brake fluid INFINITI QX56 2009 Factory Manual PDF

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2009, Model line: QX56, Model: INFINITI QX56 2009Pages: 4171, PDF Size: 84.65 MB

Page 2703 of 4171

MA-30

< ON-VEHICLE MAINTENANCE >

CHASSIS AND BODY MAINTENANCE

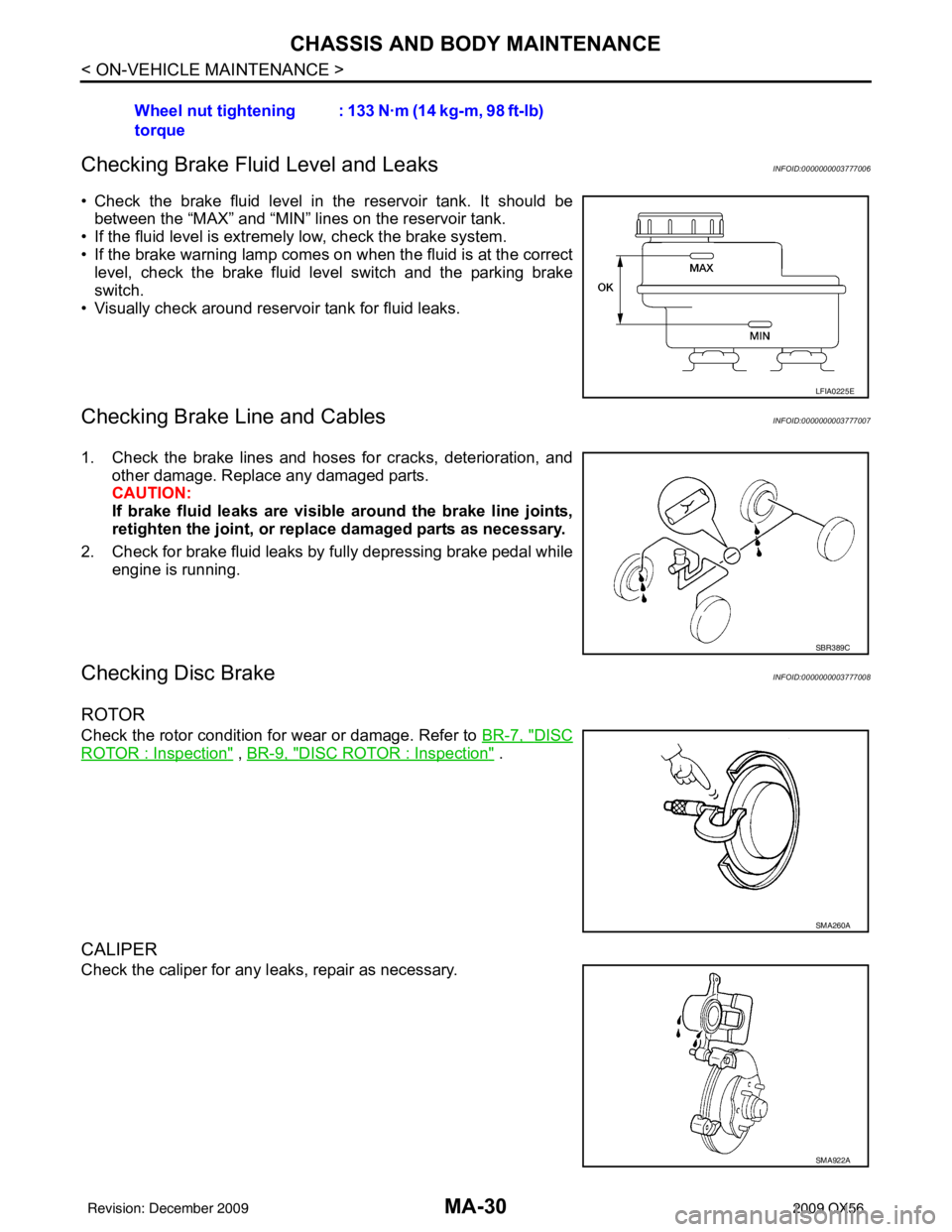

Checking Brake Fluid Level and Leaks

INFOID:0000000003777006

• Check the brake fluid level in the reservoir tank. It should be between the “MAX” and “MIN” lines on the reservoir tank.

• If the fluid level is extremely low, check the brake system.

• If the brake warning lamp comes on when the fluid is at the correct level, check the brake fluid level switch and the parking brake

switch.

• Visually check around reservoir tank for fluid leaks.

