turn signal INFINITI QX56 2009 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2009, Model line: QX56, Model: INFINITI QX56 2009Pages: 4171, PDF Size: 84.65 MB

Page 3437 of 4171

SN

SONAR SENSOR CIRCUIT INSPECTIONSN-15

< COMPONENT DIAGNOSIS >

C

DE

F

G H

I

J

K L

M B A

O P

SONAR SENSOR CIRCUIT INSPECTION

DescriptionINFOID:0000000004173802

With power and ground supplied to the sonar sensors, the sonar sensors transmit an ultrasonic signal. This

signal is reflected back to the sensor by objec ts large enough and close enough to be detected. The sonar

sensors measure the time from the transmitted signal to the time the signal is reflected back and send this

information to the sonar control unit.

Diagnosis Procedure (With Rear Sonar System)INFOID:0000000004173803

1.CHECK REAR SONAR SENSOR CIRCUITS

1. Turn ignition switch OFF.

2. Disconnect sonar control unit connector and rear sonar sensor connectors.

3. Check continuity between sonar control unit harness connector (A) and rear sonar sensor harness connectors (B).

4. Check continuity between sonar control unit harness connector and ground.

Are the inspection results normal?

YES >> Inspection End.

NO >> Repair harness or connector.

Diagnosis Procedure (With Front and Rear Sonar System)INFOID:0000000004173804

1.CHECK SONAR SENSOR CIRCUITS

1. Turn ignition switch OFF.

2. Disconnect sonar control unit connec tors and sonar sensor connectors.

3. Check continuity between sonar control unit harness connectors (A, B) and sonar sensor harness connectors (C).

Connector Terminal ConnectorTerminal Continuity

B24 (A) 16

C102, C103, C104, C105 (B) 1

Ye s

15 3

9, 10, 11, 12 2

AWNIA1501ZZ

ConnectorTerminalContinuity

B24 9, 10, 11, 12, 15, 16 Ground No

AWNIA1502ZZ

Connector TerminalConnectorTerminal Continuity

B56 (A) 9

C102, C103, C104, C105 (C) 1

Ye s

12

3

13, 14, 15, 16 2

B57 (B) 17

E158, E162, E1 63, E166 (C) 1

26 3

19, 20, 24, 25 2

AWNIA1543ZZ

Revision: December 20092009 QX56

Page 3443 of 4171

SN

SONAR CONTROL UNIT FOR REAR SONAR SYSTEMSN-21

< ECU DIAGNOSIS >

C

DE

F

G H

I

J

K L

M B A

O P

ECU DIAGNOSIS

SONAR CONTROL UNIT FO R REAR SONAR SYSTEM

Reference ValueINFOID:0000000003776753

SONAR CONTROL UNIT TERMINAL LAYOUT

TERMINALS AND REFERENCE VA LUES FOR SONAR CONTROL UNIT

WKIA5222E

Te r m i n a l

(wire color) Item Condition

Reference value (V)

(Approx.)

Ignition

switch Operation

3 (R) Sonar buzzer return ON —0 - 12 (variable)

