heater INFINITI QX56 2009 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2009, Model line: QX56, Model: INFINITI QX56 2009Pages: 4171, PDF Size: 84.65 MB

Page 1 of 4171

A

B

C

D

E

F

G

H

I

J

K

L

M

N

P

O

QUICK REFERENCE INDEX

AGENERAL INFORMATIONGIGeneral Information

BENGINEEMEngine Mechanical

LUEngine Lubrication System

COEngine Cooling System

ECEngine Control System

FLFuel System

EXExhaust System

STRStarting System

ACCAccelerator Control System

CHYBRIDHBCHybrid Control System

HBBHybrid Battery System

HBRHybrid Brake System

DTRANSMISSION & DRIVE-

LINETMTransaxle & Transmission

DLNDriveline

FAXFront Axle

RAXRear Axle

ESUSPENSIONFSUFront Suspension

RSURear Suspension

SCSSuspension Control System

WTRoad Wheels & Tires

FBRAKESBRBrake System

PBParking Brake System

BRCBrake Control System

GSTEERINGSTSteering System

STCSteering Control System

HRESTRAINTSSBSeat Belt

SBCSeat Belt Control System

SRSRS Airbag

SRCSRS Airbag Control System

IVENTILATION, HEATER &

AIR CONDITIONERVTLVentilation System

HAHeater & Air Conditioning System

HACHeater & Air Conditioning Control System

JBODY INTERIORINTInterior

IPInstrument Panel

SESeat

ADPAutomatic Drive Postioner

APAdjustable Pedal

KBODY EXTERIOR,

DOORS, ROOF & VEHICLE

SECURITYDLKDoor & Lock

SECSecurity Control System

GWGlass & Window System

PWCPower Window Control System

RFRoof

EXTExterior

BRMBody Repair Manual

LDRIVER CONTROLSMIRMirrors

EXLExterior Lighting System

INLInterior Lighting System

WWWiper & Washer

DEFDefogger

HRNHorn

MELECTRICAL & POWER

CONTROLPWOPower Outlet

BCSBody Control System

LANLAN System

PCSPower Control System

CHGCharging System

PGPower Supply, Ground & Circuit Elements

NDRIVER INFORMATION &

MULTIMEDIAMWIMeter, Warning Lamp & Indicator

WCSWarning Chime System

SNSonar System

AVAudio, Visual & Navigation System

OCRUISE CONTROLCCSCruise Control System

PMAINTENANCEMAMaintenance

All rights reserved. No part

of this Service Manual may

be reproduced or stored in a

retrieval system, or transmit-

ted in any form, or by any

means, electronic, mechani-

cal, photo-copying, record-

ing or otherwise, without the

prior written permission of

Nissan North America, Inc.

Edition: June 2008

Revision: December 2009

Publication No. SM9

E-1J60U1

Page 343 of 4171

![INFINITI QX56 2009 Factory Service Manual AV

NORMAL OPERATING CONDITIONAV-157

< SYMPTOM DIAGNOSIS > [AUDIO SYSTEM]

C

D

E

F

G H

I

J

K L

M B A

O P

NORMAL OPERATING CONDITION

DescriptionINFOID:0000000003776899

AUDIO SYSTEM

The majority of the au INFINITI QX56 2009 Factory Service Manual AV

NORMAL OPERATING CONDITIONAV-157

< SYMPTOM DIAGNOSIS > [AUDIO SYSTEM]

C

D

E

F

G H

I

J

K L

M B A

O P

NORMAL OPERATING CONDITION

DescriptionINFOID:0000000003776899

AUDIO SYSTEM

The majority of the au](/img/42/57031/w960_57031-342.png)

AV

NORMAL OPERATING CONDITIONAV-157

< SYMPTOM DIAGNOSIS > [AUDIO SYSTEM]

C

D

E

F

G H

I

J

K L

M B A

O P

NORMAL OPERATING CONDITION

DescriptionINFOID:0000000003776899

AUDIO SYSTEM

The majority of the audio troubles are the result of outside causes (bad CD, electromagnetic interference,

etc.).

