service INFINITI QX56 2009 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2009, Model line: QX56, Model: INFINITI QX56 2009Pages: 4171, PDF Size: 84.65 MB

Page 3591 of 4171

PRECAUTIONSSRC-93

< PRECAUTION >

C

DE

F

G

I

J

K L

M A

B

SRC

N

O P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005867464

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SR and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Un it or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or el ectric power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers, always switch the Ignition OFF, disconnect the battery, and wait at least 3 minutes before performing any service.

Precaution for SRS "AIR BAG" and "SEAT BELT PRE-TENSIONER" Service

INFOID:0000000003775253

• Do not use electrical test equipment to check SRS ci rcuits unless instructed to in this Service Manual.

• Before servicing the SRS, turn ignition switch OFF, disconnect both battery cables and wait at least 3 min- utes.

For approximately 3 minutes after the cables are remov ed, it is still possible for the air bag and seat belt pre-

tensioner to deploy. Therefore, do not work on any SR S connectors or wires until at least 3 minutes have

passed.

• The air bag diagnosis sensor unit must always be installed with the arrow mark “ ⇐” pointing toward the front

of the vehicle for proper operation. Also check air bag diagnosis sensor unit for cracks, deformities or rust

before installation and replace as required.

• The spiral cable must be aligned with the neutral position since its rotations are limited. Do not attempt to

turn steering wheel or column after removal of steering gear.

• Handle air bag module carefully. Always place driver and front passenger air bag modules with the pad side facing upward and seat mounted front side air bag module standing with the stud bolt side facing down.

• Conduct self-diagnosis to check entire SRS for proper function after replacing any components.

• After air bag inflates, the front instrument panel assembly should be replaced if damaged.

Occupant Classification System PrecautionINFOID:0000000003775254

Replace occupant classification system control uni t and passenger front seat cushion as an assembly.

Revision: December 20092009 QX56

Page 3592 of 4171

ST-1

STEERING

C

DE

F

H I

J

K L

M

SECTION ST

A

B

ST

N

O P

CONTENTS

STEERING SYSTEM

PRECAUTION ................ ...............................3

PRECAUTIONS .............................................. .....3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

3

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect .....................................

3

Precaution for Steering System ................................4

PREPARATION ............................................5

PREPARATION .............................................. .....5

Special Service Tool ........................................... ......5

Commercial Service Tool ..........................................6

FUNCTION DIAGNOSIS ...............................7

HEATED STEERING WHEEL ........................ .....7

System Diagram .................................................. ......7

System Description ...................................................7

Component Parts Location ........................................7

Component Description .............................................8

COMPONENT DIAGNOSIS ..........................9

HEATED STEERING WHEEL ........................ .....9

Wiring Diagram ................................................... ......9

SYMPTOM DIAGNOSIS ..............................12

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING ........................ ....

12

NVH Troubleshooting Chart ................................ ....12

ON-VEHICLE MAINTENANCE ....................13

POWER STEERING FLUID ........................... ....13

Checking Fluid Level ........................................... ....13

Checking Fluid Leakage ..........................................13

Air Bleeding Hydraulic System ................................13

ON-VEHICLE REPAIR .................................15

STEERING WHEEL ..........................................15

On-Vehicle Inspection and Service ..................... ....15

POWER STEERING OIL PUMP .......................17

On-Vehicle Inspection and Service .........................17

REMOVAL AND INSTALLATION ...............18

STEERING WHEEL ..........................................18

Removal and Installation ..................................... ....18

TILT SYSTEM ...................................................19

Removal and Installation .........................................19

STEERING COLUMN ........................................20

Removal and Installation .........................................20

POWER STEERING GEAR AND LINKAGE ....23

Removal and Installation .........................................23

POWER STEERING OIL PUMP .......................26

Removal and Installation .........................................26

HYDRAULIC LINE ............................................27

Removal and Installation .........................................27

DISASSEMBLY AND ASSEMBLY ..............29

STEERING COLUMN ........................................29

Disassembly and Assembly ................................. ....29

POWER STEERING GEAR AND LINKAGE ....32

Disassembly and Assembly .....................................32

POWER STEERING OIL PUMP .......................35

Disassembly and Assembly .....................................35

SERVICE DATA AND SPECIFICATIONS

(SDS) ............... .............................................