4 (BR/Y) Sonar system OFF

indicator output ON

Rear sonar system OFF

switch ON

0

OFF Battery voltage

5 (G/W) Reverse signal ONTransmission gear se-

lector lever

R position

Battery voltage

Transmission gear se-

lector lever Not R position

0

6 (B) Sonar control unit

ground ——

0

7 (L) Sonar buzzer drive

signal

ON

— Battery voltage

8 (G/R) Sonar control unit

power ON

— Battery voltage

9 (GR) Rear sonar sensor

signal - RH outer

ON• Rear sonar system OFF switch ON

• Transmission gear selector lever in R po-

sition

• No obstacles Battery voltage

10 (P) Rear sonar sensor

signal - LH outer

ON• Rear sonar system OFF switch ON

• Transmission gear selector lever in R po-

sition

• No obstacles Battery voltage

11 ( O ) Rear sonar sensor

signal - LH inner

ON• Rear sonar system OFF switch ON

• Transmission gear selector lever in R po-

sition

• Distance obstacles Battery voltage

12 (LG) Rear sonar sensor

signal - RH inner

ON• Rear sonar system OFF switch ON

• Transmission gear selector lever in R po-

sition

• Distance obstacles Battery voltage

13 (LG) Rear sonar system

OFF switch signal

ONRear sonar system OFF

switch ON

0

OFF Battery voltage

Revision: December 20092009 QX56

Page 3453 of 4171

SN

SONAR CONTROL UNIT FOR FRONT AND REAR SONAR SYSTEMSN-31

< ECU DIAGNOSIS >

C

DE

F

G H

I

J

K L

M B A

O P

SONAR CONTROL UNIT FOR FR ONT AND REAR SONAR SYSTEM

Reference ValueINFOID:0000000003776756

SONAR CONTROL UNIT HARNESS TERMINAL LAYOUT

TERMINALS AND REFERENCE VA LUES FOR SONAR CONTROL UNIT

AWNIA1547ZZ

Te r m i n a l

(color) Item Condition

Reference value (V)

(Approx.)

Ignition

switch Operation

1 (G/R) Sonar control unit

power ON

— Battery voltage

2 (L) Sonar buzzer drive

signal

ON Object sensed

Battery voltage

3 (G/W) Reverse signal ONTransmission gear selector lever in R posi-

tion

Battery voltage

Transmission gear selector lever not in R

position 0

4 (B) Sonar control unit

ground ——

—

5 (BR/Y) Sonar system OFF

indicator output ON

Sonar system OFF

switch ON

0

OFF Battery voltage

6 (R) Rear sonar buzzer

return

ON

— 0 - 12 (variable)

8 (G/W) K-line ON— —

9 (LG/B) Rear sonar sensor

power ON Ignition switch ON

Battery voltage

11 ( L G ) Sonar system OFF

switch signal

ONSonar system OFF

switch ON

0

OFF Battery voltage

12 (Y) Rear sonar sensor

ground ON

— —

13 (LG) Rear sonar sensor

signal - RH inner ON• Sonar system OFF switch ON

• Transmission gear selector lever in R po-

sition

• Distance obstacles Battery voltage

14 (O) Rear sonar sensor

signal - LH inner ON• Sonar system OFF switch ON

• Transmission gear selector lever in R po-

sition

• Distance obstacles Battery voltage

15 (P) Rear sonar sensor

signal - LH outer ON• Sonar system OFF switch ON

• Transmission gear selector lever in R po-

sition

• No obstacles Battery voltage

Revision: December 20092009 QX56

Page 3454 of 4171

SN-32

< ECU DIAGNOSIS >

SONAR CONTROL UNIT FOR FRONT AND REAR SONAR SYSTEM

16 (GR)Rear sonar sensor

signal - RH outer ON• Sonar system OFF switch ON

• Transmission gear selector lever in R po-

sition

• No obstacles Battery voltage

17 (LG/B) Front sonar sensor

power

ON Ignition switch ON

Battery voltage

18 (GR/R) Park position signal ON Vehicle in PARK 12

19 (GR) Front sonar sensor

signal - RH outer ON• Sonar system OFF switch ON

• Transmission gear selector lever in a for-

ward drive gear

• Distance obstacles Battery voltage

20 (LG) Front sonar sensor

signal - RH inner ON• Sonar system OFF switch ON

• Transmission gear selector lever in re-

verse or a forward drive gear

• No obstacles Battery voltage

21 (W/R) Vehicle speed signal ON Speedometer operated

[When vehicle speed is approx. 40 km/h (25

MPH)]NOTE:

Maximum voltage may be 12V due

to specifications (connected units).

