check oil INFINITI QX56 2010 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2010, Model line: QX56, Model: INFINITI QX56 2010Pages: 4210, PDF Size: 81.91 MB

Page 2390 of 4210

![INFINITI QX56 2010 Factory Service Manual HAC-50

< COMPONENT DIAGNOSIS >[AUTOMATIC AIR CONDITIONER]

BLOWER MOTOR CONTROL SYSTEM

4.CHECK FRONT BLOWER MOTOR RELAY

Turn ignition switch OFF.

Check front blower motor relay. Refer to HAC-52, "

Fro INFINITI QX56 2010 Factory Service Manual HAC-50

< COMPONENT DIAGNOSIS >[AUTOMATIC AIR CONDITIONER]

BLOWER MOTOR CONTROL SYSTEM

4.CHECK FRONT BLOWER MOTOR RELAY

Turn ignition switch OFF.

Check front blower motor relay. Refer to HAC-52, "

Fro](/img/42/57032/w960_57032-2389.png)

HAC-50

< COMPONENT DIAGNOSIS >[AUTOMATIC AIR CONDITIONER]

BLOWER MOTOR CONTROL SYSTEM

4.CHECK FRONT BLOWER MOTOR RELAY

Turn ignition switch OFF.

Check front blower motor relay. Refer to HAC-52, "

Front Blower Motor Component Inspection".

Is the inspection result normal?

YES >> GO TO 5.

NO >> Replace front blower motor relay.

5.CHECK FRONT BLOWER MOTOR RELA Y (SWITCH SIDE) CIRCUIT FOR OPEN

Check continuity between front blower motor relay harness connec-

tor M107 terminal 3 and front blower motor harness connector M62

terminal 2.

Is the inspection result normal?

YES >> GO TO 6.

NO >> Repair harness or connector.

6.CHECK FRONT BLOWER MOTOR RE LAY (COIL SIDE) POWER SUPPLY

1. Turn ignition switch ON.

2. Check voltage between front blower motor relay harness con- nector M107 terminal 2 and ground.

Is the inspection result normal?

YES >> Repair front blower motor ground circuit or connector.

NO >> Repair harness or connector.

7.REPLACE FUSES

Replace fuses.

Does the fuse blow?

YES >> • If fuse blows without activating the front blower motor, repair short between fuse and front blower motor relay.

• If fuse blows activating the front blower motor, GO TO 8.

NO >> Inspection End.

8.CHECK FRONT BLOWER MOTOR POWER SUPPLY CIRCUIT FOR SHORT

1. Turn ignition switch OFF.

2. Disconnect front blower motor connector, front blower motor relay and variable blower control connector.

3. Check continuity between variable blower control harness con- nector M122 terminal 4 and ground.

Is the inspection result normal?

YES >> GO TO 9.

NO >> Repair harness or connector.

9.CHECK FRONT BLOWER MOTOR

Check front blower motor. Refer to HAC-52, "

Front Blower Motor Component Inspection".

Is the inspection result normal?

3 - 2 : Continuity should exist.

WJIA1360E

2 - Ground: Battery voltage

WJIA1363E

4 - Ground: Continuity should not exist.

AWIIA0177ZZ

Revision: April 20092010 QX56

Page 2392 of 4210

![INFINITI QX56 2010 Factory Service Manual HAC-52

< COMPONENT DIAGNOSIS >[AUTOMATIC AIR CONDITIONER]

BLOWER MOTOR CONTROL SYSTEM

1. Reconnect all disconnected component connectors.

2. Disconnect A/C auto amp. connector.

3. Turn ignition switch INFINITI QX56 2010 Factory Service Manual HAC-52

< COMPONENT DIAGNOSIS >[AUTOMATIC AIR CONDITIONER]

BLOWER MOTOR CONTROL SYSTEM

1. Reconnect all disconnected component connectors.

2. Disconnect A/C auto amp. connector.

3. Turn ignition switch](/img/42/57032/w960_57032-2391.png)

HAC-52

< COMPONENT DIAGNOSIS >[AUTOMATIC AIR CONDITIONER]

BLOWER MOTOR CONTROL SYSTEM

1. Reconnect all disconnected component connectors.

2. Disconnect A/C auto amp. connector.

3. Turn ignition switch ON.

4. Press the blower (+) switch to maximum speed.

5. Check voltage between A/C auto amp. harness connector M49

terminal 13 and ground.