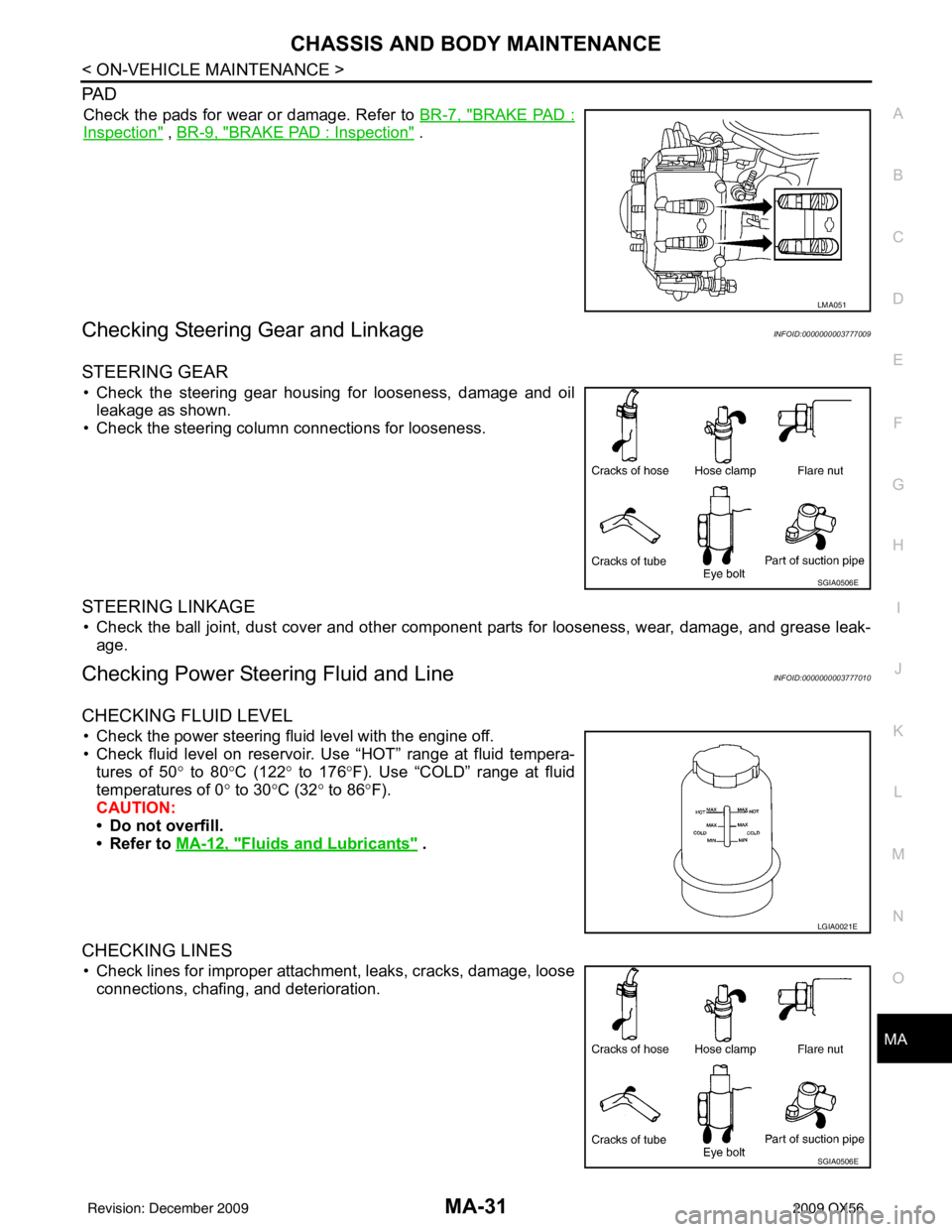

Checking Brake Line and CablesINFOID:0000000003777007

1. Check the brake lines and hoses for cracks, deterioration, and other damage. Replace any damaged parts.

CAUTION:

If brake fluid leaks are visible around the brake line joints,

retighten the joint, or replace damaged parts as necessary.

2. Check for brake fluid leaks by fully depressing brake pedal while engine is running.

Checking Disc BrakeINFOID:0000000003777008

ROTOR

Check the rotor condition for wear or damage. Refer to BR-7, "DISC

ROTOR : Inspection" , BR-9, "DISC ROTOR : Inspection" .

CALIPER

Check the caliper for any l eaks, repair as necessary.

Wheel nut tightening

torque

: 133 N·m (14 kg-m, 98 ft-lb)

LFIA0225E

SBR389C

SMA260A

SMA922A

Revision: December 20092009 QX56

Page 2704 of 4171

CHASSIS AND BODY MAINTENANCEMA-31

< ON-VEHICLE MAINTENANCE >

C

DE

F

G H

I

J

K L

M B

MA

N

O A

PA D

Check the pads for wear or damage. Refer to

BR-7, "BRAKE PAD :

Inspection" , BR-9, "BRAKE PAD : Inspection" .

Checking Steering Ge ar and LinkageINFOID:0000000003777009

STEERING GEAR

• Check the steering gear housing for looseness, damage and oil

leakage as shown.

• Check the steering column connections for looseness.

STEERING LINKAGE

• Check the ball joint, dust cover and other component parts for looseness, wear, damage, and grease leak-

age.

Checking Power Steering Fluid and LineINFOID:0000000003777010

CHECKING FLUID LEVEL

• Check the power steering fluid level with the engine off.