23 (R) Front sonar buzzer

return ON

— 0 - 12 (variable)

24 (P) Front sonar sensor

signal - LH outer

ON• Sonar system OFF switch ON

• Transmission gear selector lever in re-

verse or a forward drive gear

• No obstacles Battery voltage

25 (O) Front sonar sensor

signal - LH inner

ON• Sonar system OFF switch ON

• Transmission gear selector lever in a for-

ward drive gear

• Distance obstacles Battery voltage

26 (Y) Front sonar sensor

ground ON

— —

Te r m i n a l

(color) Item Condition

Reference value (V)

(Approx.)

Ignition

switch Operation

PKIC0643E

Revision: December 20092009 QX56

Page 3480 of 4171

SPIRAL CABLESR-7

< ON-VEHICLE REPAIR >

C

DE

F

G

I

J

K L

M A

B

SR

N

O P

SPIRAL CABLE

Removal and InstallationINFOID:0000000003775158

REMOVAL

CAUTION:

• Before servicing the SRS, turn ignition switch OFF, disconnect both battery terminals and wait at

least three minutes.

• When servicing the SRS, do not work from directly in front of air bag module.

1. Remove the instrument lower panel LH. Refer to IP-15, "

Removal and Installation".

2. Remove the steering wheel. Refer to ST-18, "

Removal and Installation".

3. Remove the column cover upper and lower.

4. Remove wiper washer switch connector, then pinch the tabs at wiper and washer switch base and slide switch away from steer-

ing column to remove.

1. Steering wheel 2. Lighting and turn signal switch 3. Wiper and washer switch

4. Spiral cable 5. Driver air bag module connector 6. Column cover upper

7. Column assembly 8. Column cover lower9. Screw (Do not remove)

10. Screw A. Refer to ST-18, "

Removal and Instal-

lation"

AWHIA0141GB

LHIA0034E

Revision: December 20092009 QX56

Page 3481 of 4171

SR-8

< ON-VEHICLE REPAIR >

SPIRAL CABLE

5. While pressing tabs, pull lighting and turn signal switch towarddriver door and disconnect from base.

6. Remove the screws, release the clip, and remove the spiral cable.

CAUTION:

• Do not disassemble spiral cable.

• Do not apply lubricant to the spiral cable.

7. Remove the spiral cable connectors. CAUTION:

With the steering linkage di sconnected, the spiral cable

may snap by turning the steer ing wheel beyond the limited

number of turns. The spiral cable can be turned counter-

clockwise about 2.5 turns fr om the neutral position.

8. Remove the steering angle sensor. Refer to BRC-118, "

Removal

and Installation".

INSTALLATION

Installation is in the reverse order of removal.

• Align spiral cable correctly when installing steering wheel. Make

sure that the spiral cable is in the neutral position. The neutral

position is detected by turning left 2.5 revolutions from the right

end position and ending with the knob at the top.

• If equipped with VDC, refer to BRC-8, "

ADJUSTMENT OF STEER-

ING ANGLE SENSOR NEUTRAL POSITION : Special Repair

Requirement" for steering angle sensor adjustment.

• After the work is completed, perform self-diagnosis to make sure no malfunction is detected. Refer to SRC-13, "

SRS Operation

Check".

CAUTION:

LHIA0035E

LHIA0036E

SHIA0193E

WGIA0038E

Revision: December 20092009 QX56

Page 3513 of 4171

ON BOARD DIAGNOSTIC (OBD) SYSTEMSRC-15

< FUNCTION DIAGNOSIS >

C

DE

F

G

I

J

K L

M A

B

SRC

N

O P

Trouble Diagnosis without CONSULT-IIIINFOID:0000000003775186

DIAGNOSTIC PROCEDURE 6

Inspect SRS Malfunction Using "AIR BAG" Warning Lamp—Diagnosis Mode

NOTE:

SRS will not enter Diagnosis mode if no malfunction is detected in User mode.