Is the inspection result normal?

YES >> Replace A/C auto amp. Refer to VTL-7, "Removal and

Installation".

NO >> GO TO 15.

15.CHECK VARIABLE BLOWER CONT ROL SIGNAL CIRCUIT FOR OPEN

1. Disconnect variable blower control connector.

2. Check continuity between A/C auto amp. harness connector M49 (B) terminal 13 and variable blower control harness con-

nector M122 (A) terminal 3.

Is the inspection result normal?

YES >> Replace variable blower control. Refer to VTL-15,

"Removal and Installation".

NO >> Repair harness or connector.

Front Blower Motor Component InspectionINFOID:0000000005147703

COMPONENT INSPECTION

Check continuity between terminals by supplying 12 volts and

ground to coil side terminals of relay.

Front Blower Motor

13 - Ground : Approx. 4.5V

AWIIA1129ZZ

13 - 3: Continuity should exist.

AWIIA0178ZZ

WJIA1401E

Revision: April 20092010 QX56

Page 2397 of 4210

![INFINITI QX56 2010 Factory Service Manual BLOWER MOTOR CONTROL SYSTEMHAC-57

< COMPONENT DIAGNOSIS > [AUTOMATIC AIR CONDITIONER]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

1. Disconnect A/C auto amp. connector.

2. Check continuity between A/C auto amp. INFINITI QX56 2010 Factory Service Manual BLOWER MOTOR CONTROL SYSTEMHAC-57

< COMPONENT DIAGNOSIS > [AUTOMATIC AIR CONDITIONER]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

1. Disconnect A/C auto amp. connector.

2. Check continuity between A/C auto amp.](/img/42/57032/w960_57032-2396.png)

BLOWER MOTOR CONTROL SYSTEMHAC-57

< COMPONENT DIAGNOSIS > [AUTOMATIC AIR CONDITIONER]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

1. Disconnect A/C auto amp. connector.

2. Check continuity between A/C auto amp. harness connector M50 (A) terminal 47 and rear air control (rear) harness connec-

tor R209 (B) terminal 5.

Is the inspection results normal?

YES >> Replace A/C auto amp. Refer to VTL-7, "Removal and

Installation".

NO >> Repair harness or connector.

Rear Blower Motor Component Inspection INFOID:0000000005147708

COMPONENT INSPECTION

Rear Blower Motor Relay

Check circuit continuity between terminals by supplying 12 volts and

ground to coil side terminals of relays.

Rear Blower Motor

Check that there are no foreign particles inside the intake unit.

Apply 12 volts to terminal 2 and ground to terminal 1 and ensure that

the blower motor rotates freely and quietly. Continuity should exist.

AWIIA0187ZZ

WJIA0973E

AWIIA1086ZZ

Revision: April 20092010 QX56

Page 2453 of 4210

![INFINITI QX56 2010 Factory Service Manual INSUFFICIENT COOLINGHAC-113

< SYMPTOM DIAGNOSIS > [AUTOMATIC AIR CONDITIONER]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

dard (usual) pressure, however, differs from vehicle to vehicle, refer to above table (A INFINITI QX56 2010 Factory Service Manual INSUFFICIENT COOLINGHAC-113

< SYMPTOM DIAGNOSIS > [AUTOMATIC AIR CONDITIONER]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

dard (usual) pressure, however, differs from vehicle to vehicle, refer to above table (A](/img/42/57032/w960_57032-2452.png)

INSUFFICIENT COOLINGHAC-113

< SYMPTOM DIAGNOSIS > [AUTOMATIC AIR CONDITIONER]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

dard (usual) pressure, however, differs from vehicle to vehicle, refer to above table (Ambient air temperature-

to-operating pressure table).

Both High- and Low-pressure Sides are Too High

High-pressure Side is Too High and Low-pressure Side is Too Low

High-pressure Side is Too Low and Low-pressure Side is Too High

Gauge indication Refrigerant cycleProbable causeCorrective action

Both high- and low-pressure sides

are too high. Pressure is reduced soon af-

ter water is splashed on con-

denser.

Excessive refrigerant charge in

refrigeration cycle

Reduce refrigerant until speci-

fied pressure is obtained.

