ECO mode INFINITI QX56 2010 Factory User Guide

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2010, Model line: QX56, Model: INFINITI QX56 2010Pages: 4210, PDF Size: 81.91 MB

Page 363 of 4210

![INFINITI QX56 2010 Factory User Guide AV-166

< PRECAUTION >[AUDIO SYSTEM]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint Syst

em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005358679

The Suppleme INFINITI QX56 2010 Factory User Guide AV-166

< PRECAUTION >[AUDIO SYSTEM]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint Syst

em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005358679

The Suppleme](/img/42/57032/w960_57032-362.png)

AV-166

< PRECAUTION >[AUDIO SYSTEM]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint Syst

em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005358679

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SR and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution Necessary for Steering W heel Rotation After Battery Disconnect

INFOID:0000000005327545

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecting both battery cables with the ignition knob in the

″LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS, an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be rotated.

4. Perform the necessary repair operation.

Revision: April 20092010 QX56

Page 400 of 4210

![INFINITI QX56 2010 Factory User Guide BCS-14

< FUNCTION DIAGNOSIS >[BCM]

POWER CONSUMPTION CONTROL SYSTEM

Sleep condition

Wake-up operation

• BCM transmits sleep wake up signal (wake up) to each unit when any condition listed below is e INFINITI QX56 2010 Factory User Guide BCS-14

< FUNCTION DIAGNOSIS >[BCM]

POWER CONSUMPTION CONTROL SYSTEM

Sleep condition

Wake-up operation

• BCM transmits sleep wake up signal (wake up) to each unit when any condition listed below is e](/img/42/57032/w960_57032-399.png)

BCS-14

< FUNCTION DIAGNOSIS >[BCM]

POWER CONSUMPTION CONTROL SYSTEM

Sleep condition

Wake-up operation

• BCM transmits sleep wake up signal (wake up) to each unit when any condition listed below is established,

and then goes into normal mode from low power consumption mode.

• Each unit starts transmissions with CAN communication by receiving sleep wake up signals. Each unit trans- mits wake up signals to BCM with CAN communication to convey the start of CAN communication.

Wake-up condition

CAN sleep condition BCM sleep condition

• Receiving the sleep-ready signal (ready) from all units

• Ignition switch: OFF

• Vehicle security system alarm: No operation

• Warning lamp: No operation

• Warning chime: No operation

• Stop lamp switch: OFF

• Key switch status: No change for 2 seconds

• Hazard warning lamp: No operation

•Exterior lamp: OFF

• Door lock status: No change for 2 seconds

• CONSULT-III communication status: No communication

• Door switch status: No change for 2 seconds The controls only BCM are completed.

(Interior room lamp battery saver: Time out etc.)

BCM wake-up condition

• Ignition switch: OFF → ACC or ON

• Stop lamp switch: ON (Depress brake pedal)

• Any door switch: OFF → ON

• Lighting switch: OFF → 1ST or PASS

• Hazard switch: OFF → ON

• Back door opener switch OFF → ON

• Remote keyless entry receiver: Receiving

• Intelligent Key unit: Receiving

Revision: April 20092010 QX56

Page 407 of 4210

![INFINITI QX56 2010 Factory User Guide BCS

DIAGNOSIS SYSTEM (BCM)BCS-21

< FUNCTION DIAGNOSIS > [BCM]

C

D

E

F

G H

I

J

K L

B A

O P

N

Auto locking function mode

Panic alarm operation mode

Back door open operation mode

Keyless power window dow INFINITI QX56 2010 Factory User Guide BCS

DIAGNOSIS SYSTEM (BCM)BCS-21

< FUNCTION DIAGNOSIS > [BCM]

C

D

E

F

G H

I

J

K L

B A

O P

N

Auto locking function mode

Panic alarm operation mode

Back door open operation mode

Keyless power window dow](/img/42/57032/w960_57032-406.png)

BCS

DIAGNOSIS SYSTEM (BCM)BCS-21

< FUNCTION DIAGNOSIS > [BCM]

C

D

E

F

G H

I

J

K L

B A

O P

N

Auto locking function mode

Panic alarm operation mode

Back door open operation mode

Keyless power window down operation mode

DATA MONITOR

ACTIVE TEST

HEADLAMP

M

ODE 1M ODE 2M ODE 3

Auto locking function 5 minutesNothing1 minute

M ODE 1M ODE 2M ODE 3

Keyfob operation 0.5 secondsNothing1.5 seconds

M ODE 1M ODE 2M ODE 3

Keyfob operation 0.5 secondsNothing0.5 seconds

MODE 1 MODE 2 MODE 3

Keyfob operation 3 secondsNothing5 seconds

Monitored Item Description

DOOR SW-AS Indicates [ON/OFF] condition of front door switch RH.

