diagram INFINITI QX56 2010 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2010, Model line: QX56, Model: INFINITI QX56 2010Pages: 4210, PDF Size: 81.91 MB

Page 743 of 4210

CHG

CHG-1

ELECTRICAL & POWER CONTROL

C

DE

F

G H

I

J

K L

B

SECTION CHG

A

O P

N

CONTENTS

CHARGING SYSTEM

PRECAUTION .......

........................................2

PRECAUTIONS .............................................. .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

2

Precaution for Power Generation Variable Voltage

Control System ..........................................................

3

PREPARATION ............................................4

PREPARATION .............................................. .....4

Special Service Tool ........................................... ......4

Commercial Service Tool ..........................................4

BASIC INSPECTION ....................................5

DIAGNOSIS AND REPAIR WORKFLOW ..... .....5

Work Flow ........................................................... ......5

FUNCTION DIAGNOSIS ...............................6

CHARGING SYSTEM ..................................... .....6

System Diagram .................................................. ......6

System Description ...................................................6

Component Description ............................................6

POWER GENERATION VOLTAGE VARI-

ABLE CONTROL SYSTEM .................................

7

System Diagram .................................................. ......7

System Description ...................................................7

Component Description .............................................7

COMPONENT DIAGNOSIS ..........................8

CHARGING SYSTEM PRELIMINARY IN-

SPECTION ....... ..................................................

8

Inspection Procedure ........................................... .....8

POWER GENERATION VOLTAGE VARI-

ABLE CONTROL SYSTEM OPERATION IN-

SPECTION .........................................................

9

Diagnosis Procedure ........................................... .....9

B TERMINAL CIRCUIT .....................................11

Description ...............................................................11

Diagnosis Procedure ...............................................11

L TERMINAL CIRCUIT .....................................12

Description ...............................................................12

Diagnosis Procedure ...............................................12

S TERMINAL CIRCUIT .....................................13

Description ...............................................................13

Diagnosis Procedure ...............................................13

CHARGING SYSTEM .......................................14

Wiring Diagram ........................................................14

SYMPTOM DIAGNOSIS ..............................20

CHARGING SYSTEM .......................................20

Symptom Table ................................................... ....20

ON-VEHICLE REPAIR .................................21

GENERATOR ....................................................21

Removal and Installation ..................................... ....21

SERVICE DATA AND SPECIFICATIONS

(SDS) ............... .......................................... ...

