cruise control INFINITI QX56 2009 Factory Owner's Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2009, Model line: QX56, Model: INFINITI QX56 2009Pages: 4171, PDF Size: 84.65 MB

Page 1714 of 4171

![INFINITI QX56 2009 Factory Owners Manual

ASCD INDICATOREC-387

< COMPONENT DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

ASCD INDICATOR

Component DescriptionINFOID:0000000003771706

ASCD indicator lamp illuminates to indicate ASCD oper INFINITI QX56 2009 Factory Owners Manual

ASCD INDICATOREC-387

< COMPONENT DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

ASCD INDICATOR

Component DescriptionINFOID:0000000003771706

ASCD indicator lamp illuminates to indicate ASCD oper](/img/42/57031/w960_57031-1713.png)

ASCD INDICATOREC-387

< COMPONENT DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

ASCD INDICATOR

Component DescriptionINFOID:0000000003771706

ASCD indicator lamp illuminates to indicate ASCD operation status. Lamp has two indicators, CRUISE and

SET, and is integrated in combination meter.

CRUISE indicator illuminates when MAIN switch on ASCD st

eering switch is turned ON to indicate that ASCD

system is ready for operation.

SET indicator illuminates when following conditions are met.

CRUISE indicator is illuminated.

SET/COAST switch on ASCD steering switch is tur ned ON while vehicle speed is within the range of ASCD

setting.

SET indicator remains lit during ASCD control.

Refer to EC-33

for the ASCD function.

Diagnosis ProcedureINFOID:0000000003771707

1.CHECK OVERALL FUNCTION

Check ASCD indicator under the following conditions.

OK or NG

OK >> INSPECTION END

NG >> GO TO 2.

2.CHECK DTC

Check that DTC U1000 or U1001 is not displayed.

OK or NG

OK >> GO TO 3.

NG >> Perform trouble diagnosis for DTC U1000, U1001. Refer to EC-86

.

3.CHECK COMBINATION METER FUNCTION

Refer to MWI-5

.

OK or NG

OK >> GO TO 4.

NG >> Go to MWI-5

.

4.CHECK INTERMITTENT INCIDENT

Refer to GI-35, "How to Check Terminal"

and GI-38, "Intermittent Incident".

>> INSPECTION END

ASCD INDICATOR CONDITION SPECIFICATION

CRUISE LAMP Ignition switch: ON MAIN switch: Pressed at the 1st

time → at the 2nd time ON

→ OFF

SET LAMP MAIN switch: ON

When vehicle speed is between

40 km/h (25 MPH) and 144 km/h

(89 MPH) ASCD: Operating ON

ASCD: Not operating OFF

Revision: December 20092009 QX56

Page 1748 of 4171

![INFINITI QX56 2009 Factory Owners Manual

ECM

EC-421

< ECU DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

*1: Accelerator pedal position sensor 2 signal and throttle position sensor 2 signal are converted by ECM internally. Thus, the

y INFINITI QX56 2009 Factory Owners Manual

ECM

EC-421

< ECU DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

*1: Accelerator pedal position sensor 2 signal and throttle position sensor 2 signal are converted by ECM internally. Thus, the

y](/img/42/57031/w960_57031-1747.png)

ECM

EC-421

< ECU DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

*1: Accelerator pedal position sensor 2 signal and throttle position sensor 2 signal are converted by ECM internally. Thus, the

y differ

from ECM terminals voltage signal.

*2: Before measuring the terminal voltage, confirm the battery is fully charged. Refer to PG-77

.

I/P PULLY SPD Vehicle speed: More than 20 km/h (12 MPH)

Almost the same speed as the

tachometer indication

VEHICLE SPEED Turn drive wheels and compare CONSULT-IIl value with the speedometer

indication. Almost the same speed as the

speedometer indication

TRVL AFTER MIL Ignition switch: ON Vehicle has traveled after MIL has

turned ON.0 - 65,535 km

(0 - 40,7

23 mile)

A/F S1 HTR (B1)

A/F S1 HTR (B2) Engine: After warming up, idle the engine 4 - 100%

AC PRESS SEN Engine: Idle

Both A/C switch and blower fan switch: ON (Compressor operates.)

1.0 - 4.0V

VHCL SPEED SE Turn drive wheels and compare CONSULT-IIl value with the speedometer

indication. Almost the same speed as the

speedometer indication

SET VHCL SPD Engine: Running ASCD: Operating. The preset vehicle speed is dis-

played.

