heating INFINITI QX56 2009 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2009, Model line: QX56, Model: INFINITI QX56 2009Pages: 4171, PDF Size: 84.65 MB

Page 632 of 4171

BRM-36

< SERVICE INFORMATION >

BODY REPAIR

SP130 is the most commonly used HSS.

SP150 HSS is used only on parts that require much more strength.

Read the following precautions when repairing HSS:

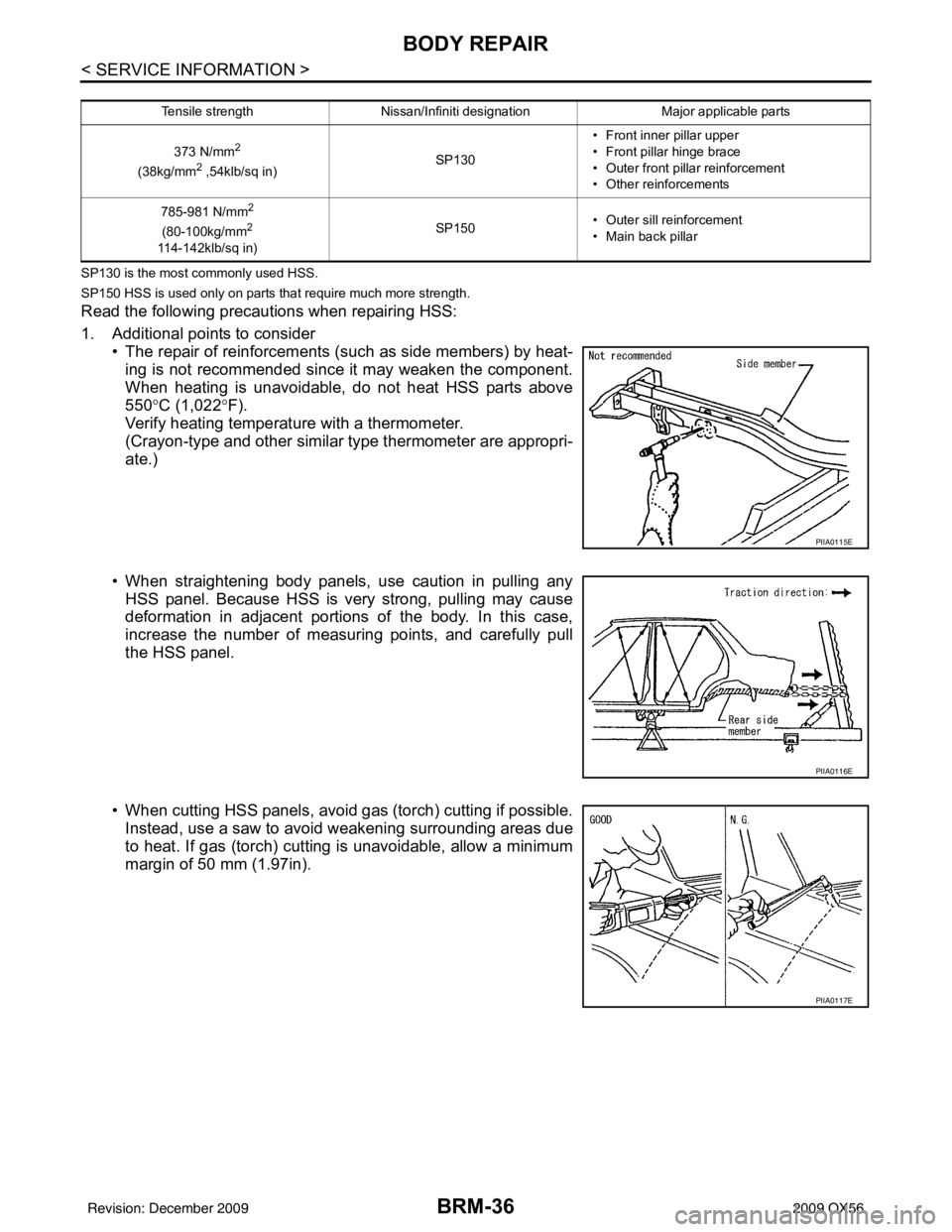

1. Additional points to consider• The repair of reinforcements (such as side members) by heat-ing is not recommended since it may weaken the component.

When heating is unavoidable, do not heat HSS parts above

550° C (1,022° F).

Verify heating temperature with a thermometer.