Noise

The following noise results from variations in field strength, such as fading noise and multi-path noise, or

external noise from trains and other sources. It is not a malfunction.

• Fading noise: This noise occurs because of variations in the field strength in a narrow range due to moun-

tains or buildings blocking the signal.

• Multi-path noise: This noise results from the waves sent directly from the broadcast station arriving at the antenna at a different time from the waves which reflect off mountains or buildings.

The vehicle itself can be a source of noise if noise prevention parts or electrical equipment is malfunctioning.

Check if noise is caused and/or changed by engine speed, ignition switch turned to each position, and opera-

tion of each piece of electrical equipment, and determine the cause.

NOTE:

The source of the noise can be found easily by listening to the noise while removing the fuses of electrical

components, one by one.

Type of Noise and Possible Cause

NAVIGATION SYSTEM

Basic Operation

Vehicle Mark

Occurrence condition Possible cause

Occurs only when engine is ON. A continuous growling noise occurs. The speed of

the noise varies with changes in the engine speed. • Ignition components

The occurrence of the noise is linked with the operation of the fuel pump. • Fuel pump condenser

Noise only occurs when various

electrical components are oper-

ating. A cracking or snapping sound occurs with the op-

eration of various switches.

• Relay malfunction, audio unit malfunction

The noise occurs when various motors are operat-

ing. • Motor case ground

•Motor

The noise occurs constantly, not just under certain conditions. • Rear defogger coil malfunction

• Open circuit in printed heater

• Poor ground of antenna feeder line

A cracking or snapping sound occurs while the vehicle is being driven, especially when

it is vibrating excessively. • Ground wire of body parts

• Ground due to improper part installation

• Wiring connections or a short circuit

Symptom

Cause Remedy

No image is shown. Display brightness adjustment is set fully to DARK

side. Adjust the display brightness.

No guide sound is heard.

Audio guide volume is too low or

too high. Volume control is set to OFF, MIN or MAX. Adjust the audio guide volume.

Audio guidance is not available while the vehicle is

driving on a dark pink route.

System is not malfunctioning.

Screen is too dark.

Motion of the image is too slow. Temperature inside the vehicle is low.

Wait until the temperature inside the vehicle

reaches the proper temperature.

Small black or bright spots appear

on the screen. Symptom peculiar to a liquid crystal display (dis-

play unit). System is not malfunction.

Revision: December 20092009 QX56

Page 756 of 4171

CO-12

< ON-VEHICLE MAINTENANCE >

ENGINE COOLANT

5. Remove the reservoir tank to drain the engine coolant, then clean the reservoir tank before installing it.

6. Check the drained coolant for contaminants such as rust, corrosion or discoloration.

If the coolant is contaminated, flus h the engine cooling system. Refer to CO-11, "

Changing Engine Cool-

ant".

REFILLING ENGINE COOLANT

1. Close the radiator drain plug. Install the reservoir t ank, cylinder block drain plug, and the oil cooler hose, if

removed for a total system drain or for engine removal or repair.

• The radiator must be completely empty of coolant and water.

• Apply sealant to the threads of the cylinder bl ock drain plug. Use Genuine High Performance Thread

Sealant or equivalent. Refer to GI-15, "

Recommended Chemical Products and Sealants".

2. Set the vehicle heater controls to the full HOT and heat er ON position. Turn the vehicle ignition ON with

the engine OFF as necessary to activate the heater mode.

3. Remove the vented reservoir cap and replace it with a non-vented reservoir cap before filling the cooling

system.

