heating INFINITI QX56 2009 Factory User Guide

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2009, Model line: QX56, Model: INFINITI QX56 2009Pages: 4171, PDF Size: 84.65 MB

Page 1508 of 4171

![INFINITI QX56 2009 Factory User Guide

P0181 FTT SENSOREC-181

< COMPONENT DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

OK or NG

OK >> GO TO 6.

NG >> Replace “fuel level sensor unit and fuel pump”.

6.CHECK INTERMITTENT INCIDENT INFINITI QX56 2009 Factory User Guide

P0181 FTT SENSOREC-181

< COMPONENT DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

OK or NG

OK >> GO TO 6.

NG >> Replace “fuel level sensor unit and fuel pump”.

6.CHECK INTERMITTENT INCIDENT](/img/42/57031/w960_57031-1507.png)

P0181 FTT SENSOREC-181

< COMPONENT DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

OK or NG

OK >> GO TO 6.

NG >> Replace “fuel level sensor unit and fuel pump”.

6.CHECK INTERMITTENT INCIDENT

Refer to GI-35, "How to Check Terminal"

and GI-38, "Intermittent Incident".

>> INSPECTION END

Component InspectionINFOID:0000000003771443

FUEL TANK TEMPERATURE SENSOR

1. Remove fuel level sensor unit.

2. Check resistance between “fuel level sensor unit and fuel pump”

terminals 3 and 4 by heating with hot water as shown in the fig-

ure.

If NG, replace fuel level sensor unit.

Temperature °C ( °F)] Resistance (k Ω)

20 (68) 2.3 - 2.7

50 (122) 0.79 - 0.90

SEF476YA

Revision: December 20092009 QX56

Page 1511 of 4171

![INFINITI QX56 2009 Factory User Guide

EC-184

< COMPONENT DIAGNOSIS >[VK56DE]

P0182, P0183 FTT SENSOR

>>

INSPECTION END

Component InspectionINFOID:0000000003771448

FUEL TANK TEMPERATURE SENSOR

1. Remove fuel level sensor unit.

2. Check re INFINITI QX56 2009 Factory User Guide

EC-184

< COMPONENT DIAGNOSIS >[VK56DE]

P0182, P0183 FTT SENSOR

>>

INSPECTION END

Component InspectionINFOID:0000000003771448

FUEL TANK TEMPERATURE SENSOR

1. Remove fuel level sensor unit.

2. Check re](/img/42/57031/w960_57031-1510.png)

EC-184

< COMPONENT DIAGNOSIS >[VK56DE]

P0182, P0183 FTT SENSOR

>>

INSPECTION END

Component InspectionINFOID:0000000003771448

FUEL TANK TEMPERATURE SENSOR

1. Remove fuel level sensor unit.

2. Check resistance between “fuel level sensor unit and fuel pump”

terminals 3 and 4 by heating with hot water as shown in the fig-

ure.

If NG, replace fuel level sensor unit.

Temperature °C ( °F)] Resistance (k Ω)

20 (68) 2.3 - 2.7

50 (122) 0.79 - 0.90

SEF476YA

Revision: December 20092009 QX56

Page 1516 of 4171

![INFINITI QX56 2009 Factory User Guide

P0300, P0301, P0302, P0303, P0304, P0305, P0306, P0307, P0308 MISFIRE

EC-189

< COMPONENT DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

P0300, P0301, P0302, P0303, P0304,

P0305, P0306, P0307, INFINITI QX56 2009 Factory User Guide

P0300, P0301, P0302, P0303, P0304, P0305, P0306, P0307, P0308 MISFIRE

EC-189

< COMPONENT DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

P0300, P0301, P0302, P0303, P0304,

P0305, P0306, P0307,](/img/42/57031/w960_57031-1515.png)

P0300, P0301, P0302, P0303, P0304, P0305, P0306, P0307, P0308 MISFIRE

EC-189

< COMPONENT DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

P0300, P0301, P0302, P0303, P0304,

P0305, P0306, P0307, P0308 MIS-

FIRE

On Board Diagnosis LogicINFOID:0000000003771454

When a misfire occurs, engine speed will fluctuate. If the engine speed fluctuates enough to cause the crank-

shaft position (CKP) sensor (POS) signal to vary , ECM can determine that a misfire is occurring.

The misfire detection logic consists of the following two conditions.

