coolant INFINITI QX56 2009 Factory Owner's Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2009, Model line: QX56, Model: INFINITI QX56 2009Pages: 4171, PDF Size: 84.65 MB

Page 767 of 4171

THERMOSTAT AND WATER PIPINGCO-23

< ON-VEHICLE REPAIR >

C

DE

F

G H

I

J

K L

M A

CO

NP

O

CAUTION:

Perform when the engine is cold.

2. Disconnect the water cut valve connector.

3. Disconnect the water hoses from the water cut valve.

4. Remove the water cut valve.

INSPECTION AFTER REMOVAL

• Place a thread so that it is caught in the valve of the thermostat.

Immerse fully in a container filled with water. Heat while stirring.

• The valve opening temperature is the temperature at which the valve opens and falls from the thread.

• Continue heating. Check the full-open lift amount.

• After checking the full-open lift amount, lower the water tempera- ture and check the valve closing temperature.

Standard values:

INSTALLATION

Installation is in the reverse order of removal.

Installation of Thermostat

• Install the thermostat with the whole circumference of each flange

part fit securely inside the rubber ring as shown.

• Install the thermostat with the jiggle valve facing upwards.

Installation of Water Outlet Pipe and Heater Pipe

First apply a neutral detergent to the O- rings, then quickly insert the insertion parts of the water outlet pipe and

heater pipe into the installation holes.

INSPECTION AFTER INSTALLATION

• Check for leaks of the engine coolant. Refer to CO-10, "Inspection".

• Start and warm up the engine. Visually check for leaks of the engine coolant.

SLC252B

Thermostat

Valve opening temperature 80 - 84°C (176 - 183 ° F)

Full-open lift amount More than 10 mm/ 95°C (0.39 in/ 203° F)

Valve closing temperature 77°C (171 °F) or higher

KBIA2502E

Revision: December 20092009 QX56

Page 768 of 4171

CO-24

< SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

Standard and LimitINFOID:0000000003771292

ENGINE COOLANT CAPACITY (APPROXIMATE)

Unit: (US qt, Imp qt)

THERMOSTAT

RADIATOR

Unit: kPa (kg/cm2, psi)

Engine coolant capacity with reservoir ("MAX" level)14.4 (15 1/4, 12 5/8)

Valve opening temperature80 - 84°C (176 - 183 °F)

Full-open lift amount More than 10 mm/95°C (0.39 in/203°F)

Valve closing temperature 77°C (171 °F) or higher

Reservoir cap relief pressure Standard 95 - 125 (0.97- 1.28, 14 - 18)

Leakage test pressure 137 (1.4, 20)

