warning INFINITI QX56 2009 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2009, Model line: QX56, Model: INFINITI QX56 2009Pages: 4171, PDF Size: 84.65 MB

Page 2852 of 4171

![INFINITI QX56 2009 Factory Service Manual PCS

DIAGNOSIS SYSTEM (IPDM E/R)PCS-15

< FUNCTION DIAGNOSIS > [IPDM E/R]

C

D

E

F

G H

I

J

K L

B A

O P

N

ACTIVE TEST

Te s t i t e m

Monitor Item

[Unit] MAIN SIG-

NALS Description

MOTOR FAN REQ

[1/2/3/4] INFINITI QX56 2009 Factory Service Manual PCS

DIAGNOSIS SYSTEM (IPDM E/R)PCS-15

< FUNCTION DIAGNOSIS > [IPDM E/R]

C

D

E

F

G H

I

J

K L

B A

O P

N

ACTIVE TEST

Te s t i t e m

Monitor Item

[Unit] MAIN SIG-

NALS Description

MOTOR FAN REQ

[1/2/3/4]](/img/42/57031/w960_57031-2851.png)

PCS

DIAGNOSIS SYSTEM (IPDM E/R)PCS-15

< FUNCTION DIAGNOSIS > [IPDM E/R]

C

D

E

F

G H

I

J

K L

B A

O P

N

ACTIVE TEST

Te s t i t e m

Monitor Item

[Unit] MAIN SIG-

NALS Description

MOTOR FAN REQ

[1/2/3/4] ×Displays the status of the cooling fan speed request signal received from ECM via

CAN communication.

A/C COMP REQ

[OFF/ON] ×Displays the status of the A/C request signal received from AV control unit via

CAN communication.

TAIL&CLR REQ

[OFF/ON] ×

Displays the status of the position light request signal received from BCM via CAN

communication.

HL LO REQ

[OFF/ON] ×Displays the status of the low beam request signal received from BCM via CAN

communication.

HL HI REQ

[OFF/ON] ×Displays the status of the high beam request signal received from BCM via CAN

communication.

FR FOG REQ

[OFF/ON] ×

Displays the status of the front fog lamp request signal received from BCM via

CAN communication.

FR WIP REQ

[STOP/1LOW/LOW/HI] ×Displays the status of the front wiper request signal received from BCM via CAN

communication.

WIP AUTO STOP

[STOP P/ACT P] ×

Displays the status of the front wiper auto stop signal judged by IPDM E/R.

WIP PROT

[OFF/Block] ×

Displays the status of the front wiper fail-safe operation judged by IPDM E/R.

ST RLY REQ

[OFF/ON] Displays the status of the starter request signal received from ECM via CAN com-

munication.

IGN RLY

[OFF/ON] ×

Displays the status of the ignition relay judged by IPDM E/R.

RR DEF REQ

[OFF/ON] ×

Displays the status of the rear defogger request signal received from AV control

unit via CAN communication.

OIL P SW

[OPEN/CLOSE] Displays the status of the oil pressure switch judged by IPDM E/R.

DTRL REQ

[OFF] Displays the status of the daytime light request signal received from BCM via CAN

communication.

HOOD SW

[OPEN/CLOSE] Displays the status of the hood switch judged by IPDM E/R.

THFT HRN REQ

[OFF/ON] Displays the status of the theft warning horn request signal received from BCM

via CAN communication.

HORN CHIRP

[OFF/ON] Displays the status of the horn reminder signal received from BCM via CAN com-

munication.

Test item

Operation Description

REAR DEFOGGER OFF

OFF

ON Operates rear window defogger relay.

FRONT WIPER OFF

OFF

LO Operates the front wiper relay.

HI Operates the front wiper relay and front wiper high relay.