MAIN SW Ignition switch: ON MAIN switch: Pressed ON

MAIN switch: Released OFF

CANCEL SW Ignition switch: ON CANCEL switch: Pressed ON

CANCEL switch: Released OFF

RESUME/ACC SW Ignition switch: ON RESUME/ACCELERATE switch:

Pressed

ON

RESUME/ACCELERATE switch: Re-

leased OFF

SET SW Ignition switch: ON SET/COAST switch: Pressed ON

SET/COAST switch: Released OFF

DIST SW Ignition switch: ON DISTANCE switch: Pressed ON

DISTANCE switch: Released OFF

BRAKE SW1 Ignition switch: ON Brake pedal: Fully released ON

Brake pedal: Slightly depressed OFF

BRAKE SW2 Ignition switch: ON Brake pedal: Fully released OFF

Brake pedal: Slightly depressed ON

CRUISE LAMP Ignition switch: ON MAIN switch: Pressed at the 1st time

→

at the 2nd time ON

→ OFF

SET LAMP MAIN switch: ON

Vehicle speed: Between 40 km/h

(25 MPH) and 144 km/h (89

MPH) ASCD: Operating ON

ASCD: Not operating OFF

ALT DUTY Engine: Idle 0 - 80%

BAT CUR SEN Engine speed: Idle

Battery: Fully charged*

2

Selector lever: P or N

Air conditioner switch: OFF

No load Approx. 2,600 - 3,500mV

ALT DUTY SIG Power generation voltage variable control: Operating ON

Power generation voltage variable control: Not operating OFF

MONITOR ITEM CONDITION SPECIFICATION

Revision: December 20092009 QX56

Page 2241 of 4171

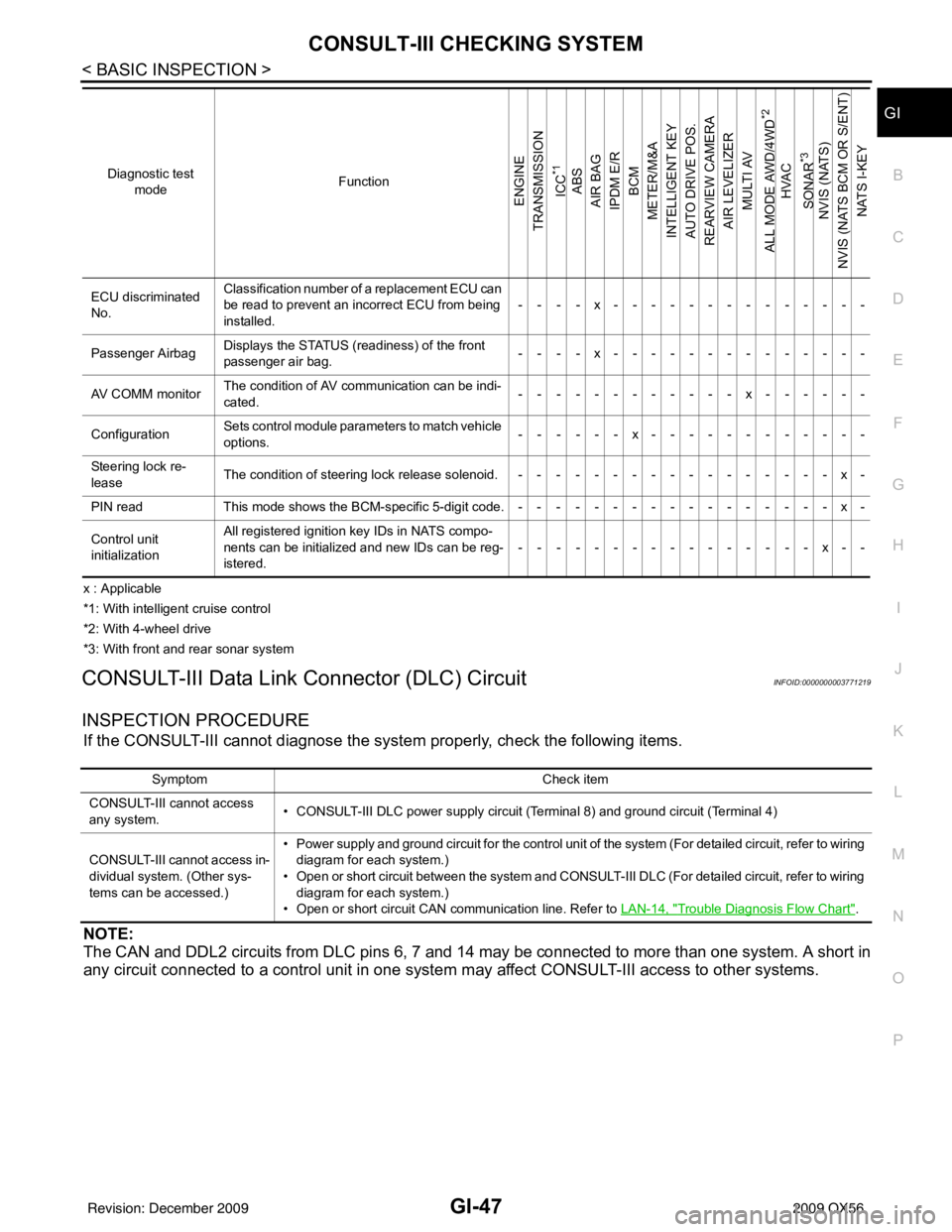

CONSULT-III CHECKING SYSTEMGI-47

< BASIC INSPECTION >

C

DE

F

G H

I

J

K L

M B

GI

N

O P

x : Applicable

*1: With intelligent cruise control

*2: With 4-wheel drive

*3: With front and rear sonar system

CONSULT-III Data Link Connector (DLC) CircuitINFOID:0000000003771219

INSPECTION PROCEDURE

If the CONSULT-III cannot diagnose the sys tem properly, check the following items.

NOTE:

The CAN and DDL2 circuits from DLC pins 6, 7 and 14 may be connected to more than one system. A short in

any circuit connected to a control unit in one system may affect CONSULT-III access to other systems.

ECU discriminated

No.Classification number of a replacement ECU can

be read to prevent an incorrect ECU from being

installed.

----x--------------

Passenger Airbag Displays the STATUS (readiness) of the front

passenger air bag.

----x--------------