Revision: December 20092009 QX56

Page 1334 of 4171

EC-7

C

DE

F

G H

I

J

K L

M

EC A

N

O P

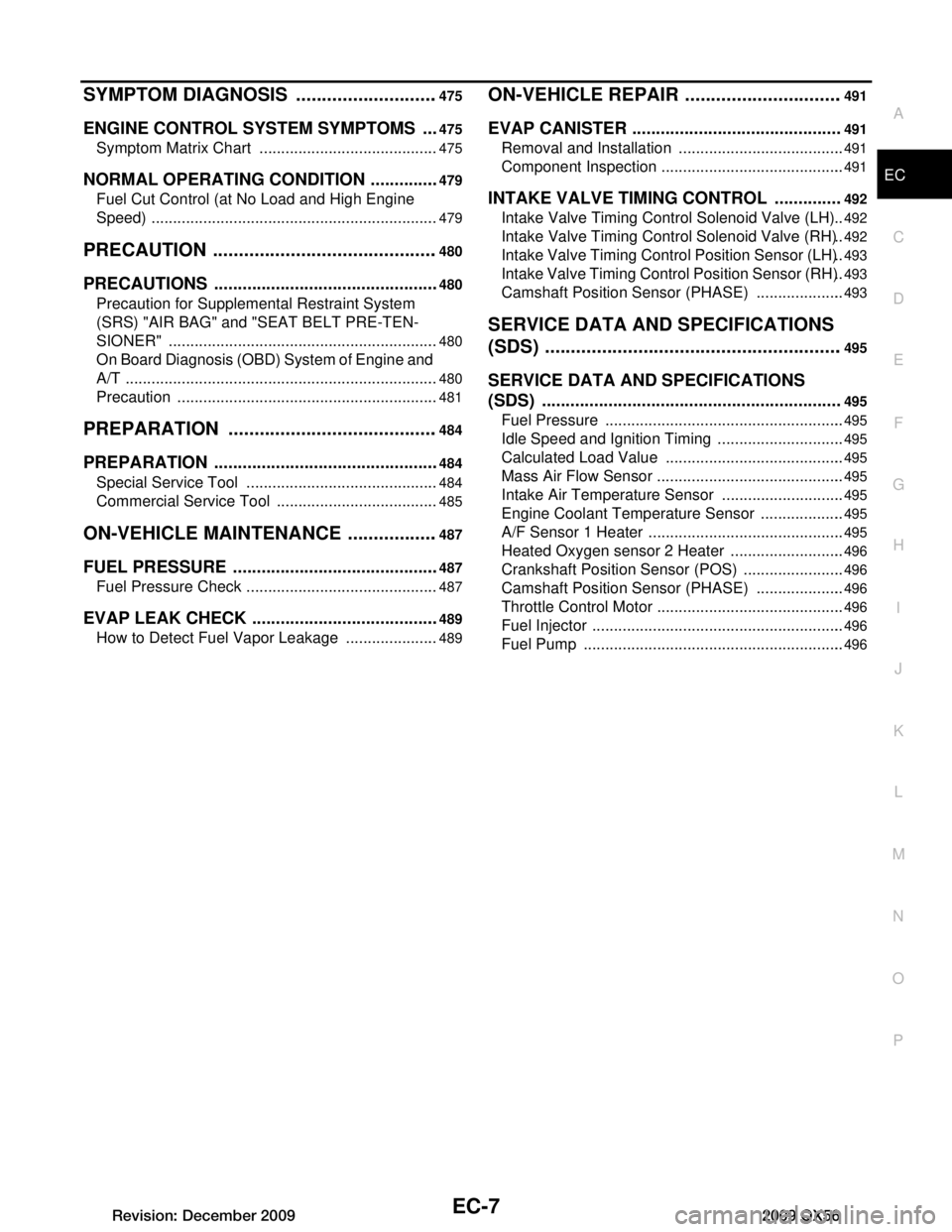

SYMPTOM DIAGNOSIS ..... .......................475

ENGINE CONTROL SYSTEM SYMPTOMS .. ..475

Symptom Matrix Chart ........................................ ..475

NORMAL OPERATING CONDITION ...............479

Fuel Cut Control (at No Load and High Engine

Speed) ................................................................. ..

479

PRECAUTION ............................................480

PRECAUTIONS .............................................. ..480

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ..

480

On Board Diagnosis (OBD) System of Engine and

A/T .........................................................................

480

Precaution .............................................................481

PREPARATION .........................................484

PREPARATION .............................................. ..484

Special Service Tool ........................................... ..484

Commercial Service Tool ......................................485

ON-VEHICLE MAINTENANCE ..................487

FUEL PRESSURE .......................................... ..487

Fuel Pressure Check ........................................... ..487

EVAP LEAK CHECK ........................................489

How to Detect Fuel Vapor Leakage .................... ..489

ON-VEHICLE REPAIR ...............................491

EVAP CANISTER ............................................491

Removal and Installation ..................................... ..491

Component Inspection ...........................................491

INTAKE VALVE TIMING CONTROL ..............492

Intake Valve Timing Control Solenoid Valve (LH) ..492

Intake Valve Timing Cont rol Solenoid Valve (RH) ..492

Intake Valve Timing Control Position Sensor (LH) ..493

Intake Valve Timing Control Position Sensor (RH) ..493

Camshaft Position Sensor (PHASE) .....................493

SERVICE DATA AND SPECIFICATIONS

(SDS) ............... ...........................................

