adding oil INFINITI QX56 2009 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2009, Model line: QX56, Model: INFINITI QX56 2009Pages: 4171, PDF Size: 84.65 MB

Page 1919 of 4171

EM-96

< DISASSEMBLY AND ASSEMBLY >

ENGINE UNIT

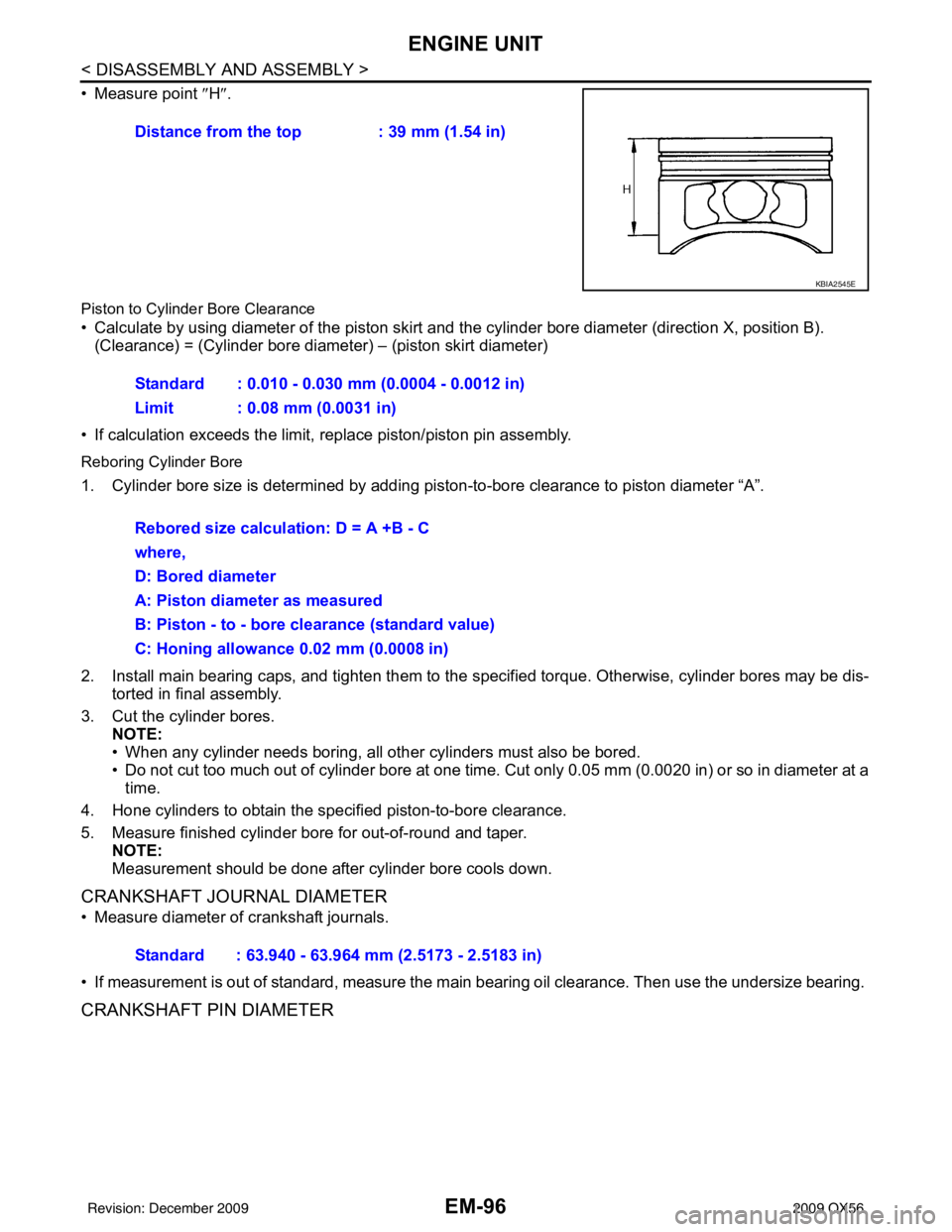

• Measure point ″H″.

Piston to Cylinde r Bore Clearance

• Calculate by using diameter of the piston skirt and the cylinder bore diameter (direction X, position B).