• Check fluid level on reservoir. Use “HOT” range at fluid tempera- tures of 50 ° to 80° C (122° to 176° F). Use “COLD” range at fluid

temperatures of 0 ° to 30° C (32° to 86° F).

CAUTION:

• Do not overfill.

• Refer to MA-12, "

Fluids and Lubricants" .

CHECKING LINES

• Check lines for improper attachment, leaks, cracks, damage, loose

connections, chafing, and deterioration.

LMA051

SGIA0506E

LGIA0021E

SGIA0506E

Revision: December 20092009 QX56

Page 2730 of 4171

MWI-8

< FUNCTION DIAGNOSIS >

METER SYSTEM

SPEEDOMETER

SPEEDOMETER : System DiagramINFOID:0000000003776585

SPEEDOMETER : System DescriptionINFOID:0000000003776586

The ABS actuator and electric unit (control unit) provides a vehicle speed signal to the combination meter via

CAN communication lines.

ABS actuator and electric unit

(control unit) Transmits the vehicle speed signal to the combination meter with CAN communication line.

BCM • Transmits signals provided by various units to the combination meter with CAN communication

line.

• Transmits the security signal to the combination meter.

TCM • Transmits shift position signal to the combination meter with CAN communication line.

• Transmits A/T oil temperature signal to the combination meter with CAN communication line.

Washer level switch Transmits the washer level signal to the combination meter.

Brake fluid level switch Transmits the brake fluid level switch signal to the combination meter.

Parking brake switch Refer to MWI-36, "

Description".

Unit

Description

WKIA5370E

Revision: December 20092009 QX56

Page 2742 of 4171

MWI-20

< FUNCTION DIAGNOSIS >

METER SYSTEM

INFORMATION DISPLAY : System Diagram

INFOID:0000000003776621

INFORMATION DISPLAY : System DescriptionINFOID:0000000003776622

FUNCTION

The information display can indicate the following items.

• Intelligent Key operation information

• Maintenance information

• Warning/Indication messages (Door/liftgate/liftgate glass open, low fuel, low washer fluid, parking brake, A/T

oil temp)

DOOR OPEN WARNING

This warning appears when the ignition switch is ON and the front door LH, front door RH, rear door LH, rear

door RH, back door or glass hatch is opened. The BCM receives a door switch signal from the front door

switch LH, front door switch RH, rear door switch LH, rear door switch RH, back door latch and glass hatch

ajar switch. The BCM sends the door switch signal to the combination meter via CAN communication lines.

Then, when the ignition switch is turned ON, the warning message is displayed.

LOW FUEL WARNING

This warning appears when the fuel level in the fuel tank is less than approximately 11.4 (3 US gal, 2.5 Imp

gal). A variable resistor signal is supplied to the combination meter from the fuel level sensor unit to determine

the amount of fuel in the fuel tank.

LOW WINDSHIELD WASHER FLUID WARNING

This warning appears when the windshield washer fluid level is low. When the windshield washer fluid level is

low, the washer level switch provides a ground signal to the combination meter (unified meter control unit).

Once fluid is added, the message will stay on for 30 seconds and then turn off.

PARKING BRAKE INDICATOR

When the parking brake is applied, the parking brake switch provides a ground signal to the combination

meter (unified meter control unit). Then, when the igni tion switch is turned ON and vehicle speed is greater

than 7 km/h (4 MPH), the message is displayed.

Refer to Owner’s Manual for additional information display items.

AWNIA0202GB

Revision: December 20092009 QX56

Page 2749 of 4171

MWI

DIAGNOSIS SYSTEM (METER)MWI-27

< FUNCTION DIAGNOSIS >

C

DE

F

G H

I

J

K L

M B A

O P

NOTE:

Some items are not available due to vehicle specification.

*: The monitor will indicate “OFF” even though the brake warnin g lamp is on if either of the following conditions exist.

• The parking brake is engaged

• The brake fluid level is low CRUISE W/L [ON/OFF]

X Indicates [ON/OFF] condition of CRUISE warning lamp.

4WD LOCK SW [ON/OFF] X Indicates [ON/OFF] condition of 4WD lock switch.

4WD LOCK IND [ON/OFF] X Indicates [ON/OFF] condition of 4WD lock indicator.

SEAT BELT W/L [ON/OFF] X Indicates [ON/OFF] condition of seat belt warning lamp.

FR FOG IND [ON/OFF] X This item is not used for this model. “OFF” is always displayed.

RR FOG IND [ON/OFF] X This item is not used for this model. “OFF” is always displayed.

LIGHT IND [ON/OFF] X Indicates [ON/OFF] condition of light indicator.

PNP P SW [ON/OFF] XX Indicates [ON/OFF] condition of park/neutral position P switch.

PNP N SW [ON/OFF] XX Indicates [ON/OFF] condition of park/neutral position N switch.

4WD W/L [ON/OFF] X Indicates [ON/OFF] condition of 4WD warning lamp.