1. Turn ignition switch ON.

2. After “AIR BAG” warning lamp lights for 7 seconds, turn ignition switch OFF within 1 second.

3. Wait more than 3 seconds.

4. Repeat steps 1 to 3 two more times (3 times total).

5. Turn ignition switch ON.

SRS is now in Diagnosis mode. Refer to SRC-85, "

Trouble Diagnosis without CONSULT-III".

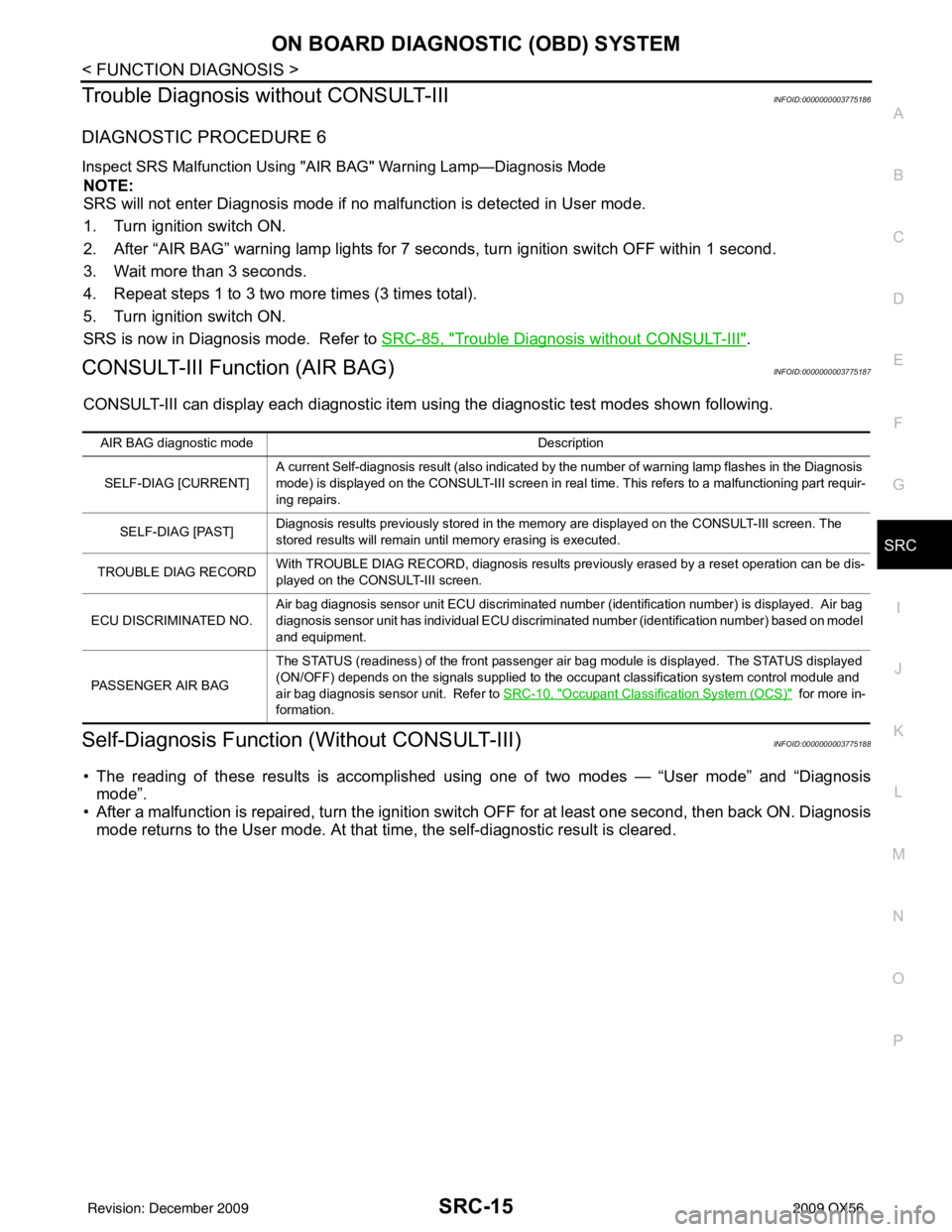

CONSULT-III Function (AIR BAG)INFOID:0000000003775187

CONSULT-III can display each diagnostic item using the diagnostic test modes shown following.