AV COMM monitor The condition of AV communication can be indi-

cated. ------------x------

Configuration Sets control module para

meters to match vehicle

options. ------x------------

Steering lock re-

lease The condition of steering lock release solenoid. -----------------x-

PIN read This mode shows the BCM-specific 5-digit code.-----------------x-

Control unit

initialization All registered ignition key IDs in NATS compo-

nents can be initialized and new IDs can be reg-

istered.

----------------x--

Diagnostic test

mode Function

ENGINE

TRANSMISSION

ICC

*1

ABS

AIR BAG

IPDM E/R BCM

METER/M&A

INTELLIGENT KEY

AUTO DRIVE POS.

REARVIEW CAMERA AIR LEVELIZER

MULTI AV

ALL MODE AWD/4WD

*2

HVAC

SONAR

*3

NVIS (NATS)

NVIS (NATS BCM OR S/ENT) NATS I-KEY

Symptom Check item

CONSULT-III cannot access

any system. • CONSULT-III DLC power supply circuit (Terminal 8) and ground circuit (Terminal 4)

CONSULT-III cannot access in-

dividual system. (Other sys-

tems can be accessed.) • Power supply and ground circuit for the control unit of the system (For detailed circuit, refer to wiring

diagram for each system.)

• Open or short circuit between the system and CONSULT-III DLC (For detailed circuit, refer to wiring diagram for each system.)

• Open or short circuit CAN communication line. Refer to LAN-14, "

Trouble Diagnosis Flow Chart".

Revision: December 20092009 QX56

Page 2613 of 4171

![INFINITI QX56 2009 Factory Owners Manual LAN-44

< FUNCTION DIAGNOSIS >[CAN]

CAN COMMUNICATION SYSTEM

FUNCTION DIAGNOSIS

CAN COMMUNICATION SYSTEM

CAN System Specification ChartINFOID:0000000003776453

Determine CAN system type from the followi INFINITI QX56 2009 Factory Owners Manual LAN-44

< FUNCTION DIAGNOSIS >[CAN]

CAN COMMUNICATION SYSTEM

FUNCTION DIAGNOSIS

CAN COMMUNICATION SYSTEM

CAN System Specification ChartINFOID:0000000003776453

Determine CAN system type from the followi](/img/42/57031/w960_57031-2612.png)

LAN-44

< FUNCTION DIAGNOSIS >[CAN]

CAN COMMUNICATION SYSTEM

FUNCTION DIAGNOSIS

CAN COMMUNICATION SYSTEM

CAN System Specification ChartINFOID:0000000003776453

Determine CAN system type from the following specificat

ion chart. Then choose the correct diagnosis sheet.

