engine INFINITI QX56 2009 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2009, Model line: QX56, Model: INFINITI QX56 2009Pages: 4171, PDF Size: 84.65 MB

Page 2427 of 4171

![INFINITI QX56 2009 Factory Service Manual HAC-114

< SYMPTOM DIAGNOSIS >[AUTOMATIC AIR CONDITIONER]

INSUFFICIENT COOLING

TEST READING

Recirculating-to-discharge Air Temperature Table

Ambient Air Temperature-to-operating Pressure Table

Trouble INFINITI QX56 2009 Factory Service Manual HAC-114

< SYMPTOM DIAGNOSIS >[AUTOMATIC AIR CONDITIONER]

INSUFFICIENT COOLING

TEST READING

Recirculating-to-discharge Air Temperature Table

Ambient Air Temperature-to-operating Pressure Table

Trouble](/img/42/57031/w960_57031-2426.png)

HAC-114

< SYMPTOM DIAGNOSIS >[AUTOMATIC AIR CONDITIONER]

INSUFFICIENT COOLING

TEST READING

Recirculating-to-discharge Air Temperature Table

Ambient Air Temperature-to-operating Pressure Table

Trouble Diagnoses fo

r Abnormal PressureINFOID:0000000003775395

Whenever system′s high and/or low side pressure is unusual, diagnose using a manifold gauge. The marker

above the gauge scale in the following tables indicates the standard (usual) pressure range. Since the stan-

Vehicle location Indoors or in the shade (in a well-ventilated place)

Doors Closed

Door window Open

Hood Open

TEMP. Max. COLD

Mode switch (Ventilation) set

Recirculation (REC) switch (Recirculation) set

Blower speed Max. speed set

Engine speed Idle speed

Operate the air conditioning system for 10 minutes before taking measurements.

Inside air (Recirculating air) at blower assembly inlet Discharge air temperature at center ventilator

°C ( °F)

Relative humidity

% Air temperature

°C ( °F)

50 - 60 20 (68)

9.9 - 13.9 (50 - 57)

25 (77) 14.6 - 18.6 (58 - 65)

30 (86) 16.8 - 21.8 (62 - 71)

35 (95) 21.1 - 27.1 (70 - 81)

40 (104) 25.3 - 31.5 (78 - 89)

60 - 70 20 (68)

11.4 - 15.2 (53 - 59)

25 (77) 15.5 - 20.0 (60 - 68)

30 (86) 19.9 - 25.0 (68 - 77)

35 (95) 24.5 - 29.6 (76 - 85)

40 (104) 28.7 - 34.9 (84 - 95)

Ambient air High-pressure (Discharge side)

kPa (kg/cm

2 , psi) Low-pressure (Suction side)

kPa (kg/cm2 , psi)

Relative humidity

% Air temperature

°C ( °F)

50 - 70 20 (68)

1020 - 1250

(10.4 - 12.7, 147.9 - 181.3) 160 - 190

(1.63 - 1.94, 23.2 - 27.6)

25 (77) 1236 - 1510

(12.6 - 15.4, 179.2 - 219) 206 - 245

(2.1 - 2.5, 29.9 - 35.6)

30 (86) 1569 - 1,922

(16.0 - 19.6, 227.6 - 278.8) 265 - 324

(2.7 - 3.3, 38.4 - 46.9)

35 (95) 1,697 - 2079

(17.3 - 21.2, 246.1 - 301.5) 304 - 363

(3.1 - 3.7, 44.1 - 52.6)

40 (104) 1971 - 2403

(20.1 - 24.5, 285.9 - 348.5) 373 - 451

(3.8 - 4.6, 54.0 - 65.4)

Revision: December 20092009 QX56

Page 2428 of 4171

![INFINITI QX56 2009 Factory Service Manual INSUFFICIENT COOLINGHAC-115

< SYMPTOM DIAGNOSIS > [AUTOMATIC AIR CONDITIONER]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

dard (usual) pressure, however, differs from vehicle to vehicle, refer to above table (A INFINITI QX56 2009 Factory Service Manual INSUFFICIENT COOLINGHAC-115