Display item [Unit]

MAIN

SIGNALS SELECTION

FROM MENU Description

Revision: December 20092009 QX56

Page 2764 of 4171

MWI-42

< ECU DIAGNOSIS >

COMBINATION METER

ECU DIAGNOSIS

COMBINATION METER

Reference ValueINFOID:0000000003776653

TERMINAL LAYOUT

PHYSICAL VALUES

WKIA5724E

Te r m i -nal Wire

color Item Condition

Reference value (V)

(Approx.)

Ignition

switch Operation or condition

3 Y/L Fuel level sensor signal — —Refer to MWI-12, "

FUEL GAUGE : System

Description".

4 B/P Fuel level sensor ground ON —0

6 BR/W Generator ONGenerator voltage low

0

Generator voltage normal Battery voltage

10 L CAN-H —— —

11 P C A N - L —— —

13 P Air bag warning lamp in-

put ONAir bag warning lamp ON

4

Air bag warning lamp OFF 0

15 BR CK SUSP warning lamp

input —CK SUSP warning lamp

ON

0

CK SUSP warning lamp

OFF Battery voltage

20 B Ground —— 0

21 O/L Ignition switch ON or

START ON

— Battery voltage

23 W/L Washer fluid level switch ON Washer fluid level low

0

Washer fluid level normal Battery voltage

24 O/B Seat belt buckle switch

LH ONUnfastened (ON)

0

Fastened (OFF) Battery voltage

25 P/L Seat belt buckle switch

RH ONUnfastened (ON)