495

SERVICE DATA AND SPECIFICATIONS

(SDS) ...............................................................

495

Fuel Pressure ...................................................... ..495

Idle Speed and Ignition Timing ..............................495

Calculated Load Value ..........................................495

Mass Air Flow Sensor ............................................495

Intake Air Temperature Sensor .............................495

Engine Coolant Temperature Sensor ....................495

A/F Sensor 1 Heater ..............................................495

Heated Oxygen sensor 2 Heater ...........................496

Crankshaft Position Sensor (POS) ........................496

Camshaft Position Sensor (PHASE) .....................496

Throttle Control Motor ............................................496

Fuel Injector ...........................................................496

Fuel Pump .............................................................496

Revision: December 20092009 QX56

Page 1340 of 4171

![INFINITI QX56 2009 Factory Owners Manual

INSPECTION AND ADJUSTMENTEC-13

< BASIC INSPECTION > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

INSPECTION AND ADJUSTMENT

Basic InspectionINFOID:0000000003771294

1.INSPECTION START

1. Check service reco INFINITI QX56 2009 Factory Owners Manual

INSPECTION AND ADJUSTMENTEC-13

< BASIC INSPECTION > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

INSPECTION AND ADJUSTMENT

Basic InspectionINFOID:0000000003771294

1.INSPECTION START

1. Check service reco](/img/42/57031/w960_57031-1339.png)

INSPECTION AND ADJUSTMENTEC-13

< BASIC INSPECTION > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

INSPECTION AND ADJUSTMENT

Basic InspectionINFOID:0000000003771294

1.INSPECTION START

1. Check service records for any recent repairs that ma y indicate a related malfunction, or a current need for

scheduled maintenance.

2. Open engine hood and check the following:

- Harness connectors for improper connections

- Wiring harness for improper connections, pinches and cut

- Vacuum hoses for splits, kinks and improper connections

- Hoses and ducts for leaks

- Air cleaner clogging

- Gasket

3. Confirm that electrical or mechanical loads are not applied.

- Headlamp switch is OFF.

- Air conditioner switch is OFF.

- Rear window defogger switch is OFF.

- Steering wheel is in the straight-ahead position, etc.

4. Start engine and warm it up until engine coolant temperature indicator points the middle of gauge.

Ensure engine stays below 1,000 rpm.

5. Run engine at about 2,000 rpm for about 2 minutes under no load.

6. Make sure that no DTC is displayed with CONSULT-III or GST.

OK or NG

OK >> GO TO 3.

NG >> GO TO 2.

2.REPAIR OR REPLACE

Repair or replace components as necessary according to corresponding Diagnostic Procedure.

>> GO TO 3.

3.CHECK TARGET IDLE SPEED

With CONSULT-III

1. Run engine at about 2,000 rpm for about 2 minutes under no load.

SEF983U

SEF976U

SEF977U

Revision: December 20092009 QX56

Page 1345 of 4171

![INFINITI QX56 2009 Factory Owners Manual

EC-18

< BASIC INSPECTION >[VK56DE]

INSPECTION AND ADJUSTMENT

With CONSULT-III

1. Check the VIN of the vehicle and note it. Refer to

GI-20, "Model Variation".

2. Turn ignition switch ON and engine s INFINITI QX56 2009 Factory Owners Manual

EC-18

< BASIC INSPECTION >[VK56DE]

INSPECTION AND ADJUSTMENT

With CONSULT-III

1. Check the VIN of the vehicle and note it. Refer to

GI-20, "Model Variation".