MOTOR FAN 1O

FF

2O FF

3 Operates the cooling fan relay.

4 Operates the cooling fan relay.

Revision: December 20092009 QX56

Page 2857 of 4171

![INFINITI QX56 2009 Factory Service Manual PCS-20

< ECU DIAGNOSIS >[IPDM E/R]

IPDM E/R (INTELLIGENT POWER DI

STRIBUTION MODULE ENGINE ROOM)

THFT HRN REQNot operated

OFF

• Panic alarm is activated

• Horn is activated with VEHICLE SECURITY ( INFINITI QX56 2009 Factory Service Manual PCS-20

< ECU DIAGNOSIS >[IPDM E/R]

IPDM E/R (INTELLIGENT POWER DI

STRIBUTION MODULE ENGINE ROOM)

THFT HRN REQNot operated

OFF

• Panic alarm is activated

• Horn is activated with VEHICLE SECURITY (](/img/42/57031/w960_57031-2856.png)

PCS-20

< ECU DIAGNOSIS >[IPDM E/R]

IPDM E/R (INTELLIGENT POWER DI

STRIBUTION MODULE ENGINE ROOM)

THFT HRN REQNot operated

OFF

• Panic alarm is activated

• Horn is activated with VEHICLE SECURITY (THEFT WARNING) SYS- TEM ON

HORN CHIRP Not operated

OFF

Door locking with Intelligent Key (horn chirp mode) ON

Monitor Item

ConditionValue/Status

Revision: December 20092009 QX56

Page 2869 of 4171

![INFINITI QX56 2009 Factory Service Manual PCS-32

< PRECAUTION >[IPDM E/R]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint Syst

em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005851897

The Supplemental INFINITI QX56 2009 Factory Service Manual PCS-32

< PRECAUTION >[IPDM E/R]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint Syst

em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005851897

The Supplemental](/img/42/57031/w960_57031-2868.png)

PCS-32

< PRECAUTION >[IPDM E/R]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint Syst

em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005851897

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SR and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution Necessary for Steering W heel Rotation After Battery Disconnect

INFOID:0000000005851898

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecting both battery cables with the ignition knob in the

″LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS, an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be rotated.

4. Perform the necessary repair operation.

Revision: December 20092009 QX56

Page 2873 of 4171

PG-2

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005852239

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SR and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution Necessary for Steering W heel Rotation After Battery Disconnect

INFOID:0000000005852240

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecting both battery cables with the ignition knob in the

″LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS, an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be rotated.

4. Perform the necessary repair operation.

Revision: December 20092009 QX56

Page 2876 of 4171

PG

BATTERYPG-5

< BASIC INSPECTION >

C

DE

F

G H

I

J

K L

B A

O P

N

BASIC INSPECTION

BATTERY

How to Handle BatteryINFOID:0000000003776564

CAUTION:

• If it becomes necessary to start the engine with

a booster battery and jumper cables, use a 12-volt

booster battery.

• After connecting battery cables, ensure that they are tightly clamped to battery terminals for good

contact.

• Never add distilled water through the hole used to check specific gravity.

METHODS OF PREVENTING OVER-DISCHARGE

The following precautions must be taken to prevent over-discharging a battery.

• The battery surface (particularly its top) should always be kept

clean and dry.

• The terminal connections should be clean and tight.

• At every routine maintenance, check the electrolyte level. This also applies to batteries designated as “low maintenance” and

“maintenance-free”.

• When the vehicle is not going to be used over a long period of time, disconnect the battery cable from the negative terminal. (If

the vehicle has an extended storage switch, turn it off.)

• Check the charge condition of the battery. Periodically check the specific gr avity of the electrolyte. Keep a

close check on charge condition to prevent over-discharge.

CHECKING ELECTROLYTE LEVEL

WARNING:

Never allow battery fluid to come in contact with skin, eyes, fabrics, or painted surfaces. After touch-

ing a battery, never touch or rub your eyes until you have thoroughly washed your hands. If acid con-

tacts eyes, skin or clothing, imme diately flush with water for 15 minutes and seek medical attention.

MEL040F

ELA0349D

MEL042F

Revision: December 20092009 QX56

Page 2915 of 4171

PG-44

< COMPONENT DIAGNOSIS >

HARNESS

A3 M6 W/10 : To E10A3 M82 W/2 : Circuit breaker-2

A2 M7 B/5 : Passenger select unlock relay G4 M84 W/16 : To B101

A3 M8 W/16 : To D2 A3 M85 W/3 : Tilt motor assembly

A2 M9 BR/24 : To D1 B3 M86 W/2 : Tilt motor assembly

A3 M10 Y/4 : To E29 B3 M87 B/5 : Rear power vent window relay (open)

A3 M11 B/1 : Parking brake switch B3 M89 B/5 : Rear power vent window relay (close)