0

Fastened (OFF) Battery voltage

31 G Parking brake switch ON Parking brake applied

0

Parking brake released Battery voltage

32 P/B Brake fluid level switch ON Brake fluid level low

0

Brake fluid level normal Battery voltage

33 R/G Stop lamp switch —Brake pedal depressed

Battery voltage

Brake pedal released 0

Revision: December 20092009 QX56

Page 2918 of 4171

PG

HARNESSPG-47

< COMPONENT DIAGNOSIS >

C

DE

F

G H

I

J

K L

B A

O P

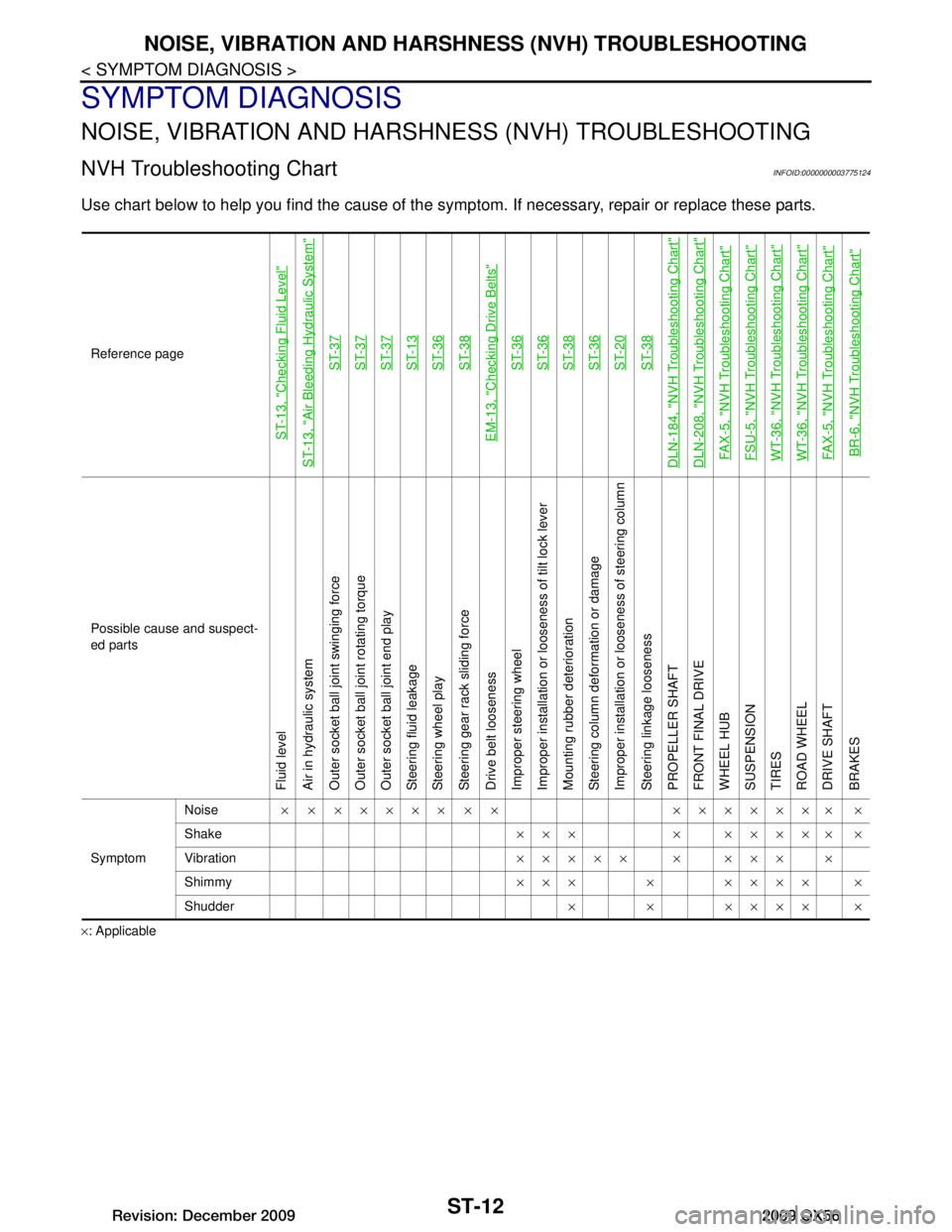

N

C1 E5 W/24 : To F14

C1 E119 W/16: IPDM E/R (intelligent power distri-

bution module engine room)

C2 E7 GR/2 : Fusible link box (battery) D1 E120 W/6: IPDM E/R (intelligent power distri-

bution module engine room)

C2 E9 — : Body ground E1 E121 BR/12: IPDM E/R (intelligent power distri-

bution module engine room)

D4 E6 B/8 : Front combination lamp LH (without

daytime light system) C1 E122 W/12: IPDM E/R (intelligent power distri-

bution module engine room)

B2 E8 W/2 : Hood switch C1 E123 BR/8: IPDM E/R (intelligent power distri-

bution module engine room)

D4 E11 B/8 : Front combination lamp LH (with

daytime light system) D1 E124 B/6

: IPDM E/R (intelligent power distri-

bution module engine room)

D3 E12 B/5 : Stop lamp relay F3 E125 B/47: ABS actuator and electric unit

(control unit)

D4 E14 — : Body ground D4 E126 — : Body ground

C2 E15 — : Body ground C2 E130 W/2 : Compressor motor relay

C1 E16 B/40 : ECM C3 E131 W/2 : Compressor motor relay

E4 E18 GR/2 : Front wheel sensor LH D2 E134 GR/6 : ICC brake hold relay

D1 E19 W/16 : To F33 C2 E135 GR/2 : Transfer dropping resistor

E3 E21 GR/2 : Brake fluid level swit chC1 E140 BR/6 : Trailer tow relay-2

E2 E23 GR/6 : Front wiper motor B2 E153 W/2 : Transfer motor relay

D4 E24 — : Body ground B2 E154 W/2 : Transfer motor relay

F3 E25 BR/3 : Intelligent key warning buzzer D3 E156 L/4 : Trailer turn relay LH

C3 E27 BR/2 : Fusible link box (battery) D3 E157 L/4 : Trailer turn relay RH

C2 E30 /1 : Fusible link box (battery) D5 E158 B/3 : Front sonar sensor LH outer

E3 E31 B/3 : Front pressure sensor D5 E159 GR/3 : To E164

E3 E32 B/3 : Rear pressure sensor B4 E160 GR/3 : To E165

E1 E39 W/2 : To F34 C3 E161 B/3 : Battery current sensor

D3 E40 B/3 : To E201 C5 E162 B/3 : Front sonar sensor LH inner

D3 E41 SMJ : To C1 B4 E163 B/3 : Front sonar sensor RH inner

D2 E42 B/6 : ICC sensor D5 E164 GR/3 : To E159

E1 E46 B/5 : Transfer shift high relay A4 E165 GR/3 : To E160

D2 E47 B/5 : Transfer shift low relay A3 E166 B/3 : Front sonar sensor RH outer

C4 E48 B/3 : Refrigerant pressure sensor Engine room sub-harness

E3 E49 B/6 : Active booster D3 E201 B/3 : To E40

D1 E69 L/4 : Transfer shut off relay C1 E202 /1 : Fusible link box (battery)

D5 E101 B/3 : Front turn-fog lamp LH C2 E203 — : Engine ground

A4 E102 B/3 : Front turn-fog lamp RH C3 E204 /1 : Generator

C3 E103 B/5 : Daytime light relay C3 E205 B/3 : Generator

D4 E105 BR/2 : Front and rear washer motor C3 E206 /1 : Generator

E4 E106 BR/2 : Washer fluid level switch

B3 E107 B/8 : Front combination lamp RH (without

daytime light system)

A3 E108 B/6 : Front combination lamp RH (without

daytime light system)