< SYMPTOM DIAGNOSIS > [AUTOMATIC AIR CONDITIONER]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

dard (usual) pressure, however, differs from vehicle to vehicle, refer to above table (A](/img/42/57031/w960_57031-2427.png)

INSUFFICIENT COOLINGHAC-115

< SYMPTOM DIAGNOSIS > [AUTOMATIC AIR CONDITIONER]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

dard (usual) pressure, however, differs from vehicle to vehicle, refer to above table (Ambient air temperature-

to-operating pressure table).

Both High- and Low-pressure Sides are Too High

High-pressure Side is Too High and Low-pressure Side is Too Low

High-pressure Side is Too Low and Low-pressure Side is Too High

Gauge indication Refrigerant cycleProbable causeCorrective action

Both high- and low-pressure sides

are too high. Pressure is reduced soon af-

ter water is splashed on con-

denser.

Excessive refrigerant charge in

refrigeration cycle

Reduce refrigerant until speci-

fied pressure is obtained.

Air suction by cooling fan is in-

sufficient. Insufficient condenser cooling

performance

↓

1. Condenser fins are

clogged.

2. Improper fan rotation of

cooling fan • Clean condenser.

• Check and repair cooling fan

if necessary.

• Low-pressure pipe is not cold.

• When compressor is

stopped high-pressure val-

ue quickly drops by approx-

imately 196 kPa (2 kg/cm

2 ,

28 psi). It then decreases

gradually thereafter. Poor heat exchange in con-

denser

(After compressor operation

stops, high-pressure decreas-

es too slowly.)

↓

Air in refrigeration cycle

Evacuate and recharge system.

Engine tends to overheat. Engine cooling systems mal-

function. Check and repair engine cool-

ing system.

• An area of the low-pressure pipe is colder than areas

near the evaporator outlet.

• Plates are sometimes cov- ered with frost. • Excessive liquid refrigerant

on low-pressure side

• Excessive refrigerant dis-

charge flow

• Expansion valve is open a lit- tle compared with the speci-

fication.

↓

Improper expansion valve ad-

justment Replace expansion valve.

AC359A

Gauge indication

Refrigerant cycleProbable causeCorrective action

High-pressure side is too high and

low-pressure side is too low. Upper side of condenser and

high-pressure side are hot,

however, liquid tank is not so

hot.High-pressure tube or parts lo-

cated between compressor

and condenser are clogged or

crushed.

• Check and repair or replace

malfunctioning parts.

• Check oil for contamination.

AC360A

Revision: December 20092009 QX56

Page 2431 of 4171

![INFINITI QX56 2009 Factory Service Manual HAC-118

< SYMPTOM DIAGNOSIS >[AUTOMATIC AIR CONDITIONER]

INSUFFICIENT HEATING

INSUFFICIENT HEATING

Component Function CheckINFOID:0000000003775396

SYMPTOM: Insufficient heating

INSPECTION FLOW

1.CONFI INFINITI QX56 2009 Factory Service Manual HAC-118

< SYMPTOM DIAGNOSIS >[AUTOMATIC AIR CONDITIONER]

INSUFFICIENT HEATING

INSUFFICIENT HEATING

Component Function CheckINFOID:0000000003775396

SYMPTOM: Insufficient heating

INSPECTION FLOW

1.CONFI](/img/42/57031/w960_57031-2430.png)

HAC-118

< SYMPTOM DIAGNOSIS >[AUTOMATIC AIR CONDITIONER]

INSUFFICIENT HEATING

INSUFFICIENT HEATING

Component Function CheckINFOID:0000000003775396

SYMPTOM: Insufficient heating

INSPECTION FLOW

1.CONFIRM SYMPTOM BY PERFORMING OPER

ATIONAL CHECK - TEMPERATURE INCREASE

1. Press the AUTO switch.

2. Turn the temperature control dial (driver) clockwise until 32 °C (90° F) is displayed.

3. Check for hot air at discharge air outlets.

Can this symptom be duplicated?

