dimensions INFINITI QX56 2009 Factory User Guide

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2009, Model line: QX56, Model: INFINITI QX56 2009Pages: 4171, PDF Size: 84.65 MB

Page 1934 of 4171

SERVICE DATA AND SPECIFICATIONS (SDS)EM-111

< SERVICE DATA AND SPECIFICATIONS (SDS)

C

DE

F

G H

I

J

K L

M A

EM

NP

O

Unit: mm (in)

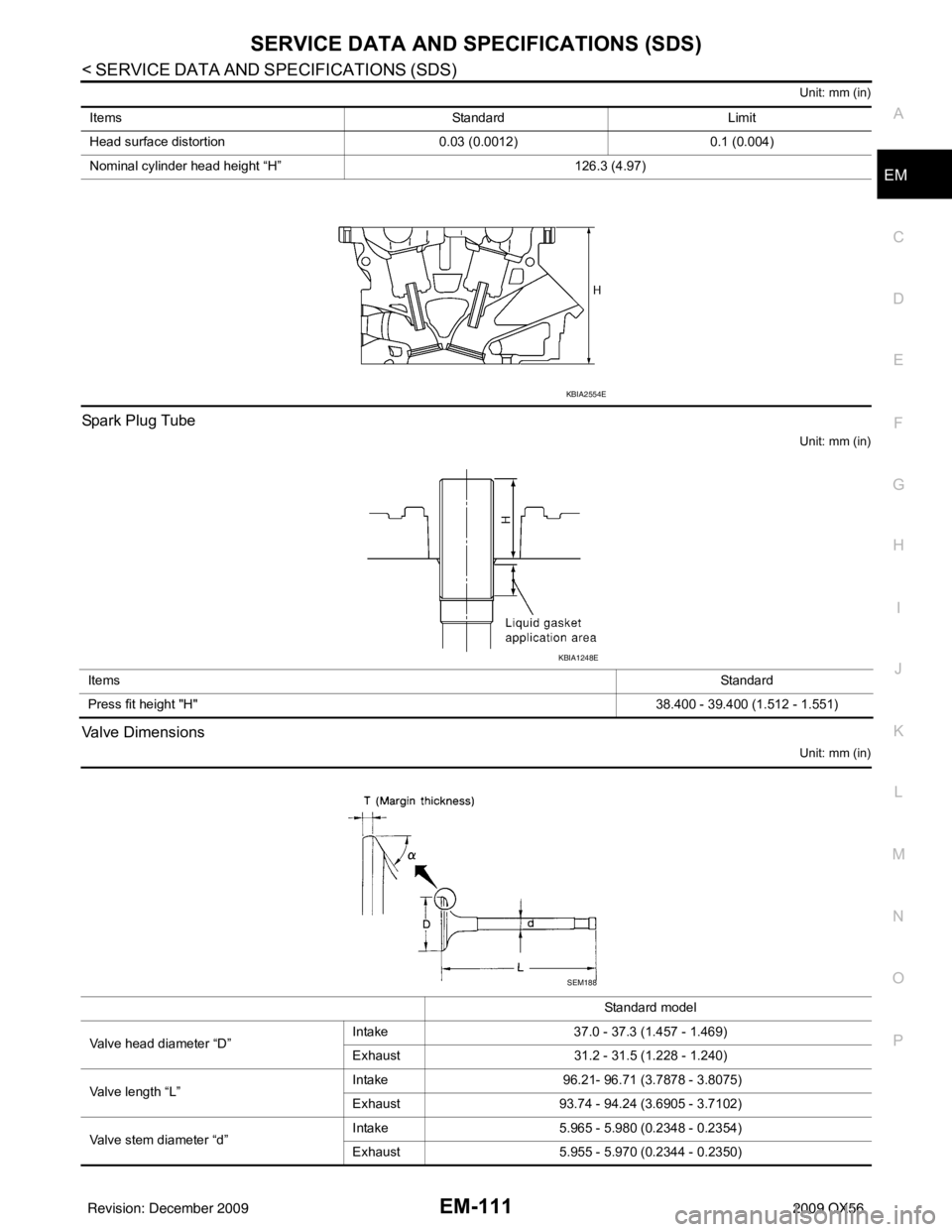

Spark Plug Tube

Unit: mm (in)

