wiring INFINITI QX56 2009 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2009, Model line: QX56, Model: INFINITI QX56 2009Pages: 4171, PDF Size: 84.65 MB

Page 3630 of 4171

STR-1

ENGINE

C

DE

F

G H

I

J

K L

M

SECTION STR

A

STR

N

O P

CONTENTS

STARTING SYSTEM

PRECAUTION ....... ........................................2

PRECAUTIONS .............................................. .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

2

Precaution for Power Generation Variable Voltage

Control System ..........................................................

3

PREPARATION ............................................4

PREPARATION .............................................. .....4

Special Service Tool ........................................... ......4

Commercial Service Tool ..........................................4

BASIC INSPECTION ....................................5

DIAGNOSIS AND REPAIR WORKFLOW ..... .....5

Work Flow ........................................................... ......5

FUNCTION DIAGNOSIS ...............................8

STARTING SYSTEM ...................................... .....8

System Diagram .................................................. ......8

System Description ...................................................8

Component Parts Location ........................................8

Component Description ............................................9

COMPONENT DIAGNOSIS .........................10

B TERMINAL CIRCUIT .....................................10

Description ........................................................... ....10

Diagnosis Procedure ...............................................10

S CONNECTOR CIRCUIT .................................11

Description ...............................................................11

Diagnosis Procedure ...............................................11

STARTING SYSTEM .........................................12

Wiring Diagram .................................................... ....12

SYMPTOM DIAGNOSIS ..............................17

STARTING SYSTEM .........................................17

Symptom Table ................................................... ....17

ON-VEHICLE REPAIR .................................18

STARTER MOTOR ...........................................18

Removal and Installation ..................................... ....18

SERVICE DATA AND SPECIFICATIONS

(SDS) ............... .......................................... ...

19

STARTER MOTOR ...........................................19

Starter .................................................................. ....19

Revision: December 20092009 QX56

Page 3631 of 4171

STR-2

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005856238

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SR and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution Necessary for Steering W heel Rotation After Battery Disconnect

INFOID:0000000005856245

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecting both battery cables with the ignition knob in the

″LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS, an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be rotated.

4. Perform the necessary repair operation.

Revision: December 20092009 QX56

Page 3641 of 4171

STR-12

< COMPONENT DIAGNOSIS >

STARTING SYSTEM

STARTING SYSTEM

Wiring DiagramINFOID:0000000003771796

ABBWA0004GB

Revision: December 20092009 QX56

Page 3651 of 4171

TM-3

CEF

G H

I

J

K L

M A

B

TM

N

O P

Diagnosis Procedure ...........................................

....

78

P1752 INPUT CLUTCH SOLENOID ..................80

Description .......................................................... ....80

CONSULT-III Reference Value in Data Monitor

Mode ................................................................... ....

80

On Board Diagnosis Logic ......................................80

Possible Cause .......................................................80

DTC Confirmation Procedure ..................................80

Diagnosis Procedure ...............................................80

P1757 FRONT BRAKE SOLENOID ...................82

Description .......................................................... ....82

CONSULT-III Reference Value in Data Monitor

Mode ................................................................... ....

82

On Board Diagnosis Logic ......................................82

Possible Cause .......................................................82

DTC Confirmation Procedure ..................................82

Diagnosis Procedure ...............................................82

P1762 DIRECT CLUTCH SOLENOID ................84

Description .......................................................... ....84

CONSULT-III Reference Value in Data Monitor

Mode ................................................................... ....

84

On Board Diagnosis Logic ......................................84

Possible Cause .......................................................84

DTC Confirmation Procedure ..................................84

Diagnosis Procedure ...............................................84

P1767 HIGH AND LOW REVERSE CLUTCH

SOLENOID .........................................................

86

Description .......................................................... ....86

CONSULT-III Reference Value in Data Monitor

Mode ................................................................... ....

86

On Board Diagnosis Logic ......................................86

Possible Cause .......................................................86

DTC Confirmation Procedure ..................................86

Diagnosis Procedure ...............................................86

P1772 LOW COAST BRAKE SOLENOID .........88

Description .......................................................... ....88

CONSULT-III Reference Value in Data Monitor

Mode ................................................................... ....

88

On Board Diagnosis Logic ......................................88

Possible Cause .......................................................88

DTC Confirmation Procedure ..................................88

Diagnosis Procedure ...............................................88

P1774 LOW COAST BRAKE SOLENOID .........90

Description .......................................................... ....90

CONSULT-III Reference Value in Data Monitor

Mode ................................................................... ....

90

On Board Diagnosis Logic ......................................90

Possible Cause .......................................................90

DTC Confirmation Procedure ..................................90

Diagnosis Procedure ...............................................90

MAIN POWER SUPPLY AND GROUND CIR-

CUIT ....................................................................