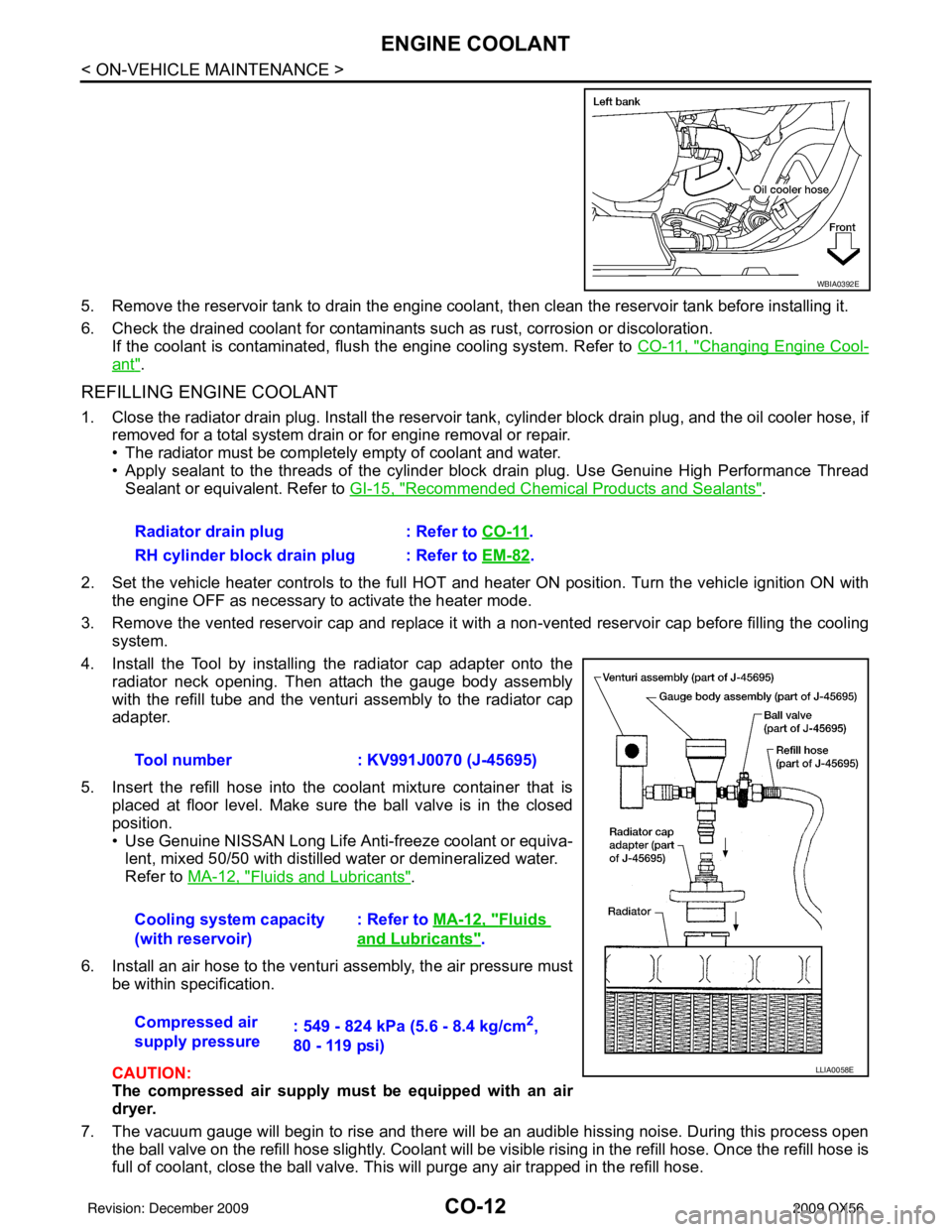

4. Install the Tool by installing the radiator cap adapter onto the radiator neck opening. Then attach the gauge body assembly

with the refill tube and the venturi assembly to the radiator cap

adapter.

5. Insert the refill hose into the coolant mixture container that is placed at floor level. Make sure the ball valve is in the closed

position.

• Use Genuine NISSAN Long Life Anti-freeze coolant or equiva-lent, mixed 50/50 with distilled water or demineralized water.

Refer to MA-12, "

Fluids and Lubricants".

6. Install an air hose to the venturi assembly, the air pressure must be within specification.

CAUTION:

The compressed air supply must be equipped with an air

dryer.