Valve Dimensions

Unit: mm (in)

Items

StandardLimit

Head surface distortion 0.03 (0.0012)0.1 (0.004)

Nominal cylinder head height “H” 126.3 (4.97)

KBIA2554E

Items Standard

Press fit height "H" 38.400 - 39.400 (1.512 - 1.551)

KBIA1248E

Standard model

Valve head diameter “D” Intake

37.0 - 37.3 (1.457 - 1.469)

Exhaust 31.2 - 31.5 (1.228 - 1.240)

Valve length “L” Intake

96.21- 96.71 (3.7878 - 3.8075)

Exhaust 93.74 - 94.24 (3.6905 - 3.7102)

Valve stem diameter “d” Intake

5.965 - 5.980 (0.2348 - 0.2354)

Exhaust 5.955 - 5.970 (0.2344 - 0.2350)

SEM188

Revision: December 20092009 QX56

Page 2195 of 4171

GI-1

GENERAL INFORMATION

C

DE

F

G H

I

J

K L

M B

GI

SECTION GI

N

O P

CONTENTS

GENERAL INFORMATION

HOW TO USE THIS MANU AL ......................3

HOW TO USE THIS MANUAL ....................... .....3

Description .......................................................... ......3

Terms ........................................................................3

Units ..........................................................................3

Contents ....................................................................3

Relation between Illustrations and Descriptions .......4

Components ..............................................................4

HOW TO FOLLOW TROUBLE DIAGNOSES .....6

Description ................................................................6

How to Follow Test Groups in Trouble Diagnosis ......6

Key to Symbols Signifying Measurements or Pro-

cedures ............................................................... ......

7

HOW TO READ WIRING DIAGRAMS ................9

Connector symbols ............................................. ......9

Sample/wiring diagram -example- ...........................10

Description ..............................................................11

ABBREVIATIONS .......................................... ....13

Abbreviation List .................................................. ....13

TIGHTENING TORQUE OF STANDARD

BOLTS ................................................................

14

Tightening Torque Table .........................................14

RECOMMENDED CHEMICAL PRODUCTS

AND SEALANTS ............................................ ....

15

Recommended Chemical Products and Sealants ....15

TERMINOLOGY .................................................16

SAE J1930 Terminology List ............................... ....16

FEATURES OF NEW MODEL .....................20

IDENTIFICATION INFORMATION .....................20

Model Variation ................................................... ....20

Identification Number ..............................................21

Identification Plate ...................................................22

Dimensions .............................................................23

Wheels & Tires .................................................... ....23

PRECAUTION ..............................................24

PRECAUTIONS .................................................24

Description ........................................................... ....24

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" .................................................................

24

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ...................................

24

Procedures without Cowl Top Cover .......................25

General Precautions ................................................25

Three Way Catalyst .................................................27

Precaution for Fuel (Unleaded Premium Gasoline

Recommended) .......................................................

27

Multiport Fuel Injection System or Engine Control

System .....................................................................

27

Hoses ......................................................................27

Engine Oils ..............................................................28

Air Conditioning .......................................................29

LIFTING POINT .................................................30

Pantograph Jack ......................................................30

Garage Jack and Safety Stand ................................30

2-Pole Lift ................................................................30

TOW TRUCK TOWING .....................................32

Tow Truck Towing ...................................................32

Vehicle Recovery (Freeing a stuck vehicle) ............33

BASIC INSPECTION ...................................34

SERVICE INFORMATION FOR ELECTRICAL

INCIDENT ..........................................................