(Crayon-type and other similar type thermometer are appropri-

ate.)

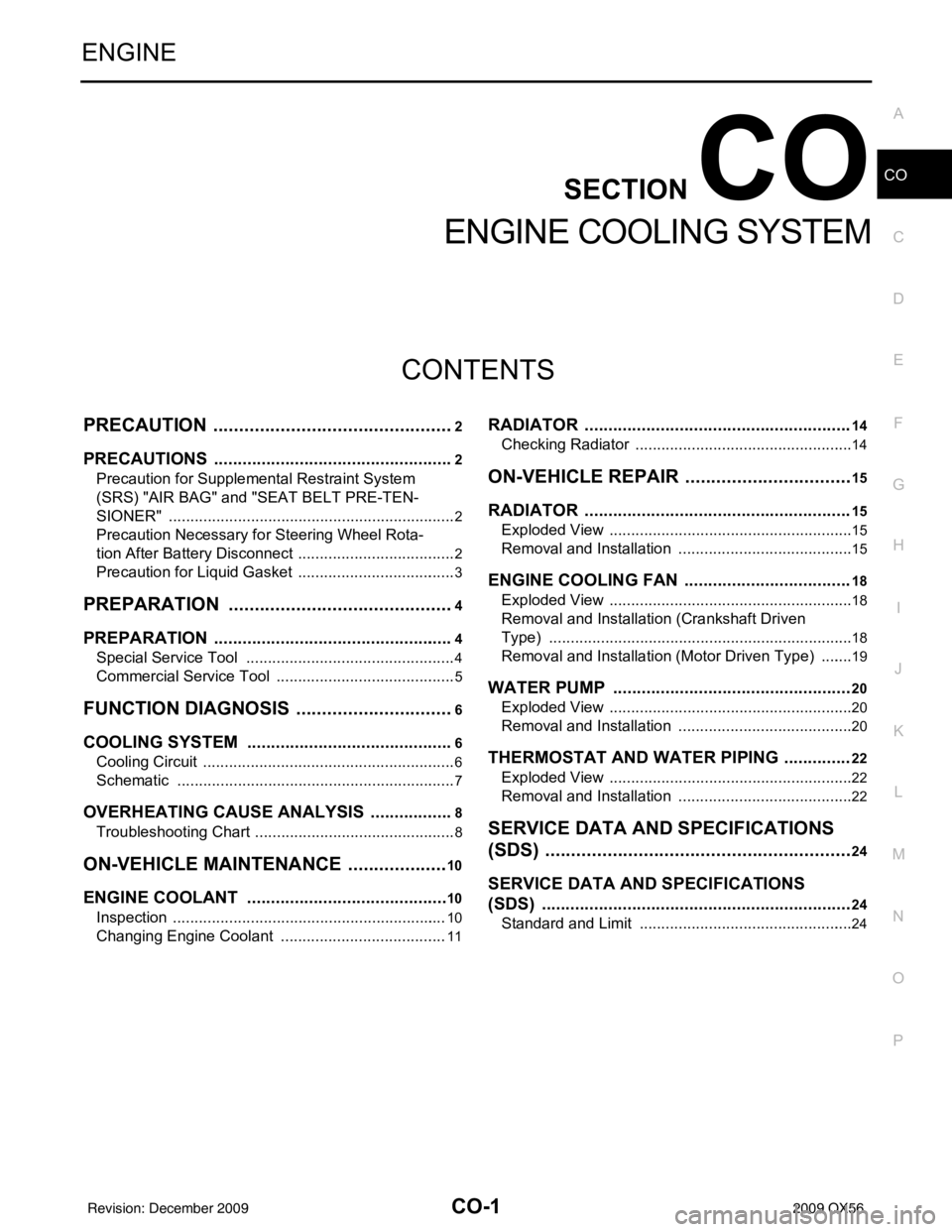

• When straightening body panels, use caution in pulling any HSS panel. Because HSS is very strong, pulling may cause

deformation in adjacent portions of the body. In this case,

increase the number of measuring points, and carefully pull

the HSS panel.

• When cutting HSS panels, avoid gas (torch) cutting if possible. Instead, use a saw to avoid weakening surrounding areas due

to heat. If gas (torch) cutting is unavoidable, allow a minimum

margin of 50 mm (1.97in).