YES >> GO TO 2.

NO >> Perform complete system operational check. Refer to HAC-4, "

Operational Check (Front)".

2.CHECK FOR SERVICE BULLETINS

Check for any service bulletins.

>> GO TO 3.

3.PERFORM SELF-DIAGNOSIS

Perform self-diagnosis. Refer to HAC-23, "

A/C Auto Amp. Self-Diagnosis".

Is the inspection result normal?

YES >> GO TO 4.

NO >> Refer to HAC-24, "

A/C System Self-Diagnosis Code Chart".

4.CHECK ENGINE COOLING SYSTEM

1. Check for proper engine coolant level. Refer to CO-10, "

Inspection".

2. Check hoses for leaks or kinks.

3. Check radiator cap. Refer to CO-10, "

Inspection".

4. Check for air in cooling system.

>> GO TO 5.

5.CHECK AIR MIX DOOR OPERATION

Check the operation of the air mix door.

Is the inspection result normal?

YES >> GO TO 6.

NO >> Check the air mix door motor circuit. Refer to HAC-32, "

Air Mix Door Motor Component Function

Check".

6.CHECK AIR DUCTS

Check for disconnected or leaking air ducts.

Is the inspection result normal?

YES >> GO TO 7.

NO >> Repair all disconnected or leaking air ducts.

7.CHECK HEATER HOSE TEMPERATURES

1. Start engine and warm it up to normal operating temperature.

2. Touch both the inlet and outlet heater hoses.

Is the inspection result normal?

YES >> Hot inlet hose and a warm outlet hose: GO TO 8.

NO >> • Inlet hose cold: GO TO 11. • Both hoses warm: GO TO 9.

8.CHECK ENGINE COOLANT SYSTEM

Check engine control temperature sensor. Refer to EC-122, "

Component Inspection".

Revision: December 20092009 QX56

Page 2432 of 4171

![INFINITI QX56 2009 Factory Service Manual INSUFFICIENT HEATINGHAC-119

< SYMPTOM DIAGNOSIS > [AUTOMATIC AIR CONDITIONER]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

Is the inspection result normal?

YES >> System OK.

NO >> Repair or replace as necessary. INFINITI QX56 2009 Factory Service Manual INSUFFICIENT HEATINGHAC-119

< SYMPTOM DIAGNOSIS > [AUTOMATIC AIR CONDITIONER]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

Is the inspection result normal?

YES >> System OK.

NO >> Repair or replace as necessary.](/img/42/57031/w960_57031-2431.png)

INSUFFICIENT HEATINGHAC-119

< SYMPTOM DIAGNOSIS > [AUTOMATIC AIR CONDITIONER]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

Is the inspection result normal?

YES >> System OK.

NO >> Repair or replace as necessary. Retest.

9.CHECK HEATER HOSES

Check heater hoses for proper installation.

Is the inspection result normal?

YES >> System OK.

NO >> 1. Back flush heater core. 2. Drain the water from the system.

3. Refill system with new engine coolant. Refer to CO-11, "

Changing Engine Coolant".

4. GO TO 10 to retest.

10.CHECK HEATER HOSE TEMPERATURES

1. Start engine and warm it up to normal operating temperature.

2. Touch both the inlet and outlet heater hoses.

Is the inspection result normal?

YES >> System OK.

NO >> Replace heater core. Refer to VTL-19, "

Removal and Installation".

11 .CHECK WATER VALVE

Check the operation of the water valve. Refer to HAC-77, "

Water Valve Diagnosis Procedure".

Is the inspection result normal?

YES >> System OK.

NO >> Replace water valve.