NOTE:

Refer to LAN-14, "

Trouble Diagnosis Procedure" for how to use CAN system specification chart.

×: Applicable

VEHICLE EQUIPMENT IDENTIFICATION INFORMATION

NOTE:

Check CAN system type from the vehicle shape and equipment.

CAN Communication Signal ChartINFOID:0000000003776454

Refer to LAN-13, "How to Use CAN Communication Signal Chart" for how to use CAN communication signal

chart.

NOTE:

Refer to LAN-36, "

Abbreviation List" for the abbreviations of the connecting units.

T: Transmit R: Receive

Body type Wagon

Axle 2WD4WD

Engine VK56DE

Transmission A/T

Brake control VDC

ICC system ××

CAN system type 1234

Diagnosis sheet LAN-40

LAN-41LAN-42LAN-43

AWMIA0012GB

Signal name/Connecting unitECM

TCM

LASER ICC

ADP

AV

BCM

HVAC I-KEY M&A

STRG 4WDABS

IPDM-E

Accelerator pedal position signal T RR R R

A/C compressor request signal T R

ASCD CRUISE lamp signal T R

ASCD OD cancel request signal T R

ASCD operation signal T R

ASCD SET lamp signal T R

Battery voltage signal T R

Closed throttle position signal T RR

Cooling fan speed request signal T R

Engine coolant temperature signal T RR

Revision: December 20092009 QX56

Page 2784 of 4171

MWI-62

< ECU DIAGNOSIS >

COMBINATION METER

DTC Index

INFOID:0000000003776656

Function Specifications

Speedometer

Zero indication.

Tachometer

Fuel gauge

Engine coolant temperature gauge

Engine oil pressure gauge

Voltage gauge

A/T oil temperature gauge

Illumination control

Meter illumination Change to nighttime mode when communication is lost.

Segment LCD Odometer

Freeze current indication.

A/T position Display turns off.

Buzzer Buzzer turns off.

Warning lamp/indicator lamp ABS warning lamp

Lamp turns on when communication is lost.

Brake warning lamp

VDC OFF indicator lamp

SLIP indicator lamp

A/T CHECK warning lamp

Lamp turns off when communication is lost.

Oil pressure/coolant temperature

warning lamp

Light indicator

Malfunction indicator lamp

Master warning lamp

Air bag warning lamp

High beam indicator

Turn signal indicator lamp

CRUISE indicator lamp

Driver and passenger seat belt warn-

ing lamp

Lamp turns off when disconnected.

Charge warning lamp

Security indicator lamp

4WD indicator lamp

AT P i n d i c a t o r l a m p

CK SUSP warning lamp

Low tire pressure warning lamp

Lamp will flash every second for 1 minute and then stay on con-

tinuously thereafter.

CONSULT-III display

MalfunctionReference

page

CAN COMM CIRC

[U1000] Malfunction is detected in CAN communication.

CAUTION:

Even when there is no malfunction on CAN communication system, malfunction may be

misinterpreted when battery has low voltage (when maintaining 7 - 8 V for about 2 sec-

onds) or 10A fuse [No. 3, located in

the fuse block (J/B)] is disconnected. MWI-28

VEHICLE SPEED

CIRC

[B2205]Malfunction is detected when an erroneous speed signal is input.

CAUTION:

Even when there is no malfunction on speed signal system, malfunction may be misin-

terpreted when battery has lo

w voltage (when maintaining 7 - 8 V for about 2 seconds). MWI-29

Revision: December 20092009 QX56

Page 3652 of 4171

TM-4

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ................................................................

174

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect .................................

174

Precaution for On Board Diagnosis (OBD) System

of A/T and Engine ..................................................