1. One Trip Detection Logic (Three Way Catalyst Damage) On the 1st trip, when a misfire condition occurs that can damage the three way catalyst (TWC) due to

overheating, the MIL will blink.

When a misfire condition occurs, the ECM monitors the CKP sensor signal every 200 engine revolutions

for a change.

When the misfire condition decreases to a level t hat will not damage the TWC, the MIL will turn off.

If another misfire condition occurs that can damage the TWC on a second trip, the MIL will blink.

When the misfire condition decreases to a level t hat will not damage the TWC, the MIL will remain on.

If another misfire condition occurs that can damage the TWC, the MIL will begin to blink again.

2. Two Trip Detection Logic (Exhaust quality deterioration) For misfire conditions that will not damage the TWC (but will affect vehicle emissions), the MIL will only

light when the misfire is detected on a second trip. Du ring this condition, the ECM monitors the CKP sen-

sor signal every 1,000 engine revolutions.

A misfire malfunction can be detected on any one cylinder or on multiple cylinders.

DTC Confirmation ProcedureINFOID:0000000003771455

CAUTION:

Always drive vehicle in safe manner according to traf fic conditions and obey all traffic laws when driv-

ing.

NOTE:

If DTC Confirmation Procedure has been previously conduc ted, always perform the following before conduct-

ing the next step.

1. Turn ignition swich OFF and wait at least 10 seconds.

2. Turn ignition swich ON.

Sensor Input signal to ECM ECM function

Crankshaft position sensor (POS) Engine speed On board diagnosis of misfire

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0300

0300 Multiple cylinder misfire

detected

Multiple cylinder misfire.

Improper spark plug

Insufficient compression

Incorrect fuel pressure

The injector circuit is open or shorted

Fuel injector

Intake air leak

The ignition signal circuit is open or short-ed

Lack of fuel

Signal plate

Air fuel ratio (A/F) sensor 1

Incorrect PCV hose connection

P0301

0301

No.1 cylinder misfire de-

tected

No. 1 cylinder misfires.

P0302

0302 No. 2 cylinder misfire

detected

No. 2 cylinder misfires.

P0303

0303 No. 3 cylinder misfire

detected

No. 3 cylinder misfires.

P0304

0304 No. 4 cylinder misfire

detected

No. 4 cylinder misfires.

P0305

0305 No. 5 cylinder misfire

detected

No. 5 cylinder misfires.

P0306

0306 No. 6 cylinder misfire

detected

No. 6 cylinder misfires.

P0307

0307 No. 7 cylinder misfire

detected

No. 7 cylinder misfires.

P0308

0308 No. 8 cylinder misfire

detected

No. 8 cylinder misfires.

Revision: December 20092009 QX56

Page 1625 of 4171

![INFINITI QX56 2009 Factory User Guide

EC-298

< COMPONENT DIAGNOSIS >[VK56DE]

P1217 ENGINE OVER TEMPERATURE

P1217 ENGINE OVER TEMPERATURE

On Board Diagn

osis LogicINFOID:0000000003771589

NOTE:

If DTC P1217 is displayed with DTC U1000 or INFINITI QX56 2009 Factory User Guide

EC-298

< COMPONENT DIAGNOSIS >[VK56DE]

P1217 ENGINE OVER TEMPERATURE

P1217 ENGINE OVER TEMPERATURE

On Board Diagn

osis LogicINFOID:0000000003771589

NOTE:

If DTC P1217 is displayed with DTC U1000 or](/img/42/57031/w960_57031-1624.png)

EC-298

< COMPONENT DIAGNOSIS >[VK56DE]

P1217 ENGINE OVER TEMPERATURE

P1217 ENGINE OVER TEMPERATURE

On Board Diagn

osis LogicINFOID:0000000003771589

NOTE:

If DTC P1217 is displayed with DTC U1000 or U1001, first perform the trouble diagnosis for DTC

U1000, U1001. Refer to EC-86

.

If DTC P1217 is displayed with DTC P0607, first pe rform the trouble diagnosis for DTC P0607. Refer

to EC-284

.

If the cooling fan or another component in the coo ling system malfunctions, engine coolant temperature will

rise.

When the engine coolant temperature reaches an abnorma lly high temperature condition, a malfunction is

indicated.

This self-diagnosis has the one trip detection logic.