Tensile strength Nissan/Infiniti designation Major applicable parts

373 N/mm

2

(38kg/mm2 ,54klb/sq in) SP130• Front inner pillar upper

• Front pillar hinge brace

• Outer front pillar reinforcement

• Other reinforcements

785-981 N/mm

2

(80-100kg/mm2

114-142klb/sq in) SP150

• Outer sill reinforcement

• Main back pillar

PIIA0115E

PIIA0116E

PIIA0117E

Revision: December 20092009 QX56

Page 745 of 4171

CO-1

ENGINE

C

DE

F

G H

I

J

K L

M

SECTION CO

A

CO

N

O P

CONTENTS

ENGINE COOLING SYSTEM

PRECAUTION ....... ........................................2

PRECAUTIONS .............................................. .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

2

Precaution for Liquid Gasket .....................................3

PREPARATION ............................................4

PREPARATION .............................................. .....4

Special Service Tool ........................................... ......4

Commercial Service Tool ..........................................5

FUNCTION DIAGNOSIS ...............................6

COOLING SYSTEM ....................................... .....6

Cooling Circuit ..................................................... ......6

Schematic .................................................................7

OVERHEATING CAUSE ANALYSIS ..................8

Troubleshooting Chart ...............................................8

ON-VEHICLE MAINTENA NCE ....................10

ENGINE COOLANT ....................................... ....10

Inspection ............................................................ ....10

Changing Engine Coolant .......................................11

RADIATOR ........................................................14

Checking Radiator ............................................... ....14

ON-VEHICLE REPAIR .................................15

RADIATOR ....... .................................................15

Exploded View ..................................................... ....15

Removal and Installation .........................................15

ENGINE COOLING FAN ...................................18

Exploded View .........................................................18

Removal and Installation (Crankshaft Driven

Type) .......................................................................

18

Removal and Installation (Motor Driven Type) ........19

WATER PUMP ..................................................20

Exploded View .........................................................20

Removal and Installation .........................................20

THERMOSTAT AND WATER PIPING ..............22

Exploded View .........................................................22

Removal and Installation .........................................22

SERVICE DATA AND SPECIFICATIONS

(SDS) ............... .......................................... ...

24

SERVICE DATA AND SPECIFICATIONS

(SDS) .................................................................