175

Precaution .............................................................175

Service Notice or Precaution .................................176

PREPARATION ..........................................177

PREPARATION .............................................. .177

Special Service Tool ............................................ ..177

Commercial Service Tool ......................................178

ON-VEHICLE MAINTENANCE ..................179

A/T FLUID ....................................................... .179

Checking the A/T Fluid (ATF) .............................. ..179

Changing the A/T Fluid (ATF) ................................181

A/T FLUID COOLER ........................................183

A/T Fluid Cooler Cleaning ................................... ..183

Inspection ..............................................................185

STALL TEST ....................................................186

Inspection and Judgment .................................... ..186

LINE PRESSURE TEST ..................................188

Inspection and Judgment .................................... ..188

ROAD TEST .....................................................190

Description ........................................................... ..190

Check Before Engine Is Started ............................190

Check At Idle .........................................................190

Cruise Test - Part 1 ...............................................191

Cruise Test - Part 2 ...............................................193

Cruise Test - Part 3 ...............................................194

Vehicle Speed When Shifting Gears .....................194

Vehicle Speed When Performing and Releasing

Complete Lock-up .................................................

194

A/T POSITION .................................................195

Adjustment of A/T Position .................................. ..195

Checking of A/T Position .......................................195

ON-VEHICLE REPAIR ............................. ..196

SHIFT CONTROL SYSTEM ........................... .196

A/T Shift Selector Removal and Installation ........ ..196

AIR BREATHER HOSE ...................................197

2WD ........................................................................ ..197

2WD : Removal and Installation ............................197

4WD ........................................................................ ..197

4WD : Removal and Installation ............................197

OIL PAN ...........................................................201

Oil Pan ................................................................. .201

CONTROL VALVE WITH TCM ........................203

Control Valve with TCM and A/T Fluid Tempera-

ture Sensor 2 ....................................................... .

203

REAR OIL SEAL ..............................................212

Rear Oil Seal ........................................................ .212

FLUID COOLER SYSTEM ...............................213

Exploded View ..................................................... .213

Removal and Installation .......................................213

REMOVAL AND INSTALLATION .............214

TRANSMISSION ASSEMBLY ........................ ..214

Removal and Installation (2WD) .......................... .214

Removal and Installation (4WD) ...........................216

DISASSEMBLY AND ASSEMBLY ...........220

OVERHAUL .................................................... ..220

Component .......................................................... .220

Oil Channel ...........................................................227

Location of Adjusting Shims, Needle Bearings,

Thrust Washers and Snap Rings ......................... .

229

DISASSEMBLY .............................................. ..232

Disassembly ......................................................... .232

REPAIR FOR COMPONENT PARTS ..............249

Oil Pump .............................................................. .249

Front Sun Gear, 3rd One-Way Clutch ...................251

Front Carrier, Input Clutch, Rear Internal Gear .....253

Mid Sun Gear, Rear Sun Gear, High and Low Re-

verse Clutch Hub ..................................................

258

High and Low Reverse Clutch ..............................263

Direct Clutch .........................................................265

ASSEMBLY .................................................... ..268

Assembly (1) ........................................................ .268

Adjustment ............................................................281

Assembly (2) .........................................................283

SERVICE DATA AND SPECIFICATIONS

(SDS) ............... ..........................................

290

SERVICE DATA AND SPECIFICATIONS

(SDS) .............................................................. ..

290

General Specification ........................................... .290

Vehicle Speed at Which Gear Shifting Occurs .....290

Vehicle Speed at Which Lock-up Occurs/Releas-

es ..........................................................................

291

Stall Speed ............................................................291

Line Pressure ........................................................291

Input Speed Sensor ..............................................291

Output Speed Sensor ...........................................291

Reverse Brake ......................................................291

Total End Play .......................................................292

Torque Converter .................................................

Revision: December 20092009 QX56

Page 3683 of 4171

DIAGNOSIS SYSTEM (TCM)TM-35

< FUNCTION DIAGNOSIS >

CEF

G H

I

J

K L

M A

B

TM

N

O P

RANGE SW 1 (ON-OFF display) X — X

RANGE SW 2 (ON-OFF display) X — X

RANGE SW 3 (ON-OFF display) X — X

RANGE SW 4 (ON-OFF display) X — X

SLCT LVR POSI — X X Selector lever position is recognized by the TCM.

For fail-safe operation, the specific value used

for control is displayed.

1 POSITION SW (ON-OFF display) X — X 1st position switch

OD CONT SW (ON-OFF display) X — X 4th position switch

POWERSHIFT SW (ON-OFF display) X — X

Not mounted but displayed.