22

GENERATOR ....................................................22

Generator ............................................................ ....22

Revision: April 20092010 QX56

Page 748 of 4210

CHG-6

< FUNCTION DIAGNOSIS >

CHARGING SYSTEM

FUNCTION DIAGNOSIS

CHARGING SYSTEM

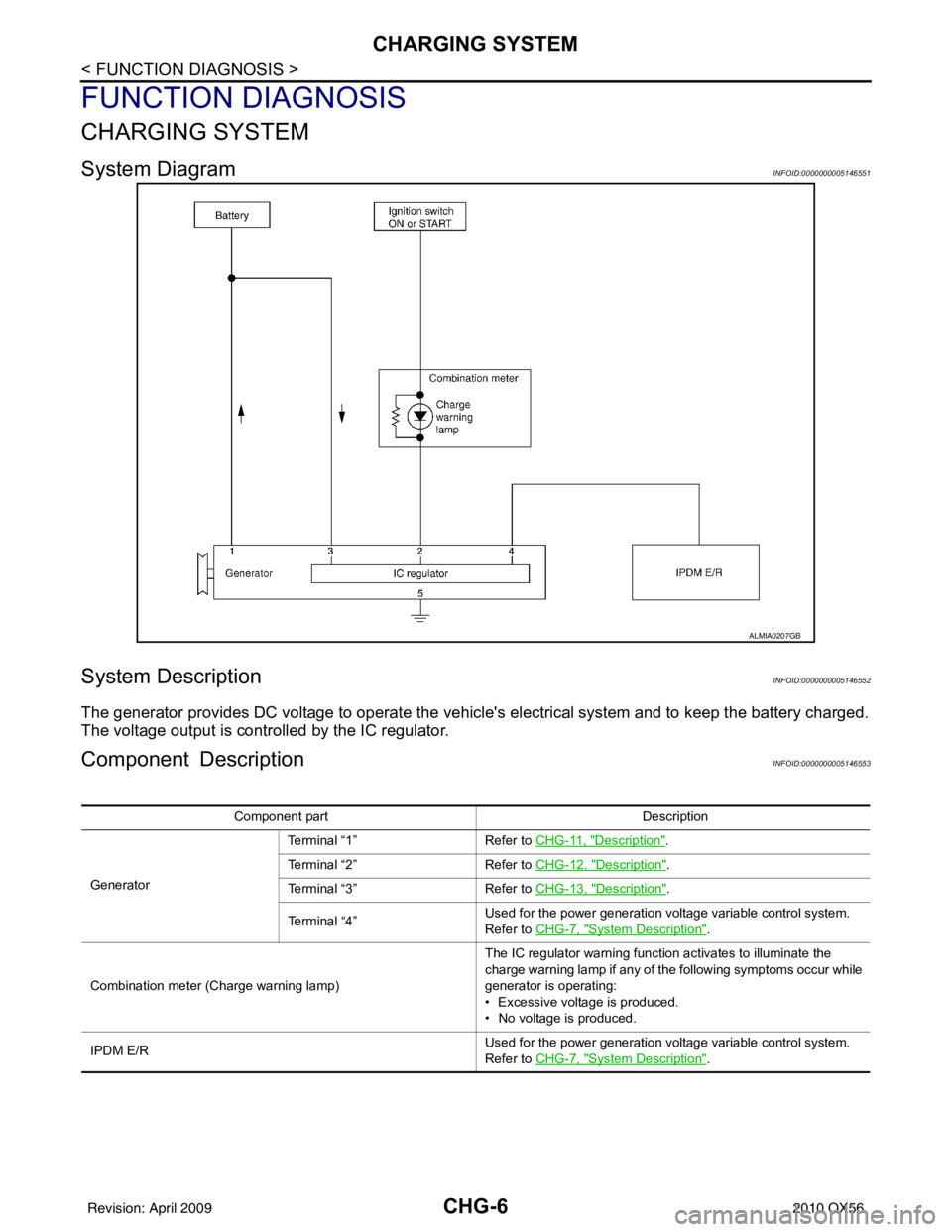

System DiagramINFOID:0000000005146551

System DescriptionINFOID:0000000005146552

The generator provides DC voltage to operate the vehicle's electrical system and to keep the battery charged.

The voltage output is controlled by the IC regulator.

Component DescriptionINFOID:0000000005146553

ALMIA0207GB

Component part Description

Generator Terminal “1”

Refer to CHG-11, "

Description".

Terminal “2” Refer to CHG-12, "

Description".

Terminal “3” Refer to CHG-13, "

Description".

Terminal “4” Used for the power generation voltage variable control system.

Refer to

CHG-7, "

System Description".

Combination meter (C harge warning lamp) The IC regulator warning function activates to illuminate the

charge warning lamp if any of the following symptoms occur while

generator is operating:

• Excessive voltage is produced.

• No voltage is produced.

IPDM E/R Used for the power generation voltage variable control system.

Refer to

CHG-7, "

System Description".

Revision: April 20092010 QX56

Page 749 of 4210

CHG

POWER GENERATION VOLTAGE VARIABLE CONTROL SYSTEM

CHG-7

< FUNCTION DIAGNOSIS >

C

D E

F

G H

I

J

K L

B A

O P

N

POWER GENERATION VOLTAG

E VARIABLE CONTROL SYSTEM

System DiagramINFOID:0000000005146554

System DescriptionINFOID:0000000005146555

Power generation variable voltage control system has been adopted. By varying the voltage to the generator,

engine load due to power generation of the generator is reduced and fuel consumption is decreased.

NOTE:

When any malfunction is detected in the power generat ion variable voltage control system, power generation

is performed according to the characterist ic of the IC regulator in the generator.

Component DescriptionINFOID:0000000005146556

ALMIA0057GB

Component part Description

Battery current sensor The battery current sensor is installed on the battery cable at the

negative terminal. The battery current sensor detects the charg-

ing/discharging current of the battery and sends a voltage signal

to the ECM according to the current value detected.

ECM The battery current sensor detects the charging/discharging cur-

rent of the battery. The ECM judges the battery condition based on

this signal.

The ECM judges whether to request more output via the power

generation voltage variable control according to the battery condi-

tion.

When performing the power generation voltage variable control,

the ECM calculates the target power generation voltage according

to the battery condition and sends the calculated value as the pow-

er generation command value to the IPDM E/R.

IPDM E/R The IPDM E/R converts the received power generation command

value into a pulse width modulated (PWM) command signal and

sends it to the IC regulator.

Generator (IC regulator) The IC regulator controls the power generation voltage by the tar-

get power generation voltage based on the received PWM com-

mand signal.

When there is no PWM command signal, the generator performs

the normal power generation according to the characteristic of the

IC regulator.

