200 INFINITI QX56 2009 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2009, Model line: QX56, Model: INFINITI QX56 2009Pages: 4171, PDF Size: 84.65 MB

Page 3974 of 4171

VTL-34

< ON-VEHICLE REPAIR >

DUCTS AND GRILLES

REAR OVERHEAD DUCTS

Removal

1. Remove the luggage side finisher lower RH. Refer to INT-19, "Removal and Installation".

2. Remove the headliner. Refer to INT-17, "

Removal and Installation".

NOTE:

The rear headliner duct connected to the rear overhead duct is part of the headlining trim panel and is

replaced as an assembly.

3. Remove the two bolts and remove the rear upper and lower overhead ducts.

Installation

Installation is in the reverse order of removal.

REAR FLOOR DUCT

Removal

1. Remove the luggage side finisher lower RH. Refer to INT-19, "Removal and Installation".

2. Reposition the floor carpet out of the way.

3. Remove the two bolts and remove the rear floor duct.

Installation

Installation is in the reverse order of removal.

GRILLES

Removal

1. Remove the interior trim panels as necessary. Refer to IP-13, "Removal and Installation" or INT-14,

"Removal and Installation".

2. Remove the grille from the interior trim panel. NOTE:

To remove the rear roof console grilles, turn the gr ille counter-clockwise to release the grille from the rear

roof console.

Installation

Installation is in the reverse order of removal.