HOLD SW (ON-OFF display) X — X

MANU MODE SW (ON-OFF display) X — X

NON M-MODE SW (ON-OFF display) X — X

UP SW LEVER (ON-OFF display) X — X

DOWN SW LEVER (ON-OFF display) X — X

SFT UP ST SW (ON-OFF display) — — X

SFT DWN ST SW (ON-OFF display) — — X

ASCD-OD CUT (ON-OFF display) — — X

ASCD-CRUISE (ON-OFF display) — — X

ABS SIGNAL (ON-OFF display) — — X

ACC OD CUT (ON-OFF display) — — X

ICC (Intelligent cruise control)

ACC SIGNAL (ON-OFF display) — — X

TCS GR/P KEEP (ON-OFF display) — — X

TCS SIGNAL 2 (ON-OFF display) — — X

TCS SIGNAL 1 (ON-OFF display) — — X

TCC SOLENOID (A) — X X

LINE PRES SOL (A) — X X

I/C SOLENOID (A) — X X

FR/B SOLENOID (A) — X X

D/C SOLENOID (A) — X X

HLR/C SOL (A) — X X

ON OFF SOL (ON-OFF display) — — X LC/B solenoid

TCC SOL MON (A) — — X

L/P SOL MON (A) — — X

I/C SOL MON (A) — — X

FR/B SOL MON (A) — — X

D/C SOL MON (A) — — X

HLR/C SOL MON (A) — — X

ONOFF SOL MON (ON-OFF display) — — X LC/B solenoid

P POSI IND (ON-OFF display) — — X

R POSI IND (ON-OFF display) — — X

N POSI IND (ON-OFF display) — — X Monitored item (Unit)

Monitor Item Selection

Remarks

ECU IN-

PUT SIG- NALS MAIN SIG-

NALS SELEC-

TION

FROM

MENU

Revision: December 20092009 QX56

Page 3777 of 4171

SYSTEM SYMPTOMTM-129

< SYMPTOM DIAGNOSIS >

CEF

G H

I

J

K L

M A

B

TM

N

O P

Vehicle Cannot Be Started from D1INFOID:0000000003771998

SYMPTOM:

Vehicle cannot be started from D1 on cruise test - Part 1.

DIAGNOSTIC PROCEDURE

1.CONFIRM THE SYMPTOM

Check if vehicle creeps in “R” position.

OK or NG

OK >> GO TO 2.

NG >> Refer to TM-124, "Vehicle Does Not Creep Backward in "R" Position"

.

2.CHECK SELF-DIAGNOSTIC RESULTS

Perform self-diagnosis. Refer to TM-32, "CONSULT-III Function (TRANSMISSION)"

.

Is any malfunction detected by self-diagnostic results?

YES >> Check the malfunctioning system.

NO >> GO TO 3.

3.CHECK ACCELERATOR PEDA L POSITION(APP) SENSOR

Check accelerator pedal position (APP) sensor. Refer to TM-70, "Diagnosis Procedure"

.

OK or NG

OK >> GO TO 4.

NG >> Repair or replace accelerator pedal position (APP) sensor.

4.CHECK A/T FLUID LEVEL

Check A/T fluid level. Refer to TM-179, "Checking the A/T Fluid

(ATF)".

OK or NG

OK >> GO TO 5.

NG >> Refill ATF.

5.CHECK LINE PRESSURE

Check line pressure at the engine stall point. Refer to TM-188,

"Inspection and Judgment".

OK or NG

OK >> GO TO 8.

NG - 1 >> Line pressure high. GO TO 6.

NG - 2 >> Line pressure low. GO TO 7.

6.DETECT MALFUNCTIONING ITEM

1. Check control valve with TCM. Refer to TM-203, "Control Valve with TCM and A/T Fluid Temperature Sen-

sor 2".

2. Disassemble A/T. Refer to TM-232, "Disassembly"

.

3. Check the following items:

- Oil pump assembly. Refer to TM-249, "Oil Pump"

.

OK or NG

SAT638A

SAT494G

Revision: December 20092009 QX56

Page 3778 of 4171

TM-130

< SYMPTOM DIAGNOSIS >

SYSTEM SYMPTOM

OK >> GO TO 8.

NG >> Repair or replace damaged parts.