7. The vacuum gauge will begin to rise and there will be an audible hissing noise. During this process open the ball valve on the refill hose slightly. Coolant will be vi sible rising in the refill hose. Once the refill hose is

full of coolant, close the ball valve. This will purge any air trapped in the refill hose.

WBIA0392E

Radiator drain plug : Refer to CO-11.

RH cylinder block drain plug : Refer to EM-82

.

Tool number : KV991J0070 (J-45695)

Cooling system capacity

(with reservoir) : Refer to

MA-12, "

Fluids

and Lubricants".

Compressed air

supply pressure : 549 - 824 kPa (5.6 - 8.4 kg/cm

2,

80 - 119 psi)

LLIA0058E

Revision: December 20092009 QX56

Page 766 of 4171

CO-22

< ON-VEHICLE REPAIR >

THERMOSTAT AND WATER PIPING

THERMOSTAT AND WATER PIPING

Exploded ViewINFOID:0000000004129535

Removal and InstallationINFOID:0000000003771291

REMOVAL

Removal of Thermostat

1. Partially drain engine coolant from the radiator. Refer to CO-11, "Changing Engine Coolant".

CAUTION:

Perform when engine is cold.

2. Remove the air duct and resonator assembly. Refer to EM-25, "

Exploded View".

3. Disconnect the water suction hose from the water inlet.

4. Remove the water inlet and thermostat.

Removal of Thermostat Housing, Water Outlet and Heater Pipe

1. Remove the intake manifold. Refer to EM-26, "Removal and Installation".

2. Remove the thermostat housing, water outlet and heater pipe.

Removal of Water Cut Valve

1. Partially drain the engine coolant from the radiator. Refer to CO-11, "Changing Engine Coolant".

1. Heater pipe2. Gasket 3. Water outlet

4. Gasket 5. O-ring 6. O-ring

7. Thermostat housing 8. Rubber ring 9. Thermostat

10. Water inlet 11. Water suction hose 12. Water suction pipe

13. Gasket 14. Heater pipe

KBIA2501E

Revision: December 20092009 QX56

Page 767 of 4171

THERMOSTAT AND WATER PIPINGCO-23

< ON-VEHICLE REPAIR >

C

DE

F

G H

I

J

K L

M A

CO

NP

O

CAUTION:

Perform when the engine is cold.

2. Disconnect the water cut valve connector.

3. Disconnect the water hoses from the water cut valve.

4. Remove the water cut valve.

INSPECTION AFTER REMOVAL

• Place a thread so that it is caught in the valve of the thermostat.

Immerse fully in a container filled with water. Heat while stirring.

• The valve opening temperature is the temperature at which the valve opens and falls from the thread.

• Continue heating. Check the full-open lift amount.

• After checking the full-open lift amount, lower the water tempera- ture and check the valve closing temperature.

Standard values:

INSTALLATION

Installation is in the reverse order of removal.

Installation of Thermostat

• Install the thermostat with the whole circumference of each flange

part fit securely inside the rubber ring as shown.

• Install the thermostat with the jiggle valve facing upwards.

Installation of Water Outlet Pipe and Heater Pipe

First apply a neutral detergent to the O- rings, then quickly insert the insertion parts of the water outlet pipe and

heater pipe into the installation holes.

INSPECTION AFTER INSTALLATION

• Check for leaks of the engine coolant. Refer to CO-10, "Inspection".

• Start and warm up the engine. Visually check for leaks of the engine coolant.

SLC252B

Thermostat

Valve opening temperature 80 - 84°C (176 - 183 ° F)

Full-open lift amount More than 10 mm/ 95°C (0.39 in/ 203° F)

Valve closing temperature 77°C (171 °F) or higher

KBIA2502E

Revision: December 20092009 QX56

Page 1328 of 4171

EC-1

ENGINE

C

DE

F

G H

I

J

K L

M

SECTION EC

A

EC

N

O P

CONTENTS

ENGINE CONTROL SYSTEM

VK56DE

BASIC INSPECTION ....... .............................