CAUTION:

When a malfunction is indicated, be su re to replace the coolant. Refer to CO-11, "Changing Engine

Coolant". Also, replace the engine oil. Refer to LU-9, "Changing Engine Oil".

1. Fill radiator with coolant up to specified level with a filling speed of 2 liters per minute. Be sure to

use coolant with the proper mixture ratio. Refer to CO-10

.

2. After refilling coolant, run engine to en sure that no water-flow noise is emitted.

Overall Function CheckINFOID:0000000003771590

Use this procedure to check the overall function of the cooling fan. During this check, a DTC might not be con-

firmed.

WARNING:

Never remove the radiator cap and/or reservoir tank cap when the engine is hot. Serious burns could

be caused by high pressure fluid escaping fr om the radiator and/or reservoir tank.

Wrap a thick cloth around cap. Carefully remove the cap by turning it a quarter turn to allow built-up

pressure to escape. Then turn the cap all the way off.

WITH CONSULT-III

1. Check the coolant level in the reservoir tank and radiator. Allow engine to cool before checking coolant level.

If the coolant level in the reservoir tank and/or radiator is below

the proper range, skip the following steps and go to EC-388,

"Diagnosis Procedure".

2. Confirm whether customer filled the coolant or not. If customer

filled the coolant, skip the following steps and go to EC-388,

"Diagnosis Procedure".

3. Turn ignition switch ON.

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P1217

1217 Engine over tempera-

ture (Overheat) Cooling fan does not operate properly (Over-

heat).

Cooling fan system does not operate proper-

ly (Overheat).

Engine coolant was not added to the system using the proper filling method.

Engine coolant is not within the specified range. Harness or connectors

(The cooling fan circuit is open or short-

ed.)

Cooling fan

Cooling fan (crankshaft diven)

IPDM E/R (Cooling fan relay)

Radiator hose

Radiator

Radiator cap

Reservoir tank

Reservoir tank cap

Water pump

Thermostat

For more informat ion, refer to EC-300,

"Main 13 Causes of Overheating".

SEF621W

Revision: December 20092009 QX56

Page 1627 of 4171

![INFINITI QX56 2009 Factory User Guide

EC-300

< COMPONENT DIAGNOSIS >[VK56DE]

P1217 ENGINE OVER TEMPERATURE

4. Make sure that cooling fan operates.

OK or NG

OK >> GO TO 4.

NG >> Check cooling fan control circuit. (Go to "PROCEDURE

A".)

4. INFINITI QX56 2009 Factory User Guide

EC-300

< COMPONENT DIAGNOSIS >[VK56DE]

P1217 ENGINE OVER TEMPERATURE

4. Make sure that cooling fan operates.

OK or NG

OK >> GO TO 4.

NG >> Check cooling fan control circuit. (Go to "PROCEDURE

A".)

4.](/img/42/57031/w960_57031-1626.png)

EC-300

< COMPONENT DIAGNOSIS >[VK56DE]

P1217 ENGINE OVER TEMPERATURE

4. Make sure that cooling fan operates.

OK or NG

OK >> GO TO 4.

NG >> Check cooling fan control circuit. (Go to "PROCEDURE

A".)

4.CHECK COOLING SYSTEM FOR LEAK

Refer to CO-10, "Inspection"

.

OK or NG

OK >> GO TO 5.

NG >> Check the following for leak. Hose

Radiator

Radiator cap

Water pump

Reservoir tank

5.CHECK COMPONENT PARTS

Check the following.

RESERVOIR TANK CAP (Refer to CO-10, "Inspection"

.)

Thermostat. (Refer to CO-22, "Removal and Installation"

.)

Engine coolant temperature sensor. (Refer to EC-122, "Component Inspection"

.)

OK or NG

OK >> GO TO 7.

NG >> Replace malfunctioning component.

6.CHECK MAIN 13 CAUSES

If the cause cannot be isolated, go to EC-300, "Main 13 Causes of Overheating"

.