7.DETECT MALFUNCTIONING ITEM

1. Check control valve with TCM. Refer to TM-203, "Control Valve with TCM and A/T Fluid Temperature Sen-

sor 2".

2. Disassemble A/T. Refer to TM-232, "Disassembly"

.

3. Check the following items:

- Oil pump assembly. Refer to TM-249, "Oil Pump"

.

- Power train system. Refer to TM-232, "Disassembly"

.

- Transmission case. Refer to TM-232, "Disassembly"

.

OK or NG

OK >> GO TO 8.

NG >> Repair or replace damaged parts.

8.CHECK A/T FLUID CONDITION

1. Remove oil pan. Refer to TM-201, "Oil Pan"

.

2. Check A/T fluid condition. Refer to TM-179, "Checking the A/T

Fluid (ATF)".

OK or NG

OK >> GO TO 9.

NG >> GO TO 12.

9.DETECT MALFUNCTIONING ITEM

Check the malfunction items. If any items are dam aged, repair or replace damaged parts. Refer to TM-152,

"Symptom Table" (Symptom No.23).

OK or NG

OK >> GO TO 10.

NG >> Repair or replace damaged parts.

10.CHECK SYMPTOM

Check again. Refer to TM-191, "Cruise Test - Part 1"

, TM-193, "Cruise Test - Part 2".

OK or NG

OK >> INSPECTION END

NG >> GO TO 11.

11 .PERFORM TCM INSPECTION

1. Perform TCM input/output signals inspection. Refer to TM-104, "Reference Value"

.

2. If NG, recheck A/T assembly harness connector terminals for damage or loose connection with harness

connector.

OK or NG

OK >> INSPECTION END

NG >> Repair or replace damaged parts.

12.DETECT MALFUNCTIONING ITEM

Check the malfunction items. If any items are dam aged, repair or replace damaged parts. Refer to TM-152,

"Symptom Table" (Symptom No.23).

OK or NG

OK >> GO TO 10.

NG >> Repair or replace damaged parts.

SCIA5199E

Revision: December 20092009 QX56

Page 3780 of 4171

TM-132

< SYMPTOM DIAGNOSIS >

SYSTEM SYMPTOM

1. Check control valve with TCM. Refer to TM-203, "Control Valve with TCM and A/T Fluid Temperature Sen-

sor 2".

2. Disassemble A/T. Refer to TM-232, "Disassembly"

.

3. Check the following items:

- Oil pump assembly. Refer to TM-249, "Oil Pump"

.

- Power train system. Refer to TM-232, "Disassembly"

.

- Transmission case. Refer to TM-232, "Disassembly"

.

OK or NG

OK >> GO TO 7.

NG >> Repair or replace damaged parts.

7.CHECK A/T FLUID CONDITION

1. Remove oil pan. Refer to TM-201, "Oil Pan"

.

2. Check A/T fluid condition. Refer to TM-179, "Checking the A/T

Fluid (ATF)".

OK or NG

OK >> GO TO 8.

NG >> GO TO 11.

8.DETECT MALFUNCTIONING ITEM

Check the malfunction items. If any items are dam aged, repair or replace damaged parts. Refer to TM-152,

"Symptom Table" (Symptom No.10).

OK or NG

OK >> GO TO 9.

NG >> Repair or replace damaged parts.

9.CHECK SYMPTOM

Check again. Refer to TM-191, "Cruise Test - Part 1"

, TM-193, "Cruise Test - Part 2", TM-194, "Cruise Test -

Part 3"

OK or NG

OK >> INSPECTION END

NG >> GO TO 10.

10.PERFORM TCM INSPECTION

1. Perform TCM input/output signals inspection. Refer to TM-104, "Reference Value"

.

2. If NG, recheck A/T assembly harness connector terminals for damage or loose connection with harness

connector.

OK or NG

OK >> INSPECTION END

NG >> Repair or replace damaged parts.

11 .DETECT MALFUNCTIONING ITEM

Check the malfunction items. If any items are dam aged, repair or replace damaged parts. Refer to TM-152,

"Symptom Table" (Symptom No.10).

OK or NG

OK >> GO TO 9.

NG >> Repair or replace damaged parts.

A/T Does Not Shift: D2 →D3INFOID:0000000003772000

SYMPTOM:

The vehicle does not shift-up from D2 to D3 gear at the specified speed.

SCIA5199E

Revision: December 20092009 QX56