Revision: April 20092010 QX56

Page 751 of 4210

CHG

POWER GENERATION VOLTAGE VARIABLE CONTROL SYSTEM OPERATION

INSPECTION

CHG-9

< COMPONENT DIAGNOSIS >

C

DE

F

G H

I

J

K L

B A

O P

N

POWER GENERATION VOLTAGE VARI

ABLE CONTROL SYSTEM OPER-

ATION INSPECTION

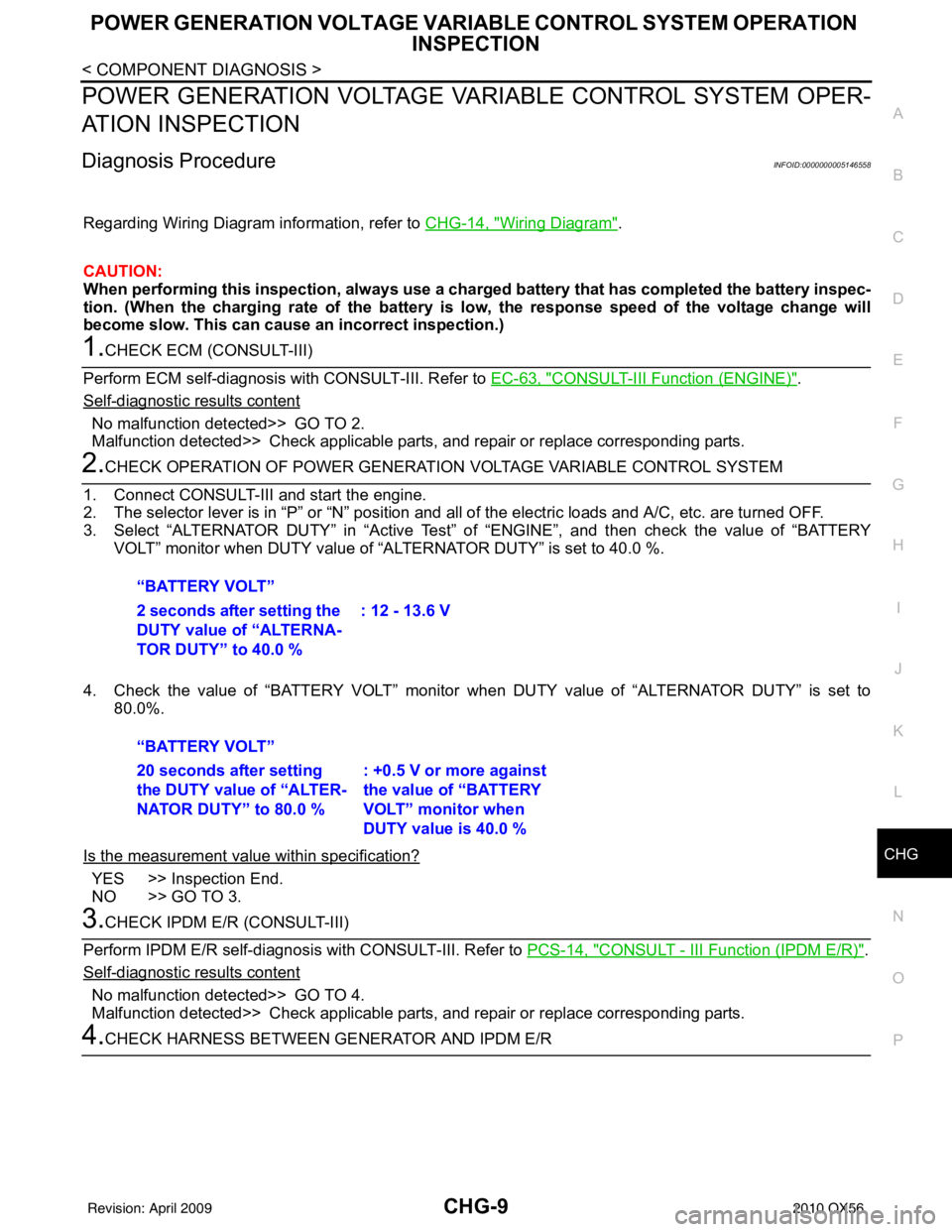

Diagnosis ProcedureINFOID:0000000005146558

Regarding Wiring Diagram information, refer to CHG-14, "Wiring Diagram".

CAUTION:

When performing this inspection, always use a charged battery that has completed the battery inspec-

tion. (When the charging rate of the battery is low, the response speed of the voltage change will

become slow. This can cause an incorrect inspection.)

1.CHECK ECM (CONSULT-III)

Perform ECM self-diagnosis with CONSULT-III. Refer to EC-63, "

CONSULT-III Function (ENGINE)".