2. Turn ignition switch ON and engine s](/img/42/57031/w960_57031-1344.png)

EC-18

< BASIC INSPECTION >[VK56DE]

INSPECTION AND ADJUSTMENT

With CONSULT-III

1. Check the VIN of the vehicle and note it. Refer to

GI-20, "Model Variation".

2. Turn ignition switch ON and engine stopped.

3. Select “VIN REGISTRATION ” in “WORK SUPPORT” mode.

4. Follow the instruction of CONSULT-III display.

Accelerator Pedal Released Position LearningINFOID:0000000003771298

DESCRIPTION

Accelerator Pedal Released Position Learning is an operati on to learn the fully released position of the accel-

erator pedal by monitoring the accelerator pedal positi on sensor output signal. It must be performed each time

harness connector of accelerator pedal pos ition sensor or ECM is disconnected.

OPERATION PROCEDURE

1. Make sure that accelerator pedal is fully released.

2. Turn ignition switch ON and wait at least 2 seconds.

3. Turn ignition switch OFF and wait at least 10 seconds.

4. Turn ignition switch ON and wait at least 2 seconds.

5. Turn ignition switch OFF and wait at least 10 seconds.

Throttle Valve Closed Position LearningINFOID:0000000003771299

DESCRIPTION

Throttle Valve Closed Position Learning is an operation to l earn the fully closed position of the throttle valve by

monitoring the throttle position sensor output signal . It must be performed each time harness connector of

electric throttle control actuator or ECM is disconnected.

OPERATION PROCEDURE

1. Make sure that accelerator pedal is fully released.

2. Turn ignition switch ON.

3. Turn ignition switch OFF wait at least 10 seconds. Make sure that throttle valve moves during above 10 seconds by confirming the operating sound.

Idle Air Volume LearningINFOID:0000000003771300

DESCRIPTION

Idle Air Volume Learning is an operation to learn the idle air volume that keeps each engine within the specific

range. It must be performed under any of the following conditions:

Each time electric throttle control actuator or ECM is replaced.

Idle speed or ignition timing is out of specification.

PREPARATION

Before performing Idle Air Volume Learning, make sure that all of the following conditions are satisfied.

Learning will be cancelled if any of the following conditions are missed for even a moment.

Battery voltage: More than 12.9V (At idle)

Engine coolant temperature: 70 - 100 °C (158 - 212 °F)

Select lever: P or N

Electric load switch: OFF (Air conditioner, headlamp, rear window defogger)

On vehicles equipped with daytime light systems, if the parking brake is applied before the engine is

start the headlamp will not be illuminated.

Steering wheel: Neutral (Straight-ahead position)

Vehicle speed: Stopped

Transmission: Warmed-up

- With CONSULT-III: Drive vehicle until “ATF TEMP SE 1” in “DATA MONITOR” mode of “A/T” system indi-

cates less than 0.9V.

- Without CONSULT-III: Drive vehicle for 10 minutes.

OPERATION PROCEDURE

Revision: December 20092009 QX56

Page 1349 of 4171

![INFINITI QX56 2009 Factory Owners Manual

EC-22

< FUNCTION DIAGNOSIS >[VK56DE]

ENGINE CONTROL SYSTEM

Engine Control Comp onent Parts Location

INFOID:0000000003771302

1. ECM 2. Battery current sensor 3. Power steering pressure sensor

4. Ignit INFINITI QX56 2009 Factory Owners Manual

EC-22

< FUNCTION DIAGNOSIS >[VK56DE]

ENGINE CONTROL SYSTEM

Engine Control Comp onent Parts Location

INFOID:0000000003771302

1. ECM 2. Battery current sensor 3. Power steering pressure sensor

4. Ignit](/img/42/57031/w960_57031-1348.png)

EC-22

< FUNCTION DIAGNOSIS >[VK56DE]