C5 E113 W/2 : Cooling fan motor

Revision: December 20092009 QX56

Page 3603 of 4171

ST-12

< SYMPTOM DIAGNOSIS >

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

SYMPTOM DIAGNOSIS

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

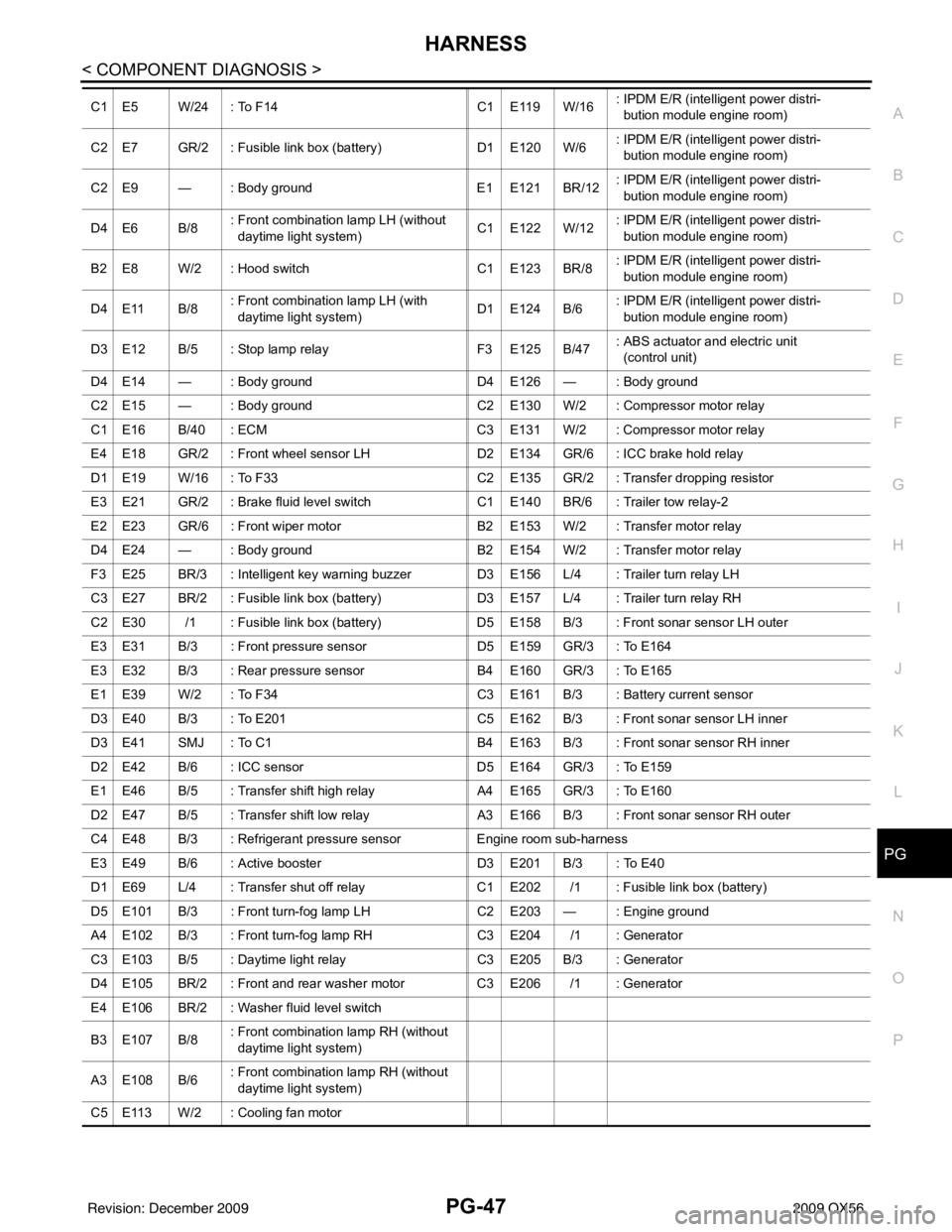

NVH Troubleshooting ChartINFOID:0000000003775124

Use chart below to help you find the cause of the symp tom. If necessary, repair or replace these parts.

×: ApplicableReference page

ST-13, "Checking Fluid Level"

ST-13, "Air Bleeding Hydraulic System"

ST-37ST-37ST-37ST-13ST-36ST-38

EM-13, "Checking Drive Belts"

ST-36ST-36ST-38ST-36ST-20ST-38

DLN-184, "NVH Troubleshooting Chart"DLN-208, "NVH Troubleshooting Chart"FAX-5, "NVH Troubleshooting Chart"FSU-5, "NVH Troubleshooting Chart"WT-36, "NVH Troubleshooting Chart"WT-36, "NVH Troubleshooting Chart"FAX-5, "NVH Troubleshooting Chart"BR-6, "NVH Troubleshooting Chart"

Possible cause and suspect-

ed parts

Fluid level

Air in hydraulic system

Outer socket ball joint swinging force

Outer socket ball joint rotating torque

Outer socket ball joint end play

Steering fluid leakage

Steering wheel play

Steering gear rack sliding force

Drive belt looseness

Improper steering wheel

Improper installation or looseness of tilt lock lever

Mounting rubber deterioration

Steering column deformation or damage

Improper installation or looseness of steering column

Steering linkage looseness

PROPELLER SHAFT

FRONT FINAL DRIVE

WHEEL HUB

SUSPENSION

TIRES

ROAD WHEEL

DRIVE SHAFT

BRAKES

Symptom

Noise

× × ××××× × × ××××××× ×

Shake ××× × ××××× ×

Vibration ××××× × ××× ×

Shimmy ××× × ×××× ×

Shudder × × ×××× ×

Revision: December 20092009 QX56

Page 3606 of 4171

STEERING WHEELST-15

< ON-VEHICLE REPAIR >

C

DE

F

H I

J

K L

M A

B

ST

N

O P

ON-VEHICLE REPAIR

STEERING WHEEL

On-Vehicle Inspection and ServiceINFOID:0000000004187602

CHECKING CONDITION OF INSTALLATION

Check installation condition of steering gear assemb ly, front suspension, axle and steering column.