24

Standard and Limit .............................................. ....24

Revision: December 20092009 QX56

Page 752 of 4171

CO-8

< FUNCTION DIAGNOSIS >

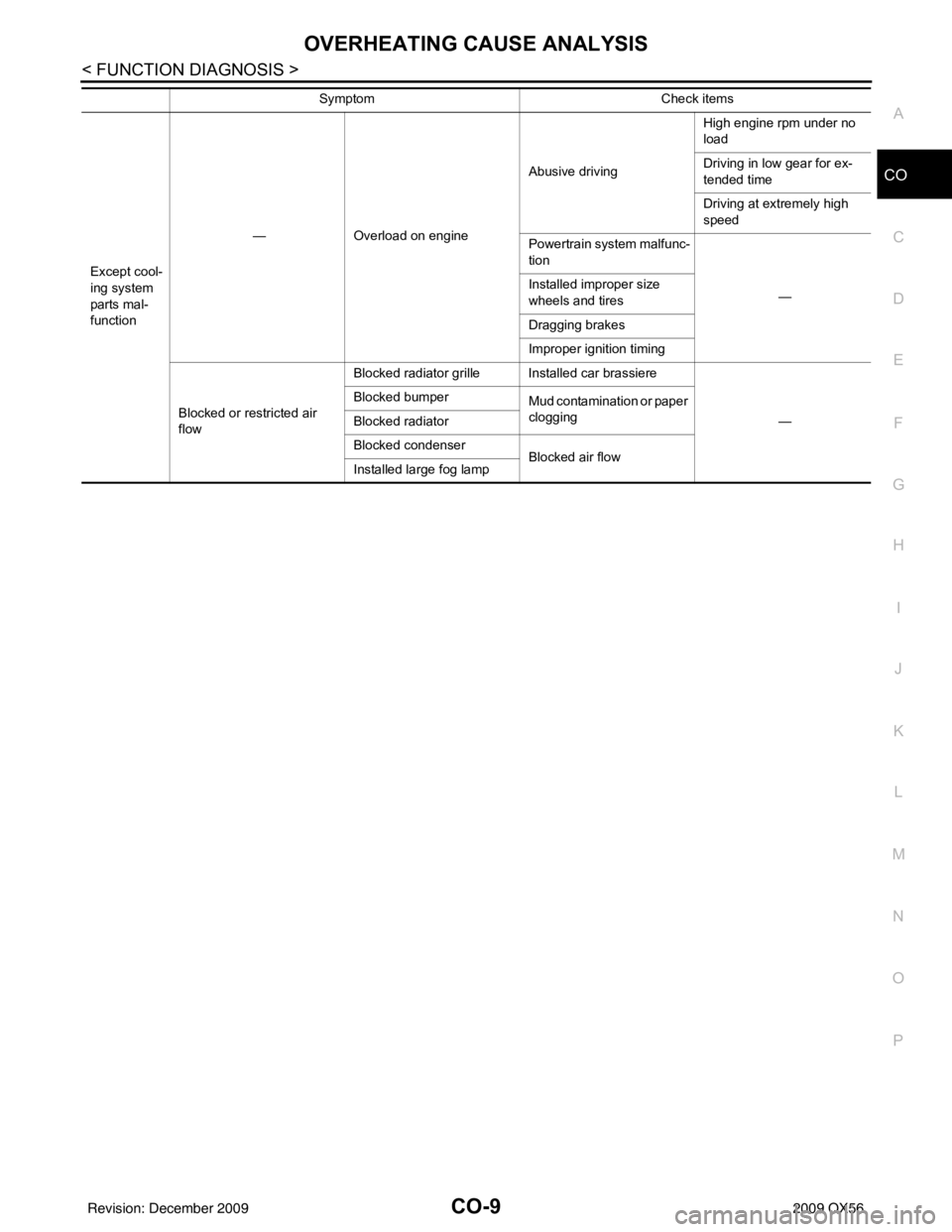

OVERHEATING CAUSE ANALYSIS

OVERHEATING CAUSE ANALYSIS

Troubleshooting ChartINFOID:0000000003771283

SymptomCheck items

Cooling sys-

tem parts

malfunction Poor heat transfer

Water pump malfunction Worn or loose drive belt

—

Thermostat stuck closed Coolant circulation

Damaged fins

Dust contamination or pa-

per clogging

Physical damage

Clogged radiator cooling

tube Excess foreign material

(rust, dirt, sand, etc.)

Water cut valve malfunction Excess foreign material

(rust, dirt, sand, etc.), phys-

ical damage

Reduced air flow Cooling fan does not oper-

ate

Fan assembly —

High resistance to fan rota-

tion

Damaged fan blades

Damaged radiator shroud —Radiator shroud —

Improper engine coolant

mixture ratio —

Engine coolant viscosity —

Poor engine coolant quality —Engine coolant density —

Insufficient engine coolant Engine coolant leaksCooling hose

Loose clamp

Cracked hose

Water pump Poor sealing

Radiator cap Loose

Poor sealing

Radiator O-ring for da

mage, deterio-

ration or improper fitting

Cracked radiator tank

Cracked radiator core

Reservoir tank Cracked reservoir tank

Overflowing reservoir tank Exhaust gas leaks into cool-

ing system Cylinder head deterioration

Cylinder head gasket deteri-

oration

Revision: December 20092009 QX56

Page 753 of 4171

OVERHEATING CAUSE ANALYSISCO-9

< FUNCTION DIAGNOSIS >

C

DE

F

G H

I

J

K L

M A

CO

NP

O

Except cool-

ing system

parts mal-

function —

Overload on engine Abusive driving

High engine rpm under no

load

Driving in low gear for ex-

tended time

Driving at extremely high

speed

Powertrain system malfunc-

tion

—

Installed improper size

wheels and tires

Dragging brakes

Improper ignition timing

Blocked or restricted air

flow Blocked radiator grille Installed car brassiere

—

Mud contamination or paper

clogging

Blocked bumper

Blocked radiator

Blocked condenser

Blocked air flow

Installed large fog lamp

Symptom

Check items

Revision: December 20092009 QX56

Page 767 of 4171

THERMOSTAT AND WATER PIPINGCO-23

< ON-VEHICLE REPAIR >

C

DE

F

G H

I

J

K L

M A

CO

NP

O

CAUTION:

Perform when the engine is cold.

2. Disconnect the water cut valve connector.

3. Disconnect the water hoses from the water cut valve.

4. Remove the water cut valve.

INSPECTION AFTER REMOVAL

• Place a thread so that it is caught in the valve of the thermostat.

Immerse fully in a container filled with water. Heat while stirring.

