warning INFINITI QX56 2009 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2009, Model line: QX56, Model: INFINITI QX56 2009Pages: 4171, PDF Size: 84.65 MB

Page 3063 of 4171

PRECAUTIONSPWC-115

< PRECAUTION >

C

DE

F

G H

I

J

L

M A

B

PWC

N

O P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005856661

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SR and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the SR section.

Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

When working near the Airbag Diagnosis Sensor Un it or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or el ectric power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minutes before performing any service.

Precaution Necessary for Steering Wh eel Rotation After Battery Disconnect

INFOID:0000000005885965

NOTE:

This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

Remove and install all control units after disconnecti ng both battery cables with the ignition knob in the

″ LOCK ″ position.

Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS , an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be

rotated.

4. Perform the necessary repair operation.

Revision: December 20092009 QX56

Page 3070 of 4171

PWO-2

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005867509

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SR and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution Necessary for Steering W heel Rotation After Battery Disconnect

INFOID:0000000005867510

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecting both battery cables with the ignition knob in the

″LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS, an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be rotated.

4. Perform the necessary repair operation.

Revision: December 20092009 QX56

Page 3077 of 4171

RAX-2

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005873184

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SR and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISS AN/INFINITI dealer.

Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution Necessary for Steering W heel Rotation After Battery Disconnect

INFOID:0000000005873185

NOTE:

This Procedure is applied only to models with Intelli gent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

Remove and install all control units after disconnecting both battery cables with the ignition knob in the

″LOCK ″ position.

Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS, an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be

rotated.

4. Perform the necessary repair operation.

Revision: December 20092009 QX56

Page 3099 of 4171

RF-8

< FUNCTION DIAGNOSIS >

DIAGNOSIS SYSTEM (BCM)

DIAGNOSIS SYSTEM (BCM)

