCUIT

1. Turn the ignition switch OFF.

2. Disconnect IPDM E/R and front wiper motor.

3. Check continuity between IPDM E/R harness connector and front wiper motor harness connector.

Does continuity exist?

YES >> Replace front wiper motor. Refer to WW-75, "Wiper

Motor and Linkage".

NO >> Repair or replace harness.

Te r m i n a l s Te s t i t e m

Voltage

(Approx.)

(+)

(-)

IPDM E/R

GroundFRONT WIPER

Connector Terminal

E121 32 LO

Battery

voltage

OFF 0V

WKIA3759E

IPDM E/R Front wiper motor

Continuity

Connector Terminal Connector Terminal

E121 32 E233Yes

WKIA2830E

Revision: December 20092009 QX56

Page 4108 of 4171

FRONT WIPER MOTOR HI CIRCUITWW-21

< COMPONENT DIAGNOSIS >

C

DE

F

G H

I

J

K

M A

B

WW

N

O P

FRONT WIPER MOTOR HI CIRCUIT

Component Function CheckINFOID:0000000003776292

1. CHECK FRONT WIPER HI OPERATION

IPDM E/R AUTO ACTIVE TEST

1. Start IPDM E/R auto active test. Refer to PCS-12, "

Diagnosis Description".

2. Check that the front wiper operates at the HI operation.

CONSULT-III ACTIVE TEST

1. Select "FRONT WIPER" of IPDM E/R active test item.

2. While operating the test item, check front wiper operation.

Is front wiper (HI) operation normal?

YES >> Front wiper motor HI circuit is normal.

NO >> Refer to WW-21, "

Diagnosis Procedure".

Diagnosis ProcedureINFOID:0000000003776293

1. CHECK FRONT WIPER MOTOR FUSE

1. Turn the ignition switch OFF.

2. Check that the following fuse is not blown.

Is the fuse blown?

YES >> GO TO 2

NO >> GO TO 3

2. CHECK FRONT WIPER MOTOR (HI) SHORT CIRCUIT

1. Disconnect IPDM E/R and front wiper motor.

2. Check continuity between IPDM E/R harness connector and ground.

Does continuity exist?

YES >> Repair or replace harness.

NO >> Replace the fuse. (Replace IPDM E/R if the fuse is blown again.)

3. CHECK FRONT WIPER MOTOR (HI) OUTPUT VOLTAGE

CONSULT-III ACTIVE TEST HI : Front wiper (HI) operation

OFF : Stop the front wiper.