92

Diagnosis Procedure ........................................... ....92

CLOSED THROTTLE POSITION AND WIDE

OPEN THROTTLE POSITION CIRCUIT ...........

94

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... ....

94

Diagnosis Procedure ...............................................94

BRAKE SIGNAL CIRCUIT ................................95

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... ....

95

Diagnosis Procedure ...............................................95

TOW MODE SWITCH .......................................96

Description ...............................................................96

Diagnosis Procedure ...............................................96

A/T SHIFT LOCK SYSTEM ...............................97

Wiring Diagram - A/T Shift Lock System .................97

Terminals And Reference Values ..........................101

Component Description .........................................101

ECU DIAGNOSIS .......................................104

TCM .................................................................104

Reference Value .................................................. ..104

Wiring Diagram — A/T CONTROL SYSTEM — .. ..106

Fail-Safe .............................................................. ..115

DTC Inspection Priority Chart ................................117

DTC No. Index .......................................................117

DTC Alphabetical Index .........................................118

SYMPTOM DIAGNOSIS ............................119

SYSTEM SYMPTOM .......................................119

A/T Check Indicator Lamp Does Not Come On ... ..119

Engine Cannot Be Started in "P" or "N" Position ...119

In "P" Position, Vehicle Moves When Pushed .......120

In "N" Position, Vehicle Moves ..............................120

Large Shock("N" to "D" Position) ...........................122

Vehicle Does Not Creep Backward in "R" Position ..124

Vehicle Does Not Creep Forward in "D" Position ..126

Vehicle Cannot Be Started from D1 ......................129

A/T Does Not Shift: D1ÆD2 ..................................131

A/T Does Not Shift: D2ÆD3 ..................................132

A/T Does Not Shift: D3ÆD4 ..................................134

A/T Does Not Shift: D4ÆD5 ..................................136

A/T Does Not Perform Lock-up .............................138

A/T Does Not Hold Lock-up Condition ...................140

Lock-up Is Not Released .......................................141

Engine Speed Does Not Return to Idle .................142

A/T Does Not Shift: 5GR Æ 4GR ..........................143

A/T Does Not Shift: 4GR Æ 3GR ..........................145

A/T Does Not Shift: 3GR Æ 2GR ..........................147

A/T Does Not Shift: 2GR Æ 1GR ..........................148

Vehicle Does Not Decelerate By Engine Brake .....150

Symptom Table .....................................................152

PRECAUTION ............................................174

PRECAUTIONS ...............................................174

Revision: December 20092009 QX56

Page 3653 of 4171

DIAGNOSIS AND REPAIR WORKFLOWTM-5

< BASIC INSPECTION >

CEF

G H

I

J

K L

M A

B

TM

N

O P

BASIC INSPECTION

DIAGNOSIS AND REPAIR WORKFLOW

Work FlowINFOID:0000000003771803