Self

-diagnostic results content

No malfunction detected>> GO TO 2.

Malfunction detected>> Check applicable parts, and repair or replace corresponding parts.

2.CHECK OPERATION OF POWER GENERATION VOLTAGE VARIABLE CONTROL SYSTEM

1. Connect CONSULT-III and start the engine.

2. The selector lever is in “P” or “N” position and a ll of the electric loads and A/C, etc. are turned OFF.

3. Select “ALTERNATOR DUTY” in “Active Test” of “ENGINE”, and then check the value of “BATTERY

VOLT” monitor when DUTY value of “ALTERNATOR DUTY” is set to 40.0 %.

4. Check the value of “BATTERY VOLT” monitor when DUTY value of “ALTERNATOR DUTY” is set to 80.0%.

Is the measurement val ue within specification?

YES >> Inspection End.

NO >> GO TO 3.

3.CHECK IPDM E/R (CONSULT-III)

Perform IPDM E/R self-diagnosis with CONSULT-III. Refer to PCS-14, "

CONSULT - III Function (IPDM E/R)".

Self

-diagnostic results content

No malfunction detected>> GO TO 4.

Malfunction detected>> Check applicable parts, and repair or replace corresponding parts.

4.CHECK HARNESS BETWEEN GE NERATOR AND IPDM E/R

“BATTERY VOLT”

2 seconds after setting the

DUTY value of “ALTERNA-

TOR DUTY” to 40.0 %

: 12 - 13.6 V

“BATTERY VOLT”