Air suction by cooling fan is in-

sufficient. Insufficient condenser cooling

performance

↓

1. Condenser fins are

clogged.

2. Improper fan rotation of

cooling fan • Clean condenser.

• Check and repair cooling fan

if necessary.

• Low-pressure pipe is not cold.

• When compressor is

stopped high-pressure val-

ue quickly drops by approx-

imately 196 kPa (2 kg/cm

2 ,

28 psi). It then decreases

gradually thereafter. Poor heat exchange in con-

denser

(After compressor operation

stops, high-pressure decreas-

es too slowly.)

↓

Air in refrigeration cycle

Evacuate and recharge system.

Engine tends to overheat. Engine cooling systems mal-

function. Check and repair engine cool-

ing system.

• An area of the low-pressure pipe is colder than areas

near the evaporator outlet.

• Plates are sometimes cov- ered with frost. • Excessive liquid refrigerant

on low-pressure side

• Excessive refrigerant dis-

charge flow

• Expansion valve is open a lit- tle compared with the speci-

fication.

↓

Improper expansion valve ad-

justment Replace expansion valve.

AC359A

Gauge indication

Refrigerant cycleProbable causeCorrective action

High-pressure side is too high and

low-pressure side is too low. Upper side of condenser and

high-pressure side are hot,

however, liquid tank is not so

hot.High-pressure tube or parts lo-

cated between compressor

and condenser are clogged or

crushed.

• Check and repair or replace

malfunctioning parts.

• Check oil for contamination.

AC360A

Revision: April 20092010 QX56

Page 2454 of 4210

![INFINITI QX56 2010 Factory Service Manual HAC-114

< SYMPTOM DIAGNOSIS >[AUTOMATIC AIR CONDITIONER]

INSUFFICIENT COOLING

Both High- and Low-pressure Sides are Too Low

Low-pressure Side Sometimes Becomes Negative

Gauge indication

Refrigerant cy INFINITI QX56 2010 Factory Service Manual HAC-114

< SYMPTOM DIAGNOSIS >[AUTOMATIC AIR CONDITIONER]

INSUFFICIENT COOLING

Both High- and Low-pressure Sides are Too Low

Low-pressure Side Sometimes Becomes Negative

Gauge indication

Refrigerant cy](/img/42/57032/w960_57032-2453.png)

HAC-114

< SYMPTOM DIAGNOSIS >[AUTOMATIC AIR CONDITIONER]

INSUFFICIENT COOLING

Both High- and Low-pressure Sides are Too Low

Low-pressure Side Sometimes Becomes Negative

Gauge indication

Refrigerant cycleProbable causeCorrective action

High-pressure side is too low and

low-pressure side is too high. High- and low-pressure sides

become equal soon after com-

pressor operation stops.Compressor pressure opera-

tion is improper.

↓

Damaged inside compressor

packings.

Replace compressor.

No temperature difference be-

tween high- and low-pressure

sides. Compressor pressure opera-

tion is improper.

↓

Damaged inside compressor

packings.

Replace compressor.

AC356A

Gauge indication

Refrigerant cycleProbable causeCorrective action

Both high- and low-pressure sides

are too low. • There is a big temperature

difference between liquid

tank outlet and inlet. Outlet

temperature is extremely

low.

• Liquid tank inlet and expan- sion valve are frosted. Liquid tank inside is slightly

clogged.

• Replace liquid tank.

• Check oil for contamination.

• Temperature of expansion valve inlet is extremely low

as compared with areas

near liquid tank.

• Expansion valve inlet may be frosted.

• Temperature difference oc-

curs somewhere in high-

pressure side. High-pressure pipe located be-

tween liquid tank and expan-

sion valve is clogged.

• Check and repair malfunc-

tioning parts.

• Check oil for contamination.

Expansion valve and liquid

tank are warm or only cool

when touched. Low refrigerant charge.

↓

Leaking fittings or compo-

nents. Check refrigerant system for

leaks. Refer to

HA-24, "

Check-

ing of Refrigerant Leaks".

There is a big temperature dif-

ference between expansion

valve inlet and outlet while the

valve itself is frosted. Expansion valve closes a little

compared with the specifica-

tion.

↓

1. Improper expansion

valve adjustment.

2. Malfunctioning expansion valve.

3. Outlet and inlet may be clogged. • Remove foreign particles by

using compressed air.