Self-Diagnosis Function (Without CONSULT-III)INFOID:0000000003775188

• The reading of these results is accomplished using one of two modes — “User mode” and “Diagnosis

mode”.

• After a malfunction is repaired, turn the ignition s witch OFF for at least one second, then back ON. Diagnosis

mode returns to the User mode. At that time, the self-diagnostic result is cleared.

AIR BAG diagnostic mode Description

SELF-DIAG [CURRENT] A current Self-diagnosis result (also indicated by the number of warning lamp flashes in the Diagnosis

mode) is displayed on the CONSULT-III screen in real

time. This refers to a malfunctioning part requir-

ing repairs.

SELF-DIAG [PAST] Diagnosis results previously stored in the memo

ry are displayed on the CONSULT-III screen. The

stored results will remain until memory erasing is executed.

TROUBLE DIAG RECORD With TROUBLE DIAG RECORD, diagnosis results previously erased by a reset operation can be dis-

played on the CONSULT-III screen.

ECU DISCRIMINATED NO. Air bag diagnosis sensor unit ECU discriminated number (identification number) is displayed. Air bag

diagnosis sensor unit has individual ECU discriminated number (identification number) based on model

and equipment.

PASSENGER AIR BAG The STATUS (readiness) of the front passenger air bag module is displayed. The STATUS displayed

(ON/OFF) depends on the signals supplied to the occupant classification system control module and

air bag diagnosis sensor unit. Refer to

SRC-10, "

Occupant Classification System (OCS)" for more in-

formation.

Revision: December 20092009 QX56

Page 3599 of 4171

ST-8

< FUNCTION DIAGNOSIS >

HEATED STEERING WHEEL

Component Description

INFOID:0000000003775122

Heated steering wheel switch Controls the heated steering relay and operates the heated steering system.

Turns the indicator lamp ON when the system is activated.

Heated steering relay Operates the heated steering system with the control signal from the heated steering

wheel switch.

Heated steering wheel Heats the heating element with the power supplied from the heated steering relay.

Revision: December 20092009 QX56

Page 3638 of 4171

STARTING SYSTEMSTR-9

< FUNCTION DIAGNOSIS >

C

DE

F

G H

I

J

K L

M A

STR

NP

O

Component DescriptionINFOID:0000000003771791

Component part

Description

TCM TCM supplies power to the starter relay inside the IPDM E/R when

the selector lever is shifted to the P or N position.

BCM BCM sends a starter request signal to the CPU of the IPDM E/R

over the CAN communication lines.

IPDM E/R CPU inside IPDM E/R operates the starter relay at the request of

the BCM over the CAN communication lines.

Starter motor The starter motor plunger closes and the motor is supplied with

battery power, which in turn cranks the engine, when the “S” ter-

minal is supplied with electric power.

Revision: December 20092009 QX56

Page 3651 of 4171

TM-3

CEF

G H

I

J

K L

M A

B

TM

N

O P

Diagnosis Procedure ...........................................

....

78

P1752 INPUT CLUTCH SOLENOID ..................80

Description .......................................................... ....80

CONSULT-III Reference Value in Data Monitor

Mode ................................................................... ....

80

On Board Diagnosis Logic ......................................80

Possible Cause .......................................................80

DTC Confirmation Procedure ..................................80

Diagnosis Procedure ...............................................80

P1757 FRONT BRAKE SOLENOID ...................82

Description .......................................................... ....82

CONSULT-III Reference Value in Data Monitor

Mode ................................................................... ....

82

On Board Diagnosis Logic ......................................82

Possible Cause .......................................................82

DTC Confirmation Procedure ..................................82

Diagnosis Procedure ...............................................82

P1762 DIRECT CLUTCH SOLENOID ................84

Description .......................................................... ....84

CONSULT-III Reference Value in Data Monitor

Mode ................................................................... ....