20 seconds after setting

the DUTY value of “ALTER-

NATOR DUTY” to 80.0 % : +0.5 V or more against

the value of “BATTERY

VOLT” monitor when

DUTY value is 40.0 %

Revision: April 20092010 QX56

Page 753 of 4210

CHG

B TERMINAL CIRCUITCHG-11

< COMPONENT DIAGNOSIS >

C

DE

F

G H

I

J

K L

B A

O P

N

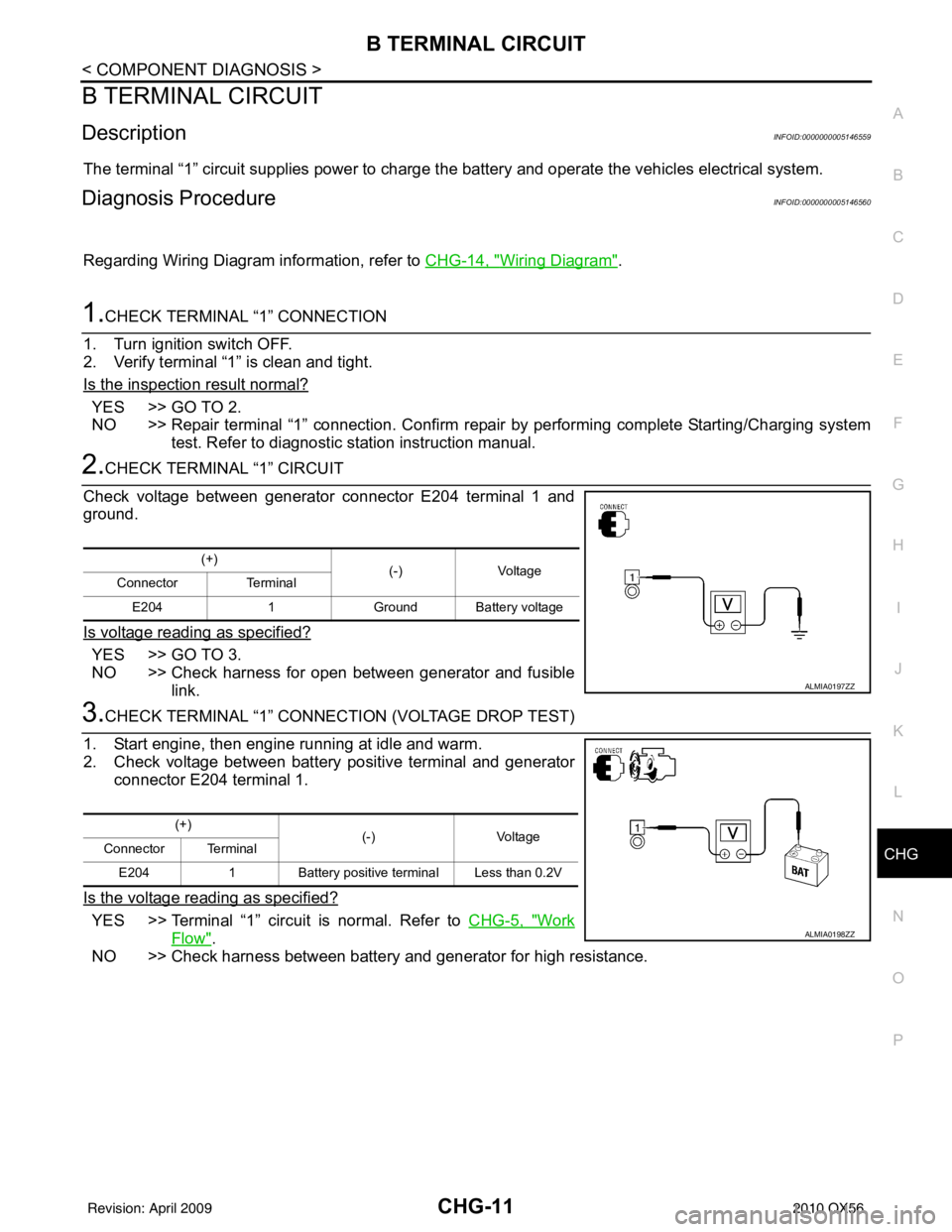

B TERMINAL CIRCUIT

DescriptionINFOID:0000000005146559

The terminal “1” circuit supplies power to charge the battery and operate the vehicles electrical system.

Diagnosis ProcedureINFOID:0000000005146560

Regarding Wiring Diagram information, refer to

CHG-14, "Wiring Diagram".

1.CHECK TERMINAL “1” CONNECTION

1. Turn ignition switch OFF.

2. Verify terminal “1” is clean and tight.

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair terminal “1” connection. Confirm repa ir by performing complete Starting/Charging system

test. Refer to diagnostic station instruction manual.

2.CHECK TERMINAL “1” CIRCUIT

Check voltage between generator connector E204 terminal 1 and

ground.

Is voltage reading as specified?

YES >> GO TO 3.

NO >> Check harness for open between generator and fusible link.

3.CHECK TERMINAL “1” CONNECTION (VOLTAGE DROP TEST)

1. Start engine, then engine running at idle and warm.

2. Check voltage between battery positive terminal and generator connector E204 terminal 1.

Is the voltage reading as specified?

YES >> Terminal “1” circuit is normal. Refer to CHG-5, "Work

Flow".

NO >> Check harness between battery and generator for high resistance.

(+) (-) Voltage

Connector Terminal

E204 1Ground Battery voltage

ALMIA0197ZZ

(+)

(-)Voltage

Connector Terminal

E204 1 Battery positive terminal Less than 0.2V

ALMIA0198ZZ

Revision: April 20092010 QX56

Page 754 of 4210

CHG-12

< COMPONENT DIAGNOSIS >

L TERMINAL CIRCUIT

L TERMINAL CIRCUIT

DescriptionINFOID:0000000005146561

The terminal “2” (L) circuit controls the charge warning lamp. The charge warning lamp illuminates when the

ignition switch is set to ON or START. When the generator is providing sufficient voltage with the engine run-

ning, the charge warning lamp will go off. If the c harge warning lamp illuminates with the engine running, a

malfunction is indicated.

Diagnosis ProcedureINFOID:0000000005146562

Regarding Wiring Diagram information, refer to CHG-14, "Wiring Diagram".

1.CHECK CHARGE WARNING LAMP CIRCUIT CONNECTION

Verify generator connector E205 terminal 2 is clean and tight.

Is the connection secure?

YES >> GO TO 2.

NO >> Repair the connection. Confirm repair by per forming complete Starting/Charging system test.

Refer to diagnostic station instruction manual.