Revision: December 20092009 QX56

Page 2436 of 4171

![INFINITI QX56 2009 Factory Service Manual PRECAUTIONSHAC-123

< PRECAUTION > [AUTOMATIC AIR CONDITIONER]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE INFINITI QX56 2009 Factory Service Manual PRECAUTIONSHAC-123

< PRECAUTION > [AUTOMATIC AIR CONDITIONER]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE](/img/42/57031/w960_57031-2435.png)

PRECAUTIONSHAC-123

< PRECAUTION > [AUTOMATIC AIR CONDITIONER]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005867494

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SR and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Un it or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or el ectric power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers, always switch the Ignition OFF, disconnect the battery, and wait at least 3 minutes before performing any service.

Working with HFC-134a (R-134a)INFOID:0000000003775400

WARNING:

• CFC-12 (R-12) refrigerant and HFC-134a (R-134a) refr igerant are not compatible. If the refrigerants

are mixed compressor failure is likely to occur. Refer to HA-4, "

Contaminated Refrigerant". To deter-

mine the purity of HFC-134a (R-134a) in the vehic le and recovery tank, use Refrigerant Recovery/

Recycling Recharging equipment and Refrigerant Identifier.

• Use only specified oil for the HFC-134a (R-134a) A/C system and HFC-134a (R-134a) components. If oil other than that specified is used, compressor fa ilure is likely to occur.

• The specified HFC-134a (R-134a) oil rapidly absorb s moisture from the atmosphere. The following

handling precautions must be observed:

- When removing refrigerant components from a vehicle, immediately cap (seal) the component to

minimize the entry of mois ture from the atmosphere.

- When installing refrigerant components to a vehicle, do not remove the caps (unseal) until just

before connecting the co mponents. Connect all refrigerant lo op components as quickly as possible

to minimize the entry of moisture into system.

- Only use the specified oil from a sealed container. Immediately r eseal containers of oil. Without

proper sealing, oil will become moisture saturat ed and should not be used.

- Avoid breathing A/C refrigerant and oil vapor or mist. Exposure may irritate eyes, nose and throat.

Remove HFC-134a (R-134a) from the A/C system usi ng certified service equipment meeting require-

ments of SAE J2210 [HFC-134a (R-134a) recycling equipment], or J2209 [HFC-134a (R-134a) recy-

cling equipment], If accidental system discharge occurs, ventilate work area before resuming

service. Additional health and safety information may be obtained from refrigerant and oil manufac-

turers.

- Do not allow A/C oil to come in contact with styrofoam parts. Damage may result.

CONTAMINATED REFRIGERANT

Revision: December 20092009 QX56

Page 2439 of 4171

HRN-2

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005856032

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SR and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution Necessary for Steering W heel Rotation After Battery Disconnect

INFOID:0000000005887777

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecting both battery cables with the ignition knob in the

″LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS, an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be rotated.

4. Perform the necessary repair operation.

Revision: December 20092009 QX56

Page 2453 of 4171

ILLUMINATION CONTROL SYSTEMINL-9

< FUNCTION DIAGNOSIS >

C

DE

F

G H

I

J

K

M A

B

INL

N

O P

ILLUMINATION CONTROL SYSTEM

System DiagramINFOID:0000000003776243

System DescriptionINFOID:0000000003776244

The illumination lamps operation is dependent upon the posit ion of the lighting switch (combination switch).

When the lighting switch is placed in the 1ST or 2ND posit ion (or if the auto light system is activated) the BCM

(body control module) receives input requesting the park ing lamps to illuminate. This input is communicated to

the IPDM E/R (intelligent power distribution module engine room) via the CAN communication lines. The CPU

(central processing unit) of the IPDM E/R controls the tail lamp relay coil. When energized, this relay directs

power to the parking and illumination lamps, which then illuminate.