8

DIAGNOSIS AND REPAIR WORKFLOW ..... .....8

Trouble Diagnosis Introduction ........................... ......8

INSPECTION AND ADJUSTMENT ....................13

Basic Inspection .................................................. ....13

Idle Speed and Ignition Timing Check ....................17

Procedure After Replacing ECM .............................17

VIN Registration ......................................................17

Accelerator Pedal Released Position Learning .......18

Throttle Valve Closed Position Learning .................18

Idle Air Volume Learning .........................................18

FUNCTION DIAGNOSIS ..............................21

ENGINE CONTROL SYSTEM ........................ ....21

System Diagram .................................................. ....21

Engine Control Component Parts Location .............22

MULTIPORT FUEL INJECTION SYSTEM .........28

System Description ............................................. ....28

ELECTRIC IGNITION SYSTEM ..................... ....31

System Description ............................................. ....31

AIR CONDITIONING CUT CONTROL ...............32

Input/Output Signal Chart .................................... ....32

System Description .................................................32

AUTOMATIC SPEED CONTROL DEVICE

(ASCD) ...............................................................

33

System Description ............................................. ....33

Component Description ...........................................34

CAN COMMUNICATION ....................................35

System Description ............................................. ....35

COOLING FAN CONTROL ................................36

Description .......................................................... ....36

EVAPORATIVE EMISSION SYSTEM ...............37

Description ........................................................... ....37

INTAKE VALVE TIMING CONTROL ................40

Description ...............................................................40

ON BOARD DIAGNOSTIC (OBD) SYSTEM ....41

Introduction ..............................................................41

Two Trip Detection Logic .........................................41

Emission-related Diagnostic Information .................42

Malfunction Indicator Lamp (MIL) ............................55

OBD System Operation Chart .................................58

CONSULT-III Function (ENGINE) ...........................63

Generic Scan Tool (GST) Function .........................72

COMPONENT DIAGNOSIS .........................74

TROUBLE DIAGNOSIS - SPECIFICATION

VALUE ...............................................................

74

Description ........................................................... ....74

Testing Condition .....................................................74

Inspection Procedure ...............................................74

Diagnosis Procedure ...............................................75

POWER SUPPLY AND GROUND CIRCUIT ....82

Diagnosis Procedure ...............................................82

Ground Inspection ...................................................85

U1000, U1001 CAN COMM CIRCUIT ...............86

Description ...............................................................86

On Board Diagnosis Logic .......................................86

DTC Confirmation Procedure ..................................86

Diagnosis Procedure ...............................................86

P0011, P0021 IVT CONTROL ...........................87

On Board Diagnosis Logic .......................................87

DTC Confirmation Procedure ..................................87

Diagnosis Procedure ...............................................88

Component Inspection .............................................92

P0031, P0032, P0051, P0052 A/F SENSOR 1

HEATER ............................................................

94

Revision: December 20092009 QX56

Page 1334 of 4171

EC-7

C

DE

F

G H

I

J

K L

M

EC A

N

O P

SYMPTOM DIAGNOSIS ..... .......................475

ENGINE CONTROL SYSTEM SYMPTOMS .. ..475

Symptom Matrix Chart ........................................ ..475

NORMAL OPERATING CONDITION ...............479

Fuel Cut Control (at No Load and High Engine

Speed) ................................................................. ..

479

PRECAUTION ............................................480

PRECAUTIONS .............................................. ..480

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ..

480

On Board Diagnosis (OBD) System of Engine and

A/T .........................................................................