Check if movement exists when steering wheel is mo ved up and down, to the left and right and to the axial

direction.

Check if the nuts for steering gear assembly are loose. Refer to ST-23, "Removal and Installation"

.

CHECKING STEERING WHEEL PLAY

1. Turn tires straight ahead, start engine, then turn steer ing wheel to the left and right lightly, and measure

steering wheel movement on the outer circumference when steering wheel is turned up to the point where

tires start moving.

CHECKING NEUTRAL POSITION ON STEERING WHEEL

Check neutral position on steering wheel after confirming that front wheel alignment is correct. Refer to FSU-

6, "Front Wheel Alignment".

1. Turn tires straight ahead, check if st eering wheel is in the neutral position.

2. If it is not in the neutral position, remo ve steering wheel and reinstall it correctly.

3. If the neutral position cannot be attained by repositi oning the steering wheel two teeth or less on steering

stem, loosen tie-rod lock nuts of steering outer socket s, then adjust tie-rods by the same amount in the

opposite direction.

CHECKING STEERING WHEEL TURNING FORCE

1. Park vehicle on a level, dry surface and set parking brake.

2. Start engine.

3. Bring power steering fluid up to operating temperature of 60 °– 80 °C (140 °– 176 °F).

4. Tires need to be inflated to specified pressure. Refer to WT-45, "Tire"

.

End play of the axial direction for steering wheel : Refer to

ST-

36, "Steering

Wheel"

LGIA0024E

Steering wheel play on the outer circumference : Refer to ST-36, "Steering

Wheel"