COMMON ITEM

COMMON ITEM : CONSULT-III Function (BCM - COMMON ITEM)INFOID:0000000005867481

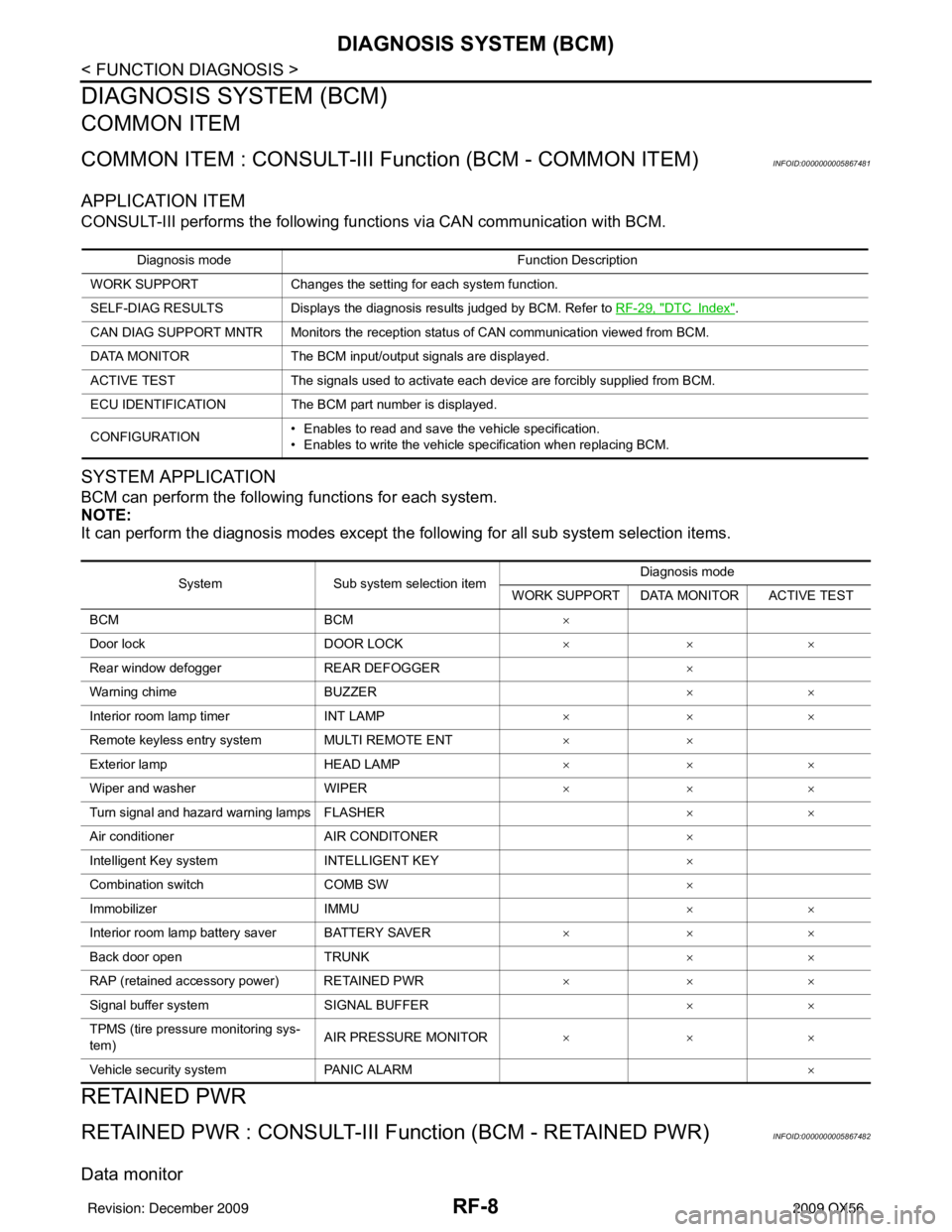

APPLICATION ITEM

CONSULT-III performs the following functions via CAN communication with BCM.

SYSTEM APPLICATION

BCM can perform the following functions for each system.

NOTE:

It can perform the diagnosis modes except the following for all sub system selection items.

RETAINED PWR

RETAINED PWR : CONSULT-III Function (BCM - RETAINED PWR)INFOID:0000000005867482

Data monitor

Diagnosis mode Function Description

WORK SUPPORT Changes the setting for each system function.

SELF-DIAG RESULTS Displays the diagnosis results judged by BCM. Refer to RF-29, "

DTCIndex".

CAN DIAG SUPPORT MNTR Monitors the reception status of CAN communication viewed from BCM.

DATA MONITOR The BCM input/output signals are displayed.

ACTIVE TEST The signals used to activate each device are forcibly supplied from BCM.

ECU IDENTIFICATION The BCM part number is displayed.

CONFIGURATION • Enables to read and save the vehicle specification.

• Enables to write the vehicle specification when replacing BCM.

System

Sub system selection item Diagnosis mode

WORK SUPPORT DATA MONITOR ACTIVE TEST

BCM BCM ×

Door lock DOOR LOCK ×××

Rear window defogger REAR DEFOGGER ×

Warning chime BUZZER ××

Interior room lamp timer INT LAMP ×××

Remote keyless entry system MULTI REMOTE ENT ××

Exterior lamp HEAD LAMP ×××

Wiper and washer WIPER ×××

Turn signal and hazard warning lamps FLASHER ××

Air conditioner AIR CONDITONER ×

Intelligent Key system INTELLIGENT KEY ×

Combination switch COMB SW ×

Immobilizer IMMU ××

Interior room lamp battery saver BATTERY SAVER ×××

Back door open TRUNK ××

RAP (retained accessory power) RETAINED PWR ×××

Signal buffer system SIGNAL BUFFER ××

TPMS (tire pressure monitoring sys-

tem) AIR PRESSURE MONITOR

×××

Vehicle security system PANIC ALARM ×

Revision: December 20092009 QX56

Page 3110 of 4171

BCM (BODY CONTROL MODULE)RF-19

< ECU DIAGNOSIS >

C

DE

F

G H

I

J

L

M A

B

RF

N

O P

Te r m i n a l Wire

color Signal name Signal

input/

output Measuring condition

Reference value or waveform

(Approx.)