84

On Board Diagnosis Logic ......................................84

Possible Cause .......................................................84

DTC Confirmation Procedure ..................................84

Diagnosis Procedure ...............................................84

P1767 HIGH AND LOW REVERSE CLUTCH

SOLENOID .........................................................

86

Description .......................................................... ....86

CONSULT-III Reference Value in Data Monitor

Mode ................................................................... ....

86

On Board Diagnosis Logic ......................................86

Possible Cause .......................................................86

DTC Confirmation Procedure ..................................86

Diagnosis Procedure ...............................................86

P1772 LOW COAST BRAKE SOLENOID .........88

Description .......................................................... ....88

CONSULT-III Reference Value in Data Monitor

Mode ................................................................... ....

88

On Board Diagnosis Logic ......................................88

Possible Cause .......................................................88

DTC Confirmation Procedure ..................................88

Diagnosis Procedure ...............................................88

P1774 LOW COAST BRAKE SOLENOID .........90

Description .......................................................... ....90

CONSULT-III Reference Value in Data Monitor

Mode ................................................................... ....

90

On Board Diagnosis Logic ......................................90

Possible Cause .......................................................90

DTC Confirmation Procedure ..................................90

Diagnosis Procedure ...............................................90

MAIN POWER SUPPLY AND GROUND CIR-

CUIT ....................................................................

92

Diagnosis Procedure ........................................... ....92

CLOSED THROTTLE POSITION AND WIDE

OPEN THROTTLE POSITION CIRCUIT ...........

94

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... ....

94

Diagnosis Procedure ...............................................94

BRAKE SIGNAL CIRCUIT ................................95

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... ....

95

Diagnosis Procedure ...............................................95

TOW MODE SWITCH .......................................96

Description ...............................................................96

Diagnosis Procedure ...............................................96

A/T SHIFT LOCK SYSTEM ...............................97

Wiring Diagram - A/T Shift Lock System .................97

Terminals And Reference Values ..........................101

Component Description .........................................101

ECU DIAGNOSIS .......................................104

TCM .................................................................104

Reference Value .................................................. ..104

Wiring Diagram — A/T CONTROL SYSTEM — .. ..106

Fail-Safe .............................................................. ..115

DTC Inspection Priority Chart ................................117

DTC No. Index .......................................................117

DTC Alphabetical Index .........................................118

SYMPTOM DIAGNOSIS ............................119

SYSTEM SYMPTOM .......................................119

A/T Check Indicator Lamp Does Not Come On ... ..119

Engine Cannot Be Started in "P" or "N" Position ...119

In "P" Position, Vehicle Moves When Pushed .......120

In "N" Position, Vehicle Moves ..............................120

Large Shock("N" to "D" Position) ...........................122

Vehicle Does Not Creep Backward in "R" Position ..124

Vehicle Does Not Creep Forward in "D" Position ..126

Vehicle Cannot Be Started from D1 ......................129

A/T Does Not Shift: D1ÆD2 ..................................131

A/T Does Not Shift: D2ÆD3 ..................................132

A/T Does Not Shift: D3ÆD4 ..................................134

A/T Does Not Shift: D4ÆD5 ..................................136

A/T Does Not Perform Lock-up .............................138

A/T Does Not Hold Lock-up Condition ...................140

Lock-up Is Not Released .......................................141

Engine Speed Does Not Return to Idle .................142

A/T Does Not Shift: 5GR Æ 4GR ..........................143

A/T Does Not Shift: 4GR Æ 3GR ..........................145

A/T Does Not Shift: 3GR Æ 2GR ..........................147

A/T Does Not Shift: 2GR Æ 1GR ..........................148

Vehicle Does Not Decelerate By Engine Brake .....150

Symptom Table .....................................................152

PRECAUTION ............................................174

PRECAUTIONS ...............................................174

Revision: December 20092009 QX56