Revision: December 20092009 QX56

Page 3652 of 4171

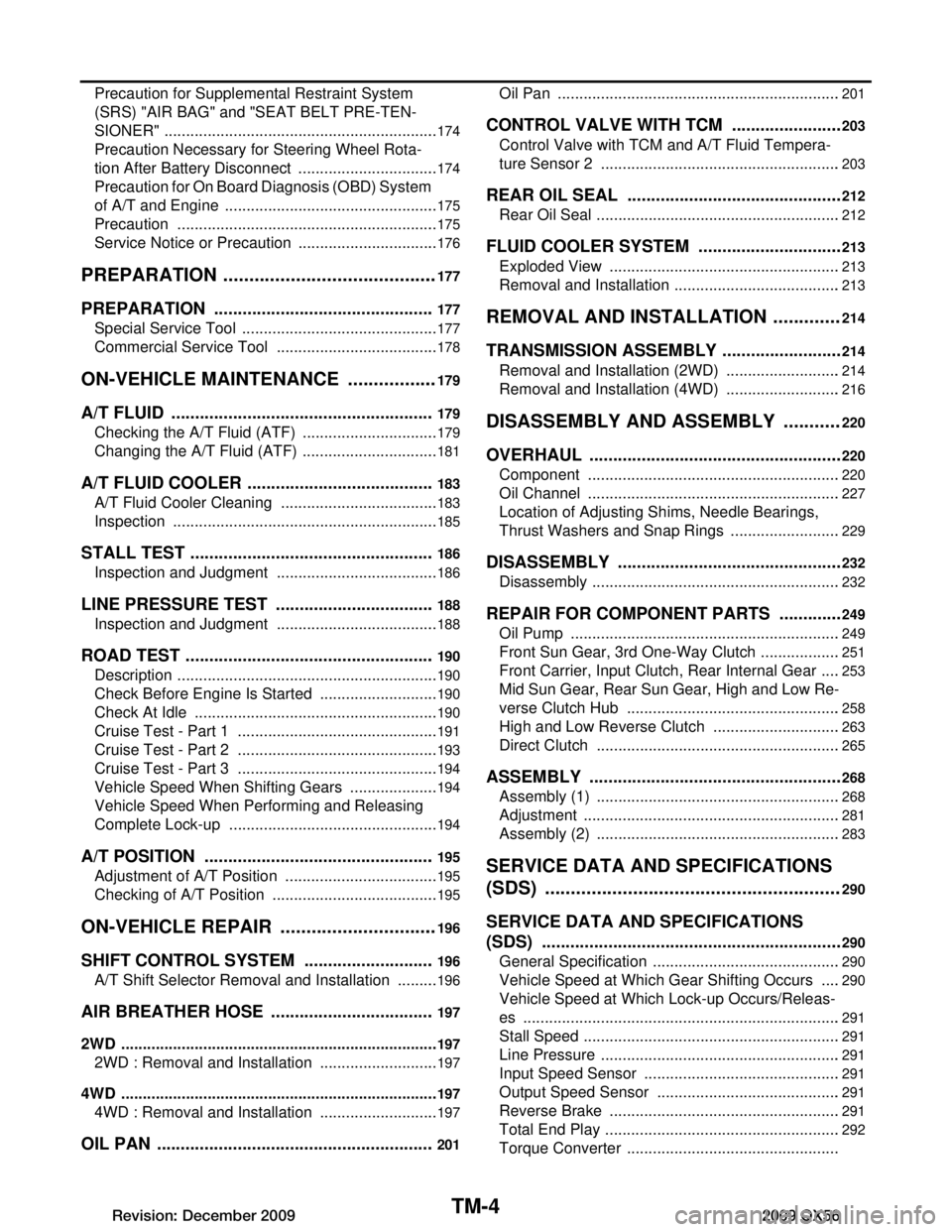

TM-4

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ................................................................

174

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect .................................

174

Precaution for On Board Diagnosis (OBD) System

of A/T and Engine ..................................................

175

Precaution .............................................................175

Service Notice or Precaution .................................176

PREPARATION ..........................................177

PREPARATION .............................................. .177

Special Service Tool ............................................ ..177

Commercial Service Tool ......................................178

ON-VEHICLE MAINTENANCE ..................179

A/T FLUID ....................................................... .179

Checking the A/T Fluid (ATF) .............................. ..179

Changing the A/T Fluid (ATF) ................................181

A/T FLUID COOLER ........................................183

A/T Fluid Cooler Cleaning ................................... ..183

Inspection ..............................................................185

STALL TEST ....................................................186

Inspection and Judgment .................................... ..186

LINE PRESSURE TEST ..................................188

Inspection and Judgment .................................... ..188

ROAD TEST .....................................................190

Description ........................................................... ..190

Check Before Engine Is Started ............................190

Check At Idle .........................................................190

Cruise Test - Part 1 ...............................................191

Cruise Test - Part 2 ...............................................193

Cruise Test - Part 3 ...............................................194

Vehicle Speed When Shifting Gears .....................194

Vehicle Speed When Performing and Releasing

Complete Lock-up .................................................

194

A/T POSITION .................................................195

Adjustment of A/T Position .................................. ..195

Checking of A/T Position .......................................195

ON-VEHICLE REPAIR ............................. ..196

SHIFT CONTROL SYSTEM ........................... .196

A/T Shift Selector Removal and Installation ........ ..196

AIR BREATHER HOSE ...................................197

2WD ........................................................................ ..197

2WD : Removal and Installation ............................197

4WD ........................................................................ ..197

4WD : Removal and Installation ............................197

OIL PAN ...........................................................201

Oil Pan ................................................................. .201

CONTROL VALVE WITH TCM ........................203

Control Valve with TCM and A/T Fluid Tempera-

ture Sensor 2 ....................................................... .

203

REAR OIL SEAL ..............................................212

Rear Oil Seal ........................................................ .212

FLUID COOLER SYSTEM ...............................213

Exploded View ..................................................... .213

Removal and Installation .......................................213

REMOVAL AND INSTALLATION .............214

TRANSMISSION ASSEMBLY ........................ ..214

Removal and Installation (2WD) .......................... .214

Removal and Installation (4WD) ...........................216

DISASSEMBLY AND ASSEMBLY ...........220

OVERHAUL .................................................... ..220

Component .......................................................... .220

Oil Channel ...........................................................227

Location of Adjusting Shims, Needle Bearings,

Thrust Washers and Snap Rings ......................... .

229

DISASSEMBLY .............................................. ..232

Disassembly ......................................................... .232

REPAIR FOR COMPONENT PARTS ..............249

Oil Pump .............................................................. .249

Front Sun Gear, 3rd One-Way Clutch ...................251

Front Carrier, Input Clutch, Rear Internal Gear .....253

Mid Sun Gear, Rear Sun Gear, High and Low Re-

verse Clutch Hub ..................................................

258

High and Low Reverse Clutch ..............................263

Direct Clutch .........................................................265

ASSEMBLY .................................................... ..268

Assembly (1) ........................................................ .268

Adjustment ............................................................281

Assembly (2) .........................................................283

SERVICE DATA AND SPECIFICATIONS

(SDS) ............... ..........................................

290

SERVICE DATA AND SPECIFICATIONS

(SDS) .............................................................. ..

290

General Specification ........................................... .290

Vehicle Speed at Which Gear Shifting Occurs .....290

Vehicle Speed at Which Lock-up Occurs/Releas-

es ..........................................................................

291

Stall Speed ............................................................291

Line Pressure ........................................................291

Input Speed Sensor ..............................................291

Output Speed Sensor ...........................................291

Reverse Brake ......................................................291

Total End Play .......................................................292

Torque Converter .................................................

Revision: December 20092009 QX56