36

SERVICE DATA AND SPECIFICATIONS

(SDS) .................................................................

36

Steering Wheel .................................................... ....36

Revision: December 20092009 QX56

Page 3594 of 4171

PRECAUTIONSST-3

< PRECAUTION >

C

DE

F

H I

J

K L

M A

B

ST

N

O P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005867894

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SR and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the SR section.

Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

When working near the Airbag Diagnosis Sensor Un it or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or el ectric power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minutes before performing any service.

Precaution Necessary for Steering Wh eel Rotation After Battery Disconnect

INFOID:0000000005867895

NOTE:

This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

Remove and install all control units after disconnecti ng both battery cables with the ignition knob in the

″ LOCK ″ position.

Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS , an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be

rotated.

4. Perform the necessary repair operation.

Revision: December 20092009 QX56

Page 3596 of 4171

PREPARATIONST-5

< PREPARATION >

C

DE

F

H I

J

K L

M A

B

ST

N

O P

PREPARATION

PREPARATION

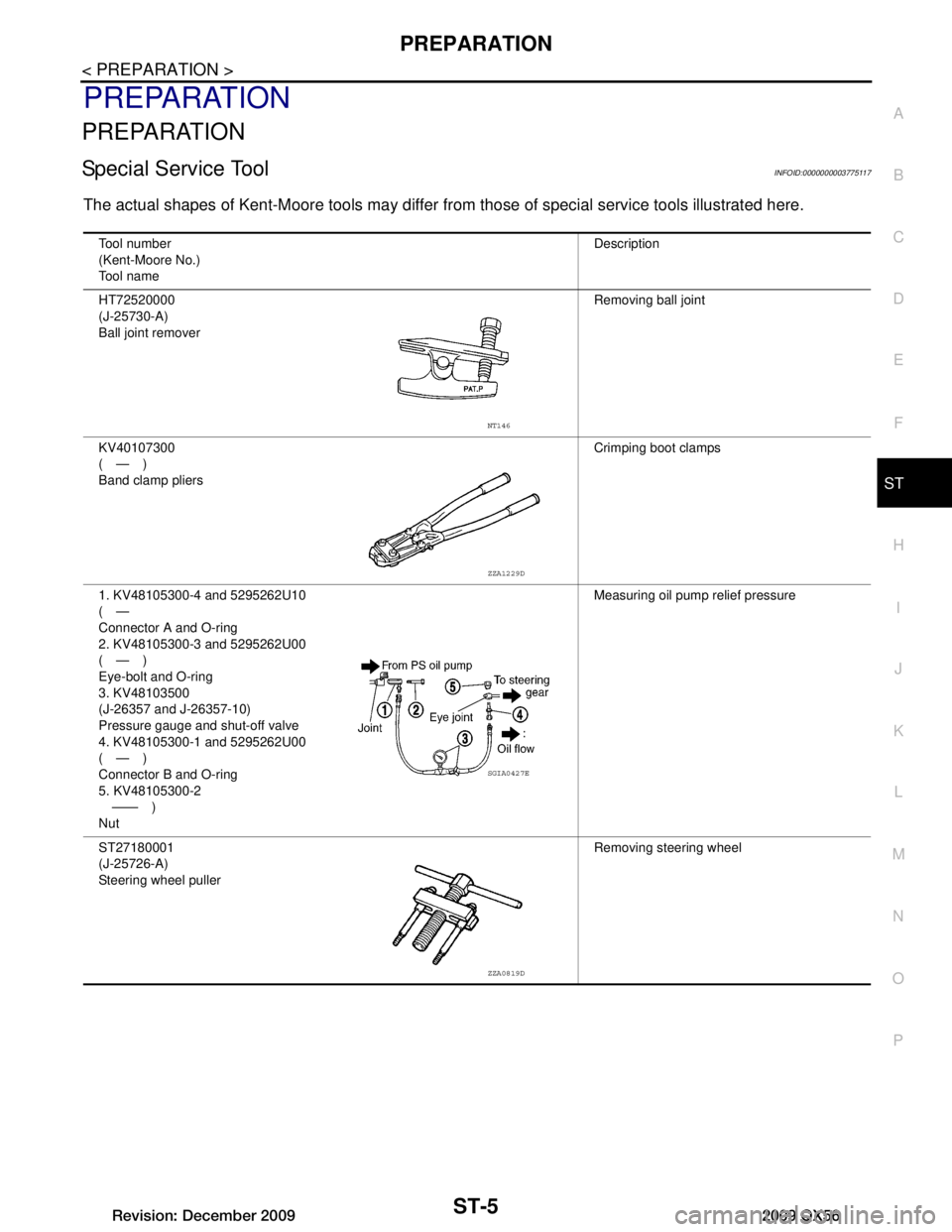

Special Service ToolINFOID:0000000003775117

The actual shapes of Kent-Moore tools may differ fr om those of special service tools illustrated here.

Tool number

(Kent-Moore No.)

Tool name Description

HT72520000

(J-25730-A)

Ball joint remover Removing ball joint

KV40107300

(—)

Band clamp pliers Crimping boot clamps

1. KV48105300-4 and 5295262U10

(—

Connector A and O-ring

2. KV48105300-3 and 5295262U00

(—)

Eye-bolt and O-ring

3. KV48103500

(J-26357 and J-26357-10)

Pressure gauge and shut-off valve

4. KV48105300-1 and 5295262U00

(—)

Connector B and O-ring

5. KV48105300-2 —— )

Nut Measuring oil pump relief pressure

ST27180001

(J-25726-A)

