Air INFINITI QX56 2010 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2010, Model line: QX56, Model: INFINITI QX56 2010Pages: 4210, PDF Size: 81.91 MB

Page 3930 of 4210

REPAIR FOR COMPONENT PARTSTM-235

< DISASSEMBLY AND ASSEMBLY >

CEF

G H

I

J

K L

M A

B

TM

N

O P

b. Remove 1st one-way clutch from rear sun gear.

5. Remove seal rings from mid sun gear.

INSPECTION

High and Low Reverse Clutch Hub Snap Ring, Rear Sun Gear Snap Ring

• Check for deformation, fatigue or damage.

CAUTION:

If necessary, replace the snap ring.

1st One-way Clutch

• Check frictional surface for wear or damage.CAUTION:

If necessary, replace the 1st one-way clutch.

Mid Sun Gear

• Check for deformation, fatigue or damage.CAUTION:

If necessary, replace the mid sun gear.

Rear Sun Gear

• Check for deformation, fatigue or damage.CAUTION:

If necessary, replace the rear sun gear.

High and Low Reverse Clutch Hub

• Check for deformation, fatigue or damage.CAUTION:

If necessary, replace the high and low reverse clutch hub.

ASSEMBLY

SCIA4633E

SCIA2861E

Revision: April 20092010 QX56

Page 3931 of 4210

TM-236

< DISASSEMBLY AND ASSEMBLY >

REPAIR FOR COMPONENT PARTS

1. Install new seal rings to mid sun gear.CAUTION:

• Do not reuse seal rings.

• Apply petroleum jelly to seal rings.

2. Install 1st one-way clutch to rear sun gear. CAUTION:

Apply petroleum jelly to 1st one-way clutch.

3. Install snap ring to rear sun gear using suitable tool.

4. Install rear sun gear assembly to mid sun gear assembly.

5. Install needle bearing to high and low reverse clutch hub. CAUTION:

• Take care with the direction of needle bearing. Refer to

TM-201, "

Location of Adjusting Shims, Needle Bearings,

Thrust Washers and Snap Rings".

• Apply petroleum jelly to needle bearing.

SCIA2861E

SCIA4633E

SCIA2859E

SCIA2858E

SCIA2857E

Revision: April 20092010 QX56

Page 3932 of 4210

REPAIR FOR COMPONENT PARTSTM-237

< DISASSEMBLY AND ASSEMBLY >

CEF

G H

I

J

K L

M A

B

TM

N

O P

6. Install high and low reverse clutch hub to mid sun gear assem- bly.

7. Install snap ring to mid sun gear assembly using suitable tool. CAUTION:

Do not expand snap ring excessively.

8. Check operation of 1st one-way clutch.

a. Hold mid sun gear and turn rear sun gear.

b. Check 1st one-way clutch for correct locking and unlocking directions.

CAUTION:

If not as shown, check installa tion direction of 1st one-way

clutch.

9. Install needle bearing and bearing races to high and low reverse clutch hub.

CAUTION:

• Apply petroleum jelly to needle bearing and bearingraces.

• Take care with order of bearing races.

High and Low Reverse ClutchINFOID:0000000005148753

COMPONENTS

SCIA2856E

SCIA2855E

SCIA3132E

SCIA5238E

Revision: April 20092010 QX56

Page 3933 of 4210

TM-238

< DISASSEMBLY AND ASSEMBLY >

REPAIR FOR COMPONENT PARTS

DISASSEMBLY

1. Remove bearing race from high and low reverse clutch drum.

2. Remove snap ring from high and low reverse clutch drum usingsuitable tool.

3. Remove drive plates, driven plates and retaining plate from high and low reverse clutch drum.

INSPECTION

•Check the following, and re place high and low reverse clutch assembly if necessary.

High and Low Reverse Clutch Snap Ring

• Check for deformation, fatigue or damage.

High and Low Reverse Clutch Drive Plates

• Check facing for burns, cracks or damage.

High and Low Reverse Clutch Retaining Plate and Driven Plates

• Check facing for burns, cracks or damage.

ASSEMBLY

1. High and low reverse clutch drum 2. Driven plate 3. Retaining plate

4. Snap ring 5. Drive plate6. Bearing race

SCIA5239E

SCIA5240E

SCIA2868E

Revision: April 20092010 QX56

Page 3934 of 4210

REPAIR FOR COMPONENT PARTSTM-239

< DISASSEMBLY AND ASSEMBLY >

CEF

G H

I

J

K L

M A

B

TM

N

O P

1. Install drive plates, driven plates and retaining plate in high and low reverse clutch drum.

CAUTION:

Take care with the order of plates.

2. Install snap ring in high and low reverse clutch drum using suit- able tool.

3. Install bearing race to high and low reverse clutch drum. CAUTION:

Apply petroleum jelly to bearing race.