DOOR SW-RR Indicates [ON/OFF] condition of rear door switch RH.

DOOR SW-RL Indicates [ON/OFF] condition of rear door switch LH.

DOOR SW-DR Indicates [ON/OFF] condition of front door switch LH.

KEY ON SW Indicates [ON/OFF] condition of key switch.

ACC ON SW Indicates [ON/OFF] condition of ignition switch in ACC position.

IGN ON SW Indicates [ON/OFF] condition of ignition switch in ON position.

KEYLESS PANIC Indicates [ON/OFF] condition of pani c signal from keyfob.

KEYLESS UNLOCK Indicates [ON/OFF] condition of unlock signal from keyfob.

KEYLESS LOCK Indicates [ON/OFF] condition of lock signal from keyfob.

KEY CYL LK-SW Indicates [ON/OFF] condition of lock signal from door key cylinder switch.

KEY CYL UN-SW Indicates [ON/OFF] condition of unlock signal from door key cylinder switch.

CDL UNLOCK SW Indicates [ON/OFF] condition of unlock signal from lock/unlock switch.

CDL LOCK SW Indicates [ON/OFF] condition of lock signal from lock/unlock switch.

DOOR SW-RL Indicates [ON/OFF] condition of rear door switch LH.

DOOR SW-RR Indicates [ON/OFF] condition of rear door switch RH.

RKE LCK-UNLCK Indicates [ON/OFF] condition of lock/unlock signal at the same time from keyfob.

RKE KEEP UNLK Indicates [ON/OFF] condition of unlock signal from keyfob.

Test Item Description

FLASHER This test is able to check right and left hazard reminder operation. The right hazard lamp turns on

when “RH” on CONSULT-III screen is touched and th e left hazard lamp turns on when "LH" on CON-

SULT-III screen is touched.

POWER WINDOW DOWN This test is able to check power window down operation. The windows are lowered when “ON” on CONSULT-III screen is touched.

HORN This test is able to check panic alarm and horn reminder operations. The alarm activate for 0.5 sec-

onds after “ON” on CONSULT-III screen is touched.

DOOR LOCK This test is able to check door lock operation. The doors lock and unlock based on the item on CON-

SULT-III screen touched.

Revision: April 20092010 QX56

Page 414 of 4210

![INFINITI QX56 2010 Factory User Guide BCS-28

< FUNCTION DIAGNOSIS >[BCM]

DIAGNOSIS SYSTEM (BCM)

SIGNAL BUFFER : CONSULT-III Fu nction (BCM - SIGNAL BUFFER)

INFOID:0000000005146411

DATA MONITOR

ACTIVE TEST

AIR PRESSURE MONITOR

AIR PRESSURE INFINITI QX56 2010 Factory User Guide BCS-28

< FUNCTION DIAGNOSIS >[BCM]

DIAGNOSIS SYSTEM (BCM)

SIGNAL BUFFER : CONSULT-III Fu nction (BCM - SIGNAL BUFFER)

INFOID:0000000005146411

DATA MONITOR

ACTIVE TEST

AIR PRESSURE MONITOR

AIR PRESSURE](/img/42/57032/w960_57032-413.png)

BCS-28

< FUNCTION DIAGNOSIS >[BCM]

DIAGNOSIS SYSTEM (BCM)

SIGNAL BUFFER : CONSULT-III Fu nction (BCM - SIGNAL BUFFER)

INFOID:0000000005146411

DATA MONITOR

ACTIVE TEST

AIR PRESSURE MONITOR

AIR PRESSURE MONITOR : Diagnosis DescriptionINFOID:0000000005146412

DESCRIPTION

During driving, the TPMS receives the signal transmitt ed from the transmitter installed in each wheel, when

the tire pressure becomes low. The control unit (BCM ) of this system has pressure judgment and trouble diag-

nosis functions.

When the TPMS detects low inflation pressure or another unusual symptom, the warning lamps in the combi-

nation meter comes on.