34

Work Flow ............................................................ ....34

Control Units and Electrical Parts ............................34

How to Check Terminal ...........................................35

Intermittent Incident ............................................. ....38

Circuit Inspection .....................................................41

CONSULT-III CHECKING SYSTEM .................46

Revision: December 20092009 QX56

Page 2217 of 4171

IDENTIFICATION INFORMATIONGI-23

< FEATURES OF NEW MODEL >

C

DE

F

G H

I

J

K L

M B

GI

N

O P

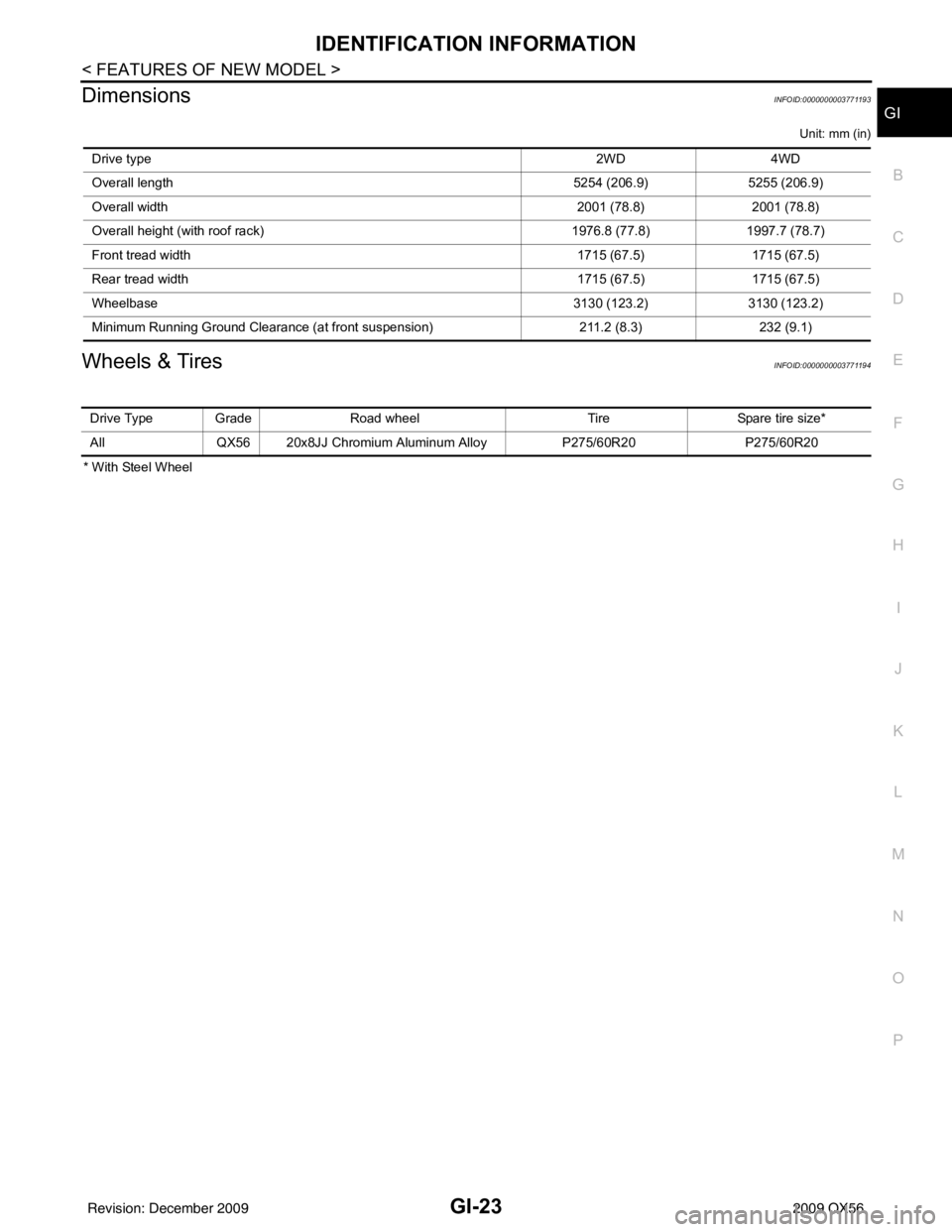

DimensionsINFOID:0000000003771193

Unit: mm (in)