Revision: December 20092009 QX56

Page 3975 of 4171

REFRIGERANT LINESVTL-35

< ON-VEHICLE REPAIR >

C

DE

F

G H

J

K L

M A

B

VTL

N

O P

REFRIGERANT LINES

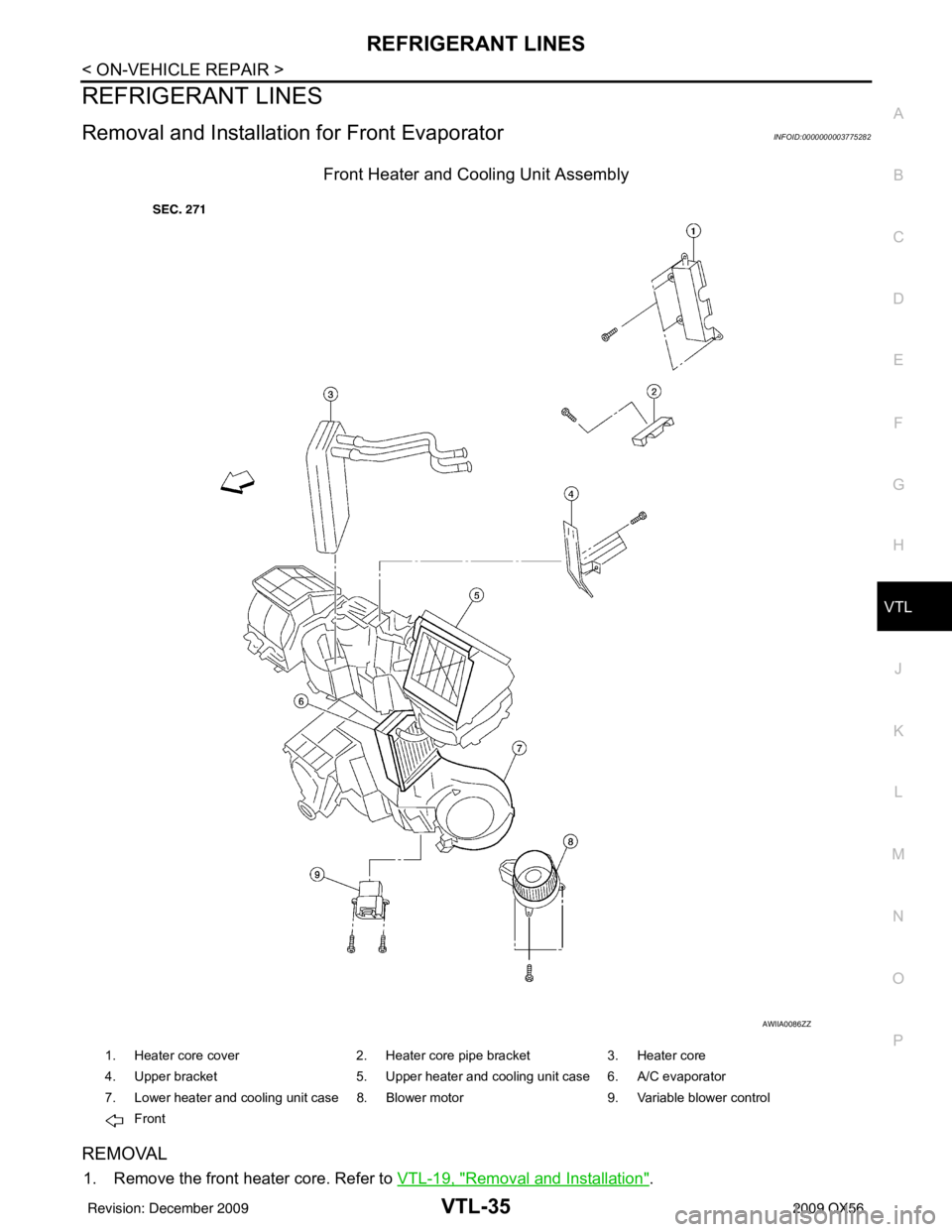

Removal and Installation for Front EvaporatorINFOID:0000000003775282

Front Heater and Cooling Unit Assembly

REMOVAL

1. Remove the front heater core. Refer to VTL-19, "Removal and Installation".

AWIIA0086ZZ

1. Heater core cover 2. Heater core pipe bracket3. Heater core

4. Upper bracket 5. Upper heater and cooling unit case 6. A/C evaporator

7. Lower heater and cooling unit case 8. Blower motor 9. Variable blower control

Front

Revision: December 20092009 QX56

Page 3976 of 4171

VTL-36

< ON-VEHICLE REPAIR >

REFRIGERANT LINES

2. Remove the defroster mode door arm.

3. Separate the heater core and cooling unit case.

4. Remove the evaporator.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• Replace the O-rings on the A/C refrigerant pipes with new ones, then apply compressor oil to them

when installing them.

• After charging the refrigerant, check for leaks.

Removal and Installation for Rear EvaporatorINFOID:0000000003775283

Rear Heater and Cooling Unit Assembly

AWIIA0087ZZ

1. Front cover 2. Evaporator and heater core case 3. Evaporator

4. Side cover 5. Heater core6. Blower motor

7. Blower motor case 8. Variable blower control

Front

Revision: December 20092009 QX56

Page 3977 of 4171

REFRIGERANT LINESVTL-37

< ON-VEHICLE REPAIR >

C

DE

F

G H

J

K L

M A

B

VTL

N

O P

REMOVAL

1. Remove the rear heater and cooling unit assembly from the vehicle. Refer to VTL-16, "Removal and

Installation".

2. Remove the blower motor.

3. Remove the variable blower control.

4. Remove the air mix door motor.

5. Remove the mode door motor.

6. Remove the rear duct and mode door assembly. Refer to VTL-33, "

Removal and Installation".

7. Disassemble the rear heater and cooling unit assembly to remove the evaporator.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• Replace the O-rings on the rear A/C pipes with new ones. Apply compressor oil to the O-rings when installing them.

• After charging the refrigerant, check for leaks.

Removal and Installation for Rear Expansion ValveINFOID:0000000003775284

REMOVAL

1. Discharge the refrigerant. Refer to HA-20, "HFC-134a (R-134a) Service Procedure".

2. Remove the luggage side finisher lower (RH). Refer to INT-19, "

Removal and Installation".

3. Disconnect the A/C refrigerant pi pes from the expansion valve.

CAUTION:

Cap or wrap the A/C refrigerant pipe ends with a suitable material such as vinyl tape to avoid the

entry of air and contaminants.

4. Remove the expansion valve.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• Replace the O-rings on the A/C refrigerant pipes with new ones, th en apply compressor oil to them

when installing them.

• After charging the refrigerant, check for leaks. Expansion valve bolts : 4 N·m (0.41 kg-m, 35 in-lb)

A/C refrigerant pipe to expansion valve bolt : Refer to HA-29, "

Component".

Revision: December 20092009 QX56

Page 3978 of 4171

WCS

WCS-1

DRIVER INFORMATION & MULTIMEDIA

C

DE

F

G H

I

J

K L

M B

SECTION WCS

A

O P

CONTENTS

WARNING CHIME SYSTEM

BASIC INSPECTION ....... .............................3

DIAGNOSIS AND REPAIR WORKFLOW ..... .....3

Work Flow ........................................................... ......3

FUNCTION DIAGNOSIS ...............................4

WARNING CHIME SYSTEM .......................... .....4

WARNING CHIME SYSTEM .......................................4

WARNING CHIME SYSTEM : System Diagram . ......4

WARNING CHIME SYSTEM : System Description

......