(Clearance) = (Cylinder bore diameter) – (piston skirt diameter)

• If calculation exceeds the limit, replace piston/piston pin assembly.

Reboring Cylinder Bore

1. Cylinder bore size is determined by adding pi ston-to-bore clearance to piston diameter “A”.

2. Install main bearing caps, and tighten them to the specified torque. Otherwise, cylinder bores may be dis-

torted in final assembly.

3. Cut the cylinder bores. NOTE:

• When any cylinder needs boring, all other cylinders must also be bored.

• Do not cut too much out of cylinder bore at one time. Cut only 0.05 mm (0.0020 in) or so in diameter at atime.

4. Hone cylinders to obtain the specified piston-to-bore clearance.

5. Measure finished cylinder bore for out-of-round and taper. NOTE:

Measurement should be done after cylinder bore cools down.

CRANKSHAFT JOURNAL DIAMETER

• Measure diameter of crankshaft journals.

• If measurement is out of standard, measure the main bearing oil clearance. Then use the undersize bearing.

CRANKSHAFT PIN DIAMETER

Distance from the top : 39 mm (1.54 in)

KBIA2545E

Standard : 0.010 - 0.030 mm (0.0004 - 0.0012 in)

Limit : 0.08 mm (0.0031 in)

Rebored size calculation: D = A +B - C

where,

D: Bored diameter

A: Piston diameter as measured

B: Piston - to - bore clearance (standard value)

C: Honing allowance 0.02 mm (0.0008 in)

Standard : 63.940 - 63.964 mm (2.5173 - 2.5183 in)

Revision: December 20092009 QX56

Page 2109 of 4171

PRECAUTIONSEXT-3

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

EXT

N

O P

5. When the repair work is completed, return the ignition switch to the ″LOCK ″ position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of al l control units using CONSULT-III.

Service NoticeINFOID:0000000003776097

• When removing or installing various parts, place a cloth or padding on the vehicle body to prevent scratches.

• Handle trim, molding, instruments, grille, etc. carefully during removing or installing. Be careful not to soil or

damage them.

• Apply sealing compound where necessary when installing parts.

• When applying sealing compound, be careful that the sealing compound does not protrude from parts.

• When replacing any metal parts (for example body outer panel, members, etc.), be sure to take rust preven-

tion measures.

Revision: December 20092009 QX56

Page 2532 of 4171

PRECAUTIONSINT-9

< PRECAUTION >

C

DE

F

G H

I

K L

M A

B

INT

N

O P

5. When the repair work is completed, return the ignition switch to the ″LOCK ″ position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of al l control units using CONSULT-III.

Service NoticeINFOID:0000000003775406

• When removing or installing various parts, place a cloth or padding on the vehicle body to prevent scratches.

• Handle trim, molding, instruments, grille, etc. carefully during removing or installing. Be careful not to soil or

damage them.

• Apply sealing compound where necessary when installing parts.

• When applying sealing compound, be careful that the sealing compound does not protrude from parts.

• When replacing any metal parts (for example body outer panel, members, etc.), be sure to take rust preven-

tion measures.