C3 M12 GR/6 : Key switch and ignition knob switch B3 M91 W/16 : To E26

D3 M13 BR/2 : Front passenger air bag OFF indicator A2 M92 B/6 : Power liftgate switch

A2 M14 GR/6 : Diode-3 D1 M93 W/24 : Display unit

B3 M15 W/4 : Steering lock solenoid A2 M95 W/6 : Rear power vent window switch

A2 M16 GR/6 : ADP steering switch A2 M96 BR/6 : Pedal adjusting switch

B2 M17 W/8 : Steering angle sensor C2 M98 W/16 : A/C and AV switch assembly

C2 M18 W/40 : BCM (body control module) C3 M99 BR/2 : Foot lamp LH

C2 M19 W/15 : BCM (body control module) F4 M100 BR/2 : Foot lamp RH

C2 M20 B/15 : BCM (body control module) E3 M104 W/4 : Aux jack

C3 M21 W/4 : NATS antenna AMP. F2 M105 Y/2 : Front passenger air bag module

C3 M22 W/16 : Data link connector F2 M106 O/2 : Front passenger air bag module

B1 M23 W/12 : Combination meter F3 M107 B/5 : Front blower relay

C1 M24 W/40 : Combination meter D5 M108 B/6 : Yaw rate/ side/ decel G sensor

F2 M25 B/4 : Remote keyless entry receiver A1 M109 BR/2 : Front tweeter LH

B2 M26 W/6 : Ignition switch D2 M110 BR/2 : Center speaker

B2 M28 W/16 : Combination switch F2 M111 BR/2 : Front tweeter RH

B2 M29 Y/6 : Combination switch (spiral cable) C2 M112 BR/14 : BOSE speaker amp.

B3 M30 GR/8 : Combination switch (spiral cable) C2 M113 BR/23 : BOSE speaker amp.

G4 M31 SMJ : To E152 A2 M116 GR/8 : Sonar system OFF switch

C3 M32 W/4 : In-vehicle sensor A2 M117 GR/8 : Rear sonar system OFF switch

B3 M33 W/32 : Automatic drive position control unit B1 M118 B/2 : Front sonar buzzer

B3 M34 W/16 : Automatic drive position control unit F2 M120 W/4 : Remote keyless entry receiver

C5 M35 Y/28 : Air bag diagnosis sensor unit F4 M122 W/4 : Variable blower control (front)

G4 M36 SMJ : To B149 C3 M123 W/2 : Tire pressure warning check connector

G3 M37 B/1 : Fuse block (J/B) D2 M139 B/2 : Diode-1

G3 M38 B/2 : Fuse block (J/B) D1 M140 B/2 : Diode-2

D3 M39 W/8 : Fuse block (J/B) C2 M141 GR/8 : 4WD shift switch

A3 M40 SMJ : To B69 E1 M142 B/6 : Mode door motor (front)

D2 M42 W/20 : AV control unit E3 M143 B/6 : Air mix door motor (passenger)

D2 M43 W/12 : AV control unit C1 M144 B/6 : Defroster door motor

D2 M44 W/32 : AV control unit E3 M146 GR/2 : Intake sensor

D3 M45 W/40 : AV control unit D3 M147B/6 : Air mix doo r motor (driver)