Steering wheel puller Removing steering wheel

NT146

ZZA1229D

SGIA0427E

ZZA0819D

Revision: December 20092009 QX56

Page 3597 of 4171

ST-6

< PREPARATION >

PREPARATION

Commercial Service Tool

INFOID:0000000003775118

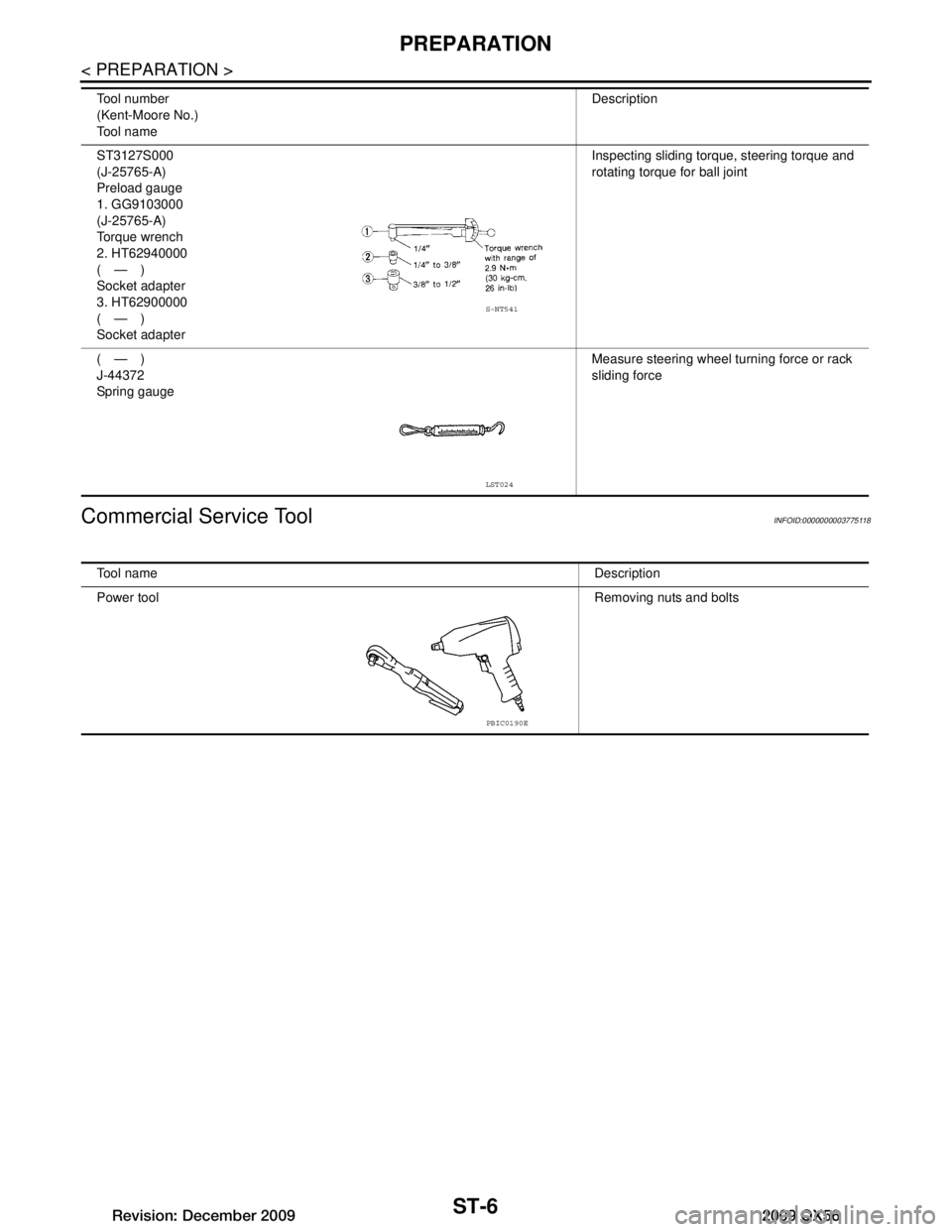

ST3127S000

(J-25765-A)

Preload gauge

1. GG9103000

(J-25765-A)

Torque wrench

2. HT62940000

(—)

Socket adapter

3. HT62900000

(—)

Socket adapter Inspecting sliding torque, steering torque and

rotating torque for ball joint

(—)

J-44372

Spring gauge Measure steering wheel turning force or rack

sliding force

Tool number

(Kent-Moore No.)

Tool name

Description

S-NT541

LST024

Tool name

Description

Power tool Removing nuts and bolts

PBIC0190E

Revision: December 20092009 QX56

Page 3606 of 4171

STEERING WHEELST-15

< ON-VEHICLE REPAIR >

C

DE

F

H I

J

K L

M A

B

ST

N

O P

ON-VEHICLE REPAIR

STEERING WHEEL

On-Vehicle Inspection and ServiceINFOID:0000000004187602

CHECKING CONDITION OF INSTALLATION

Check installation condition of steering gear assemb ly, front suspension, axle and steering column.

Check if movement exists when steering wheel is mo ved up and down, to the left and right and to the axial

direction.

Check if the nuts for steering gear assembly are loose. Refer to ST-23, "Removal and Installation"

.