Unit Location Fuse No. Capacity

Front wiper motor IPDM E/R39 30 A

IPDM E/R

GroundContinuity

Connector Terminal

E121 35 No

ALLIA0448ZZ

Revision: December 20092009 QX56

Page 4109 of 4171

WW-22

< COMPONENT DIAGNOSIS >

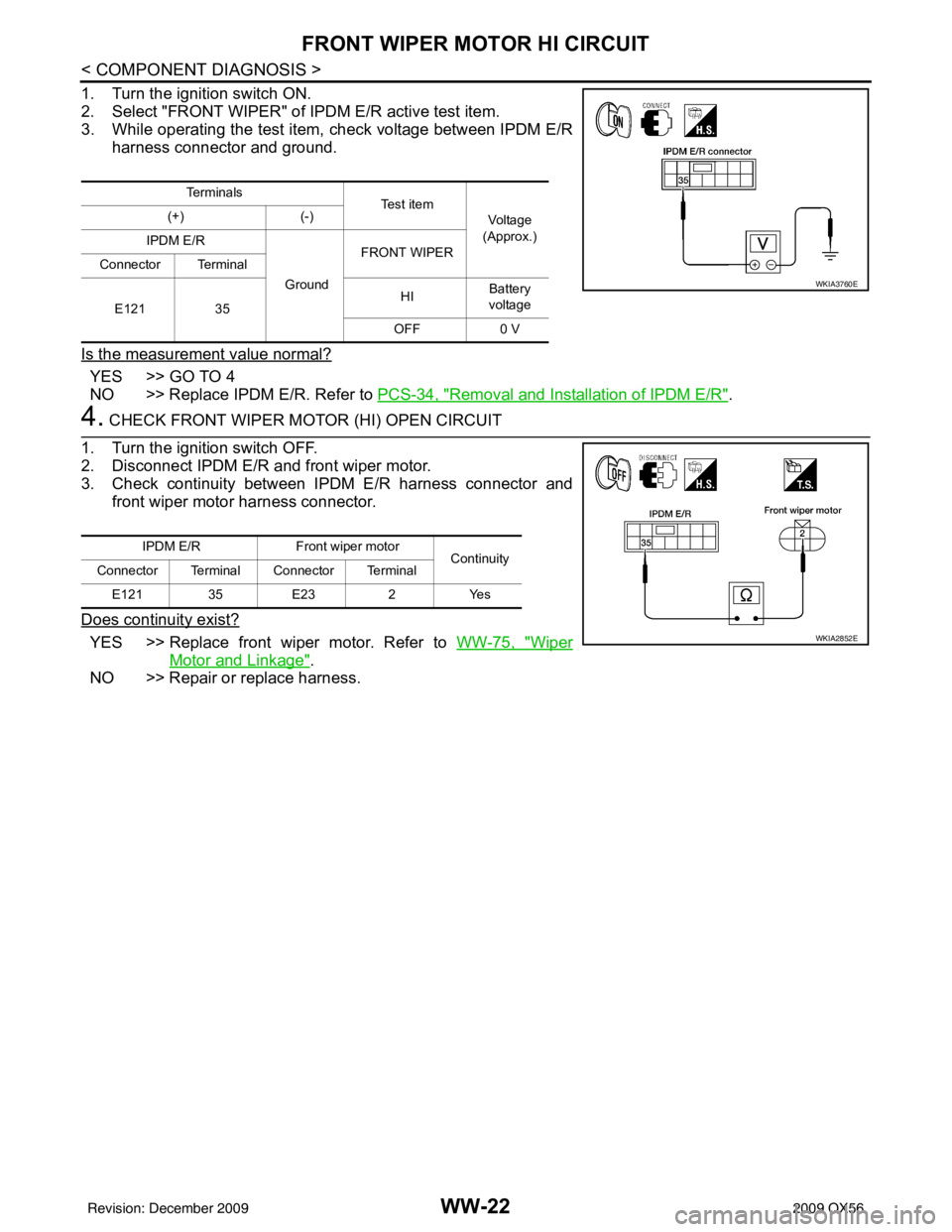

FRONT WIPER MOTOR HI CIRCUIT

1. Turn the ignition switch ON.

2. Select "FRONT WIPER" of IPDM E/R active test item.

3. While operating the test item, check voltage between IPDM E/Rharness connector and ground.

Is the measurement value normal?

YES >> GO TO 4

NO >> Replace IPDM E/R. Refer to PCS-34, "

Removal and Installation of IPDM E/R".

4. CHECK FRONT WIPER MOTOR (HI) OPEN CIRCUIT

1. Turn the ignition switch OFF.

2. Disconnect IPDM E/R and front wiper motor.

3. Check continuity between IPDM E/R harness connector and front wiper motor harness connector.

Does continuity exist?

YES >> Replace front wiper motor. Refer to WW-75, "Wiper

Motor and Linkage".

NO >> Repair or replace harness.

Te r m i n a l s Te s t i t e m

Voltage

(Approx.)

(+)

(-)

IPDM E/R

GroundFRONT WIPER

Connector Terminal

E121 35 HI

Battery

voltage

OFF 0 V

WKIA3760E

IPDM E/R Front wiper motor

Continuity

Connector Terminal Connector Terminal

E121 35 E232Yes

WKIA2852E

Revision: December 20092009 QX56

Page 4110 of 4171

FRONT WIPER AUTO STOP SIGNAL CIRCUITWW-23

< COMPONENT DIAGNOSIS >

C

DE

F

G H

I

J

K

M A

B

WW

N

O P

FRONT WIPER AUTO ST OP SIGNAL CIRCUIT

Component Function CheckINFOID:0000000003776294

1. CHECK FRONT WIPER (AUTO STOP) SIGNAL CHECK

CONSULT-III DATA MONITOR

1. Select "FR WIPER STOP" of IPDM E/R data monitor item.

2. Operate the front wiper.

3. Check that "FR WIPER STOP" changes to "ON" and "OFF" linked with the wiper operation.

Is the status of item normal?