4

WARNING CHIME SYSTEM : Component Parts

Location ............................................................... ......

5

WARNING CHIME SYSTEM : Component De-

scription .....................................................................

5

LIGHT REMINDER WARNING CHIME ................. ......6

LIGHT REMINDER WARNING CHIME : System

Diagram .....................................................................

6

LIGHT REMINDER WARNING CHIME : System

Description ................................................................

6

LIGHT REMINDER WARNING CHIME : Compo-

nent Parts Location ...................................................

7

LIGHT REMINDER WARNING CHIME : Compo-

nent Description ........................................................

7

SEAT BELT WARNING CHIME ............................ ......7

SEAT BELT WARNING CHIME : System Diagram

......

8

SEAT BELT WARNING CHIME : System Descrip-

tion ...................................................................... ......

8

SEAT BELT WARNING CHIME : Component

Parts Location ...........................................................

9

SEAT BELT WARNING CHIME : Component De-

scription .....................................................................

9

KEY WARNING CHIME ......................................... ....10

KEY WARNING CHIME : System Diagram ............10

KEY WARNING CHIME : System Description ........10

KEY WARNING CHIME : Component Parts Loca-

tion ....................................................................... ....

11

KEY WARNING CHIME : Component Description ....11

DIAGNOSIS SYSTEM (METER) .......................12

CONSULT-III Function (METER/M&A) ....................12

DIAGNOSIS SYSTEM (BCM) ...........................14

BUZZER ................................................................. ....14

BUZZER : CONSULT-III Function (BCM - BUZZ-

ER) ..........................................................................

14

COMPONENT DIAGNOSIS .........................15

POWER SUPPLY AND GROUND CIRCUIT ....15

COMBINATION METER ........................................ ....15

COMBINATION METER : Diagnosis Procedure .....15

COMBINATION METER : Diagnosis Procedure .....16

BCM (BODY CONTROL MODULE) ...................... ....16

BCM (BODY CONTROL MODULE) : Diagnosis

Procedure ............................................................ ....

16

METER BUZZER CIRCUIT ...............................18

Description ...............................................................18

Component Function Check ....................................18

Diagnosis Procedure ..............................................18

SEAT BELT BUCKLE SWITCH SIGNAL CIR-

CUIT ..................................................................

19

Description ...............................................................19

Component Function Check ..................................19

Diagnosis Procedure ..............................................19

Component Inspection .............................................20

KEY SWITCH SIGNAL CIRCUIT ......................21

Description ...............................................................21

Component Function Check ..................................21

Diagnosis Procedure ..............................................21

Component Inspection .............................................22

Revision: December 20092009 QX56

Page 3979 of 4171

WCS-2

WARNING CHIME SYSTEM .............................23

Wiring Diagram .................................................... ...23

ECU DIAGNOSIS ..................................... ...28

COMBINATION METER ................................. ...28

Reference Value .................................................. ...28

Wiring Diagram .......................................................30

Fail Safe .................................................................46

DTC Index ..............................................................47

BCM (BODY CONTROL MODULE) ..................49

Reference Value .................................................. ...49

Terminal Layout ......................................................51

Physical Values ......................................................51

Wiring Diagram .......................................................57

SYMPTOM DIAGNOSIS .............................62

THE LIGHT REMINDER WARNING DOES

NOT SOUND ................................................... ...

62

Description ........................................................... ...62

Diagnosis Procedure ...............................................62

THE SEAT BELT WARNING CONTINUES

SOUNDING, OR DOES NOT SOUND ...............

63

Description ........................................................... ...63

Diagnosis Procedure ...............................................63

THE KEY WARNING DOES NOT SOUND .......64

Description ........................................................... ...64

Diagnosis Procedure ...............................................64

PRECAUTION ............................................65

PRECAUTIONS .............................................. ...65

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" .............................................................. ...

65

Revision: December 20092009 QX56

Page 3980 of 4171

WCS

DIAGNOSIS AND REPAIR WORKFLOWWCS-3

< BASIC INSPECTION >

C

DE

F

G H

I

J

K L

M B A

O P

BASIC INSPECTION

DIAGNOSIS AND REPAIR WORKFLOW

Work FlowINFOID:0000000003776687

DETAILED FLOW

1.OBTAIN INFORMATION ABOUT SYMPTOM

Interview the customer to obtain as much informa tion as possible about the conditions and environment under

which the malfunction occurred.

>> GO TO 2

2.CHECK SYMPTOM

• Check the symptom based on the information obtained from the customer.

• Check to see if any other malfunctions are present.