CHECKING STEERING WHEEL PLAY

1. Turn tires straight ahead, start engine, then turn steer ing wheel to the left and right lightly, and measure

steering wheel movement on the outer circumference when steering wheel is turned up to the point where

tires start moving.

CHECKING NEUTRAL POSITION ON STEERING WHEEL

Check neutral position on steering wheel after confirming that front wheel alignment is correct. Refer to FSU-

6, "Front Wheel Alignment".

1. Turn tires straight ahead, check if st eering wheel is in the neutral position.

2. If it is not in the neutral position, remo ve steering wheel and reinstall it correctly.

3. If the neutral position cannot be attained by repositi oning the steering wheel two teeth or less on steering

stem, loosen tie-rod lock nuts of steering outer socket s, then adjust tie-rods by the same amount in the

opposite direction.

CHECKING STEERING WHEEL TURNING FORCE

1. Park vehicle on a level, dry surface and set parking brake.

2. Start engine.

3. Bring power steering fluid up to operating temperature of 60 °– 80 °C (140 °– 176 °F).

4. Tires need to be inflated to specified pressure. Refer to WT-45, "Tire"

.

End play of the axial direction for steering wheel : Refer to

ST-

36, "Steering

Wheel"

LGIA0024E

Steering wheel play on the outer circumference : Refer to ST-36, "Steering

Wheel"