480

Precaution .............................................................481

PREPARATION .........................................484

PREPARATION .............................................. ..484

Special Service Tool ........................................... ..484

Commercial Service Tool ......................................485

ON-VEHICLE MAINTENANCE ..................487

FUEL PRESSURE .......................................... ..487

Fuel Pressure Check ........................................... ..487

EVAP LEAK CHECK ........................................489

How to Detect Fuel Vapor Leakage .................... ..489

ON-VEHICLE REPAIR ...............................491

EVAP CANISTER ............................................491

Removal and Installation ..................................... ..491

Component Inspection ...........................................491

INTAKE VALVE TIMING CONTROL ..............492

Intake Valve Timing Control Solenoid Valve (LH) ..492

Intake Valve Timing Cont rol Solenoid Valve (RH) ..492

Intake Valve Timing Control Position Sensor (LH) ..493

Intake Valve Timing Control Position Sensor (RH) ..493

Camshaft Position Sensor (PHASE) .....................493

SERVICE DATA AND SPECIFICATIONS

(SDS) ............... ...........................................

495

SERVICE DATA AND SPECIFICATIONS

(SDS) ...............................................................

495

Fuel Pressure ...................................................... ..495

Idle Speed and Ignition Timing ..............................495

Calculated Load Value ..........................................495

Mass Air Flow Sensor ............................................495

Intake Air Temperature Sensor .............................495

Engine Coolant Temperature Sensor ....................495

A/F Sensor 1 Heater ..............................................495

Heated Oxygen sensor 2 Heater ...........................496

Crankshaft Position Sensor (POS) ........................496

Camshaft Position Sensor (PHASE) .....................496

Throttle Control Motor ............................................496

Fuel Injector ...........................................................496

Fuel Pump .............................................................496

Revision: December 20092009 QX56

Page 1378 of 4171

![INFINITI QX56 2009 Factory Service Manual

ON BOARD DIAGNOSTIC (OBD) SYSTEMEC-51

< FUNCTION DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

EGR

SYSTEM

31H EGR function P0400 80H 96H

Low Flow Faults: EGR temp change

rate (short term)

P0 INFINITI QX56 2009 Factory Service Manual

ON BOARD DIAGNOSTIC (OBD) SYSTEMEC-51

< FUNCTION DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

EGR

SYSTEM

31H EGR function P0400 80H 96H

Low Flow Faults: EGR temp change

rate (short term)

P0](/img/42/57031/w960_57031-1377.png)

ON BOARD DIAGNOSTIC (OBD) SYSTEMEC-51

< FUNCTION DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

EGR

SYSTEM

31H EGR function P0400 80H 96H

Low Flow Faults: EGR temp change

rate (short term)

P0400 81H 96H Low Flow Faults: EGR temp change

rate (long term)

P0400 82H 96H Low Flow Faults: Difference between

max EGR temp and EGR temp under

idling condition

P0400 83H 96H Low Flow Faults: Max EGR temp

P1402 84H 96H High Flow Faults: EGR temp increase

rate

VVT

SYSTEM 35H VVT Monitor (Bank1)

P0011 80H 9DH

VTC intake function diagnosis (VTC

alignment check diagnosis)

P0014 81H 9DH VTC exhaust function diagnosis (VTC

alignment check diagnosis)

P0011 82H 9DH VTC intake function diagnosis (VTC

drive failure diagnosis)

P0014 83H 9DH VTC exhaust function diagnosis (VTC

drive failure diagnosis)

36H VVT Monitor (Bank2) P0021 80H 9DH

VTC intake function diagnosis (VTC

alignment check diagnosis)

P0024 81H 9DH VTC exhaust function diagnosis (VTC

alignment check diagnosis)

P0021 82H 9DH VTC intake function diagnosis (VTC

drive failure diagnosis)

P0024 83H 9DH VTC exhaust function diagnosis (VTC

drive failure diagnosis)

EVAP

SYSTEM 39H

EVAP control system leak

(Cap Off) P0455 80H 0CH

Difference in pressure sensor output

voltage before and after pull down

3BH EVAP control system leak

(Small leak) P0442 80H 05H

Leak area index (for more than 0.04

inch)

3CH EVAP control system leak

(Very small leak) P0456 80H 05H

Leak area index (for more than 0.02

inch)