SELF DIAGNOSIS (WITH CONSULT-III)

With CONSULT-III

• Touch “SELF-DIAG RESULTS” display to show malfunction experienced since the last erasing operation. Refer to WT-11, "

CONSULT-III Function (BCM)".

SELF DIAGNOSIS (WITHOUT CONSULT-III)

Without CONSULT-III

To start the self-diagnostic results mode, ground terminal of the tire pressure warning check connector. The

malfunction location is indicated by the warning lamp flashing.

NOTE:

When the low tire warning lamp flashes 5 Hz and continues repeating it, the system is normal.

Monitor Item

[Unit] Description

OIL PRESS SW [ON/OFF] Displays the status of oil pressure switch received from IPDM E/R via CAN communication.

Test ItemOperation Description

OIL PRESSURE SW OFF OFF

ON

BCM transmits the oil pressure switch signal to the combination meter via CAN communica-

tion, which operates the oil pressure gauge in the combination meter.

SEIA0745E

Flickering

pattern Items

Diagnostic items detected when··· Check item

15 Tire pressure value (Front LH) Front LH tire pressure drops to 181 kPa (1.8 kg/cm, 25.25 psi) or less.

–

16 Tire pressure value (Front RH) Front RH tire pressure drops to 181 kPa (1.8 kg/cm, 25.25 psi) or less.

17 Tire pressure value (Rear RH) Rear RH tire pressure drops to 181 kPa (1.8 kg/cm, 25.25 psi) or less.

18 Tire pressure value (Rear LH) Rear LH tire pressure drops to 181 kPa (1.8 kg/cm, 25.25 psi) or less.

Revision: April 20092010 QX56

Page 416 of 4210

![INFINITI QX56 2010 Factory User Guide BCS-30

< FUNCTION DIAGNOSIS >[BCM]

DIAGNOSIS SYSTEM (BCM)

AIR PRESSURE MONITOR : CONSULT-III Function

INFOID:0000000005146413

WORK SUPPORT

ID Read

The registered ID number is displayed.

ID Regist

Refe INFINITI QX56 2010 Factory User Guide BCS-30

< FUNCTION DIAGNOSIS >[BCM]

DIAGNOSIS SYSTEM (BCM)

AIR PRESSURE MONITOR : CONSULT-III Function

INFOID:0000000005146413

WORK SUPPORT

ID Read

The registered ID number is displayed.

ID Regist

Refe](/img/42/57032/w960_57032-415.png)

BCS-30

< FUNCTION DIAGNOSIS >[BCM]

DIAGNOSIS SYSTEM (BCM)

AIR PRESSURE MONITOR : CONSULT-III Function

INFOID:0000000005146413

WORK SUPPORT

ID Read

The registered ID number is displayed.

ID Regist

Refer to WT-6, "ID Registration Procedure".

SELF-DIAG RESULTS

Operation Procedure

Refer to WT-11, "CONSULT-III Function (BCM)".

DATA MONITOR

Screen of data monitor mode is displayed. Refer to WT-11, "CONSULT-III Function (BCM)".

NOTE:

When malfunction is detected, CONSUL T-III perform REAL-TIME DIAGNOSIS.

Also, any malfunction detected while in this mode will be displayed at real time.

ACTIVE TEST

NOTE:

Before performing the self-diagnosis, be sure to register the ID, or else the actual malfunction may be different

from that displayed on CONSULT-III.

TEST ITEM LIST

THEFT ALM

THEFT ALM : CONSULT-III F unction (BCM - THEFT ALM)INFOID:0000000005370264

WORK SUPPORT

DATA MONITOR

Test item Content

WARNING LAMP This test is able to check to make sure that the warning lamp turns on.

ID REGIST WARNING This test is able to check to make su re that the buzzer sounds or the warning lamp turns on.

FLAT TIRE WARNING This test is able to check to make sure that the buzzer sounds.

HORN This test is able to check to make sure that the horn sounds.

FLASHER This test is able to check to make sure that each turn signal lamp turns on.

Test Item Description

SECURITY ALARM SET This mo de is able to confirm and change security alarm ON-OFF setting.

THEFT ALM TRG The switch which triggered vehicle security alarm is recorded. This mode is able to confirm and

erase the record of vehicle security alarm. The trigger data can be erased by touching “CLEAR” on

CONSULT-III screen.