>> INSPECTION END

Main 13 Causes of OverheatingINFOID:0000000003771592

SEF882V

Engine Step Inspection item Equipment Standard Reference page

OFF 1 Blocked radiator Blocked condenser

Blocked radiator grille

Blocked bumper Visual No blocking —

2 Coolant mixture Coolant tester 50 - 50% coolant mixture CO-10

3 Coolant level Visual Coolant up to MAX level in

reservoir tank and radiator

filler neckCO-11, "Changing Engine

Coolant"

4 Reservoir tank cap Pre

ssure tester 95 - 125 kPa

(0.97 - 1.28 kg/cm2, 14 -

18 psi) (Limit) CO-10, "Inspection"

ON*25 Coolant leaks Visual No leaks

CO-10, "Inspection"

ON*26 Thermostat Touch the upper and

lower radiator hosesBoth hoses should be hot

CO-22, "Removal and In-

stallation"

ON*17 Cooling fan CONSULT-III Operating See trouble diagnosis for

DTC P1217 (EC-36

).

Revision: December 20092009 QX56

Page 1633 of 4171

![INFINITI QX56 2009 Factory User Guide

EC-306

< COMPONENT DIAGNOSIS >[VK56DE]

P1421 COLD START CONTROL

P1421 COLD START CONTROL

DescriptionINFOID:0000000003771601

ECM controls ignition timing and engine idle speed when engine is started w INFINITI QX56 2009 Factory User Guide

EC-306

< COMPONENT DIAGNOSIS >[VK56DE]

P1421 COLD START CONTROL

P1421 COLD START CONTROL

DescriptionINFOID:0000000003771601

ECM controls ignition timing and engine idle speed when engine is started w](/img/42/57031/w960_57031-1632.png)

EC-306

< COMPONENT DIAGNOSIS >[VK56DE]

P1421 COLD START CONTROL

P1421 COLD START CONTROL

DescriptionINFOID:0000000003771601

ECM controls ignition timing and engine idle speed when engine is started with prewarming up condition.

This control promotes the activation of three way ca

talyst by heating the catalyst and reduces emissions.

On Board Diagnosis LogicINFOID:0000000003771602

DTC Confirmation ProcedureINFOID:0000000003771603

NOTE:

If DTC Confirmation Procedure has been previously conducted, always perform the following before con-

ducting the next step.

1. Turn ignition swich OFF and wait at least 10 seconds.

2. Turn ignition swich ON.

3. Turn ignition swich OFF and wait at least 10 seconds.

If DTC P1421 is displayed with other DTC, firs t perform the trouble diagnosis for other DTC.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more than 11V at idle.

1. Turn ignition switch OFF and wait at least 10 seconds.

2. Turn ignition switch ON.

3. Select “DATA MONITOR” mode with CONSULT-IIl.

4. Check that the “COOLAN TEMP/S” indication is between 4 °C (39 °F) and 36 °C (97 °F).

If “COOLAN TEMP/S” indication is within t he specified value, go to the following step.

If “COOLANT TEMP/S” indication is out of the s pecified value, cool engine down or warm engine up and

go to step 1.

5. Start engine and let it idle for 5 minutes.

6. Check 1st trip DTC.

7. If 1st trip DTC is detected, go to EC-306, "Diagnosis Procedure"

.

Diagnosis ProcedureINFOID:0000000003771604

1.PERFORM IDLE AIR VOLUME LEARNING

Perform EC-18, "Idle Air Volume Learning"

.

Is Idle Air Volume Lear ning carried out successfully?

Ye s o r N o

Ye s > > G O T O 2 .

No >> Follow the instruction of Idle Air Volume Learning.

2.CHECK INTAKE SYSTEM

Check for the cause of intake air volume lacking. Refer to the following.

Crushed intake air passage

Intake air passage clogging

OK or NG

OK >> GO TO 3.

NG >> Repair or replace malfunctioning part

3.CHECK FUEL INJECTION SYSTEM FUNCTION

Perform EC-169, "DTC Confirmation Procedure"

in DTC P0171, P0174 FUEL INJECTION SYSTEM FUNC-

TION.

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P1421

1421 Cold start emission reduction

strategy monitoring ECM does not control ignition timing and engine

idle speed properly when engine is started with

prewarming up condition. Lack of intake air volume

Fuel injection system

ECM

Revision: December 20092009 QX56

Page 2234 of 4171

GI-40

< BASIC INSPECTION >

SERVICE INFORMATION FOR ELECTRICAL INCIDENT

An unclamped or loose harness can cause wiring to be pinched by seat components (such as slide guides)

during vehicle vibration. If the wiring runs under s eating areas, inspect wire routing for possible damage or

pinching.

HEAT SENSITIVE

• The customer's concern may occur during hot weather or after car has sat for a short time. In such cases you will want to check for a

heat sensitive condition.