• Check oil for contamination.

An area of the low-pressure

pipe is colder than areas near

the evaporator outlet. Low-pressure pipe is clogged

or crushed. • Check and repair malfunc-

tioning parts.

• Check oil for contamination.

Air flow volume is too low. Evaporator is frozen. • Check intake sensor circuit.

Refer to HAC-83, "

Intake

Sensor Diagnosis Proce-

dure".

• Repair evaporator fins.

• Replace evaporator.

•Refer to HAC-48, "

Front

Blower Motor Component

Function Check".

AC353A

Revision: April 20092010 QX56

Page 2455 of 4210

![INFINITI QX56 2010 Factory Service Manual INSUFFICIENT COOLINGHAC-115

< SYMPTOM DIAGNOSIS > [AUTOMATIC AIR CONDITIONER]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

Low-pressure Side Becomes Negative

Gauge indication

Refrigerant cycleProbable causeCorre INFINITI QX56 2010 Factory Service Manual INSUFFICIENT COOLINGHAC-115

< SYMPTOM DIAGNOSIS > [AUTOMATIC AIR CONDITIONER]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

Low-pressure Side Becomes Negative

Gauge indication

Refrigerant cycleProbable causeCorre](/img/42/57032/w960_57032-2454.png)

INSUFFICIENT COOLINGHAC-115

< SYMPTOM DIAGNOSIS > [AUTOMATIC AIR CONDITIONER]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

Low-pressure Side Becomes Negative

Gauge indication

Refrigerant cycleProbable causeCorrective action

Low-pressure side sometimes be-

comes negative. • Air conditioning system does

not function and does not cy-

clically cool the compart-

ment air.

• The system constantly func- tions for a certain period of

time after compressor is

stopped and restarted. Refrigerant does not discharge

cyclically.

↓

Moisture is frozen at expan-

sion valve outlet and inlet.

↓

Water is mixed with refrigerant.

• Drain water from refrigerant

or replace refrigerant.

• Replace liquid tank.

AC354A

Gauge indication Refrigerant cycleProbable causeCorrective action

Low-pressure side becomes nega-

tive. Liquid tank or front/rear side of

expansion valve′s pipe is frost-

ed or dewed. High-pressure side is closed

and refrigerant does not flow.

↓

Expansion valve or liquid tank

is frosted.Leave the system at rest until

no frost is present. Start it

again to check whether or not

the malfunction is caused by

water or foreign particles.

• If water is the cause, initially

cooling is okay. Then the wa-

ter freezes causing a block-

age. Drain water from

refrigerant or replace refrig-

erant.

• If due to foreign particles, re- move expansion valve and

remove the particles with dry

and compressed air (not

shop air).

• If either of the above meth- ods cannot correct the mal-

function, replace expansion

valve.

• Replace liquid tank.

• Check oil for contamination.

AC362A

Revision: April 20092010 QX56

Page 2561 of 4210

PRECAUTIONSINT-9

< PRECAUTION >

C

DE

F

G H

I

K L

M A

B

INT

N

O P

5. When the repair work is completed, return the ignition switch to the ″LOCK ″ position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of al l control units using CONSULT-III.

Service NoticeINFOID:0000000005147346

• When removing or installing various parts, place a cloth or padding on the vehicle body to prevent scratches.

• Handle trim, molding, instruments, grille, etc. carefully during removing or installing. Be careful not to soil or

damage them.

• Apply sealing compound where necessary when installing parts.

• When applying sealing compound, be careful that the sealing compound does not protrude from parts.

• When replacing any metal parts (for example body outer panel, members, etc.), be sure to take rust preven-

tion measures.

Revision: April 20092010 QX56

Page 2689 of 4210

PRECAUTIONSLU-3

< PRECAUTION >

C

DE

F

G H

I

J

K L

M A

LU

NP

O

5. When the repair work is completed, return the ignition switch to the

″LOCK ″ position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of al l control units using CONSULT-III.