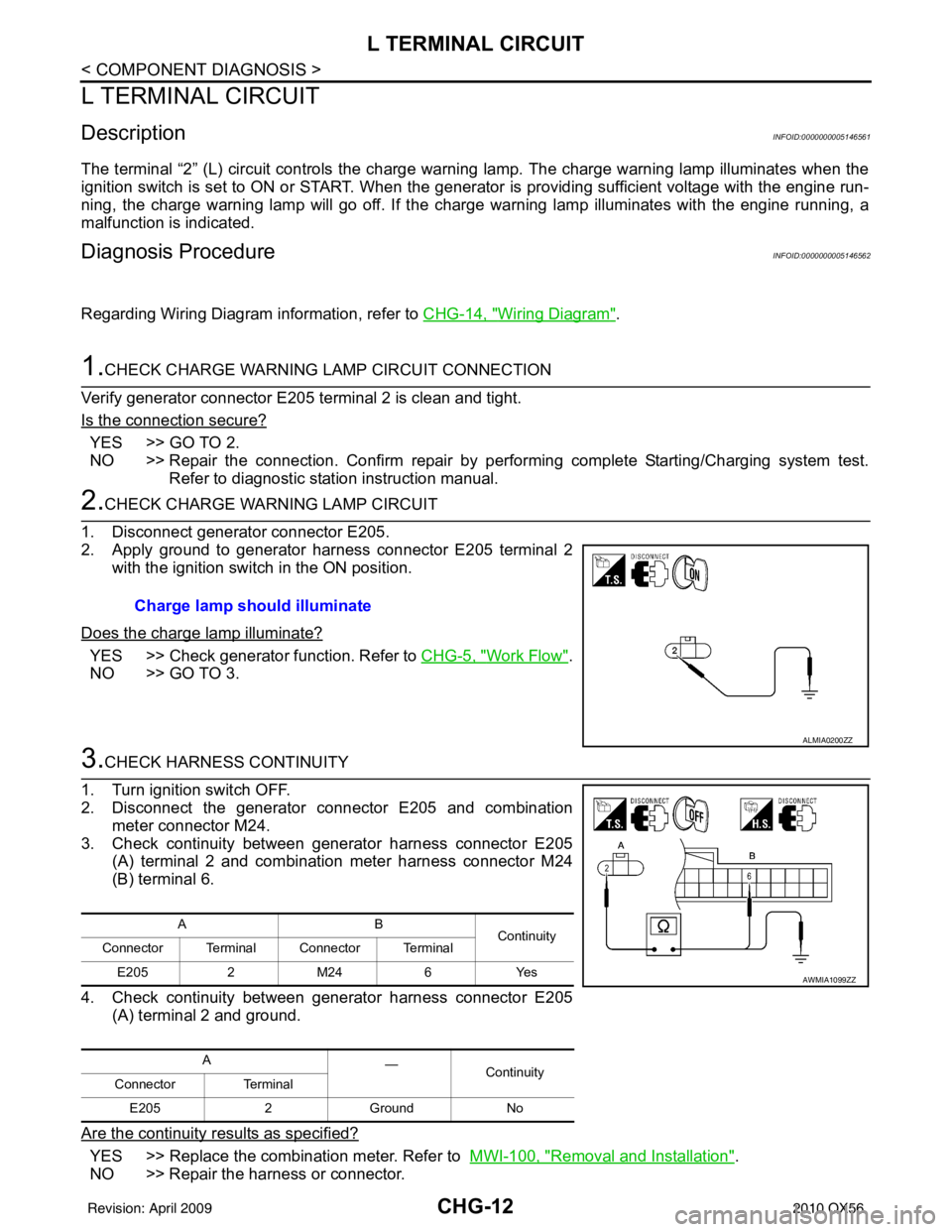

2.CHECK CHARGE WARNING LAMP CIRCUIT

1. Disconnect generator connector E205.

2. Apply ground to generator harness connector E205 terminal 2 with the ignition switch in the ON position.

Does the charge lamp illuminate?

YES >> Check generator function. Refer to CHG-5, "Work Flow".

NO >> GO TO 3.

3.CHECK HARNESS CONTINUITY

1. Turn ignition switch OFF.

2. Disconnect the generator connector E205 and combination meter connector M24.

3. Check continuity between generator harness connector E205 (A) terminal 2 and combination meter harness connector M24

(B) terminal 6.

4. Check continuity between generator harness connector E205 (A) terminal 2 and ground.

Are the continuity results as specified?

YES >> Replace the combination meter. Refer to MWI-100, "Removal and Installation".

NO >> Repair the harness or connector. Charge lamp should illuminate

ALMIA0200ZZ

AB

Continuity

Connector Terminal Connector Terminal

E205 2M24 6Yes

A —

Continuity

Connector Terminal

E205 2Ground No

AWMIA1099ZZ

Revision: April 20092010 QX56

Page 755 of 4210

CHG

S TERMINAL CIRCUITCHG-13

< COMPONENT DIAGNOSIS >

C

DE

F

G H

I

J

K L

B A

O P

N

S TERMINAL CIRCUIT

DescriptionINFOID:0000000005146563

The output voltage of the generator is controlled by the IC

regulator at terminal “3” (S) detecting the input volt-

age. Terminal “3” circuit detects the battery voltage to adjust the generator output voltage with the IC regulator.

Diagnosis ProcedureINFOID:0000000005146564

Regarding Wiring Diagram information, refer to CHG-14, "Wiring Diagram".

1.CHECK VOLTAGE REGULATOR CIRCUIT CONNECTION

Check to see if connector E205 terminal 3 is clean and tight.

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair terminal connection. Confirm repair by performing complete Starting/Charging system test.

Refer to diagnostic station instruction manual.