• To determine if an electrical component is heat sensitive, heat the component with a heat gun or equivalent.

CAUTION:

Do not heat components above 60 °C (140° ).

• If incident occurs while heating the unit, either replace or properly insulate the component.

FREEZING

• The customer may indicate the incident goes away after the carwarms up (winter time). The cause could be related to water freez-

ing somewhere in the wiring/electrical system.

• There are two methods to check for this. The first is to arrange for the owner to leave his car overnight. Make sure it will get cold

enough to demonstrate his complaint. Leave the car parked out-

side overnight. In the morning, do a quick and thorough diagnosis

of those electrical components which could be affected.

• The second method is to put the suspect component into a freezer long enough for any water to freeze. Reinstall the part into the car

and check for the reoccurrence of the incident. If it occurs, repair or

replace the component.

WATER INTRUSION

The incident may occur only during high humidity or in rainy/snowy

weather. In such cases the incident could be caused by water intru-

sion on an electrical part. This can be simulated by soaking the car

or running it through a car wash.

CAUTION:

Do not spray water directly on any electrical components.

ELECTRICAL LOAD

The incident may be electrical load sensitive. Perform diagnosis with

all accessories (including A/C, rear window defogger, radio, fog

lamps) turned on.

COLD OR HOT START UP

On some occasions an electrical incident may occur only when the car is started cold, or it may occur when

the car is restarted hot shortly after being turned off. In these cases you may have to keep the car overnight to

make a proper diagnosis.