BATTERY SAVER CONTROL

When the lighting switch (combination switch) is in t he 1ST or 2ND position and the ignition switch is turned

from ON or ACC to OFF, the battery saver control feat ure is activated. Under this condition, the illumination

lamps remain illuminated for 30 minutes unless the light ing switch position is changed. If the lighting switch

position is changed, then the illumination lamps are turned off after a 30 second delay. When the lighting

switch is turned from OFF to 1ST or 2ND position (or if auto light system is activated) after illumination lamps

have been turned off by the battery saver control, the illumination lamps illuminate again.

Component Parts LocationINFOID:0000000003776245

ALLIA0424GB

1. BCM M18, M20 (view with instrument

lower panel LH removed) 2. IPDM E/R E122, E123, E124 3. Combination switch M28

4. Combination meter (illumination con- trol switch) M23, M24

AWLIA0398ZZ

Revision: December 20092009 QX56

Page 2499 of 4171

BCM (BODY CONTROL MODULE)INL-55

< ECU DIAGNOSIS >

C

DE

F

G H

I

J

K

M A

B

INL

N

O P

ECU DIAGNOSIS

BCM (BODY CONTROL MODULE)

Reference ValueINFOID:0000000004109551

VALUES ON THE DIAGNOSIS TOOL

Monitor Item Condition Value/Status

AIR COND SW A/C switch OFF

OFF

A/C switch ON ON

AUT LIGHT SYS Outside of the room is dark

OFF

Outside of the room is bright ON

AUTO LIGHT SW Lighting switch OFF

OFF

Lighting switch AUTO ON

BACK DOOR SW Back door closed

OFF

Back door opened ON

CDL LOCK SW Door lock/unlock switch does not operate

OFF

Press door lock/unlock switch to the LOCK side ON

CDL UNLOCK SW Door lock/unlock switch does not operate

OFF

Press door lock/unlock switch to the UNLOCK side ON

DOOR SW-AS Front door RH closed

OFF

Front door RH opened ON

DOOR SW-DR Front door LH closed

OFF

Front door LH opened ON

DOOR SW-RL Rear door LH closed

OFF

Rear door LH opened ON

DOOR SW-RR Rear door RH closed

OFF

Rear door RH opened ON

ENGINE RUN Engine stopped

OFF

Engine running ON

FR FOG SW Front fog lamp switch OFF

OFF

Front fog lamp switch ON ON

FR WASHER SW Front washer switch OFF

OFF

Front washer switch ON ON

FR WIPER LOW Front wiper switch OFF

OFF

Front wiper switch LO ON

FR WIPER HI Front wiper switch OFF

OFF

Front wiper switch HI ON

FR WIPER INT Front wiper switch OFF

OFF

Front wiper switch INT ON

FR WIPER STOP Any position other than front wiper stop position

OFF

Front wiper stop position ON

HAZARD SW When hazard switch is not pressed

OFF

When hazard switch is pressed ON

LIGHT SW 1ST Lighting switch OFF

OFF

Lighting switch 1st ON

Revision: December 20092009 QX56

Page 2500 of 4171

INL-56

< ECU DIAGNOSIS >

BCM (BODY CONTROL MODULE)

HEADLAMP SW1Headlamp switch OFF OFF

Headlamp switch 1st

ON

HEADLAMP SW2 Headlamp switch OFF

OFF

Headlamp switch 1st ON

HI BEAM SW High beam switch OFF

OFF

High beam switch HI ON

H/L WASH SW NOTE:

The item is indicated, but not monitored OFF

IGN ON SW Ignition switch OFF or ACC

OFF

Ignition switch ON ON

IGN SW CAN Ignition switch OFF or ACC

OFF

Ignition switch ON ON

INT VOLUME Wiper intermittent dial is in a dial position 1 - 7 1 - 7

I-KEY LOCK LOCK button of Intelligent Key is not pressed

OFF

LOCK button of Intelligent Key is pressed ON

I-KEY UNLOCK UNLOCK button of Intelligent Key is not pressed

OFF

UNLOCK button of Intelligent Key is pressed ON

KEY ON SW Mechanical key is removed from key cylinder

OFF

Mechanical key is inserted to key cylinder ON

OIL PRESS SW • Ignition switch OFF or ACC

• Engine running

OFF

Ignition switch ON ON

PASSING SW Other than lighting switch PASS

OFF

Lighting switch PASS ON

REAR DEF SW Rear window defogger switch OFF

OFF

Rear window defogger switch ON ON

RKE LOCK AND UN-

LOCK NOTE:

The item is indicated, but not monitored OFF

ON

RR WASHER SW Rear washer switch OFF

OFF

Rear washer switch ON ON

RR WIPER INT Rear wiper switch OFF

OFF

Rear wiper switch INT ON

RR WIPER ON Rear wiper switch OFF

OFF

Rear wiper switch ON ON

RR WIPER STOP Rear wiper stop position

OFF

Other than rear wiper stop position ON

TAIL LAMP SW Lighting switch OFF

OFF

Lighting switch 1ST ON

TRNK OPNR SW When back door opener switch is not pressed

OFF

When back door opener switch is pressed ON

TURN SIGNAL L Turn signal switch OFF

OFF

Turn signal switch LH ON

TURN SIGNAL R Turn signal switch OFF

OFF

Turn signal switch RH ON

VEHICLE SPEED While driving Equivalent to speedometer reading

Monitor Item

Condition Value/Status

Revision: December 20092009 QX56

Page 2512 of 4171

INL-68

< ECU DIAGNOSIS >

BCM (BODY CONTROL MODULE)

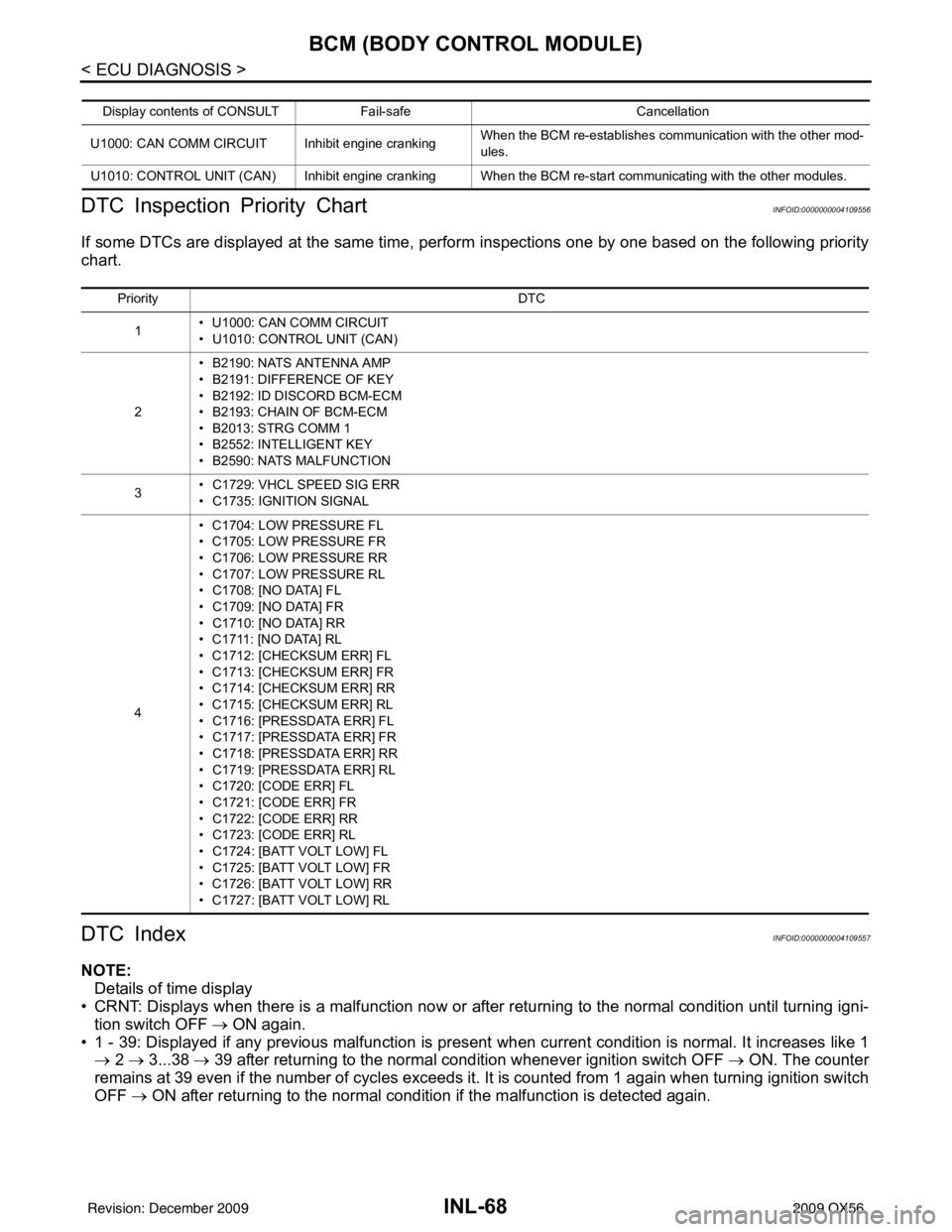

DTC Inspection Priority Chart

INFOID:0000000004109556

If some DTCs are displayed at the same time, perform inspections one by one based on the following priority

chart.

DTC IndexINFOID:0000000004109557

NOTE: Details of time display

• CRNT: Displays when there is a malfunction now or after returning to the normal condition until turning igni-

tion switch OFF → ON again.

• 1 - 39: Displayed if any previous malfunction is present when current condition is normal. It increases like 1

→ 2 → 3...38 → 39 after returning to the normal condition whenever ignition switch OFF → ON. The counter