Monitor Item

[Unit] Description

IGN ON SW [ON/OFF] Indicates ignition switch (ON) status judged from IGN signal (ignition power supply)

ACC ON SW [ON/OFF] Indicates ignition switch (ACC) status judged from ACC signal (accessory power supply)

I-KEY LOCK [ON/OFF] Indicates lock signal status received from Intelligent Key unit by CAN communication

I-KEY UNLOCK [ON/OFF] Indicates unlock si gnal status received from Intelligent Key unit by CAN communication

I-KEY TRUNK [ON/OFF] Indicates condit ion of back door opener switch

TRNK OPNR SW [ON/OFF] Indicates switch status of back door opener switch

TRNK OPN MNTR [ON/OFF] Indicates switch status of back door latch

Revision: April 20092010 QX56

Page 443 of 4210

![INFINITI QX56 2010 Factory User Guide BCS

PRECAUTIONSBCS-57

< PRECAUTION > [BCM]

C

D

E

F

G H

I

J

K L

B A

O P

N

PRECAUTION

PRECAUTIONS

Precaution for Supplemental

Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000 INFINITI QX56 2010 Factory User Guide BCS

PRECAUTIONSBCS-57

< PRECAUTION > [BCM]

C

D

E

F

G H

I

J

K L

B A

O P

N

PRECAUTION

PRECAUTIONS

Precaution for Supplemental

Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000](/img/42/57032/w960_57032-442.png)

BCS

PRECAUTIONSBCS-57

< PRECAUTION > [BCM]

C

D

E

F

G H

I

J

K L

B A

O P

N

PRECAUTION

PRECAUTIONS

Precaution for Supplemental

Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005384312

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SR and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Un it or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or el ectric power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers, always switch the Ignition OFF, disconnect the battery, and wait at least 3 minutes before performing any service.

Precaution Necessary for Steering Wheel Rotation After Battery Disconnect

INFOID:0000000005282709

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecti ng both battery cables with the ignition knob in the

″ LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS , an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery power is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be

rotated.

4. Perform the necessary repair operation.

Revision: April 20092010 QX56

Page 448 of 4210

PRECAUTIONSBR-3

< PRECAUTION >

C

DE

G H

I

J

K L

M A

B

BR

N

O P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005403123

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SR and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Un it or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or el ectric power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers, always switch the Ignition OFF, disconnect the battery, and wait at least 3 minutes before performing any service.

Precaution Necessary for Steering Wheel Rotation After Battery Disconnect

INFOID:0000000005403124

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecti ng both battery cables with the ignition knob in the

″ LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS , an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery power is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be

rotated.

4. Perform the necessary repair operation.

Revision: April 20092010 QX56

Page 490 of 4210

SERVICE DATA AND SPECIFICATIONS (SDS)BR-45

< SERVICE DATA AND SPECIFICATIONS (SDS)

C

DE

G H

I

J

K L

M A

B

BR

N

O P

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

General SpecificationINFOID:0000000005147925

Unit: mm (in)