P0456 81H FDH Maximum internal pressure of EVAP

system during monitoring

3DH Purge flow system P0441 83H 0CH Difference in pressure sensor output

voltage before and after vent control

valve close

O2 SEN-

SOR

HEATER 41H

A/F sensor 1 heater

(Bank 1) Low Input:P0031

High Input:P0032 81H 0BHConverted value of Heater electric cur-

rent to voltage

42H Heated oxygen sensor 2 heat-

er (Bank 1) Low Input:P0037

High Input:P0038 80H 0CH

Converted value of Heater electric cur-

rent to voltage

43H Heated oxygen sensor 3 heat-

er (Bank 1) P0043 80H 0CHConverted value of Heater electric cur-

rent to voltage

45H A/F sensor 1 heater

(Bank 2) Low Input:P0051

High Input:P0052

81H 0BHConverted value of Heater electric cur-

rent to voltage

46H Heated oxygen sensor 2 heat-

er (Bank 2) Low Input:P0057

High Input:P0058 80H 0CH

Converted value of Heater electric cur-

rent to voltage

47H Heated oxygen sensor 3 heat-

er (Bank 2) P0063 80H 0CHConverted value of Heater electric cur-

rent to voltage

Item

OBD-

MID Self-diagnostic test item DTC Test value and Test

limit

(GST display) Description

TID Unit and

Scaling ID

Revision: December 20092009 QX56

Page 1392 of 4171

![INFINITI QX56 2009 Factory Service Manual

ON BOARD DIAGNOSTIC (OBD) SYSTEMEC-65

< FUNCTION DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

X: Applicable

*1: This item includes 1st trip DTCs.

*2: This mode includes 1st trip freeze frame INFINITI QX56 2009 Factory Service Manual

ON BOARD DIAGNOSTIC (OBD) SYSTEMEC-65

< FUNCTION DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

X: Applicable

*1: This item includes 1st trip DTCs.

*2: This mode includes 1st trip freeze frame](/img/42/57031/w960_57031-1391.png)

ON BOARD DIAGNOSTIC (OBD) SYSTEMEC-65

< FUNCTION DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

X: Applicable

*1: This item includes 1st trip DTCs.

*2: This mode includes 1st trip freeze frame data or freeze frame data. The items appear on CONSULT-III screen in freeze frame

data

mode only if a 1st trip DTC or DTC is detected. For details, refer to "Freeze Frame Data and 1st Trip Freeze Frame Data".

*3: Always “CMPLT ” is displayed.

WORK SUPPORT MODE

Work Item

ENGINE CONTROL COMPONENT PARTS

OUTPUT

Fuel injector ××

Power transistor (Ignition timing) ××

Throttle contro l motor relay ××

Throttle control motor ×

EVAP canister purge volume con-

trol solenoid valve ××××

Air conditioner relay ×

Fuel pump relay ×××

Cooling fan relay ×××

Air fuel ratio (A/F) sensor 1 heater ×××*3

Heated oxygen sensor 2 heater ×××*3

EVAP canister vent control valve ×× ××

Intake valve timing control solenoid

valve ×××

Alternator ××

Calculated load value ××

Item

DIAGNOSTIC TEST MODE

WORK SUP-

PORT SELF-DIAGNOSTIC

RESULTS DATA

MONI- TOR ACTIVE

TEST DTC & SRT

CONFIRMATION

DTC*1 FREEZE

FRAME

DATA*2 SRT

STATUS DTC

WORK SUP-

PORT

WORK ITEM CONDITION USAGE

FUEL PRESSURE RELEASE FUEL PUMP WILL STOP BY TOUCHING “START” DUR- ING IDLING.