• The valve opening temperature is the temperature at which the valve opens and falls from the thread.

• Continue heating. Check the full-open lift amount.

• After checking the full-open lift amount, lower the water tempera- ture and check the valve closing temperature.

Standard values:

INSTALLATION

Installation is in the reverse order of removal.

Installation of Thermostat

• Install the thermostat with the whole circumference of each flange

part fit securely inside the rubber ring as shown.

• Install the thermostat with the jiggle valve facing upwards.

Installation of Water Outlet Pipe and Heater Pipe

First apply a neutral detergent to the O- rings, then quickly insert the insertion parts of the water outlet pipe and

heater pipe into the installation holes.

INSPECTION AFTER INSTALLATION

• Check for leaks of the engine coolant. Refer to CO-10, "Inspection".

• Start and warm up the engine. Visually check for leaks of the engine coolant.

SLC252B

Thermostat

Valve opening temperature 80 - 84°C (176 - 183 ° F)

Full-open lift amount More than 10 mm/ 95°C (0.39 in/ 203° F)

Valve closing temperature 77°C (171 °F) or higher

KBIA2502E

Revision: December 20092009 QX56

Page 773 of 4171

REAR WINDOW DEFOGGER SYSTEMDEF-5

< FUNCTION DIAGNOSIS >

C

DE

F

G H

I

J

K

M A

B

DEF

N

O P

Component Parts LocationINFOID:0000000003776331

Component DescriptionINFOID:0000000003776332

ALLIA0314ZZ

1. A. Steering column assembly B. BCM M18, M20 (view with instru-

ment panel removed) 2. A/C and AV switch assembly (rear

window defogger switch) M98 3. A. Rear window defogger ground

connector D604

B. Rear window defogger connector

D406

4. IPDM E/R E120, E122, E124 5. Do or mirror (door mirror defogger)

LH D4, RH D107

BCM • Operates the rear window defogger with the operation of rear window defogger switch.

• Performs the timer control of rear window defogger.

Rear window defogger relay • Operates the rear window defogger and the door mirror defogger with the control signal from

BCM.

A/C and AV switch assembly

(rear window defogger switch) • The rear window defogger switch is turned ON.

• Turns the indicator lamp ON when detecting the operation of rear window defogger.

Rear window defogger • Heats the heating wire with the power supply from the rear window defogger relay to prevent

the rear window from fogging up.

Door mirror defogger • Heats the heating wire with the power supply from the heated mirror relay to prevent the door

mirror from fogging up.

Revision: December 20092009 QX56

Page 779 of 4171

REAR WINDOW DEFOGGER POWER SUPPLY AND GROUND CIRCUIT

DEF-11

< COMPONENT DIAGNOSIS >

C

D E

F

G H

I

J

K

M A

B

DEF

N

O P

REAR WINDOW DEFOGGER POWER SUPPLY AND GROUND CIRCUIT

DescriptionINFOID:0000000003776342

Heats the heating wire with the power supply from the rear window defogger relay to prevent the rear window

from fogging up.

Component Function CheckINFOID:0000000003776343

1. CHECK REAR WINDOW DEFOGGER

Check that the heating wire of rear window defogger is heated when turning the rear window defogger switch

ON.

Is the inspection result normal?

YES >> Rear window defogger is OK.

NO >> Refer to DEF-11, "

Diagnosis Procedure".

Diagnosis ProcedureINFOID:0000000003776344

1. CHECK POWER SUPPLY CIRCUIT

1. Turn ignition switch ON.

2. Check voltage between rear window defogger connector and ground.

Is the inspection result normal?

YES >> GO TO 2

NO >> GO TO 3

2. CHECK GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect rear window defogger.

3. Check continuity between rear window defogger connector and ground.

Is the inspection result normal?

YES >> GO TO 4

NO >> Repair or replace harness.

3. CHECK HARNESS CONTINUITY

Te r m i n a l s Condition of rear window

defogger switch Voltage (V)

(Approx.)

(+)

(–)

Rear window

defogger

connector Te r m i n a l

D406 1 Ground ON Battery voltage

OFF 0

ALLIA0177ZZ

Rear window defogger connector Terminal

GroundContinuity

D604 2 Yes

ALLIA0178ZZ

Revision: December 20092009 QX56

Page 781 of 4171

DOOR MIRROR DEFOGGER LHDEF-13

< COMPONENT DIAGNOSIS >

C

DE

F

G H

I

J

K

M A

B

DEF

N

O P

DOOR MIRROR DEFOGGER LH

DescriptionINFOID:0000000003776346

Heats the heating wire with the power supply from t he rear window defogger relay to prevent the door mirror

from fogging up.