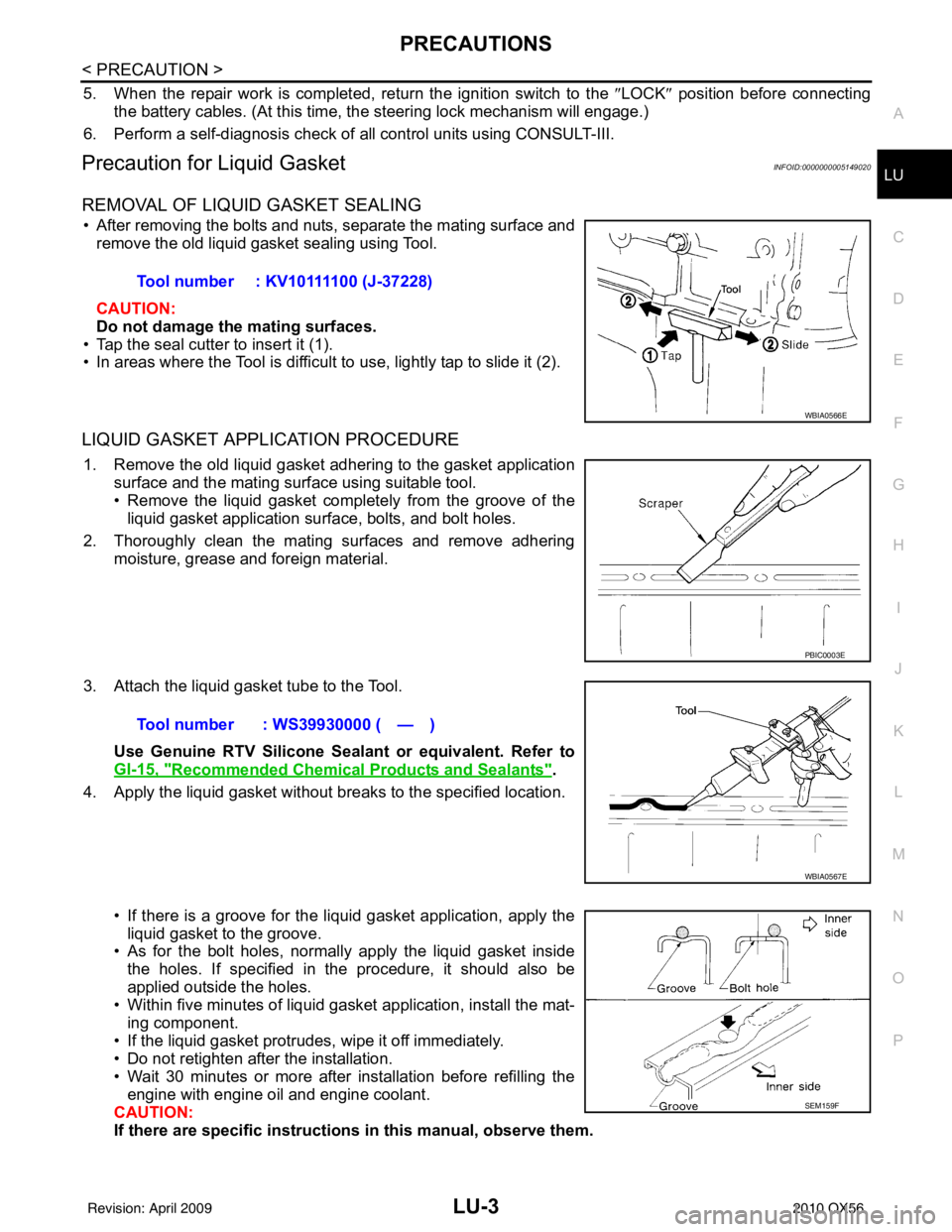

Precaution for Liquid GasketINFOID:0000000005149020

REMOVAL OF LIQUID GASKET SEALING

• After removing the bolts and nuts, separate the mating surface and

remove the old liquid gasket sealing using Tool.

CAUTION:

Do not damage the mating surfaces.

• Tap the seal cutter to insert it (1).

• In areas where the Tool is difficult to use, lightly tap to slide it (2).

LIQUID GASKET APPLICATION PROCEDURE

1. Remove the old liquid gasket adhering to the gasket application surface and the mating surface using suitable tool.

• Remove the liquid gasket completely from the groove of the

liquid gasket application surface, bolts, and bolt holes.

2. Thoroughly clean the mating surfaces and remove adhering moisture, grease and foreign material.

3. Attach the liquid gasket tube to the Tool. Use Genuine RTV Silicone Sealant or equivalent. Refer to

GI-15, "

Recommended Chemical Products and Sealants".