Ignition

switch Operation or condition

1BR/W Ignition keyhole illumi-

nation Output OFFDoor is locked (SW OFF)

Battery voltage

Door is unlocked (SW ON) 0V

2SB Combination switch

input 5 Input ON

Lighting, turn, wiper OFF

Wiper dial position 4

3G/Y Combination switch

input 4 Input ONLighting, turn, wiper OFF

Wiper dial position 4

4Y Combination switch

input 3 Input ON

Lighting, turn, wiper OFF

Wiper dial position 4

5G/B Combination switch

input 2

Input ONLighting, turn, wiper OFF

Wiper dial position 4

6V Combination switch

input 1

9GR/R Rear window defogger

switch

Input ONRear window defogger switch

ON

0V

Rear window defogger switch

OFF 5V

10 G Hazard lamp flash Input OFF ON (opening or closing)

0V

OFF (other than above) Battery voltage

11 O Ignition switch (ACC

or ON)

InputACC or

ON Ignition switch ACC or ON

Battery voltage

12 R/L Front door switch RH Input OFF ON (open)

0V

OFF (closed) Battery voltage

13 GR Rear door switch RH Input OFF ON (open)

0V

OFF (closed) Battery voltage

15 L/W Tire pressure warning

check connector

Input OFF

—5V

18 P Remote keyless entry

receiver and optical

sensor (ground)

Output OFF

—0V

SKIA5291E

SKIA5292E

SKIA5291E

SKIA5292E

Revision: December 20092009 QX56

Page 3121 of 4171

RF-30

< ECU DIAGNOSIS >

BCM (BODY CONTROL MODULE)

CONSULT displayFail-safeIntelligent Key

warning lamp ON Tire pressure

monitor warning lamp ON Reference page

No DTC is detected.

further testing

may be required. ————

U1000: CAN COMM CIRCUIT ———BCS-30

U1010: CONTROL UNIT (CAN) ———BCS-31

B2190: NATS ANTENNA AMP ———SEC-27

B2191: DIFFERENCE OF KEY ———SEC-30

B2192: ID DISCORD BCM-ECM ———SEC-31

B2193: CHAIN OF BCM-ECM ———SEC-33

B2552: INTELLIGENT KEY ———SEC-35

B2590: NATS MALFUNCTION ———SEC-36

C1704: LOW PRESSURE FL ———WT-26

C1705: LOW PRESSURE FR ———WT-26

C1706: LOW PRESSURE RR ———WT-26

C1707: LOW PRESSURE RL ———WT-26

C1708: [NO DATA] FL ———WT-14

C1709: [NO DATA] FR ———WT-14

C1710: [NO DATA] RR ———WT-14

C1711: [NO DATA] RL ———WT-14

C1712: [CHECKSUM ERR] FL ———WT-16

C1713: [CHECKSUM ERR] FR ———WT-16

C1714: [CHECKSUM ERR] RR ———WT-16

C1715: [CHECKSUM ERR] RL ———WT-16

C1716: [PRESSDATA ERR] FL ———WT-18

C1717: [PRESSDATA ERR] FR ———WT-18

C1718: [PRESSDATA ERR] RR ———WT-18

C1719: [PRESSDATA ERR] RL ———WT-18

C1720: [CODE ERR] FL ———WT-16

C1721: [CODE ERR] FR ———WT-16

C1722: [CODE ERR] RR ———WT-16

C1723: [CODE ERR] RL ———WT-16

C1724: [BATT VOLT LOW] FL ———WT-16

C1725: [BATT VOLT LOW] FR ———WT-16

C1726: [BATT VOLT LOW] RR ———WT-16

C1727: [BATT VOLT LOW] RL ———WT-16

C1729: VHCL SPEED SIG ERR ———WT-19

C1735: IGNITION SIGNAL ————

Revision: December 20092009 QX56

Page 3139 of 4171

RF-48

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005877824

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SR and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution Necessary for Steering W heel Rotation After Battery Disconnect

INFOID:0000000005890843

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecting both battery cables with the ignition knob in the

″LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS, an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be rotated.