Direct ClutchINFOID:0000000005148754

COMPONENTS

SCIA5241E

SCIA2868E

SCIA5240E

Revision: April 20092010 QX56

Page 3935 of 4210

TM-240

< DISASSEMBLY AND ASSEMBLY >

REPAIR FOR COMPONENT PARTS

DISASSEMBLY

1. Remove snap rings from direct clutch drum using suitable tool.

2. Remove drive plates, driven plates and retaining plate fromdirect clutch drum.

INSPECTION

•Check the following, and replace direct clutch assembly if necessary.

Direct Clutch Snap Rings

• Check for deformation, fatigue or damage.

Direct Clutch Drive Plates

• Check facing for burns, cracks or damage.

Direct Clutch Retaining Plate and Driven Plates

• Check facing for burns, cracks or damage.

ASSEMBLY

1. Direct clutch drum 2. Driven plate 3. Retaining plate

4. Snap ring 5. Drive plate

SCIA5242E

SCIA2868E

Revision: April 20092010 QX56

Page 3936 of 4210

REPAIR FOR COMPONENT PARTSTM-241

< DISASSEMBLY AND ASSEMBLY >

CEF

G H

I

J

K L

M A

B

TM

N

O P

1. Install drive plates, driven plates and retaining plate in direct clutch drum.

CAUTION:

Take care with the order of plates.

2. Install snap rings in direct clutch drum using suitable tool.

SCIA5243E

SCIA2868E

Revision: April 20092010 QX56

Page 3963 of 4210

VTL-1

VENTILATION, HEATER & AIR CONDITIONER

C

DE

F

G H

J

K L

M

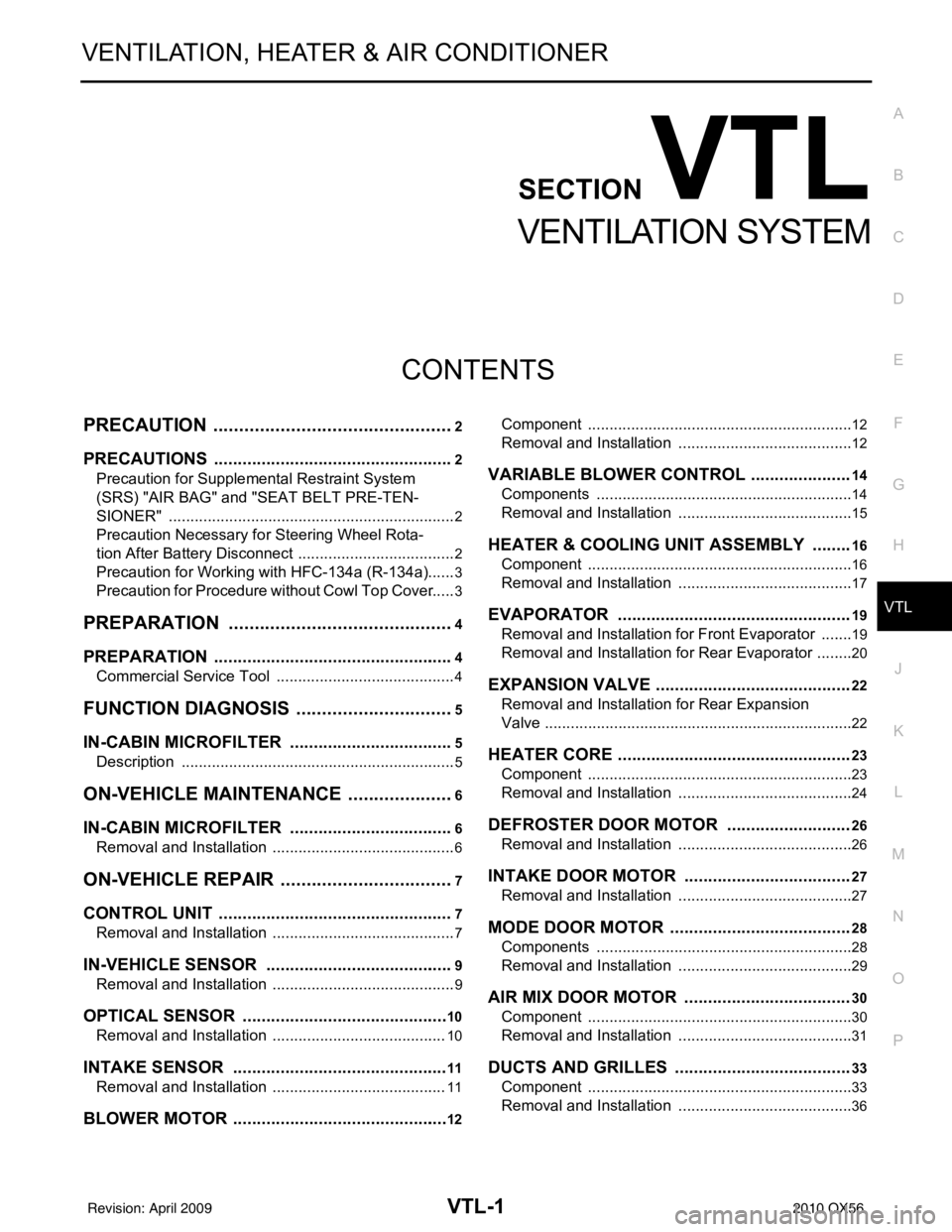

SECTION VTL

A

B

VTL

N

O P

CONTENTS

VENTILATION SYSTEM

PRECAUTION ....... ........................................2

PRECAUTIONS .............................................. .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