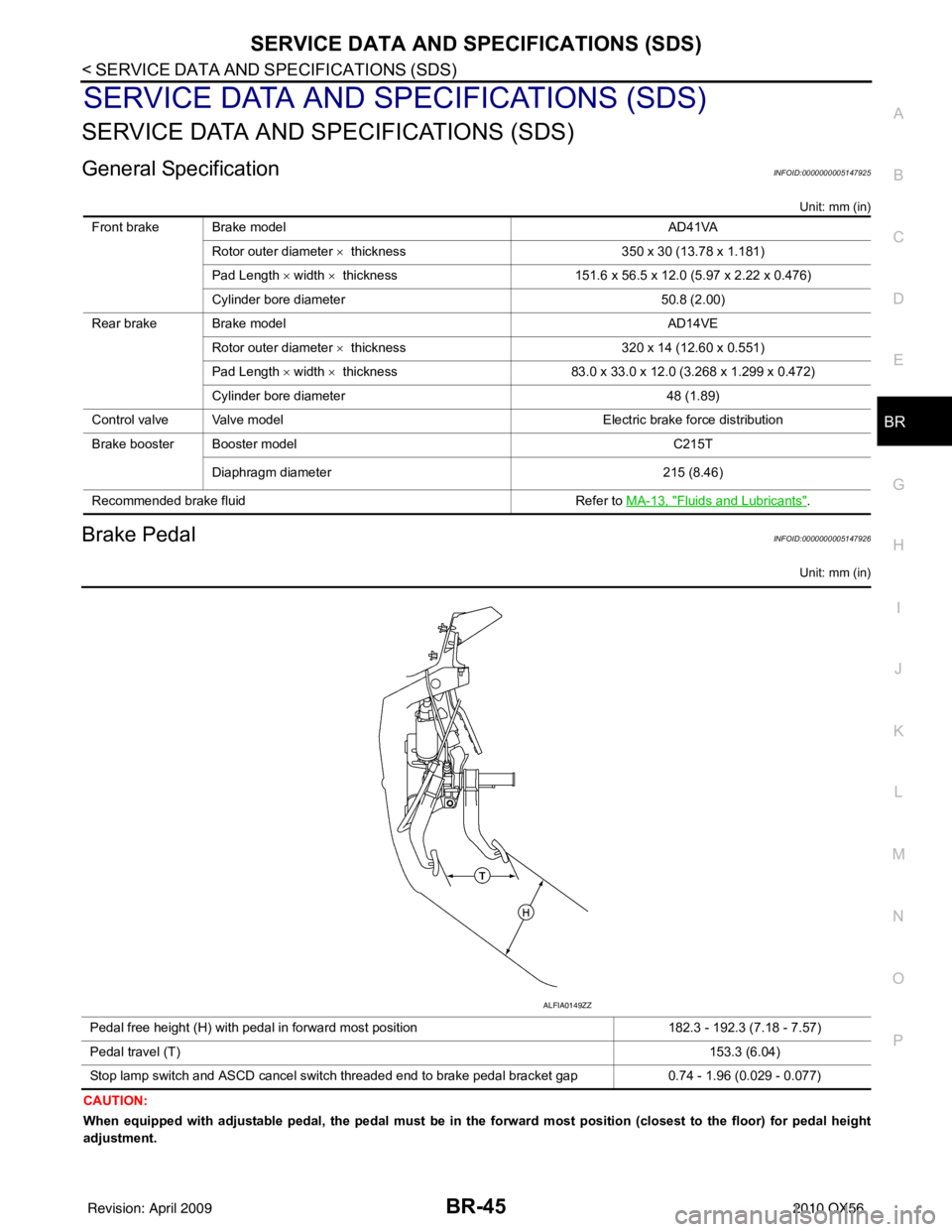

Brake PedalINFOID:0000000005147926

Unit: mm (in)

CAUTION:

When equipped with adjustable pedal, the pedal must be in the forward most position (closest to the floor) for pedal height

adjustment. Front brake Brake model

AD41VA

Rotor outer diameter × thickness 350 x 30 (13.78 x 1.181)

Pad Length × width × thickness 151.6 x 56.5 x 12.0 (5.97 x 2.22 x 0.476)

Cylinder bore diameter 50.8 (2.00)

Rear brake Brake model AD14VE

Rotor outer diameter × thickness 320 x 14 (12.60 x 0.551)

Pad Length × width × thickness 83.0 x 33.0 x 12.0 (3.268 x 1.299 x 0.472)

Cylinder bore diameter 48 (1.89)

Control valve Valve model Electric brake force distribution

Brake booster Booster model C215T

Diaphragm diameter 215 (8.46)

Recommended brake fluid Refer to MA-13, "

Fluids and Lubricants".

Pedal free height (H) with pedal in forward most position 182.3 - 192.3 (7.18 - 7.57)

Pedal travel (T) 153.3 (6.04)

Stop lamp switch and ASCD cancel switch threaded end to brake pedal bracket gap 0.74 - 1.96 (0.029 - 0.077)

ALFIA0149ZZ

Revision: April 20092010 QX56

Page 491 of 4210

BR-46

< SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

Brake Booster

INFOID:0000000005147927

Unit: mm (in)

Check ValveINFOID:0000000005147928

Front Disc BrakeINFOID:0000000005147929

Unit: mm (in)

Rear Disc BrakeINFOID:0000000005147930

Unit: mm (in)

Output rod length [at -66.7 kPa (-500 mmHg, -19.69 inHg) vacuum] 15.6 - 15.9 (0.614 - 0.626)

Input rod installation length (B) 151 (5.94)

SBR208E

WFIA0382E

Vacuum leakage

[at vacuum of – 66.7 kPa(– 500 mmHg, – 19.69 inHg)]Within 1.3 kPa (10 mmHg, 0.39 inHg) of vacuum for 15 seconds