B1 M47 B/2 : Sonar buzzer D2 M148 W/4 : Headlamp aiming switch

D2 M49 B/26 : A/C auto amp. D3 M149 W/4 : Clock

D2 M50 L/26 : A/C auto amp. B1 M150 W/2 : Ignition keyhole illumination

B3 M51 L/4 : Trailer tow relay 1 A3 M158 W/10 : To D3

B2 M52 W/2 : Combination switch (spiral cable) Console sub-harness

D3 M53 B/3 : Front power socket LH D4 M201 W/16 : To M56

E3 M54 B/3 : Front power socket RH (for cigarette

lighter) D4 M202 BR/24 : To M64

Revision: December 20092009 QX56

Page 2918 of 4171

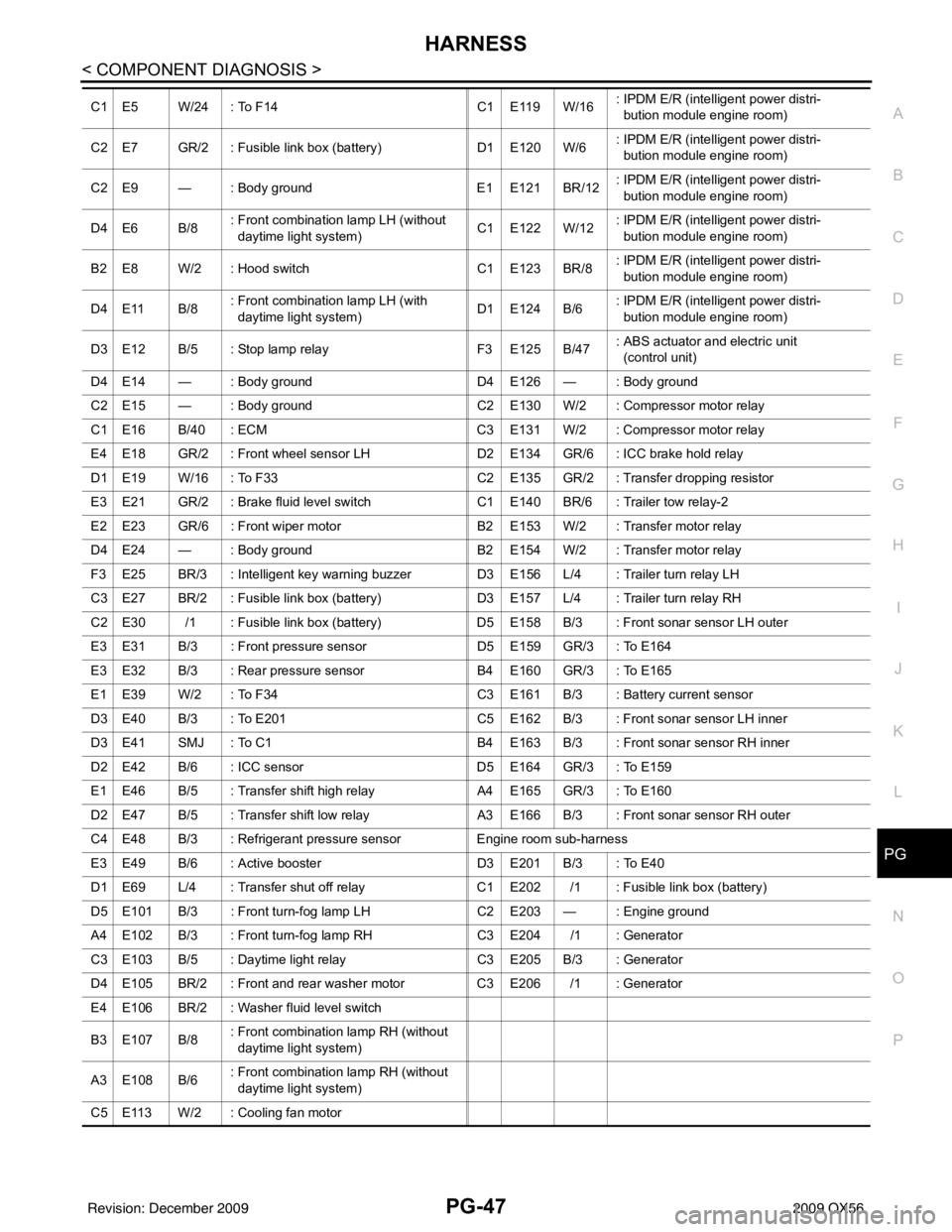

PG

HARNESSPG-47

< COMPONENT DIAGNOSIS >

C

DE

F

G H

I

J

K L

B A

O P

N

C1 E5 W/24 : To F14

C1 E119 W/16: IPDM E/R (intelligent power distri-

bution module engine room)

C2 E7 GR/2 : Fusible link box (battery) D1 E120 W/6: IPDM E/R (intelligent power distri-

bution module engine room)

C2 E9 — : Body ground E1 E121 BR/12: IPDM E/R (intelligent power distri-

bution module engine room)

D4 E6 B/8 : Front combination lamp LH (without

daytime light system) C1 E122 W/12: IPDM E/R (intelligent power distri-

bution module engine room)