SGI842

SGI843

SGI844

SGI845

Revision: December 20092009 QX56

Page 2315 of 4171

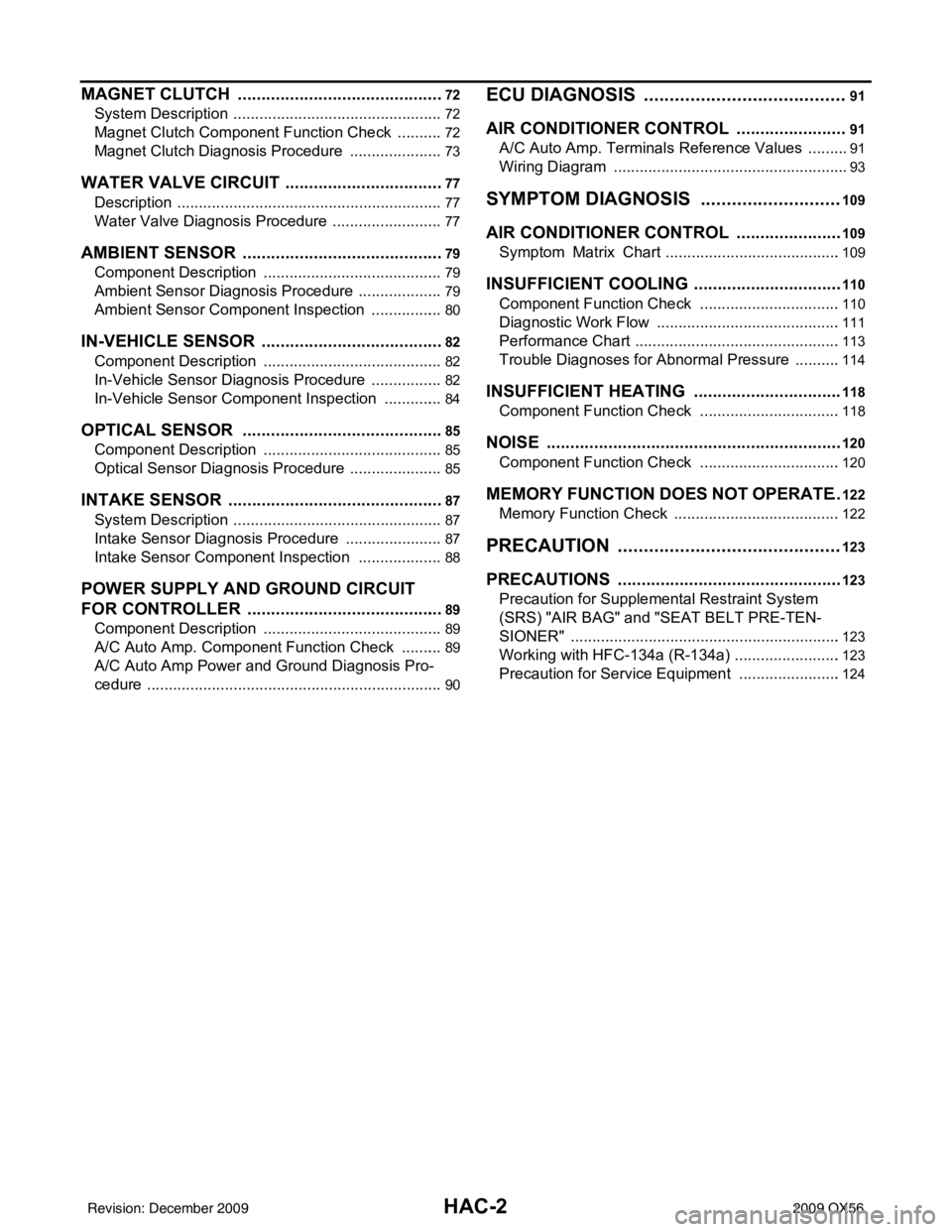

HAC-2

MAGNET CLUTCH ............................................72

System Description .............................................. ...72

Magnet Clutch Component Function Check ........ ...72

Magnet Clutch Diagnosis Procedure ................... ...73

WATER VALVE CIRCUIT ..................................77

Description ........................................................... ...77

Water Valve Diagnosis Procedure ..........................77

AMBIENT SENSOR ...........................................79

Component Description ....................................... ...79

Ambient Sensor Diagnosis Procedure ....................79

Ambient Sensor Component Inspection .................80

IN-VEHICLE SENSOR .......................................82

Component Description ....................................... ...82

In-Vehicle Sensor Diagnosis Procedure .................82

In-Vehicle Sensor Component Inspection ..............84

OPTICAL SENSOR ...........................................85

Component Description ..........................................85

Optical Sensor Diagnosis Procedure ......................85

INTAKE SENSOR ..............................................87

System Description .............................................. ...87

Intake Sensor Diagnosis Procedure .......................87

Intake Sensor Component Inspection ................. ...88

POWER SUPPLY AND GROUND CIRCUIT

FOR CONTROLLER ..........................................

89

Component Description ....................................... ...89

A/C Auto Amp. Component Function Check ..........89

A/C Auto Amp Power and Ground Diagnosis Pro-

cedure .....................................................................

90

ECU DIAGNOSIS .......................................91

AIR CONDITIONER CONTROL ..................... ...91

A/C Auto Amp. Terminals Reference Values ..........91

Wiring Diagram .................................................... ...93

SYMPTOM DIAGNOSIS ...........................109

AIR CONDITIONER CONTROL ..................... ..109

Symptom Matrix Chart ........................................ .109

INSUFFICIENT COOLING ................................110

Component Function Check ................................ .110

Diagnostic Work Flow ...........................................111

Performance Chart ................................................113

Trouble Diagnoses for Abnormal Pressure ...........114

INSUFFICIENT HEATING ................................118

Component Function Check .................................118

NOISE ...............................................................120

Component Function Check ................................ .120

MEMORY FUNCTION DOES NOT OPERATE ..122

Memory Function Check ...................................... .122

PRECAUTION ...........................................123

PRECAUTIONS .............................................. ..123

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" .............................................................. .

123

Working with HFC-134a (R-134a) ........................ .123

Precaution for Service Equipment ........................124

Revision: December 20092009 QX56

Page 2323 of 4171

![INFINITI QX56 2009 Factory User Guide HAC-10

< FUNCTION DIAGNOSIS >[AUTOMATIC AIR CONDITIONER]

FUNCTION INFORMATION

Defroster door motor is malfunctioning. Go to Trouble Diagnosis Procedure for Defroster Door Motor.

HAC-46

Front blower mo INFINITI QX56 2009 Factory User Guide HAC-10

< FUNCTION DIAGNOSIS >[AUTOMATIC AIR CONDITIONER]

FUNCTION INFORMATION

Defroster door motor is malfunctioning. Go to Trouble Diagnosis Procedure for Defroster Door Motor.

HAC-46

Front blower mo](/img/42/57031/w960_57031-2322.png)

HAC-10

< FUNCTION DIAGNOSIS >[AUTOMATIC AIR CONDITIONER]

FUNCTION INFORMATION

Defroster door motor is malfunctioning. Go to Trouble Diagnosis Procedure for Defroster Door Motor.