2

Precaution for Working with HFC-134a (R-134a) ......3

Precaution for Procedure without Cowl Top Cover ......3

PREPARATION ............................................4

PREPARATION .............................................. .....4

Commercial Service Tool .................................... ......4

FUNCTION DIAGNOSIS ...............................5

IN-CABIN MICROFILTER .............................. .....5

Description .......................................................... ......5

ON-VEHICLE MAINTENANCE .....................6

IN-CABIN MICROFILTER .............................. .....6

Removal and Installation ...........................................6

ON-VEHICLE REPAIR .... ..............................7

CONTROL UNIT ..................................................7

Removal and Installation ...........................................7

IN-VEHICLE SENSOR ................................... .....9

Removal and Installation ...........................................9

OPTICAL SENSOR ........................................ ....10

Removal and Installation .........................................10

INTAKE SENSOR ..............................................11

Removal and Installation .........................................11

BLOWER MOTOR .......................................... ....12

Component .......................................................... ....12

Removal and Installation .........................................12

VARIABLE BLOWER CONTROL .....................14

Components ............................................................14

Removal and Installation .........................................15

HEATER & COOLING UNIT ASSEMBLY ........16

Component ..............................................................16

Removal and Installation .........................................17

EVAPORATOR .................................................19

Removal and Installation for Front Evaporator ........19

Removal and Installation for Rear Evaporator .........20

EXPANSION VALVE .........................................22

Removal and Installation for Rear Expansion

Valve .................................................................... ....

22

HEATER CORE .................................................23

Component ..............................................................23

Removal and Installation .........................................24

DEFROSTER DOOR MOTOR ..........................26

Removal and Installation .........................................26

INTAKE DOOR MOTOR ...................................27

Removal and Installation .........................................27

MODE DOOR MOTOR ......................................28

Components ............................................................28

Removal and Installation .........................................29

AIR MIX DOOR MOTOR ...................................30

Component ..............................................................30

Removal and Installation .........................................31

DUCTS AND GRILLES .....................................33

Component ..............................................................33

Removal and Installation .........................................36

Revision: April 20092010 QX56

Page 3964 of 4210

VTL-2

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005403098

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SR and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution Necessary for Steering W heel Rotation After Battery Disconnect

INFOID:0000000005403099

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecting both battery cables with the ignition knob in the

″LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS, an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be rotated.

4. Perform the necessary repair operation.

Revision: April 20092010 QX56

Page 3965 of 4210

PRECAUTIONSVTL-3

< PRECAUTION >

C

DE

F

G H

J

K L

M A

B

VTL

N

O P

5. When the repair work is completed, return the ignition switch to the ″LOCK ″ position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of al l control units using CONSULT-III.

Precaution for Working with HFC-134a (R-134a)INFOID:0000000005147600

WARNING:

• CFC-12 (R-12) refrigerant and HFC-134a (R-134a) refr igerant are not compatible. If the refrigerants

are mixed compressor failure is likely to occur. Refer to HA-4, "

Contaminated Refrigerant". To deter-

mine the purity of HFC-134a (R-134a) in the vehicle and recovery tank, use recovery/recycling equip-

ment and refrigerant identifier.

• Use only specified oil for the HFC-134a (R-134a) A/C system and HFC-134a (R-134a) components. If

oil other than that specified is used, compressor fa ilure is likely to occur.

• The specified HFC-134a (R-134a) oil rapidly absorb s moisture from the atmosphere. The following

handling precautions must be observed:

- When removing refrigerant components from a vehicle, immediately cap (seal) the component to

minimize the entry of mois ture from the atmosphere.

- When installing refrigerant components to a vehicle, do not remove the caps (unseal) until just

before connecting the co mponents. Connect all refrigerant lo op components as quickly as possible

to minimize the entry of moisture into system.

- Only use the specified oil from a sealed container. Immediately r eseal containers of oil. Without

proper sealing, oil will become moisture saturat ed and should not be used.

- Avoid breathing A/C refrigerant and oil vapor or mist. Exposure may irritate eyes, nose and throat.

Remove HFC-134a (R-134a) from the A/C system usi ng certified service equipment meeting require-

ments of SAE J2210 [HFC-134a (R-134a) recycling eq uipment], or J2209 [HFC-134a (R-134a) recovery

equipment]. If accidental system discharge occurs , ventilate work area before resuming service.

Additional health and safety information may be ob tained from refrigerant and oil manufacturers.

- Do not allow A/C oil to come in contact with styrofoam parts. Damage may result.

Precaution for Procedur e without Cowl Top CoverINFOID:0000000005147601

When performing the procedure after removing cowl top cover, cover

the lower end of windshield with urethane, etc.

PIIB3706J

Revision: April 20092010 QX56