B2 E8 W/2 : Hood switch C1 E123 BR/8: IPDM E/R (intelligent power distri-

bution module engine room)

D4 E11 B/8 : Front combination lamp LH (with

daytime light system) D1 E124 B/6

: IPDM E/R (intelligent power distri-

bution module engine room)

D3 E12 B/5 : Stop lamp relay F3 E125 B/47: ABS actuator and electric unit

(control unit)

D4 E14 — : Body ground D4 E126 — : Body ground

C2 E15 — : Body ground C2 E130 W/2 : Compressor motor relay

C1 E16 B/40 : ECM C3 E131 W/2 : Compressor motor relay

E4 E18 GR/2 : Front wheel sensor LH D2 E134 GR/6 : ICC brake hold relay

D1 E19 W/16 : To F33 C2 E135 GR/2 : Transfer dropping resistor

E3 E21 GR/2 : Brake fluid level swit chC1 E140 BR/6 : Trailer tow relay-2

E2 E23 GR/6 : Front wiper motor B2 E153 W/2 : Transfer motor relay

D4 E24 — : Body ground B2 E154 W/2 : Transfer motor relay

F3 E25 BR/3 : Intelligent key warning buzzer D3 E156 L/4 : Trailer turn relay LH

C3 E27 BR/2 : Fusible link box (battery) D3 E157 L/4 : Trailer turn relay RH

C2 E30 /1 : Fusible link box (battery) D5 E158 B/3 : Front sonar sensor LH outer

E3 E31 B/3 : Front pressure sensor D5 E159 GR/3 : To E164

E3 E32 B/3 : Rear pressure sensor B4 E160 GR/3 : To E165

E1 E39 W/2 : To F34 C3 E161 B/3 : Battery current sensor

D3 E40 B/3 : To E201 C5 E162 B/3 : Front sonar sensor LH inner

D3 E41 SMJ : To C1 B4 E163 B/3 : Front sonar sensor RH inner

D2 E42 B/6 : ICC sensor D5 E164 GR/3 : To E159

E1 E46 B/5 : Transfer shift high relay A4 E165 GR/3 : To E160

D2 E47 B/5 : Transfer shift low relay A3 E166 B/3 : Front sonar sensor RH outer

C4 E48 B/3 : Refrigerant pressure sensor Engine room sub-harness

E3 E49 B/6 : Active booster D3 E201 B/3 : To E40

D1 E69 L/4 : Transfer shut off relay C1 E202 /1 : Fusible link box (battery)

D5 E101 B/3 : Front turn-fog lamp LH C2 E203 — : Engine ground

A4 E102 B/3 : Front turn-fog lamp RH C3 E204 /1 : Generator

C3 E103 B/5 : Daytime light relay C3 E205 B/3 : Generator

D4 E105 BR/2 : Front and rear washer motor C3 E206 /1 : Generator

E4 E106 BR/2 : Washer fluid level switch

B3 E107 B/8 : Front combination lamp RH (without

daytime light system)

A3 E108 B/6 : Front combination lamp RH (without

daytime light system)

C5 E113 W/2 : Cooling fan motor

Revision: December 20092009 QX56

Page 2934 of 4171

PG

HARNESSPG-63

< COMPONENT DIAGNOSIS >

C

DE

F

G H

I

J

K L

B A

O P

N

F2 D406 B/1 : Rear window defogger

D2 D705 GR/2 : Back-up lamp LH

Back door LH harness C4 D706 W/4 : Back door and glass hatch switch assembly

G3 D501 W/18 : To D405 D2 D707 B/1 : Glass hatch ajar switch

E4 D503 W/8 : Back door latch B4 D709 GR/8 : Back-up lamp RH

E4 D504 W/4 : Rear view camera B4 D711 W/4 : Glass hatch lock actuator

F4 D514 BR/2 : Back door warning chime B4 D715 BR/2 : Pinch strip RH

F4 D517 BR/2 : Pinch strip LH B4 D716 BR/2 : Back door speaker RH

F4 D518 BR/2 : Back door speaker LH

Back door No. 2 RH harness

C2 D601 W/6 : To B140

C2 D602 W/16 : To B139

D2 D603 — : Body ground

B2 D604 B/1 : Rear window defogger

A3 D605 W/6 : To D702

B3 D606 W/16 : To D701

Revision: December 20092009 QX56

Page 2958 of 4171

PWC-10

< FUNCTION DIAGNOSIS >

DIAGNOSIS SYSTEM (BCM)

DIAGNOSIS SYSTEM (BCM)

COMMON ITEM

COMMON ITEM : CONSULT-III Function (BCM - COMMON ITEM)INFOID:0000000004064497

APPLICATION ITEM

CONSULT-III performs the following functions via CAN communication with BCM.