Component Function CheckINFOID:0000000003776347

1. CHECK DOOR MIRROR DEFOGGER LH

Check that heating wire of door mirror defogger LH is heated when turning the rear window defogger switch

ON.

Is the inspection result normal?

YES >> Door mirror defogger is OK.

NO >> Refer to DEF-13, "

Diagnosis Procedure".

Diagnosis ProcedureINFOID:0000000003776348

1. CHECK POWER SUPPLY

Check if the following fuse in the IPDM E/R is blown.

Is the inspection result normal?

YES >> GO TO 2

NO >> If fuse is blown, be sure to eliminate cause of malfunction before installing new fuse.

2. CHECK DOOR MIRROR DEFOGGER POWER SUPPLY CIRCUIT

Check voltage between IPDM E/R connector and ground.

Is the inspection result normal?

YES >> GO TO 3

NO >> Replace IPDM E/R. Refer to PCS-34, "

Removal and Installation of IPDM E/R".

3. CHECK DOOR MIRROR DEFOGGER POWER SUPPLY CIRCUIT 2

1. Turn ignition switch OFF.

2. Disconnect door mirror LH.

3. Turn ignition switch ON.

4. Check voltage between door mirror LH connector and ground.

Is the inspection result normal?

YES >> GO TO 4

COMPONENT PARTS AMPEREFUSE NO.

IPDM E/R 15A43

ConnectorTe r m i n a l

ConditionVoltage (V)

(Approx.)

(+) (-)

E120 23 Ground Rear window defogger

switch ON

Battery voltage

Rear window defogger

switch OFF 0

LIIA2049E

ConnectorTe r m i n a l

ConditionVoltage (V)

(Approx.)

(+) (-)

D4 10 Ground Rear window defogger

switch ON

Battery voltage

Rear window defogger

switch OFF 0

LIIA1456E

Revision: December 20092009 QX56

Page 783 of 4171

DOOR MIRROR DEFOGGER RHDEF-15

< COMPONENT DIAGNOSIS >

C

DE

F

G H

I

J

K

M A

B

DEF

N

O P

DOOR MIRROR DEFOGGER RH

DescriptionINFOID:0000000003776350

Heats the heating wire with the power supply from t he rear window defogger relay to prevent the door mirror

from fogging up.

Component Function CheckINFOID:0000000003776351

1.CHECK DOOR MIRROR DEFOGGER RH

Check that the heating wire of door mirror defogger RH is heated when turning the rear window defogger

switch ON.

Is the inspection result normal?

YES >> Door mirror defogger RH is OK.

NO >> Refer to DEF-15, "

Diagnosis Procedure".

Diagnosis ProcedureINFOID:0000000003776352

1. CHECK POWER SUPPLY

Check if the following fuse in the IPDM E/R is blown.

Is the inspection result normal?

YES >> GO TO 2

NO >> If fuse is blown, be sure to eliminate cause of malfunction before installing new fuse.

2. CHECK DOOR MIRROR DEFOGGER POWER SUPPLY CIRCUIT

Check voltage between IPDM E/R connector and ground.

Is the inspection result normal?

YES >> GO TO 3

NO >> Replace IPDM E/R. Refer to PCS-34, "

Removal and Installation of IPDM E/R".

3. CHECK DOOR MIRROR DEFOGGER POWER SUPPLY CIRCUIT 2

1. Turn ignition switch OFF.

2. Disconnect door mirror RH.

3. Turn ignition switch ON.

4. Check voltage between door mirror RH connector and ground.

Is the inspection result normal?

YES >> GO TO 4

COMPONENT PARTS AMPEREFUSE NO.

IPDM E/R 15A43

ConnectorTe r m i n a l

ConditionVoltage (V)

(Approx.)

(+) (-)

E120 23 Ground Rear window defogger

switch ON

Battery voltage

Rear window defogger

switch OFF 0

LIIA2049E

ConnectorTe r m i n a l

ConditionVoltage (V)

(Approx.)

(+) (-)

D107 10 Ground Rear window defogger

switch ON

Battery voltage

Rear window defogger

switch OFF 0

LIIA1456E

Revision: December 20092009 QX56

Page 1332 of 4171

EC-5

C

DE

F

G H

I

J

K L

M

EC A

N

O P

On Board Diagnosis Logic ..................................