CRANK A FEW TIMES AFTER ENGINE STALLS. When releasing fuel pressure from

fuel line

IDLE AIR VOL LEARN THE IDLE AIR VOLUME THAT KEEPS THE ENGINE WITHIN THE SPECIFIED RANGE IS MEMORIZED IN

ECM. When learning the idle air volume

SELF-LEARNING CONT THE COEFFICI ENT OF SELF-LEARNING CONTROL

MIXTURE RATIO RETURNS TO THE ORIGINAL COEF-

FICIENT. When clearing the coefficient of

self-learning control value

Revision: December 20092009 QX56

Page 1395 of 4171

![INFINITI QX56 2009 Factory Service Manual

EC-68

< FUNCTION DIAGNOSIS >[VK56DE]

ON BOARD DIAGNOSTIC (OBD) SYSTEM

TP SEN 1-B1 [V]

××

The throttle position sensor signal volt-

age is displayed. TP SEN 2-B1 signal is converted by

ECM inte INFINITI QX56 2009 Factory Service Manual

EC-68

< FUNCTION DIAGNOSIS >[VK56DE]

ON BOARD DIAGNOSTIC (OBD) SYSTEM

TP SEN 1-B1 [V]

××

The throttle position sensor signal volt-

age is displayed. TP SEN 2-B1 signal is converted by

ECM inte](/img/42/57031/w960_57031-1394.png)

EC-68

< FUNCTION DIAGNOSIS >[VK56DE]

ON BOARD DIAGNOSTIC (OBD) SYSTEM

TP SEN 1-B1 [V]

××

The throttle position sensor signal volt-

age is displayed. TP SEN 2-B1 signal is converted by

ECM internally. Thus, it differs from

ECM terminal voltage signal.

TP SEN 2-B1 [V]

××

FUEL T/TMP SE

[ ° C] or [ °F] The fuel temperature (determined by the

signal voltage of the fuel tank tempera-

ture sensor) is displayed.

INT/A TEMP SE

[ ° C] or [ °F] ×× The intake air temperature (determined

by the signal voltage of the intake air

temperature sensor) is indicated.

EVAP SYS PRES

[V] The signal voltage of EVAP control sys-

tem pressure sensor is displayed.

FUEL LEVEL SE [V] × The signal voltage of the fuel level sen-

sor is displayed.

START SIGNAL

[ON/OFF] Indicates start signal status [ON/OFF]

computed by the ECM according to the

signals of engine speed and battery volt-

age. After starting the engine, [OFF] is dis-

played regardless of the starter signal.

CLSD THL POS

[ON/OFF] ×× Indicates idle position [ON/OFF] comput-

ed by ECM according to the accelerator

pedal position sensor signal.

AIR COND SIG

[ON/OFF] ×× Indicates [ON/OFF] condition of the air

conditioner switch as determined by the

air conditioner signal.

P/N POSI SW

[ON/OFF] ××

Indicates [ON/OFF] condition from the

transmission range signal.

PW/ST SIGNAL

[ON/OFF] ×× [ON/OFF] condition of the power steering

system (determined by the signal voltage

of the power steering pressure sensor

signal) is indicated.

LOAD SIGNAL [ON/

OFF] ×× Indicates [ON/OFF] condition from the

electrical load signal.

ON: Rear window defogger switch is ON

and/or lighting switch is in 2nd position.

OFF: Both rear window defogger switch

and lighting switch are OFF.

IGNITION SW

[ON/OFF] ×× Indicates [ON/OFF] condition from igni-

tion switch signal.

HEATER FAN SW

[ON/OFF] ×

Indicates [ON/OFF] condition from heat-

er fan switch signal.

BRAKE SW

[ON/OFF] Indicates [ON/OFF] condition from the

stop lamp switch signal.

INJ PULSE-B1

[msec] Indicates the actual fuel injection pulse

width compensated by ECM according to

the input signals. When the engine is stopped, a certain

computed value is indicated.

INJ PULSE-B2

[msec]

IGN TIMING [BT-

DC] Indicates the ignition timing computed by

ECM according to the input signals. When the engine is stopped, a certain

value is indicated.

CAL/LD VALUE [%]

“Calculated load value” indicates the val- ue of the current air flow divided by peak

air flow.

MASS AIRFLOW

[g·m/s] Indicates the mass air flow computed by

ECM according to the signal voltage of

the mass air flow sensor.

Monitored item

[Unit] ECM IN-

PUT SIG-

NALS MAIN

SIGNALS Description Remarks

Revision: December 20092009 QX56