Revision: December 20092009 QX56

Page 2686 of 4171

RECOMMENDED FLUIDS AND LUBRICANTSMA-13

< ON-VEHICLE MAINTENANCE >

C

DE

F

G H

I

J

K L

M B

MA

N

O A

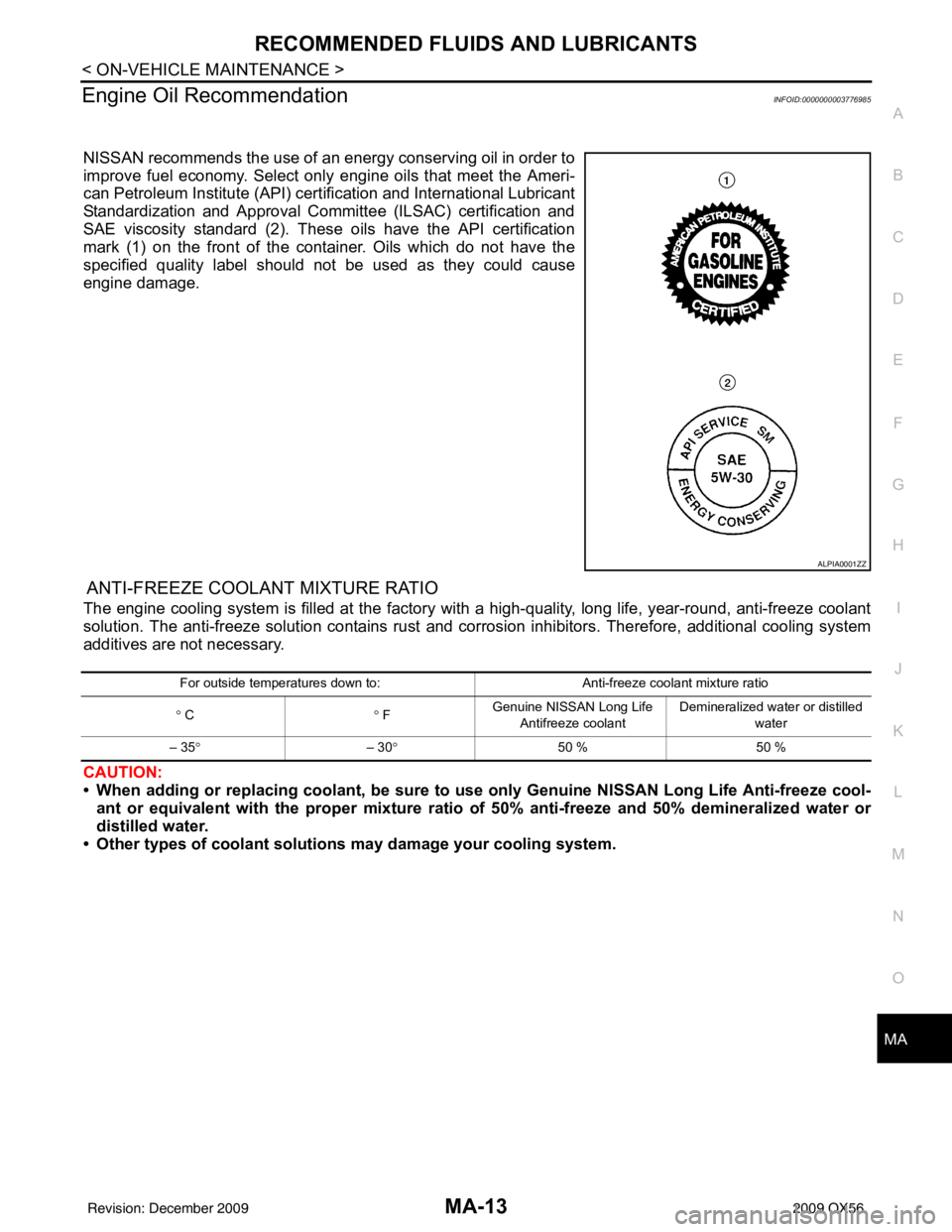

Engine Oil RecommendationINFOID:0000000003776985

NISSAN recommends the use of an energy conserving oil in order to

improve fuel economy. Select only

engine oils that meet the Ameri-

can Petroleum Institute (API) cert ification and International Lubricant

Standardization and Approval Committee (ILSAC) certification and

SAE viscosity standard (2). These oils have the API certification

mark (1) on the front of the container. Oils which do not have the

specified quality label should not be used as they could cause

engine damage.

ANTI-FREEZE COOLANT MIXTURE RATIO

The engine cooling system is filled at the factory wit h a high-quality, long life, year-round, anti-freeze coolant

solution. The anti-freeze solution contains rust and corrosion inhibitors. Therefore, additional cooling system

additives are not necessary.

CAUTION:

• When adding or replacing coolant, be sure to use only Genuine NISSAN Long Life Anti-freeze cool-

ant or equivalent with the proper mixture ratio of 50% anti-freeze and 50% demineralized water or

distilled water.

• Other types of coolant solutions may damage your cooling system.

ALPIA0001ZZ

For outside temperatures down to: Anti-freeze coolant mixture ratio

° C ° F Genuine NISSAN Long Life

Antifreeze coolant Demineralized water or distilled

water

– 35° – 30° 50 % 50 %

Revision: December 20092009 QX56