4. Perform the necessary repair operation.

Revision: December 20092009 QX56

Page 3150 of 4171

RSU-2

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005873203

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SR and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISS AN/INFINITI dealer.

Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution Necessary for Steering W heel Rotation After Battery Disconnect

INFOID:0000000005873204

NOTE:

This Procedure is applied only to models with Intelli gent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

Remove and install all control units after disconnecting both battery cables with the ignition knob in the

″LOCK ″ position.

Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS, an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be

rotated.

4. Perform the necessary repair operation.

Revision: December 20092009 QX56

Page 3154 of 4171

RSU-6

< ON-VEHICLE MAINTENANCE >

REAR SUSPENSION ASSEMBLY

ON-VEHICLE MAINTENANCE

REAR SUSPENSION ASSEMBLY

On-Vehicle Inspection and ServiceINFOID:0000000003772290

Check all of the component mountings for any excessive looseness, or back lash. Check the components for

any excessive wear, damage, or abnormal conditions. Repair or replace the components as necessary.

SHOCK ABSORBER INSPECTION

Check the shock absorbers for any air l eaks or damage, and replace as necessary.

Check the hoses for any air leaks or damage, and replace as necessary.

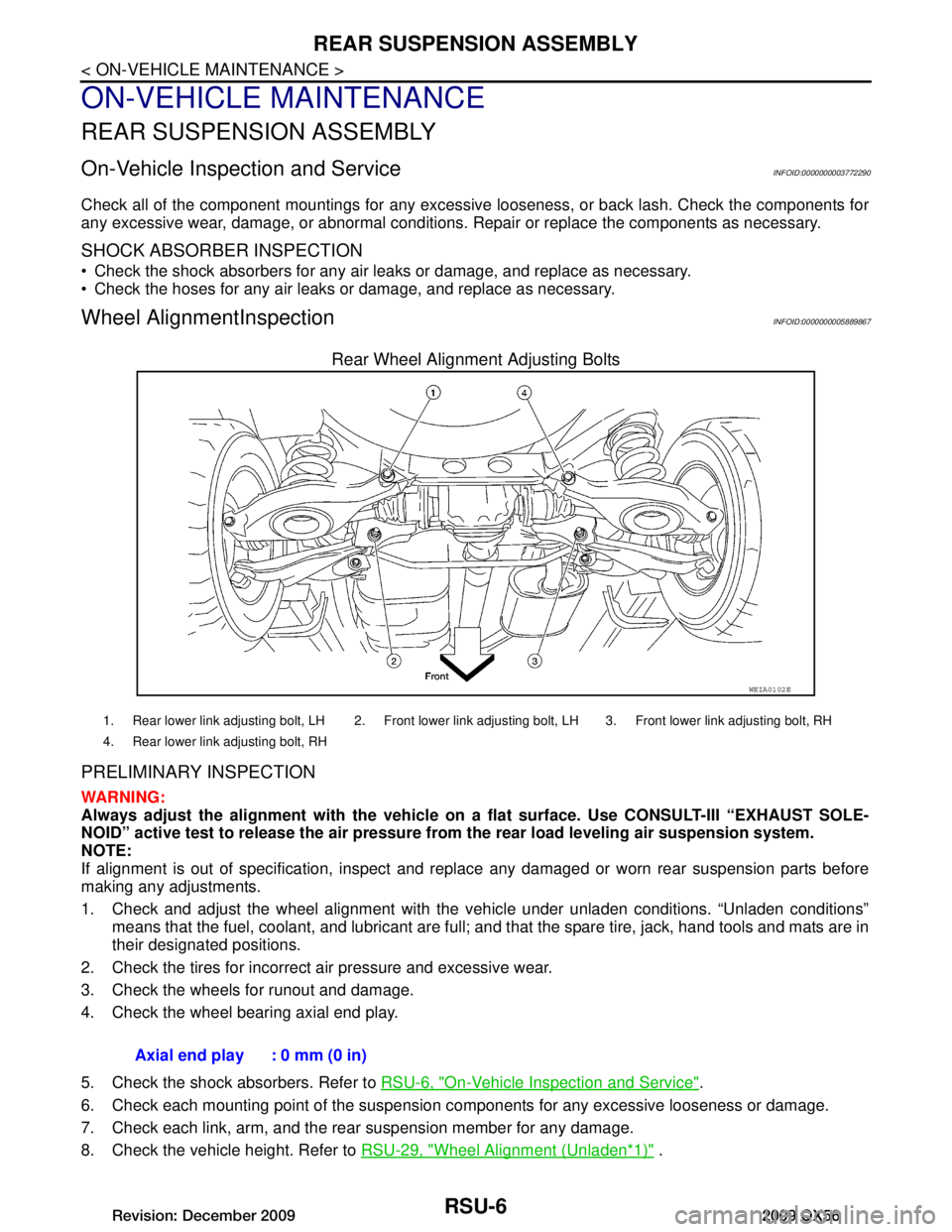

Wheel AlignmentInspectionINFOID:0000000005889867

Rear Wheel Alignment Adjusting Bolts

PRELIMINARY INSPECTION

WARNING:

Always adjust the alignm ent with the vehicle on a flat su rface. Use CONSULT-III “EXHAUST SOLE-

NOID” active test to release the air pressure from the rear load leveling air suspension system.

NOTE:

If alignment is out of specificat ion, inspect and replace any damaged or worn rear suspension parts before

making any adjustments.

1. Check and adjust the wheel alignment with the vehicle under unladen conditions. “Unladen conditions”