YES >> Front wiper auto stop signal circuit is normal.

NO >> Refer to WW-23, "

Diagnosis Procedure".

Diagnosis ProcedureINFOID:0000000003776295

1. CHECK FRONT WIPER MOTOR (A UTO STOP) OUTPUT VOLTAGE

1. Turn the ignition switch ON.

2. Check voltage between IPDM E/R harness connector and ground.

Is the measurement value normal?

YES >> GO TO 3

NO >> GO TO 2

2. CHECK FRONT WIPER MOTOR (AUTO STOP) SHORT CIRCUIT

1. Turn the ignition switch OFF.

2. Disconnect IPDM E/R and front wiper motor.

3. Check continuity between IPDM E/R harness connector and ground.

Does continuity exist?

YES >> Repair or replace harness.

NO >> Replace IPDM E/R. Refer to PCS-34, "

Removal and Installation of IPDM E/R".

3. CHECK FRONT WIPER MOTOR (AUTO STOP) CIRCUIT CONTINUITY

Monitor item ConditionMonitor status

FR WIPER STOP Front wiper motor Stop position

ON

Except stop position OFF

Te r m i n a l s

Voltage

(Approx.)

(+)

(-)

IPDM E/R Ground

Connector Terminal

E122 43 Battery voltage

WKIA1431E

IPDM E/R

GroundContinuity

Connector Terminal

E122 43 No

WKIA1429E

Revision: December 20092009 QX56

Page 4112 of 4171

FRONT WIPER MOTOR GROUND CIRCUITWW-25

< COMPONENT DIAGNOSIS >

C

DE

F

G H

I

J

K

M A

B

WW

N

O P

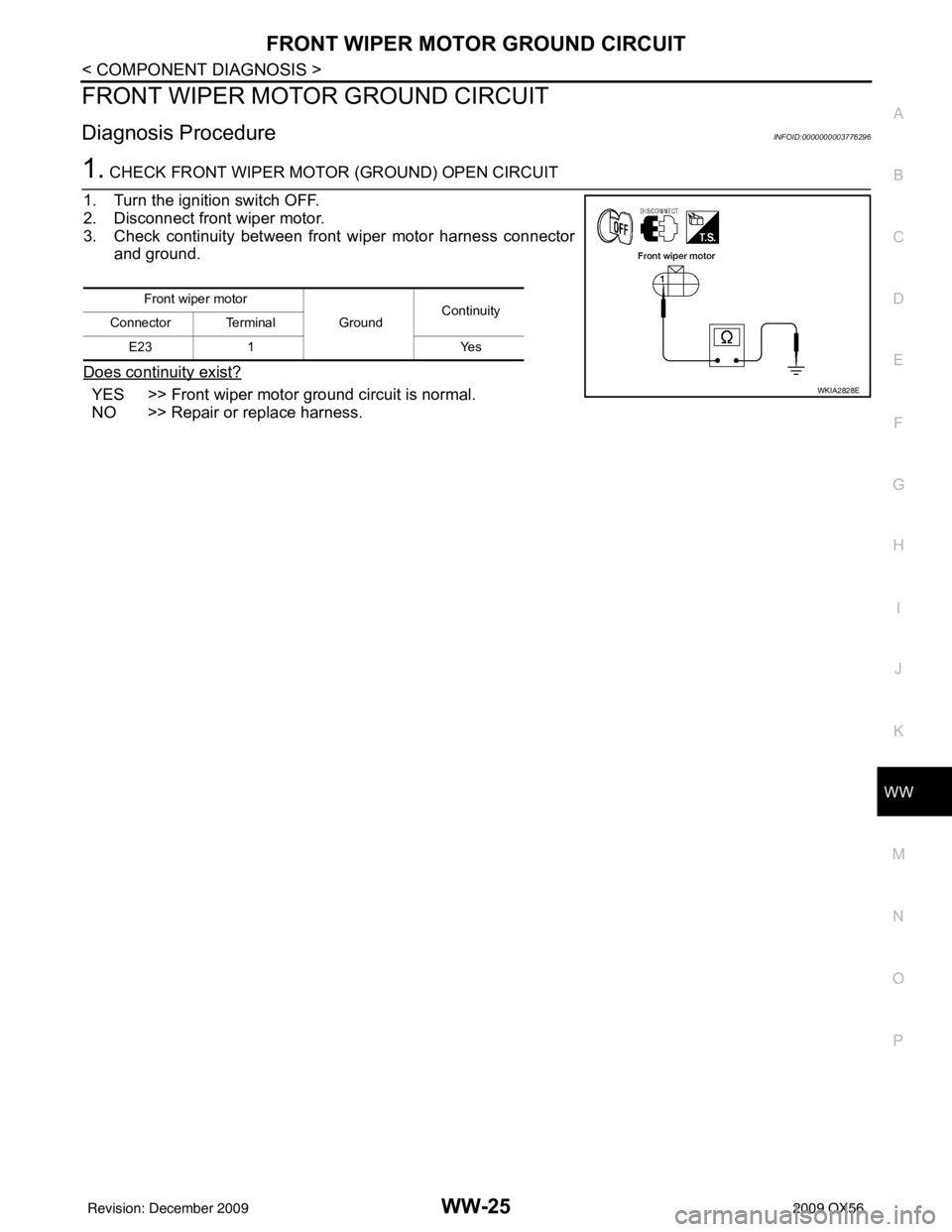

FRONT WIPER MOTOR GROUND CIRCUIT

Diagnosis ProcedureINFOID:0000000003776296

1. CHECK FRONT WIPER MOTO R (GROUND) OPEN CIRCUIT

1. Turn the ignition switch OFF.

2. Disconnect front wiper motor.

3. Check continuity between front wiper motor harness connector and ground.

Does continuity exist?

YES >> Front wiper motor ground circuit is normal.

NO >> Repair or replace harness.