ENGINE CONTROL SYSTEM

Engine Control Comp onent Parts Location

INFOID:0000000003771302

1. ECM 2. Battery current sensor 3. Power steering pressure sensor

4. Ignition coil (with power transistor)

and spark plug (bank 2) 5. Refrigerant pressure sensor 6. Intake valve timing control position

sensor (bank 2)

7. Intake valve timing control solenoid valve (bank 2) 8. Engine coolant temperature sensor 9. Electric throttle control actuator

10. Intake valve timing control position sensor (bank 1) 11. Intake valve timing control solenoid

valve (bank 1) 12. Cooling fan motor

13. Camshaft position sensor (PHASE) 14. I gnition coil (with power transistor)

and spark plug (bank 1) 15. Mass air flow sensor (with intake air

temperature sensor)

16. A/F sensor 1 (bank 1) 17. EVAP service port 18. Fuel injector (bank 1)

19. Knock sensor (bank 1) 20. EVAP canister purge volume control solenoid valve21. Knock sensor (bank 2)

22. Fuel injector (bank 2) 23. A/F sensor 1 (bank 2) 24. IPDM E/R

BBIA0743E

Revision: December 20092009 QX56

Page 1353 of 4171

![INFINITI QX56 2009 Factory Owners Manual

EC-26

< FUNCTION DIAGNOSIS >[VK56DE]

ENGINE CONTROL SYSTEM

1. Knock sensor (bank 1) (view with en-

gine removed) 2. Knock sensor (bank 2) (view with en-

gine removed) 3. Battery current sensor

4. Pow INFINITI QX56 2009 Factory Owners Manual

EC-26

< FUNCTION DIAGNOSIS >[VK56DE]

ENGINE CONTROL SYSTEM

1. Knock sensor (bank 1) (view with en-

gine removed) 2. Knock sensor (bank 2) (view with en-

gine removed) 3. Battery current sensor

4. Pow](/img/42/57031/w960_57031-1352.png)

EC-26

< FUNCTION DIAGNOSIS >[VK56DE]

ENGINE CONTROL SYSTEM

1. Knock sensor (bank 1) (view with en-

gine removed) 2. Knock sensor (bank 2) (view with en-

gine removed) 3. Battery current sensor

4. Power steering pressure sensor 5. Power steering fluid reservoir 6. Intake manifold

7. Engine coolant temperature sensor 8. Ignition coils (with power transistor) 9. Ignition coil (with power transistor)

10. Injector harness connectors (bank 2) 11. Injector harness connectors (bank 1) : Vehicle front

BBIA0384E

Revision: December 20092009 QX56

Page 1355 of 4171

![INFINITI QX56 2009 Factory Owners Manual

EC-28

< FUNCTION DIAGNOSIS >[VK56DE]

MULTIPORT FUEL INJECTION SYSTEM

MULTIPORT FUEL INJECTION SYSTEM

System DescriptionINFOID:0000000003771303

INPUT/OUTPUT SIGNAL CHART

*1: This sensor is not used to INFINITI QX56 2009 Factory Owners Manual

EC-28

< FUNCTION DIAGNOSIS >[VK56DE]

MULTIPORT FUEL INJECTION SYSTEM

MULTIPORT FUEL INJECTION SYSTEM

System DescriptionINFOID:0000000003771303

INPUT/OUTPUT SIGNAL CHART

*1: This sensor is not used to](/img/42/57031/w960_57031-1354.png)

EC-28

< FUNCTION DIAGNOSIS >[VK56DE]

MULTIPORT FUEL INJECTION SYSTEM

MULTIPORT FUEL INJECTION SYSTEM

System DescriptionINFOID:0000000003771303

INPUT/OUTPUT SIGNAL CHART

*1: This sensor is not used to control the engine system. This is used only for the on board diagnosis.

*2: This signal is sent to the ECM through CAN communication line.

*3: ECM determines the start signal status by the signals of engine speed and battery voltage.