means that the fuel, coolant, and lubricant are full; and that the spare tire, jack, hand tools and mats are in

their designated positions.

2. Check the tires for incorrect air pressure and excessive wear.

3. Check the wheels for runout and damage.

4. Check the wheel bearing axial end play.

5. Check the shock absorbers. Refer to RSU-6, "On-Vehicle Inspection and Service"

.

6. Check each mounting point of the suspension components for any excessive looseness or damage.

7. Check each link, arm, and the rear suspension member for any damage.

8. Check the vehicle height. Refer to RSU-29, "Wheel Alignment (Unladen

*1)" .

WEIA0102E

1. Rear lower link adjusting bolt, LH 2. Front lower link adjusting bolt, LH 3. Front lower link adjusting bolt, RH

4. Rear lower link adjusting bolt, RH

Axial end play : 0 mm (0 in)

Revision: December 20092009 QX56

Page 3174 of 4171

RSU-26

< REMOVAL AND INSTALLATION >

CONTROL UNIT

CONTROL UNIT

Removal and InstallationINFOID:0000000003772300

REMOVAL

1. Remove the rear LH interior trim panel. Refer to INT-14, "Removal and Installation" .

2. Disconnect the battery negative terminal.

3. Disconnect the suspension control unit electrical connector.

4. Remove the two bolts and remove the suspension control unit.

INSTALLATION

Installation is in the reverse order of removal.

Initialization ProcedureINFOID:0000000003772301

1. If control unit has been replaced, proceed to step 2. If control unit has not been replaced, use CONSULT-

III “CLEAR HEIGHT INI” work support function to clear initialization flag and value. The CK SUSP warning

lamp should illuminate. Using CONSULT-III “EXHAUST SOLENOID” active test, release the air pressure

from the rear load leveling air suspension system.

2. Roll vehicle forward and backward.

3. Use CONSULT-III “ADJUST HEIGHT INI” work support function to set initialization condition.

4. Confirm that CK SUSP warning lamp is OFF.

LEIA0100E

Suspension control unit bolts : 6 N·m (0.6 kg-m, 53 in-lb)

Revision: December 20092009 QX56