Front wiper motor GroundContinuity

Connector Terminal

E23 1 Yes

WKIA2828E

Revision: December 20092009 QX56

Page 4113 of 4171

WW-26

< COMPONENT DIAGNOSIS >

WASHER SWITCH

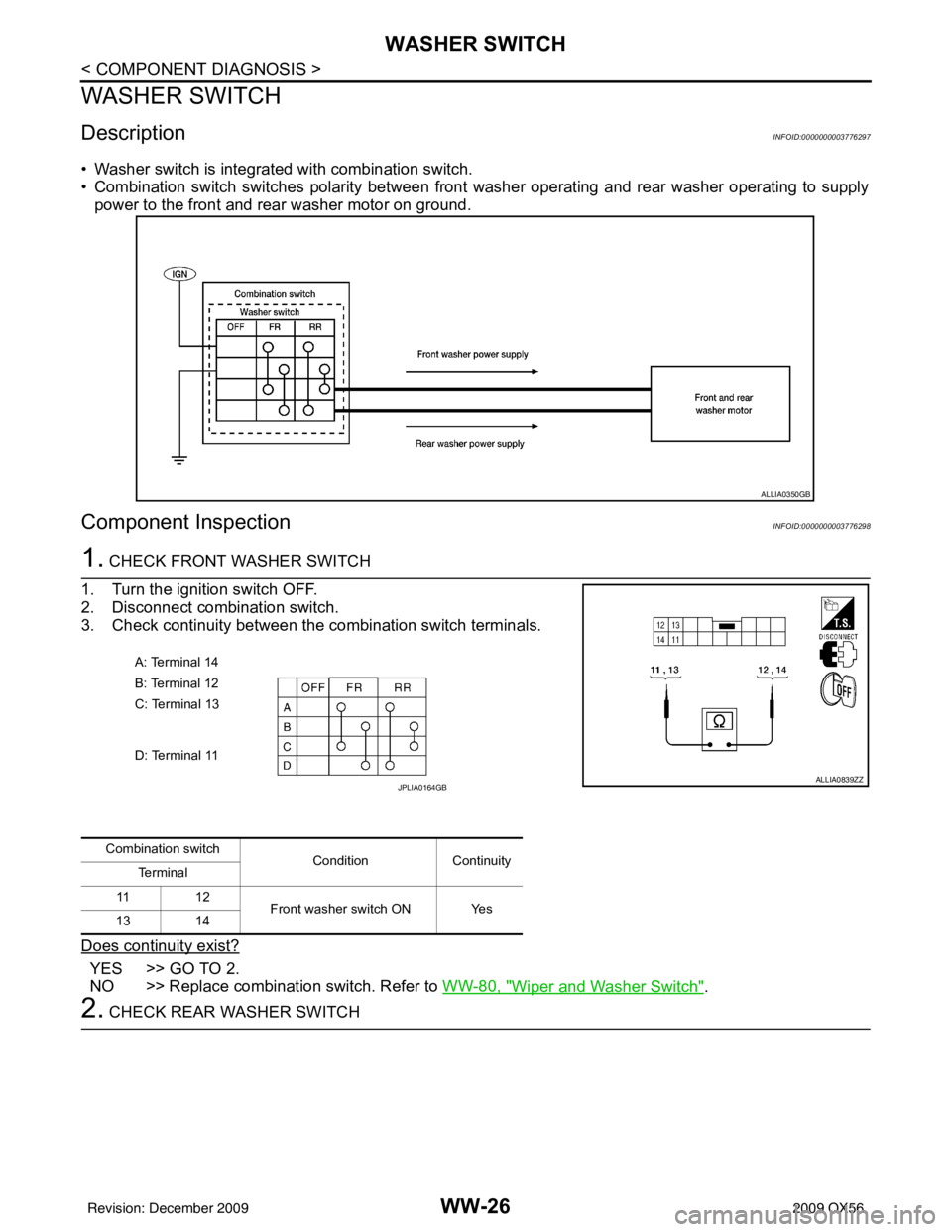

WASHER SWITCH

DescriptionINFOID:0000000003776297

• Washer switch is integrated with combination switch.

• Combination switch switches polarity between front washer operating and rear washer operating to supply

power to the front and rear washer motor on ground.

Component InspectionINFOID:0000000003776298

1. CHECK FRONT WASHER SWITCH

1. Turn the ignition switch OFF.

2. Disconnect combination switch.

3. Check continuity between the combination switch terminals.

Does continuity exist?

YES >> GO TO 2.

NO >> Replace combination switch. Refer to WW-80, "

Wiper and Washer Switch".