SYSTEM APPLICATION

BCM can perform the following functions for each system.

NOTE:

It can perform the diagnosis modes except the following for all sub system selection items.

RETAINED PWR

RETAINED PWR : CONSULT-III Function (BCM - RETAINED PWR)INFOID:0000000004064498

Data monitor

Diagnosis mode Function Description

WORK SUPPORT Changes the setting for each system function.

SELF-DIAG RESULTS Displays the diagnosis results judged by BCM. Refer to BCS-51, "DTC Index"

.

CAN DIAG SUPPORT MNTR Monitors the reception status of CAN communication viewed from BCM.

DATA MONITOR The BCM input/output signals are displayed.

ACTIVE TEST The signals used to activate each device are forcibly supplied from BCM.

ECU IDENTIFICATION The BCM part number is displayed.

CONFIGURATION Enables to read and save the vehicle specification.

Enables to write the vehicle specification when replacing BCM.

System Sub system selection item Diagnosis mode

WORK SUPPORT DATA MONITOR ACTIVE TEST

BCM BCM ×

Door lock DOOR LOCK ×××

Rear window defo gger REAR DEFOGGER ×

Warning chime BUZZER ××

Interior room lamp timer INT LAMP ×××

Remote keyless entry system MULTI REMOTE ENT ××

Exterior lamp HEAD LAMP ×××

Wiper and washer WIPER ×××

Turn signal and hazard warning lamps FLASHER ××

Air conditioner AIR CONDITONER ×

Intelligent Key system INTELLIGENT KEY ×

Combination switch COMB SW ×

Immobilizer IMMU ××

Interior room lamp battery saver BATTERY SAVER ×××

Back door open TRUNK ××

RAP (retained accessory power) RETAINED PWR ×××

Signal buffer system SIGNAL BUFFER ××

TPMS (tire pressure monitoring sys-

tem) AIR PRESSURE MONITOR

×××

Vehicle security system PANIC ALARM ×

Revision: December 20092009 QX56

Page 3005 of 4171

BCM (BODY CONTROL MODULE)PWC-57

< ECU DIAGNOSIS >

C

DE

F

G H

I

J

L

M A

B

PWC

N

O P

Te r m i n a l Wire

color Signal name Signal

input/

output Measuring condition

Reference value or waveform

(Approx.)

Ignition

switch Operation or condition

1BR/W Ignition keyhole illumi-

nation Output OFFDoor is locked (SW OFF) Battery voltage

Door is unlocked (SW ON) 0V

2SB Combination switch

input 5 Input ON

Lighting, turn, wiper OFF

Wiper dial position 4

3G/Y Combination switch

input 4 Input ONLighting, turn, wiper OFF

Wiper dial position 4

4Y Combination switch

input 3 Input ON

Lighting, turn, wiper OFF

Wiper dial position 4

5G/B Combination switch

input 2

Input ONLighting, turn, wiper OFF

Wiper dial position 4

6V Combination switch

input 1

9GR/R Rear window defogger

switch

Input ONRear window defogger switch

ON

0V

Rear window defogger switch

OFF 5V

10 G Hazard lamp flash Input OFF ON (opening or closing) 0V

OFF (other than above) Battery voltage

11 O Ignition switch (ACC

or ON)

InputACC or

ON Ignition switch ACC or ON Battery voltage

12 R/L Front door switch RH Input OFF ON (open) 0V

OFF (closed) Battery voltage

13 GR Rear door switch RH Input OFF ON (open) 0V

OFF (closed) Battery voltage

15 L/W Tire pressure warning

check connector

Input OFF — 5V

18 P Remote keyless entry

receiver and optical

sensor (ground)

Output OFF — 0V

SKIA5291E

SKIA5292E

SKIA5291E

SKIA5292E

Revision: December 20092009 QX56