4. Apply the liquid gasket without breaks to the specified location.

• If there is a groove for the liquid gasket application, apply theliquid gasket to the groove.

• As for the bolt holes, normally apply the liquid gasket inside

the holes. If specified in the procedure, it should also be

applied outside the holes.

• Within five minutes of liquid gasket application, install the mat-

ing component.

• If the liquid gasket protrudes, wipe it off immediately.

• Do not retighten after the installation.

• Wait 30 minutes or more after installation before refilling the engine with engine oil and engine coolant.

CAUTION:

If there are specific instructions in this manual, observe them.

Tool number : KV10111100 (J-37228)

WBIA0566E

PBIC0003E

Tool number : WS39930000 ( — )

WBIA0567E

SEM159F

Revision: April 20092010 QX56

Page 2694 of 4210

LU-8

< ON-VEHICLE MAINTENANCE >

ENGINE OIL

ON-VEHICLE MAINTENANCE

ENGINE OIL

InspectionINFOID:0000000005149025

OIL LEVEL

• Before starting the engine make sure the vehicle is parked on a flatand level surface, then check the oil level. If the engine is already

running, turn it off and allow 10 minutes before checking.

• Check that the oil level is within the low (L) to high (H) range as indicated on the dipstick.

• If the engine oil level is out of range, add oil as necessary. Refer to

MA-13, "

Fluids and Lubricants".

OIL APPEARANCE

• Check the engine oil for a white milky appearance or excessive contamination.

• If the engine oil is milky, it is highly probable that it is contaminated with engine coolant. Repair the broken

parts.

OIL LEAKAGE

Check for oil leakage around the following areas:

•Oil pan

• Oil pan drain plug

• Oil pressure switch

• Oil filter

• Oil cooler

• Intake valve timing control cover

• Intake valve timing control solenoid valve

• Front cover

• Mating surface between cylinder block and cylinder head

• Mating surface between cylinder head and rocker cover

• Crankshaft oil seal (front and rear)

OIL PRESSURE CHECK

WARNING:

• Be careful not to burn yoursel f, as engine oil may be hot.

• Put the selector lever in the Park “P” position.

1. Check the engine oil level. Refer to LU-8, "

Inspection".