2. CHECK REAR WASHER SWITCH

ALLIA0350GB

A: Terminal 14

B: Terminal 12

C: Terminal 13

D: Terminal 11

ALLIA0839ZZJPLIA0164GB

Combination switch ConditionContinuity

Te r m i n a l

11 1 2

Front washer switch ON Yes

13 14

Revision: December 20092009 QX56

Page 4114 of 4171

WASHER SWITCHWW-27

< COMPONENT DIAGNOSIS >

C

DE

F

G H

I

J

K

M A

B

WW

N

O P

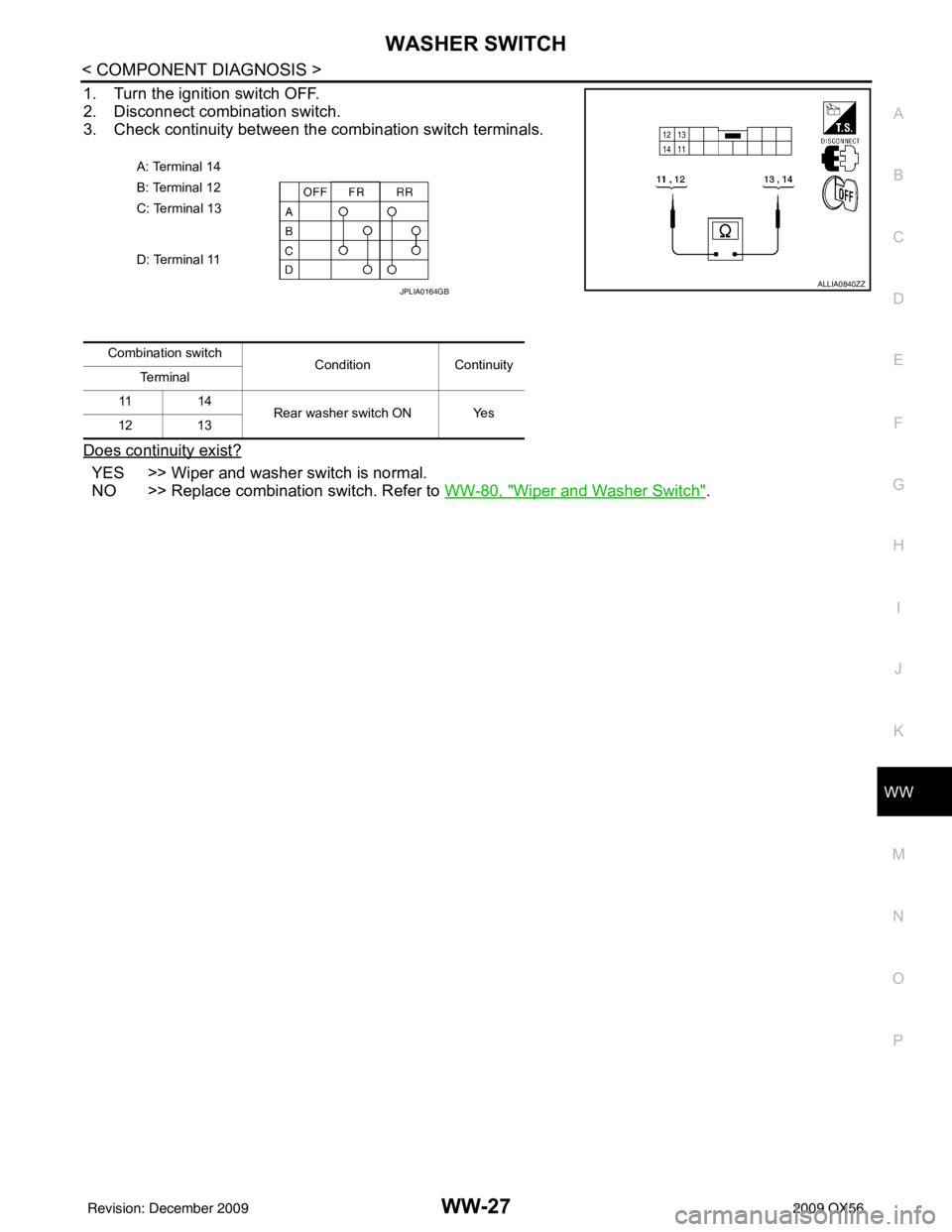

1. Turn the ignition switch OFF.

2. Disconnect combination switch.

3. Check continuity between the combination switch terminals.

Does continuity exist?

YES >> Wiper and washer switch is normal.

NO >> Replace combination switch. Refer to WW-80, "

Wiper and Washer Switch".