>> GO TO 3

3.CHECK CONSULT-III SELF -DIAGNOSIS RESULTS

Connect CONSULT-III and perform “SELF-DIAGNOSIS”. Refer to MWI-25, "

CONSULT-III Function (METER/

M&A)".

Are self-diagnosis results normal?

YES >> GO TO 4

NO >> Repair or replace the malfunctioning parts, GO TO 5

4.NARROW DOWN MALFUNCTIONING PART S THROUGH SYMPTOM DIAGNOSIS

Perform symptom diagnosis and repair or r eplace the identified malfunctioning parts.

>> GO TO 5

5.FINAL CHECK

Check that the warning buzzer in the combination meter operates normally.

Does it operate normally?

YES >> Inspection End.

NO >> GO TO 1

Revision: December 20092009 QX56

Page 3981 of 4171

WCS-4

< FUNCTION DIAGNOSIS >

WARNING CHIME SYSTEM

FUNCTION DIAGNOSIS

WARNING CHIME SYSTEM

WARNING CHIME SYSTEM

WARNING CHIME SYSTEM : System DiagramINFOID:0000000003776688

WARNING CHIME SYSTEM : System DescriptionINFOID:0000000003776689

COMBINATION METER

• The buzzer for warning chime system is installed in the combination meter.

• The buzzer sounds when the combination meter receives a buzzer output signal from each unit.

BCM

BCM receives signals from various units and transmits a buzzer output signal to the combination meter with

CAN communication line if it judges that the warning buzzer should be activated.

BCM warning function list

AWNIA0210GB

Warning functions Signal name

Light reminder warning chime • Lighting switch position signal

• Door switch signal

Seat belt warning chime Seat belt buckle switch signal

Key warning chime • Key switch signal

• Door switch signal

Revision: December 20092009 QX56

Page 3982 of 4171

WCS

WARNING CHIME SYSTEMWCS-5

< FUNCTION DIAGNOSIS >

C

DE

F

G H

I

J

K L

M B A

O P

WARNING CHIME SYSTEM : Component Parts LocationINFOID:0000000003776690

WARNING CHIME SYSTEM : Component DescriptionINFOID:0000000003776691

AWNIA0211ZZ

1. Combination meter M23, M24 2. Combination switch (lighting switch)

M283. BCM M18, M19, M20 (view with instru-

ment lower panel LH removed)

4. Front door switch LH B8 5. Key switch and ignition knob switch

M12 6. Seat belt buckle pre-tensioner assem-

bly LH (seat belt buckle switch) B74

Unit Description

Combination meter • Receives the seat belt buckle switch signal from the seat belt buckle pre-tensioner assembly

LH (seat belt buckle switch) and transmits it to BCM with CAN communication line.

• Receives a buzzer output signal from BCM with CAN communication line.

BCM Transmits signals provided by various units to the combination meter with CAN communication

line.

Key switch and ignition knob

switch Transmits key switch signal to BCM.

Revision: December 20092009 QX56

Page 3983 of 4171

WCS-6

< FUNCTION DIAGNOSIS >

WARNING CHIME SYSTEM

LIGHT REMINDER WARNING CHIME

LIGHT REMINDER WARNING CHIME : System DiagramINFOID:0000000003776692

LIGHT REMINDER WARNING CHIME : System DescriptionINFOID:0000000003776693

DESCRIPTION

With ignition switch in OFF or ACC position, driver door open, and lighting switch in 1ST or 2ND position, the

light warning chime will sound.

• BCM detects ignition switch in OFF or ACC position, front door switch LH ON, and lighting switch in 1ST or2ND position. And then transmits buzzer output signal (light reminder warning chime) to combination meter

with CAN communication line.

• When combination meter receives buzzer output signal ( light reminder warning chime), it sounds the buzzer.

WARNING OPERATION CONDITIONS

If all of the following conditions are fulfilled• Lighting switch is at 1st or 2nd position

• Ignition switch is at OFF or ACC

• Front door switch LH is ON

WARNING CANCEL CONDITIONS

Warning is canceled if any of the following conditions is fulfilled.

• Lighting switch OFF

• Ignition switch ON

• Front door switch LH is OFF

Seat belt buckle pre-tensioner as-

sembly LH (seat belt buckle

switch)Transmits a seat belt buckle switch signal to the combination meter.

Combination switch

(Lighting switch) Transmits the lighting switch position signal to BCM.

Front door switch LH Transmits the door switch signal to BCM.

Unit

Description

WKIA5465E

Revision: December 20092009 QX56