SYSTEM DESCRIPTION

The amount of fuel injected from the fuel injector is

determined by the ECM. The ECM controls the length of

time the valve remains open (injection pulse duration). T he amount of fuel injected is a program value in the

ECM memory. The program value is preset by engi ne operating conditions. These conditions are determined

by input signals (for engine speed and intake air) from both the crankshaft position sensor and the mass air

flow sensor.

VARIOUS FUEL INJECTION I NCREASE/DECREASE COMPENSATION

In addition, the amount of fuel injected is compens ated to improve engine performance under various operat-

ing conditions as listed below.

When starting the engine

During acceleration

Hot-engine operation

When selector lever is changed from N to D

High-load, high-speed operation

During deceleration

During high engine speed operation

Sensor Input signal to ECM ECM function Actuator

Crankshaft position sensor (POS) Engine speed*

3

Piston position

Fuel injection

& mixture ratio

controlFuel injector

Camshaft position sensor (PHASE)

Mass air flow sensor Amount of intake air

Engine coolant temperature sensor Engine coolant temperature

Air fuel ratio (A/F) sensor 1 Density of oxygen in exhaust gas

Throttle position sensor Throttle position

Accelerator pedal position sensor Accelerator pedal position

TCM Gear position

Knock sensor Engine knocking condition

Battery

Battery voltage*

3

Power steering pressure sensor Power steering operation

Heated oxygen sensor 2*

1Density of oxygen in exhaust gas

ABS actuator and electric unit (control unit) VDC/TCS operation command*

2

Air conditioner switchAir conditioner operation*2

Wheel sensorVehicle speed*2

Revision: December 20092009 QX56

Page 1356 of 4171

![INFINITI QX56 2009 Factory Owners Manual

MULTIPORT FUEL INJECTION SYSTEMEC-29

< FUNCTION DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

MIXTURE RATIO FEEDBACK CONTROL (CLOSED LOOP CONTROL)

The mixture ratio feedback system prov

ides t INFINITI QX56 2009 Factory Owners Manual

MULTIPORT FUEL INJECTION SYSTEMEC-29

< FUNCTION DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

MIXTURE RATIO FEEDBACK CONTROL (CLOSED LOOP CONTROL)

The mixture ratio feedback system prov

ides t](/img/42/57031/w960_57031-1355.png)

MULTIPORT FUEL INJECTION SYSTEMEC-29

< FUNCTION DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

MIXTURE RATIO FEEDBACK CONTROL (CLOSED LOOP CONTROL)

The mixture ratio feedback system prov

ides the best air-fuel mixture ratio for driveability and emission control.

The three way catalyst (manifold) can then better r educe CO, HC and NOx emissions. This system uses air

fuel ratio (A/F) sensor 1 in the exhaust manifold to monitor whether the engine operation is rich or lean. The

ECM adjusts the injection pulse width according to the sensor voltage signal. For more information about air

fuel ratio (A/F) sensor 1, refer to EC-136

. This maintains the mixture ratio within the range of stoichiometric

(ideal air-fuel mixture).

This stage is referred to as the closed loop control condition.

Heated oxygen sensor 2 is located downstream of the th ree way catalyst (manifold). Even if the switching

characteristics of air fuel ratio (A/F) sensor 1 shift, t he air-fuel ratio is controlled to stoichiometric by the signal

from heated oxygen sensor 2.

Open Loop Control

The open loop system condition refers to when the ECM detects any of the following conditions. Feedback

control stops in order to maintain stabilized fuel combustion.

Deceleration and acceleration

High-load, high-speed operation

Malfunction of A/F sensor 1 or its circuit

Insufficient activation of A/F sensor 1 at low engine coolant temperature

High engine coolant temperature

During warm-up

After shifting from N to D

When starting the engine

MIXTURE RATIO SELF-LEARNING CONTROL

The mixture ratio feedback control system monitors the mixture ratio signal transmitted from A/F sensor 1.