Wheels & TiresINFOID:0000000003771194

* With Steel Wheel Drive type

2WD4WD

Overall length 5254 (206.9)5255 (206.9)

Overall width 2001 (78.8)2001 (78.8)

Overall height (with roof rack) 1976.8 (77.8)1997.7 (78.7)

Front tread width 1715 (67.5)1715 (67.5)

Rear tread width 1715 (67.5)1715 (67.5)

Wheelbase 3130 (123.2)3130 (123.2)

Minimum Running Ground Clearance (at front suspension) 211.2 (8.3)232 (9.1)

Drive Type Grade Road wheelTireSpare tire size*

All QX56 20x8JJ Chromium Aluminum Alloy P275/60R20P275/60R20

Revision: December 20092009 QX56

Page 2658 of 4171

PRECAUTIONSLU-3

< PRECAUTION >

C

DE

F

G H

I

J

K L

M A

LU

NP

O

5. When the repair work is completed, return the ignition switch to the

″LOCK ″ position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of al l control units using CONSULT-III.

Precaution for Liquid GasketINFOID:0000000003771265

REMOVAL OF LIQUID GASKET SEALING

• After removing the bolts and nuts, separate the mating surface and

remove the old liquid gasket sealing using Tool.

CAUTION:

Do not damage the mating surfaces.

• Tap the seal cutter to insert it (1).

• In areas where the Tool is difficult to use, lightly tap to slide it (2).

LIQUID GASKET APPLICATION PROCEDURE

1. Remove the old liquid gasket adhering to the gasket application surface and the mating surface using suitable tool.

• Remove the liquid gasket completely from the groove of the

liquid gasket application surface, bolts, and bolt holes.

2. Thoroughly clean the mating surfaces and remove adhering moisture, grease and foreign material.

3. Attach the liquid gasket tube to the Tool. Use Genuine RTV Silicone Sealant or equivalent. Refer to

GI-15, "

Recommended Chemical Products and Sealants".

4. Apply the liquid gasket without breaks to the specified location with the specified dimensions.

• If there is a groove for the liquid gasket application, apply theliquid gasket to the groove.

• As for the bolt holes, normally apply the liquid gasket inside

the holes. If specified in the procedure, it should also be

applied outside the holes.

• Within five minutes of liquid gasket application, install the mat-

ing component.

• If the liquid gasket protrudes, wipe it off immediately.

• Do not retighten after the installation.

• Wait 30 minutes or more after installation before refilling the engine with engine oil and engine coolant.

CAUTION:

If there are specific instructions in this manual, observe them.

Tool number : KV10111100 (J-37228)

WBIA0566E

PBIC0003E

Tool number : WS39930000 ( — )