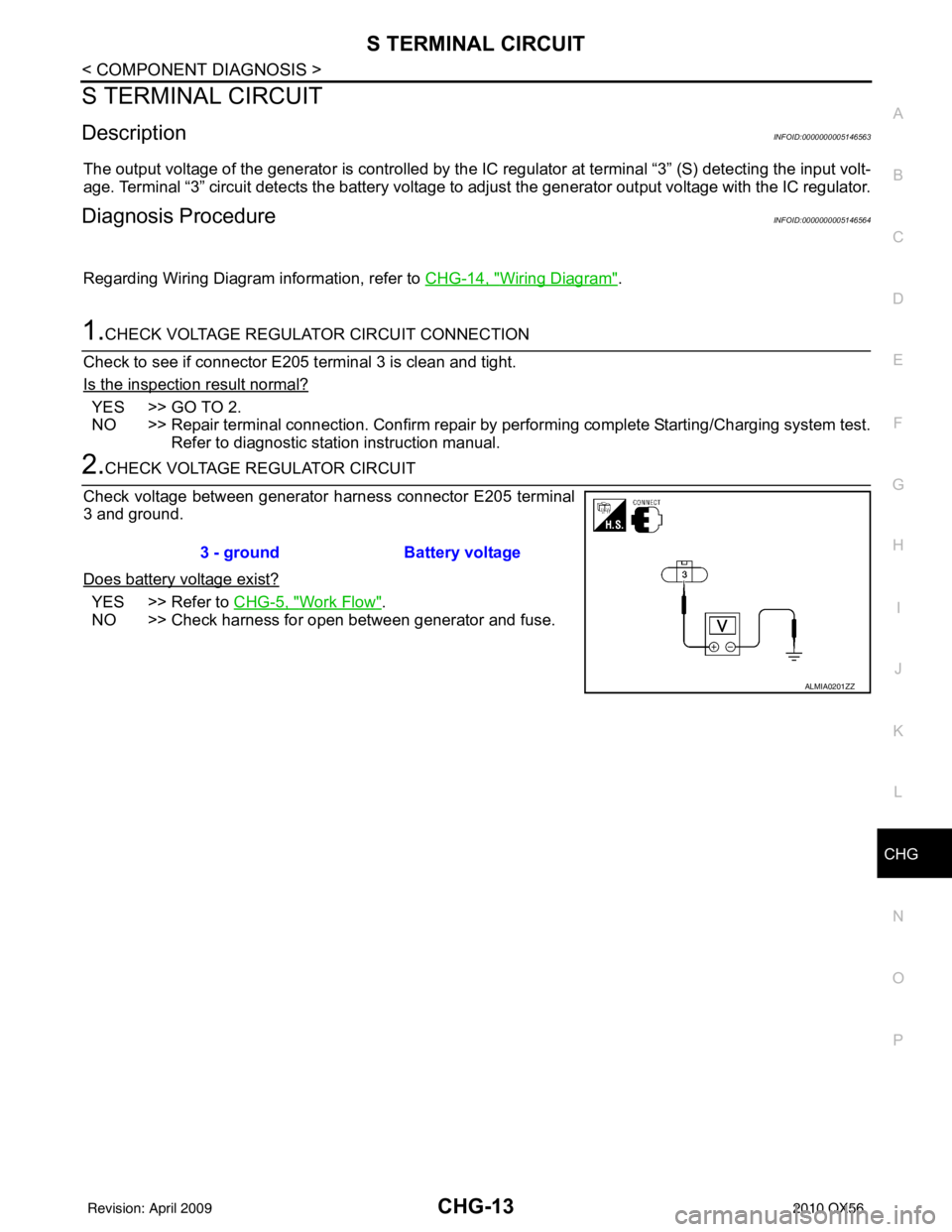

2.CHECK VOLTAGE REGULATOR CIRCUIT

Check voltage between generator harness connector E205 terminal

3 and ground.

Does battery voltage exist?

YES >> Refer to CHG-5, "Work Flow".

NO >> Check harness for open between generator and fuse. 3 - ground

Battery voltage

ALMIA0201ZZ

Revision: April 20092010 QX56

Page 756 of 4210

CHG-14

< COMPONENT DIAGNOSIS >

CHARGING SYSTEM

CHARGING SYSTEM

Wiring DiagramINFOID:0000000005146565

ABMWA0376GB

Revision: April 20092010 QX56

Page 789 of 4210

DEF-1

DRIVER CONTROLS

C

DE

F

G H

I

J

K

M

SECTION DEF

A

B

DEF

N

O P

CONTENTS

DEFOGGER

BASIC INSPECTION ....... .............................3

DIAGNOSIS AND REPAIR WORKFLOW ..... .....3

Repair Work Flow ................................................ ......3

FUNCTION DIAGNOSIS ...............................4

REAR WINDOW DEFOGGER SYSTEM ........ .....4

System Diagram .................................................. ......4

System Description ...................................................4

Component Parts Location ........................................5

Component Description .............................................5

DIAGNOSIS SYSTEM (BCM) .............................6

COMMON ITEM ..................................................... ......6

COMMON ITEM : CONSULT-III Function (BCM -

COMMON ITEM) .......................................................