A: Terminal 14

B: Terminal 12

C: Terminal 13

D: Terminal 11

ALLIA0840ZZJPLIA0164GB

Combination switch

ConditionContinuity

Te r m i n a l

11 1 4

Rear washer switch ON Yes

12 13

Revision: December 20092009 QX56

Page 4115 of 4171

WW-28

< COMPONENT DIAGNOSIS >

REAR WIPER MOTOR CIRCUIT

REAR WIPER MOTOR CIRCUIT

Component Function CheckINFOID:0000000003776299

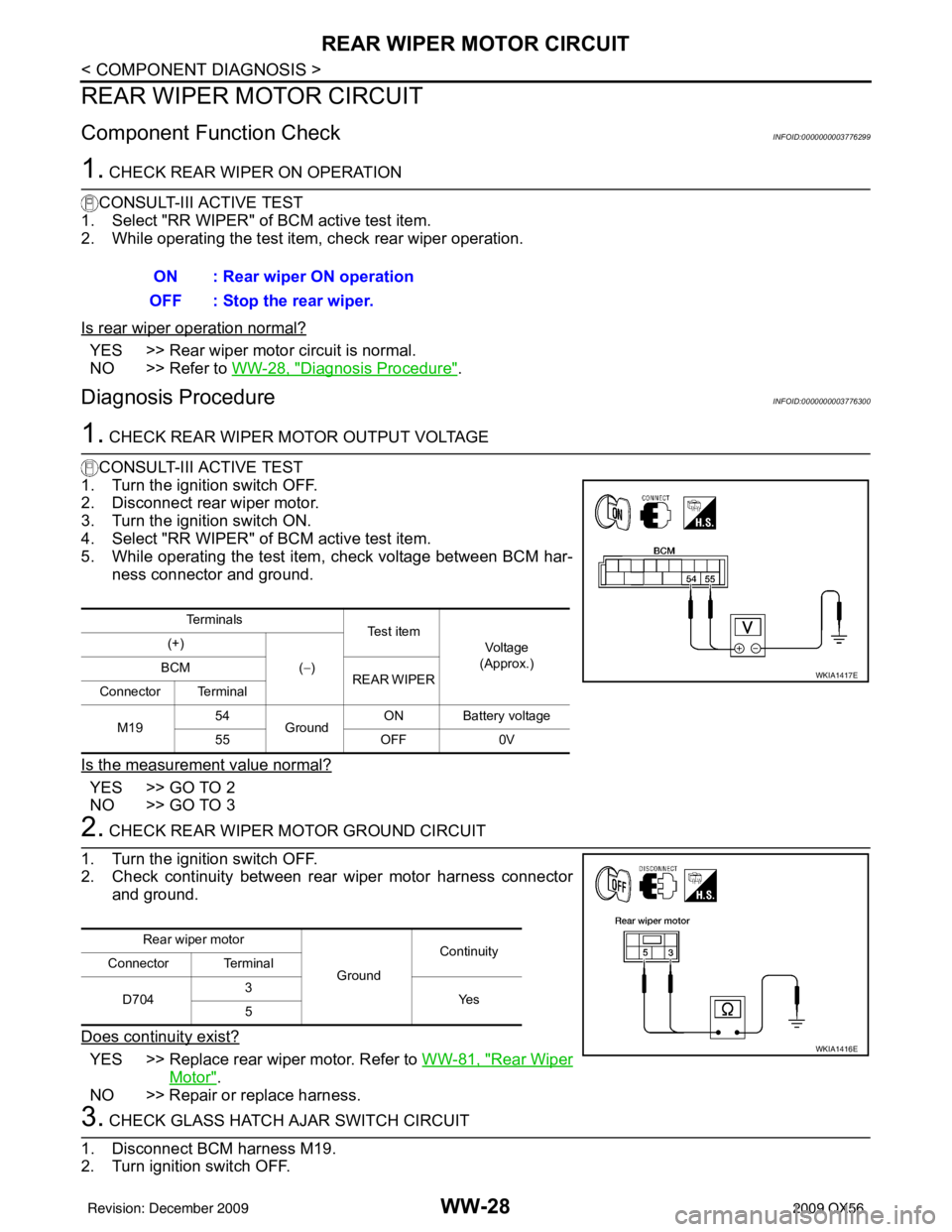

1. CHECK REAR WIPER ON OPERATION

CONSULT-III ACTIVE TEST

1. Select "RR WIPER" of BCM active test item.

2. While operating the test item, check rear wiper operation.

Is rear wiper operation normal?

YES >> Rear wiper motor circuit is normal.

NO >> Refer to WW-28, "

Diagnosis Procedure".

Diagnosis ProcedureINFOID:0000000003776300

1. CHECK REAR WIPER MOTOR OUTPUT VOLTAGE

CONSULT-III ACTIVE TEST

1. Turn the ignition switch OFF.

2. Disconnect rear wiper motor.

3. Turn the ignition switch ON.

4. Select "RR WIPER" of BCM active test item.

5. While operating the test item, check voltage between BCM har-

ness connector and ground.

Is the measurement value normal?

YES >> GO TO 2

NO >> GO TO 3

2. CHECK REAR WIPER MOTOR GROUND CIRCUIT

1. Turn the ignition switch OFF.

2. Check continuity between rear wiper motor harness connector and ground.

Does continuity exist?

YES >> Replace rear wiper motor. Refer to WW-81, "Rear Wiper

Motor".

NO >> Repair or replace harness.

3. CHECK GLASS HATCH AJAR SWITCH CIRCUIT

1. Disconnect BCM harness M19.

2. Turn ignition switch OFF. ON : Rear wiper ON operation

OFF : Stop the rear wiper.

Te r m i n a l s Te s t i t e m

Vo l ta g e

(Approx.)