remains at 39 even if the number of cycles exceeds it. It is counted from 1 again when turning ignition switch

OFF → ON after returning to the normal condition if the malfunction is detected again.

Display contents of CONS ULTFail-safe Cancellation

U1000: CAN COMM CIRCUIT I nhibit engine crankingWhen the BCM re-establishes communication with the other mod-

ules.

U1010: CONTROL UNIT (CAN) Inhibit engine cranking When the BCM re-start communicating with the other modules.

Priority DTC

1 • U1000: CAN COMM CIRCUIT

• U1010: CONTROL UNIT (CAN)

2 • B2190: NATS ANTENNA AMP

• B2191: DIFFERENCE OF KEY

• B2192: ID DISCORD BCM-ECM

• B2193: CHAIN OF BCM-ECM

• B2013: STRG COMM 1

• B2552: INTELLIGENT KEY

• B2590: NATS MALFUNCTION

3 • C1729: VHCL SPEED SIG ERR

• C1735: IGNITION SIGNAL

4 • C1704: LOW PRESSURE FL

• C1705: LOW PRESSURE FR

• C1706: LOW PRESSURE RR

• C1707: LOW PRESSURE RL

• C1708: [NO DATA] FL

• C1709: [NO DATA] FR

• C1710: [NO DATA] RR

• C1711: [NO DATA] RL

• C1712: [CHECKSUM ERR] FL

• C1713: [CHECKSUM ERR] FR

• C1714: [CHECKSUM ERR] RR

• C1715: [CHECKSUM ERR] RL

• C1716: [PRESSDATA ERR] FL

• C1717: [PRESSDATA ERR] FR

• C1718: [PRESSDATA ERR] RR

• C1719: [PRESSDATA ERR] RL

• C1720: [CODE ERR] FL

• C1721: [CODE ERR] FR

• C1722: [CODE ERR] RR

• C1723: [CODE ERR] RL

• C1724: [BATT VOLT LOW] FL

• C1725: [BATT VOLT LOW] FR

• C1726: [BATT VOLT LOW] RR

• C1727: [BATT VOLT LOW] RL

Revision: December 20092009 QX56