6

REAR WINDOW DEFOGGER ............................... ......6

REAR WINDOW DEFOGGER : CONSULT-III

Function (BCM - REAR DEFOGGER) ......................

7

COMPONENT DIAGNOSIS ..........................8

REAR WINDOW DEFOGGER SWITCH ........ .....8

Description .......................................................... ......8

Component Function Check ......................................8

Diagnosis Procedure .................................................8

REAR WINDOW DEFOGGER RELAY ...............9

Description .......................................................... ......9

Component Function Check ......................................9

Diagnosis Procedure .................................................9

REAR WINDOW DEFOGGER POWER SUP-

PLY AND GROUND CIRCUIT ............................

10

Description .......................................................... ....10

Component Function Check ....................................10

Diagnosis Procedure ...............................................10

Component Inspection ............................................11

DOOR MIRROR DEFOGGER LH ..................

....12

Description ........................................................... ....12

Component Function Check ....................................12

Diagnosis Procedure ...............................................12

Component Inspection .............................................13

DOOR MIRROR DEFOGGER RH .....................15

Description ...............................................................15

Component Function Check ....................................15

Diagnosis Procedure ...............................................15

Component Inspection .............................................16

ECU DIAGNOSIS .........................................18

BCM (BODY CONTROL MODULE) .................18

Reference Value .................................................. ....18

Terminal Layout .......................................................21

Physical Values ................................................... ....21

Wiring Diagram ........................................................27

Fail Safe ..................................................................34

DTC Inspection Priority Chart ...............................35

DTC Index ...............................................................35

SYMPTOM DIAGNOSIS ..............................37

REAR WINDOW DEFOGGER AND DOOR

MIRROR DEFOGGER DO NOT OPERATE. ....

37

Diagnosis Procedure ........................................... ....37

REAR WINDOW DEFOGGER DOES NOT

OPERATE BUT BOTH OF DOOR MIRROR

DEFOGGER OPERATE. ...................................

38

Diagnosis Procedure ...............................................38

BOTH DOORS MIRROR DEFOGGER DON’T

OPERATE BUT REAR WINDOW DEFOG-

GER OPERATES ..............................................

39

Diagnosis Procedure ...............................................39

DRIVER SIDE DOOR MIRROR DEFOGGER

DOES NOT OPERATE. .....................................

40

Diagnosis Procedure ...............................................40

Revision: April 20092010 QX56

Page 792 of 4210

DEF-4

< FUNCTION DIAGNOSIS >

REAR WINDOW DEFOGGER SYSTEM

FUNCTION DIAGNOSIS

REAR WINDOW DEFOGGER SYSTEM

System DiagramINFOID:0000000005146817

System DescriptionINFOID:0000000005146818

Operation Description

• When rear window defogger switch is turned ON while ignition switch is ON, the A/C and AV switch assem-bly (rear window defogger switch) transmits rear window defogger switch signal to BCM.

• BCM transmits rear window defogger control signal to IPDM E/R and display unit via CAN communication when rear window defogger operates.

• IPDM E/R turns rear window defogger relay and heated mirror relay ON when rear window defogger switch

signal is received.

• Rear window defogger and door mirror defogger are supplied with power and operate when rear window defogger relay and heated mirror relay turn ON.

• Rear window defogger ON is displayed when signal is received.

Timer function

• BCM turns rear window defogger relay and heated mirror relay ON for approximately 15 minutes when rear window defogger switch is turned ON while ignition switch is ON. It makes rear window defogger and door

mirror defogger operate.

• Timer is canceled after pressing rear window defogger switch again during timer operation. Then BCM turns

rear window defogger relay and heated mirror relay OFF. The same reaction also occurs during timer opera-

tion, if the ignition switch is turned OFF.

INPUT/OUTPUT SIGNAL CHART

ALLIA0892GB

Switch Input signal to BCM BCM functionActuator

Rear window defogger switch Defogger switch signal Rear window defogger & door mirror

defogger control Rear window defogger

Door mirror defogger

Ignition switch Ignition signal

Revision: April 20092010 QX56