(+)

(−)

BCM

REAR WIPER

Connector Terminal

M19 54

Ground ON Battery voltage

55 OFF0V

WKIA1417E

Rear wiper motor

GroundContinuity

Connector Terminal

D704 3

Ye s

5

WKIA1416E

Revision: December 20092009 QX56

Page 4117 of 4171

WW-30

< COMPONENT DIAGNOSIS >

REAR WIPER AUTO STOP SIGNAL CIRCUIT

REAR WIPER AUTO STOP SIGNAL CIRCUIT

Component Function CheckINFOID:0000000003776301

1. CHECK REAR WIPER (AUTO STOP) OPERATION

CONSULT-III DATA MONITOR

1. Select "WIPER" of BCM data monitor item.

2. Operate the rear wiper.

3. Check that "RR WIPER STOP" changes to "O N" and "OFF" linked with the wiper operation.

Is the status of item normal?

YES >> Rear wiper auto stop signal circuit is normal.

NO >> Refer to WW-30, "

Diagnosis Procedure".

Diagnosis ProcedureINFOID:0000000003776302

1. CHECK REAR WIPER MOTOR AUTO STOP CIRCUITS

1. Turn ignition switch OFF.

2. Disconnect BCM and rear wiper motor.

3. Check continuity between BCM harness connector terminals and rear wiper motor harness connector terminals.

Is inspection result normal?

YES >> GO TO 2

NO >> Repair or replace harness.

2. CHECK AUTO STOP CIRCUITS FOR SHORT TO GROUND

Check continuity between BCM harness connector terminals and

ground.

Is inspection result normal?

YES >> Replace BCM. Refer to BCS-56, "Removal and Installa-

tion".

NO >> Repair or replace harness.

Monitor item ConditionMonitor status

RR WIPER STOP Rear wiper motor Stop position

ON

Except stop position OFF

BCM Rear wiper motor

Continuity

Connector Terminal Connector Terminal

M18 26 D7041

Ye s

M19 44 2

WKIA1415E

BCM

GroundContinuity

Connector Terminal

M18 26 No

M19 44

WKIA1421E

Revision: December 20092009 QX56

Page 4129 of 4171

WW-42

< ECU DIAGNOSIS >

BCM (BODY CONTROL MODULE)

HEADLAMP SW1Headlamp switch OFF OFF

Headlamp switch 1st

ON

HEADLAMP SW2 Headlamp switch OFF

OFF

Headlamp switch 1st ON

HI BEAM SW High beam switch OFF

OFF

High beam switch HI ON

H/L WASH SW NOTE:

The item is indicated, but not monitored OFF

IGN ON SW Ignition switch OFF or ACC

OFF

Ignition switch ON ON

IGN SW CAN Ignition switch OFF or ACC

OFF

Ignition switch ON ON

INT VOLUME Wiper intermittent dial is in a dial position 1 - 7 1 - 7

I-KEY LOCK LOCK button of Intelligent Key is not pressed

OFF

LOCK button of Intelligent Key is pressed ON

I-KEY UNLOCK UNLOCK button of Intelligent Key is not pressed

OFF

UNLOCK button of Intelligent Key is pressed ON

KEY ON SW Mechanical key is removed from key cylinder

OFF

Mechanical key is inserted to key cylinder ON

OIL PRESS SW • Ignition switch OFF or ACC

• Engine running

OFF

Ignition switch ON ON

PASSING SW Other than lighting switch PASS

OFF

Lighting switch PASS ON

REAR DEF SW Rear window defogger switch OFF

OFF

Rear window defogger switch ON ON

RKE LOCK AND UN-

LOCK NOTE:

The item is indicated, but not monitored OFF

ON

RR WASHER SW Rear washer switch OFF

OFF

Rear washer switch ON ON

RR WIPER INT Rear wiper switch OFF

OFF

Rear wiper switch INT ON

RR WIPER ON Rear wiper switch OFF

OFF

Rear wiper switch ON ON

RR WIPER STOP Rear wiper stop position

OFF

Other than rear wiper stop position ON

TAIL LAMP SW Lighting switch OFF

OFF

Lighting switch 1ST ON

TRNK OPNR SW When back door opener switch is not pressed

OFF

When back door opener switch is pressed ON

TURN SIGNAL L Turn signal switch OFF

OFF

Turn signal switch LH ON

TURN SIGNAL R Turn signal switch OFF

OFF

Turn signal switch RH ON

VEHICLE SPEED While driving Equivalent to speedometer reading

Monitor Item

Condition Value/Status

Revision: December 20092009 QX56