..

295

P1211 TCS CONTROL UNIT ...........................296

Description .......................................................... ..296

On Board Diagnosis Logic ....................................296

DTC Confirmation Procedure ................................296

Diagnosis Procedure .............................................296

P1212 TCS COMMUNICATION LINE ..............297

Description .......................................................... ..297

On Board Diagnosis Logic ....................................297

DTC Confirmation Procedure ................................297

Diagnosis Procedure .............................................297

P1217 ENGINE OVER TEMPERATURE .........298

On Board Diagnosis Logic .................................. ..298

Overall Function Check .........................................298

Diagnosis Procedure .............................................299

Main 13 Causes of Overheating ............................300

P1225 TP SENSOR ..........................................302

Component Description ....................................... ..302

On Board Diagnosis Logic ....................................302

DTC Confirmation Procedure ................................302

Diagnosis Procedure .............................................302

P1226 TP SENSOR ..........................................304

Component Description ....................................... ..304

On Board Diagnosis Logic ....................................304

DTC Confirmation Procedure ................................304

Diagnosis Procedure .............................................304

P1421 COLD START CONTROL .....................306

Description .......................................................... ..306

On Board Diagnosis Logic ....................................306

DTC Confirmation Procedure ................................306

Diagnosis Procedure .............................................306

P1550 BATTERY CURRENT SENSOR ...........308

Component Description ....................................... ..308

On Board Diagnosis Logic ....................................308

DTC Confirmation Procedure ................................308

Diagnosis Procedure .............................................308

Component Inspection ..........................................310

P1551, P1552 BATTERY CURRENT SEN-

SOR ..................................................................

312

Component Description ....................................... ..312

On Board Diagnosis Logic ....................................312

DTC Confirmation Procedure ................................312

Diagnosis Procedure .............................................312

Component Inspection ..........................................314

P1553 BATTERY CURRENT SENSOR ...........316

Component Description ....................................... ..316

On Board Diagnosis Logic ....................................316

DTC Confirmation Procedure ................................316

Diagnosis Procedure .............................................316

Component Inspection ..........................................318

P1554 BATTERY CURRENT SENSOR ...........320

Component Description ....................................... ..320

On Board Diagnosis Logic .....................................320

Overall Function Check .........................................320

Diagnosis Procedure .............................................321

Component Inspection ...........................................322

P1564 ICC STEERING SWITCH .....................324

Component Description .........................................324

On Board Diagnosis Logic .....................................324

DTC Confirmation Procedure ................................324

Diagnosis Procedure .............................................324

Component Inspection ...........................................326

P1564 ASCD STEERING SWITCH .................328

Component Description .........................................328

On Board Diagnosis Logic .....................................328

DTC Confirmation Procedure ................................328

Diagnosis Procedure .............................................328

Component Inspection ...........................................330

P1568 ICC FUNCTION ....................................332

On Board Diagnosis Logic .....................................332

DTC Confirmation Procedure ................................332

Diagnosis Procedure .............................................332

P1572 ICC BRAKE SWITCH ..........................333

Component Description .........................................333

On Board Diagnosis Logic .....................................333

DTC Confirmation Procedure ................................333

Diagnosis Procedure .............................................334

Component Inspection ...........................................337

P1572 ASCD BRAKE SWITCH ......................339

Component Description .........................................339

On Board Diagnosis Logic .....................................339

DTC Confirmation Procedure ................................339

Diagnosis Procedure .............................................340

Component Inspection ...........................................343

P1574 ICC VEHICLE SPEED SENSOR .........344

Component Description .........................................344

On Board Diagnosis Logic .....................................344

DTC Confirmation Procedure ................................344

Diagnosis Procedure .............................................344

P1574 ASCD VEHICLE SPEED SENSOR .....346

Component Description .........................................346

On Board Diagnosis Logic .....................................346

DTC Confirmation Procedure ................................346

Diagnosis Procedure .............................................346

P1805 BRAKE SWITCH .................................348

Description .............................................................348

On Board Diagnosis Logic .....................................348

DTC Confirmation Procedure ................................348

Diagnosis Procedure .............................................348

Component Inspection ...........................................350

P2100, P2103 THROTTLE CONTROL MO-

TOR RELAY ....................................................

351

Component Description .........................................351

Revision: December 20092009 QX56