Brake model

AD41VA

Brake pad Standard thickness (new)

12.0 (0.476)

Repair limit thickness 1.0 (0.039)

Disc rotor Standard thickness (new)

30 (1.181)

Repair limit thickness 28 (1.102)

Maximum uneven wear (measured at 8 positions) 0.015 (0.0006)

Runout limit (with it attached to the vehicle) 0.03 (0.001)

Brake model AD14VE

Brake pad Standard thickness (new)

12.0 (0.472)

Repair limit thickness 1.0 (0.039)

Revision: April 20092010 QX56

Page 518 of 4210

![INFINITI QX56 2010 Factory User Guide BRC-26

< FUNCTION DIAGNOSIS >[VDC/TCS/ABS]

DIAGNOSIS SYSTEM [

ABS ACTUATOR AND ELECTRIC UNIT (CONTROL

UNIT)]

×: Applicable

–: Not applicable

ACTIVE TEST MODE

CAUTION:

• Do not perform active tes INFINITI QX56 2010 Factory User Guide BRC-26

< FUNCTION DIAGNOSIS >[VDC/TCS/ABS]

DIAGNOSIS SYSTEM [

ABS ACTUATOR AND ELECTRIC UNIT (CONTROL

UNIT)]

×: Applicable

–: Not applicable

ACTIVE TEST MODE

CAUTION:

• Do not perform active tes](/img/42/57032/w960_57032-517.png)

BRC-26

< FUNCTION DIAGNOSIS >[VDC/TCS/ABS]

DIAGNOSIS SYSTEM [

ABS ACTUATOR AND ELECTRIC UNIT (CONTROL

UNIT)]

×: Applicable

–: Not applicable

ACTIVE TEST MODE

CAUTION:

• Do not perform active test while driving vehicle.

• Make sure to completely bleed air from brake system.

• The active test cannot be performed with the ABS warning lamp, VDC OFF indicator lamp, SLIP indi-

cator lamp or brake warning lamp on.

• ABS warning lamp, VDC OFF indicator lamp, SLIP indicator lamp and brake warning lamp are on

during active test.

NOTE:

• When active test is performed while depressing the pedal, the pedal depression amount will change. This is

normal. (Only solenoid valve and ABS motor.)

• “TEST IS STOPPED” is displayed 10 seconds after operation start.

• After “TEST IS STOPPED” is display ed, to perform test again, touch BACK.

Test Item

SOLENOID VALVE• When performing an active test of the ABS function, select the “MAIN SIGNAL S” for each test item.

• For ABS solenoid valve, touch “Up”, “Keep”, and “D own” on the display screen. For ABS solenoid valve

(ACT), touch “Up”, “ACT UP”, “ACT KEEP” and confirm that solenoid valves operate as shown in the table

below.

RELEASE SW NC

(On/Off) ––

×Release switch signal (On/Off) status is displayed.

“Off” indicates that the brake pedal is depressed. “On”

indicates that the brake pedal is released.

OHB FAIL

(On/Off) ––

×OHB fail status is displayed.

HBA FAIL

(On/Off) ––

×HBA fail status is displayed.

OHB SIG

(On/Off) ––

×OHB operation (On/Off) status is displayed.

HBA SIG

(On/Off) ––

×HBA operation (On/Off) status is displayed.

STP OFF RLY

(On/Off) ––

×Stop lamp relay signal (On/Off) status is displayed.

Item

(Unit) Data monitor item selection

Remarks

ECU INPUT

SIGNALS MAIN

SIGNALS SELECTION

FROM MENU

Operation ABS solenoid valve ABS solenoid valve (ACT)

Up Keep Down Up ACT UP ACT KEEP

FR RH SOL FR RH IN SOL Off On On — —

—

FR RH OUT SOL Off Off On* — — —

FR LH SOL FR LH IN SOL Off On On — —

—

FR LH OUT SOL Off Off On* — — —

RR RH SOL RR RH IN SOL Off On On — —

—

RR RH OUT SOL Off Off On* — — —

RR LH SOL RR LH IN SOL Off On On — —

—

RR LH OUT SOL Off Off On* — — —

FR RH ABS SOLENOID (ACT) FR RH IN SOL — — — Off Off Off

FR RH OUT SOL — — — Off Off Off

CV1 ———OffOnOn

SV1

— — — Off On* Off

Revision: April 20092010 QX56