2. Remove engine front undercover using power tool.

3. Disconnect the oil pressure switch harness connector.

4. Remove the oil pressure switch (A).

SMA954C

WBIA0791E

Revision: April 20092010 QX56

Page 2695 of 4210

ENGINE OILLU-9

< ON-VEHICLE MAINTENANCE >

C

DE

F

G H

I

J

K L

M A

LU

NP

O

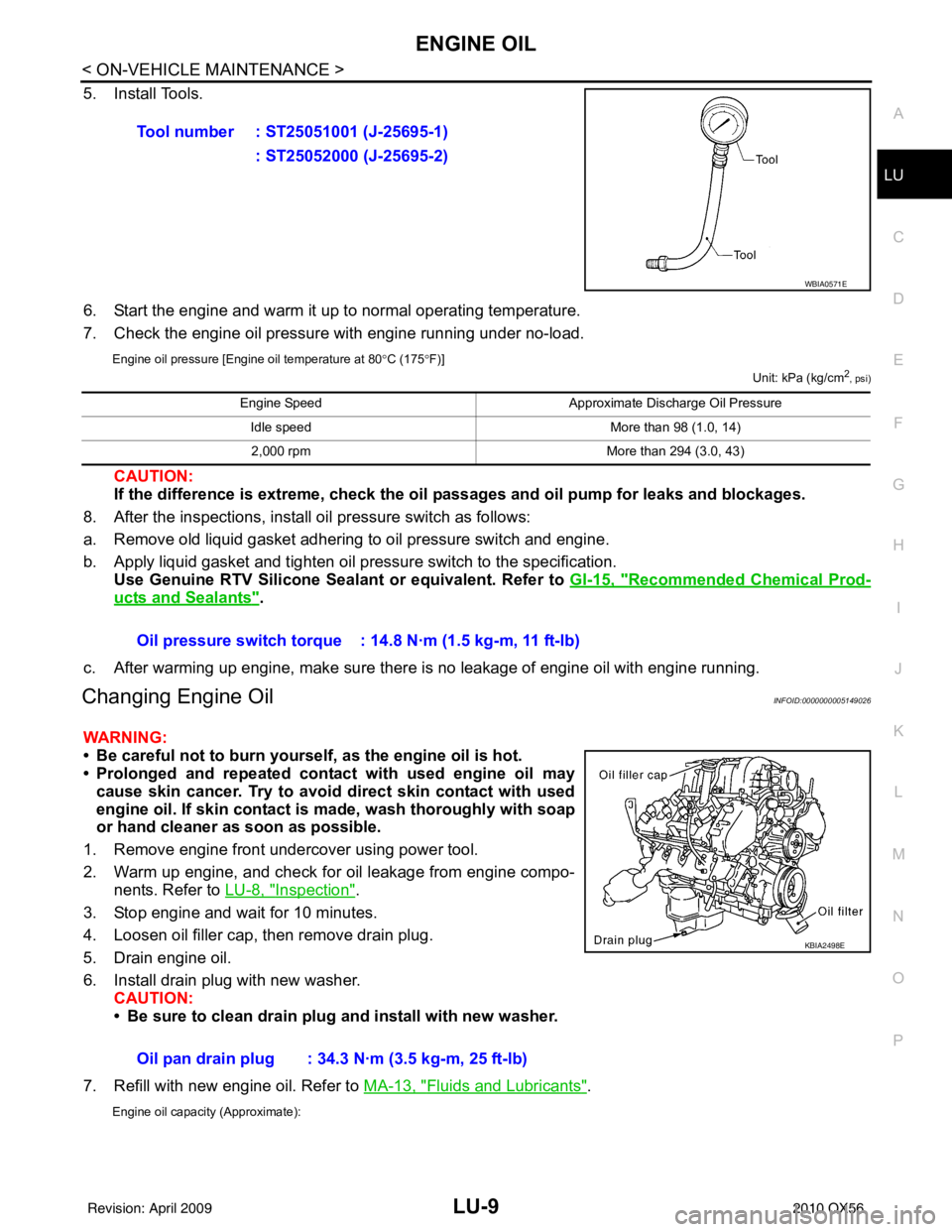

5. Install Tools.

6. Start the engine and warm it up to normal operating temperature.

7. Check the engine oil pressure with engine running under no-load.

Engine oil pressure [Engine oil temperature at 80

°C (175 °F)]

Unit: kPa (kg/cm2, psi)

CAUTION:

If the difference is extreme, check the oil passages and oil pump for leaks and blockages.

8. After the inspections, install oil pressure switch as follows:

a. Remove old liquid gasket adhering to oil pressure switch and engine.

b. Apply liquid gasket and tighten oil pressure switch to the specification. Use Genuine RTV Silicone Seal ant or equivalent. Refer to GI-15, "

Recommended Chemical Prod-

ucts and Sealants".

c. After warming up engine, make sure there is no leakage of engine oil with engine running.

Changing Engine OilINFOID:0000000005149026

WARNING:

• Be careful not to burn yourself, as the engine oil is hot.

• Prolonged and repeated contact with used engine oil may cause skin cancer. Try to avoid direct skin contact with used

engine oil. If skin contact is made, wash thoroughly with soap

or hand cleaner as soon as possible.

1. Remove engine front undercover using power tool.

2. Warm up engine, and check for oil leakage from engine compo- nents. Refer to LU-8, "

Inspection".

3. Stop engine and wait for 10 minutes.

4. Loosen oil filler cap, then remove drain plug.

5. Drain engine oil.

6. Install drain plug with new washer. CAUTION:

• Be sure to clean drain plug and install with new washer.

7. Refill with new engine oil. Refer to MA-13, "

Fluids and Lubricants".

Engine oil capacity (Approximate):

Tool number : ST25051001 (J-25695-1)

: ST25052000 (J-25695-2)

WBIA0571E

Engine Speed Approximate Discharge Oil Pressure

Idle speed More than 98 (1.0, 14)

2,000 rpm More than 294 (3.0, 43)

Oil pressure switch torque : 14.8 N·m (1.5 kg-m, 11 ft-lb)

Oil pan drain plug : 34.3 N·m (3.5 kg-m, 25 ft-lb)

KBIA2498E

Revision: April 20092010 QX56