HAC-46

Front blower motor operation is malfunction-

ing.Go to Trouble Diagnosis Procedure for Front Blower Motor.

HAC-51

Rear blower motor operation is malfunction-

ing.Go to Trouble Diagnosis Procedure for Rear Blower Motor.

HAC-57

Rear air discharge outlet does not change. Go to Trouble Diagnosis Procedure for Mode Door Motor (rear). HAC-62

Rear air temperature does not change. Go to Trouble Diagnosis Procedure for Air Mix Door Motor (rear).HAC-62

Magnet clutch does not engage.Go to Trouble Diagnosis Procedure for Magnet Clutch. HAC-72

Insufficient coolingGo to Trouble Diagnosis Procedure for Insufficient Cooling. HAC-110

Insufficient heatingGo to Trouble Diagnosis Procedure for Insufficient Heating. HAC-118

NoiseGo to Trouble Diagnosis Procedure for Noise. HAC-120

Self-diagnosis cannot be performed. Go to Trouble Diagnosis Procedure for Self-diagnosis. HAC-89

Memory function does not operate.Go to Trouble Diagnosis Procedure for Memory Function. HAC-122

SymptomReference Page

Revision: December 20092009 QX56

Page 2422 of 4171

![INFINITI QX56 2009 Factory User Guide AIR CONDITIONER CONTROLHAC-109

< SYMPTOM DIAGNOSIS > [AUTOMATIC AIR CONDITIONER]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

SYMPTOM DIAGNOSIS

AIR CONDITIONER CONTROL

Symptom Matrix ChartINFOID:0000000003775390 INFINITI QX56 2009 Factory User Guide AIR CONDITIONER CONTROLHAC-109

< SYMPTOM DIAGNOSIS > [AUTOMATIC AIR CONDITIONER]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

SYMPTOM DIAGNOSIS

AIR CONDITIONER CONTROL

Symptom Matrix ChartINFOID:0000000003775390](/img/42/57031/w960_57031-2421.png)

AIR CONDITIONER CONTROLHAC-109

< SYMPTOM DIAGNOSIS > [AUTOMATIC AIR CONDITIONER]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

SYMPTOM DIAGNOSIS

AIR CONDITIONER CONTROL

Symptom Matrix ChartINFOID:0000000003775390

SYMPTOM TABLE

Symptom Reference Page

A/C system does not come on. Go to Trouble Diagnosis Procedure for A/C System. HAC-89

A/C system display is malfunctioning. Go to Navigation System. AV- 6 9

A/C system cannot be controlled.Go to Self-diagnosis Function. HAC-23

Air outlet does not change.

Go to Trouble Diagnosis Procedure for Mode Door Motor. HAC-26

Mode door motor is malfunctioning.

Discharge air temperature does not change.

Go to Trouble Diagnosis Procedure for Air Mix Door Motor. HAC-32

Air mix door motor is malfunctioning.

Intake door does not change.

Go to Trouble Diagnosis Procedure for Intake Door Motor. HAC-42

Intake door motor is malfunctioning.

Defroster door motor is malfunctioning. Go to Trouble Diagnosis Procedure for Defroster Door Motor. HAC-46

Front blower motor operation is malfunction-

ing.Go to Trouble Diagnosis Procedure for Front Blower Motor.

HAC-51

Rear blower motor operation is malfunction-

ing.Go to Trouble Diagnosis Procedure for Rear Blower Motor.

HAC-57

Rear discharge air temperature and/or air

outlet does not change.Go to Trouble Diagnosis Procedure for Rear Air Control circuit.

HAC-62

Magnet clutch does not engage.Go to Trouble Diagnosis Procedure for Magnet Clutch. HAC-72

Insufficient coolingGo to Trouble Diagnosis Procedure for Insufficient Cooling. HAC-110

Insufficient heatingGo to Trouble Diagnosis Procedure for Insufficient Heating. HAC-118

NoiseGo to Trouble Diagnosis Procedure for Noise. HAC-120

Self-diagnosis cannot be performed. Go to Trouble Diagnosis Procedure for Self-diagnosis. HAC-89

Memory function does not operate.Go to Trouble Diagnosis Procedure for Memory Function. HAC-122

Revision: December 20092009 QX56