WBIA0567E

SEM159F

Revision: December 20092009 QX56

Page 3929 of 4171

ASSEMBLYTM-281

< DISASSEMBLY AND ASSEMBLY >

CEF

G H

I

J

K L

M A

B

TM

N

O P

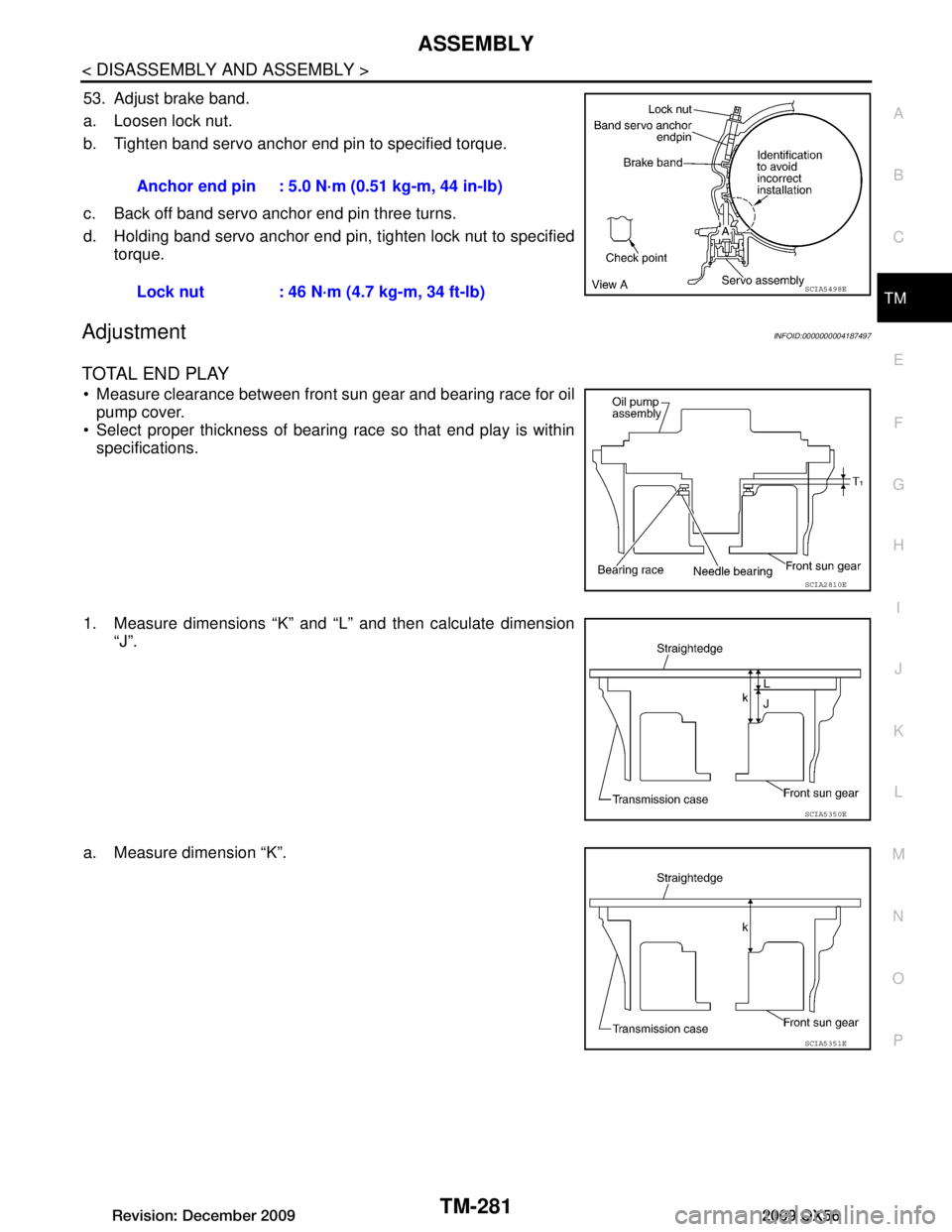

53. Adjust brake band.

a. Loosen lock nut.

b. Tighten band servo anchor end pin to specified torque.

c. Back off band servo anchor end pin three turns.

d. Holding band servo anchor end pin, tighten lock nut to specified torque.

AdjustmentINFOID:0000000004187497

TOTAL END PLAY

Measure clearance between front sun gear and bearing race for oilpump cover.

Select proper thickness of bearing race so that end play is within specifications.

1. Measure dimensions “K” and “L” and then calculate dimension “J”.

a. Measure dimension “K”. Anchor end pin : 5.0 N·m (0.51 kg-m, 44 in-lb)

Lock nut : 46 N·m (4.7 kg-m, 34 ft-lb)

SCIA5498E

SCIA2810E

SCIA5350E

SCIA5351E

Revision: December 20092009 QX56

Page 3930 of 4171

TM-282

< DISASSEMBLY AND ASSEMBLY >

ASSEMBLY

b. Measure dimension “L”.

c. Calculate dimension “J”.

2. Measure dimensions “M

1” and “M2” and then calculate dimen-

sion “M”.

a. Place bearing race and needle bearing on oil pump assembly.

b. Measure dimension “M

1”.

c. Measure dimension “M

2”.

“J”: Distance between oil pump fitting surface of

transmission case and needle

bearing mating surface

of front sun gear.

J = K – L

SCIA5352E

SCIA3125E

SCIA3124E

SCIA3126E

SCIA3127E

Revision: December 20092009 QX56