Revision: December 20092009 QX56

Page 3608 of 4171

POWER STEERING OIL PUMPST-17

< ON-VEHICLE REPAIR >

C

DE

F

H I

J

K L

M A

B

ST

N

O P

POWER STEERING OIL PUMP

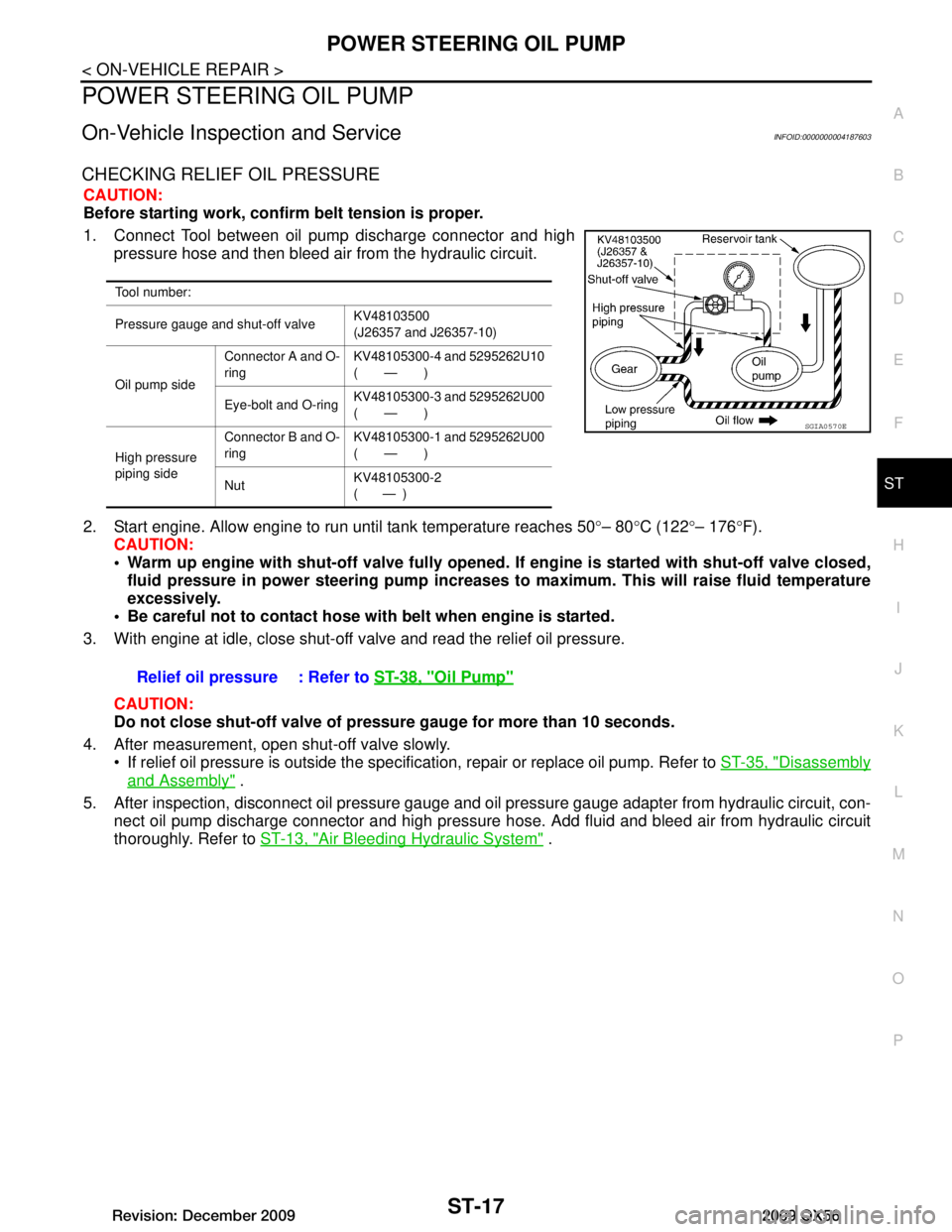

On-Vehicle Inspection and ServiceINFOID:0000000004187603

CHECKING RELIEF OIL PRESSURE

CAUTION:

Before starting work, confirm belt tension is proper.

1. Connect Tool between oil pump discharge connector and high pressure hose and then bleed air from the hydraulic circuit.

2. Start engine. Allow engine to run until tank temperature reaches 50 °– 80 °C (122 °– 176 °F).

CAUTION:

Warm up engine with shut-off valve fully opened. If engine is started with shut-off valve closed,

fluid pressure in power steering pump increases to maximum. This will raise fluid temperature

excessively.

Be careful not to contact hose with belt when engine is started.

3. With engine at idle, close shut-off valve and read the relief oil pressure.

CAUTION:

Do not close shut-off valve of pressu re gauge for more than 10 seconds.