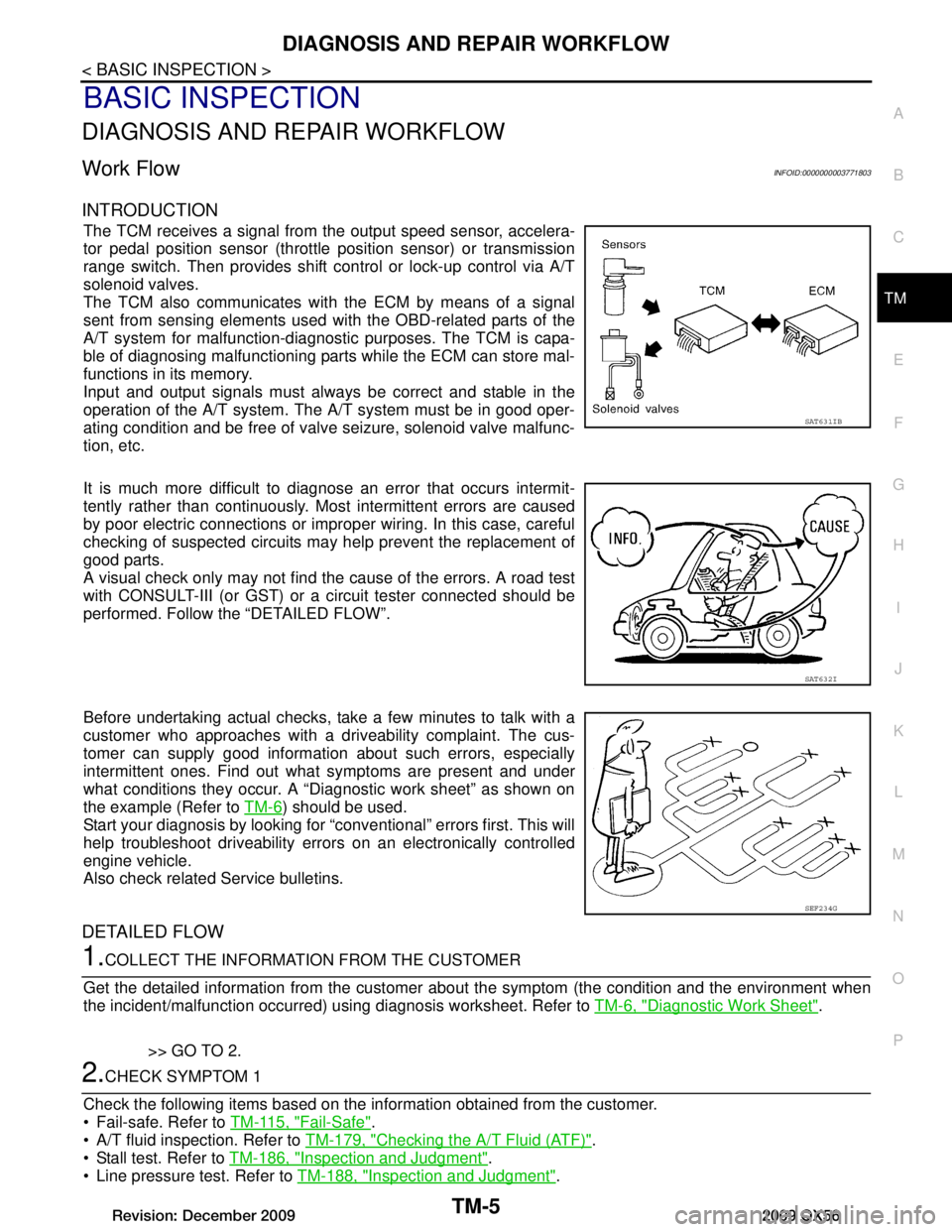

INTRODUCTION

The TCM receives a signal from the output speed sensor, accelera-

tor pedal position sensor (throttle position sensor) or transmission

range switch. Then provides shift c ontrol or lock-up control via A/T

solenoid valves.

The TCM also communicates with the ECM by means of a signal

sent from sensing elements used wit h the OBD-related parts of the

A/T system for malfunction-diagnostic purposes. The TCM is capa-

ble of diagnosing malfunctioning parts while the ECM can store mal-

functions in its memory.

Input and output signals must always be correct and stable in the

operation of the A/T system. T he A/T system must be in good oper-

ating condition and be free of valve seizure, solenoid valve malfunc-

tion, etc.

It is much more difficult to diagnose an error that occurs intermit-

tently rather than continuously. Most intermittent errors are caused

by poor electric connections or impr oper wiring. In this case, careful

checking of suspected circuits may help prevent the replacement of

good parts.

A visual check only may not find t he cause of the errors. A road test

with CONSULT-III (or GST) or a circuit tester connected should be

performed. Follow the “DETAILED FLOW”.

Before undertaking actual checks, take a few minutes to talk with a

customer who approaches with a driveability complaint. The cus-

tomer can supply good information about such errors, especially

intermittent ones. Find out what symptoms are present and under

what conditions they occur. A “Diagnostic work sheet” as shown on

the example (Refer to TM-6

) should be used.

Start your diagnosis by looking for “conventional” errors first. This will

help troubleshoot driveability errors on an electronically controlled

engine vehicle.

Also check related Service bulletins.

DETAILED FLOW

1.COLLECT THE INFORMATION FROM THE CUSTOMER

Get the detailed information from the customer about the symptom (the condition and the environment when

the incident/malfunction occurred) using diagnosis worksheet. Refer to TM-6, "Diagnostic Work Sheet"

.

>> GO TO 2.

2.CHECK SYMPTOM 1

Check the following items based on the in formation obtained from the customer.

Fail-safe. Refer to TM-115, "Fail-Safe"

.

A/T fluid inspection. Refer to TM-179, "Checking the A/T Fluid (ATF)"

.

Stall test. Refer to TM-186, "Inspection and Judgment"

.

Line pressure test. Refer to TM-188, "Inspection and Judgment"

.

SAT631IB

SAT632I

SEF234G

Revision: December 20092009 QX56

Page 3669 of 4171

A/T CONTROL SYSTEMTM-21

< FUNCTION DIAGNOSIS >

CEF

G H

I

J

K L

M A

B

TM

N

O P

CONTROL SYSTEM DIAGRAM

CAN CommunicationINFOID:0000000003771809

SYSTEM DESCRIPTION

CAN (Controller Area Network) is a serial communication li ne for real time application. It is an on-vehicle mul-

tiplex communication line with high data communication speed and excellent error detection ability. Many elec-

tronic control units are equipped onto a vehicle, and each control unit shares information and links with other

control units during operation (not independent). In CAN communication, control units are connected with 2

communication lines (CAN H line, CAN L line) allowing a high rate of information transmission with less wiring.