This feedback signal is then sent to the ECM. The ECM cont rols the basic mixture ratio as close to the theoret-

ical mixture ratio as possible. However, the basic mi xture ratio is not necessarily controlled as originally

designed. Both manufacturing differences (i.e., mass air flow sensor hot wire) and characteristic changes dur-

ing operation (i.e., injector clogging) directly affect mixture ratio.

Accordingly, the difference between the basic and theoretical mixture ratios is monitored in this system. This is

then computed in terms of “injection pulse duration” to automatically compensate for the difference between

the two ratios.

“Fuel trim” refers to the feedback compensation value co mpared against the basic injection duration. Fuel trim

includes short term fuel trim and long term fuel trim.

“Short term fuel trim” is the short-term fuel compensati on used to maintain the mixture ratio at its theoretical

value. The signal from A/F sensor 1 indicates whether the mixture ratio is RICH or LEAN compared to the the-

oretical value. The signal then triggers a reduction in fuel volume if the mixture ratio is rich, and an increase in

fuel volume if it is lean.

“Long term fuel trim” is overall fuel compensation ca rried out long-term to compensate for continual deviation

of the short term fuel trim from the central value. Such deviation will occur due to individual engine differences,

wear over time and changes in the usage environment.

PBIB3020E

Revision: December 20092009 QX56

Page 1358 of 4171

![INFINITI QX56 2009 Factory Owners Manual

ELECTRIC IGNITION SYSTEMEC-31

< FUNCTION DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

ELECTRIC IGNITION SYSTEM

System DescriptionINFOID:0000000003771304

INPUT/OUTPUT SIGNAL CHART

*1: This sig INFINITI QX56 2009 Factory Owners Manual

ELECTRIC IGNITION SYSTEMEC-31

< FUNCTION DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

ELECTRIC IGNITION SYSTEM

System DescriptionINFOID:0000000003771304

INPUT/OUTPUT SIGNAL CHART

*1: This sig](/img/42/57031/w960_57031-1357.png)

ELECTRIC IGNITION SYSTEMEC-31

< FUNCTION DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

ELECTRIC IGNITION SYSTEM

System DescriptionINFOID:0000000003771304

INPUT/OUTPUT SIGNAL CHART

*1: This signal is sent to the ECM through CAN communication line.

*2: ECM determines the start signal status by the signals of engine speed and battery voltage.

SYSTEM DESCRIPTION

Firing order: 1 - 8 - 7 - 3 - 6 - 5 - 4 -2

The ignition timing is controlled by the ECM to maintain

the best air-fuel ratio for every running condition of the

engine. The ignition timing data is stored in the ECM.

The ECM receives information such as the injection pulse width and camshaft position sensor signal. Comput-

ing this information, ignition signals are transmitted to the power transistor.

During the following conditions, the ignition timing is revi sed by the ECM according to the other data stored in

the ECM.

At starting

During warm-up

At idle

At low battery voltage

During acceleration

The knock sensor retard system is designed only for emergencies. The basic ignition timing is programmed

within the anti-knocking zone, if recommended fuel is used under dry conditions. The retard system does not

operate under normal driving conditions. If engine knocking occurs, the knock sensor monitors the condition.

The signal is transmitted to the ECM. The ECM retards the ignition timing to eliminate the knocking condition.

Sensor Input signal to ECM ECM function Actuator

Crankshaft position sensor (POS) Engine speed*

2

Piston position

Ignition timing

controlPower transistor

Camshaft position sensor (PHASE)

Mass air flow sensor Amount of intake air

Engine coolant temperature sensor Engine coolant temperature

Throttle position sensor Throttle position

Accelerator pedal position sensor Accelerator pedal position

Knock sensor Engine knocking

TCM Gear position

Battery

Battery voltage*

2

Wheel sensor

Vehicle speed*1

Revision: December 20092009 QX56