4. After measurement, open shut-off valve slowly. If relief oil pressure is outside the specific ation, repair or replace oil pump. Refer to ST-35, "Disassembly

and Assembly" .

5. After inspection, disconnect oil pressure gauge and oil pressure gauge adapter from hydraulic circuit, con-

nect oil pump discharge connector and high pressure hose. Add fluid and bleed air from hydraulic circuit

thoroughly. Refer to ST-13, "Air Bleeding Hydraulic System"

.

Tool number:

Pressure gauge and shut-off valve KV48103500

(J26357 and J26357-10)

Oil pump side Connector A and O-

ring

KV48105300-4 and 5295262U10

(—)

Eye-bolt and O-ring KV48105300-3 and 5295262U00

(—)

High pressure

piping side Connector B and O-

ring

KV48105300-1 and 5295262U00

(—)

Nut KV48105300-2

( — )

SGIA0570E

Relief oil pressure : Refer to

ST-38, "Oil Pump"

Revision: December 20092009 QX56

Page 3627 of 4171

ST-36

< SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

Steering WheelINFOID:0000000004187586

Steering ColumnINFOID:0000000004187587

Inspection After AssemblyUnit: mm (in)

Inspection After Removal Unit: mm (in)

End play of the axial direction for steering wheel 0 mm (0 in)

Steering wheel play on the outer circumference 0 − 35 mm (0 − 1.38 in)

Steering wheel turning force 3 9 N (4 kg-f, 9 lb-f) or less

Steering column length “L” 640 (25.20)

WGIA0080E

Steering column length “L1”

Steering column length “L2” 165.1 (6.50)

258 (10.16)

SGIA0475E

Revision: December 20092009 QX56

Page 3628 of 4171

SERVICE DATA AND SPECIFICATIONS (SDS)

ST-37

< SERVICE DATA AND SPECIFICATIONS (SDS)

C

D E

F

H I

J

K L

M A

B

ST

N

O P

Inspection After Installation

Steering Outer Socket and Inner SocketINFOID:0000000004187588

Unit: mm (in)

Range “A” 18°

Tilt mechanism range (Manual tilt) 3 ° per notch at 5 steps

WGIA0083E

Tie-rod ball joint outer socket Swinging torque (F) 0.3

− 2.9 N·m (0.03 − 0.29 kg-m, 3 − 25 in-lb)

Measurement on spring balance

Measuring point: cotter pin hole of stud 4.84

− 46.7 N (0.50 − 4.7 kg-f, 4 − 34 lb-f)

Rotating torque 0.3 − 2.9 N·m (0.03 − 0.29 kg-m, 3 − 25 in-lb)

Axial end play 0.5 mm (0.020 in) or less

Tie-rod ball joint inner socket Swinging torque 1.0

− 7.8 N·m (0.11 − 0.79 kg-m, 9 − 69 in-lb)

Measurement on spring balance

Measuring point: L mark see above, L=83.2 mm (3.276 in). 12.1

− 93.7 N (1.3 − 9.5 kg-f, 9 − 69 lb-f)

Axial end play 0.2 mm (0.08 in) or less

SGIA0358E

Inner socket length “L” 102.2 (4.02)

SGIA0167E

Revision: December 20092009 QX56

Page 3629 of 4171

ST-38

< SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

Steering Gear

INFOID:0000000004187589

Oil PumpINFOID:0000000004187590

Steering FluidINFOID:0000000004187591

Steering gear model PR26AM

Rack sliding force At the neutral point:

Range within

± 11.5 mm

( ± 0.453 in) from the neutral

position

(in power ON) Area average value 147

− 211 N (14.99 − 21.52 kg-f, 33.1 − 47.52 lb-f)

Allowable variation 98 N (10 kg-f, 22 lb-f) or less

Whole area (in power OFF) Peak value 294 N (30.0

kg-f, 66 lb-f) or less

Allowable variation 147 N (1 6 kg-f, 35 lb-f) or less

Relief oil pressure

9.0 − 9.8 mPa (91.77 − 99.93 kg/cm2 , 1305.34 − 1421.37 psi)

Fluid capacity

Approx. 1.0 (1-1/8 US qt, 7/8 Imp qt)

Revision: December 20092009 QX56