Each control unit transmits/receives data but selectively reads required data only. For details, refer to LAN-4,

"System Description".

SENSORS (or SIGNALS)

⇒TCM

⇒ACTUATORS

Transmission range switch

Accelerator pedal position sensor

Closed throttle position signal

Wide open throttle position signal

Engine speed signal

A/T fluid temperature sensor

Output speed sensor

Vehicle speed signal

Stop lamp switch signal

Input speed sensor

1st position switch signal

4th position switch signal

ATF pressure switch 2 signal

Tow mode switch signal Shift control

Line pressure control

Lock-up control

Engine brake control

Timing control

Fail-safe control

Self-diagnosis

CONSULT-III co

mmunication

line

Duet-EA control

CAN system Input clutch solenoid valve

Direct clutch solenoid valve

Front brake solenoid valve

High and low reverse clutch sole-

noid valve

Low coast brake solenoid valve

Torque converter clutch solenoid

valve

Line pressure solenoid valve

A/T CHECK indicator lamp

Starter relay

Back-up lamp relay

JSDIA1315GB

Revision: December 20092009 QX56

Page 3687 of 4171

U1000 CAN COMM CIRCUITTM-39

< COMPONENT DIAGNOSIS >

CEF

G H

I

J

K L

M A

B

TM

N

O P

COMPONENT DIAGNOSIS

U1000 CAN COMM CIRCUIT

DescriptionINFOID:0000000003771825

CAN (Controller Area Network) is a serial communication li ne for real time application. It is an on-vehicle mul-

tiplex communication line with high data communica tion speed and excellent malfunction detection ability.

Many electronic control units are equipped onto a vehicl e, and each control unit shares information and links

with other control units during operation (not independent ). In CAN communication, control units are con-

nected with 2 communication lines (CAN H line, CAN L li ne) allowing a high rate of information transmission

with less wiring. Each control unit transmits/recei ves data but selectively reads required data only.

On Board Diagnosis LogicINFOID:0000000003771826

This is an OBD-III self-diagnostic item.

Diagnostic trouble code “U1000” with CONSULT-III is detected when TCM cannot communicate to other

control units.

Possible CauseINFOID:0000000003771827

Harness or connectors

(CAN communication line is open or shorted.)

DTC Confirmation ProcedureINFOID:0000000003771828

NOTE:

If “DTC Confirmation Procedure” has been previously performed, always turn ignition switch “OFF”

and wait at least 10 seconds before performing the next test.

After the repair, perform the following procedure to confirm the malfunction is eliminated.

WITH CONSULT-III

1. Turn ignition switch “ON”. (Do not start engine.)

2. Select “DATA MONITOR” mode for “ENGINE” with CONSULT-III.

3. Start engine and wait for at least 6 seconds.

4. If DTC is detected, go to TM-39, "Diagnosis Procedure"

.

WITH GST

Follow the procedure “WITH CONSULT-III”.

Diagnosis ProcedureINFOID:0000000003771829

1.CHECK CAN COMMUNICATION CIRCUIT

With CONSULT-III1. Turn ignition switch “ON” and start engine.

2. Select “SELF-DIAG RESULTS” mode for “TRANSMISSION” with CONSULT-III.

Is any malfunction of the

“CAN COMM CIRCUIT” indicated?

YES >> Go to LAN section. Refer to LAN-14, "Trouble Diagnosis Flow Chart".

NO >> INSPECTION END

Revision: December 20092009 QX56

Page 3745 of 4171

A/T SHIFT LOCK SYSTEMTM-97

< COMPONENT DIAGNOSIS >

CEF

G H

I

J

K L

M A

B

TM

N

O P

A/T SHIFT LOCK SYSTEM

Wiring Diagram - A/ T Shift Lock SystemINFOID:0000000003771982

AADWA0090GB

Revision: December 20092009 QX56

Page 3754 of 4171

TM-106

< ECU DIAGNOSIS >

TCM

Wiring Diagram —A/T CONTROL SYSTEM —

INFOID:0000000003771986

AADWA0088GB

Revision: December 20092009 QX56

Page 3822 of 4171

TM-174

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005880175

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SR and SB section of this Service Man-

ual.

WARNING:

To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISS AN/INFINITI dealer.

Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution Necessary for Steering W heel Rotation After Battery Disconnect

INFOID:0000000005880176

NOTE:

This Procedure is applied only to models with Intelli gent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

Remove and install all control units after disconnecting both battery cables with the ignition knob in the

″LOCK ″ position.

Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS, an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be

rotated.

4. Perform the necessary repair operation.

Revision: December 20092009 QX56