INFINITI QX56 2010 Factory Service Manual

QX56 2010

INFINITI

INFINITI

https://www.carmanualsonline.info/img/42/57032/w960_57032-0.png

INFINITI QX56 2010 Factory Service Manual

Trending: pairing phone, stop start, B2120, brake fluid, remote start, four wheel drive, wiring

Page 2741 of 4210

CHASSIS AND BODY MAINTENANCEMA-37

< ON-VEHICLE MAINTENANCE >

C

DE

F

G H

I

J

K L

M B

MA

N

O A

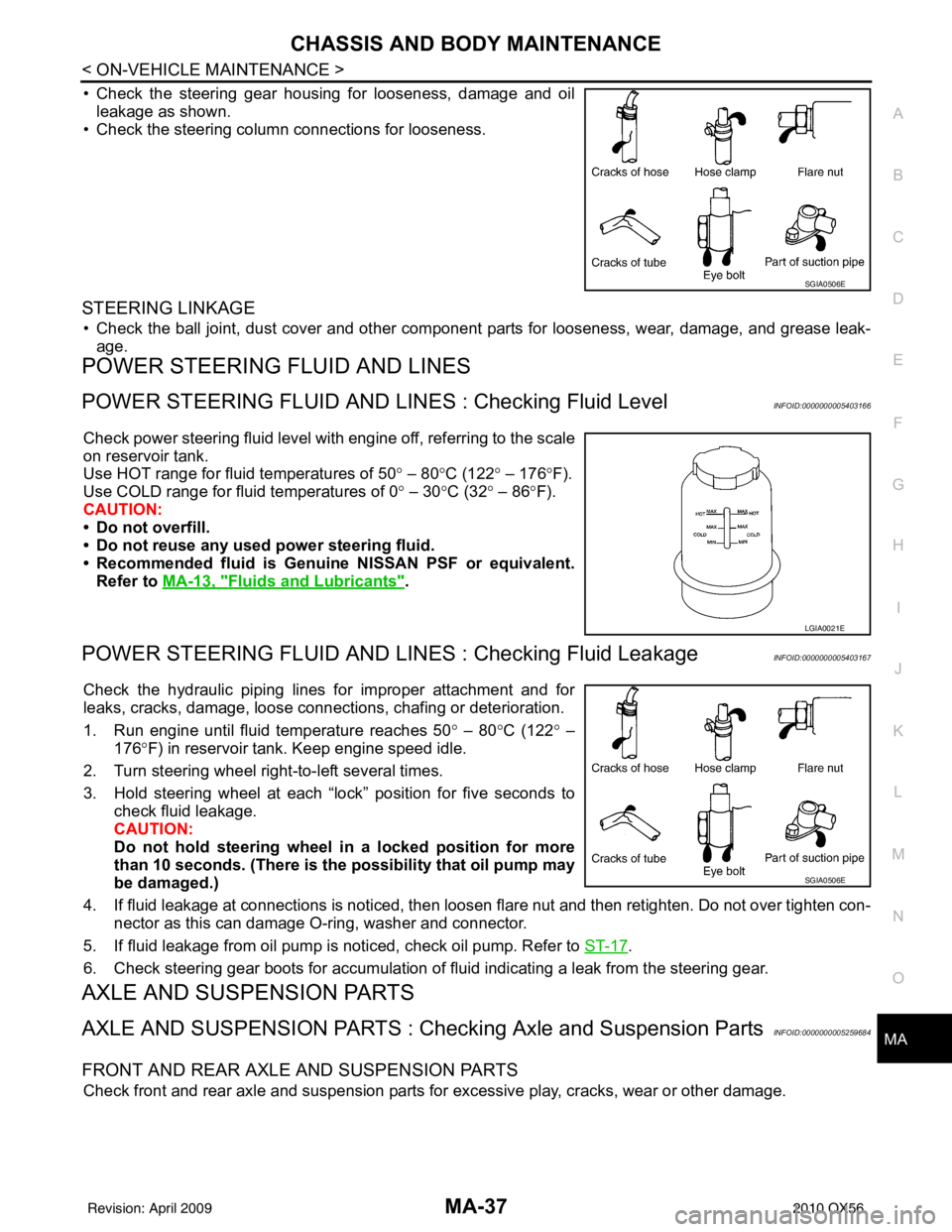

• Check the steering gear housing for looseness, damage and oil

leakage as shown.

• Check the steering column connections for looseness.

STEERING LINKAGE

• Check the ball joint, dust cover and other component parts for looseness, wear, damage, and grease leak-

age.

POWER STEERING FLUID AND LINES

POWER STEERING FLUID AND LINE S : Checking Fluid LevelINFOID:0000000005403166

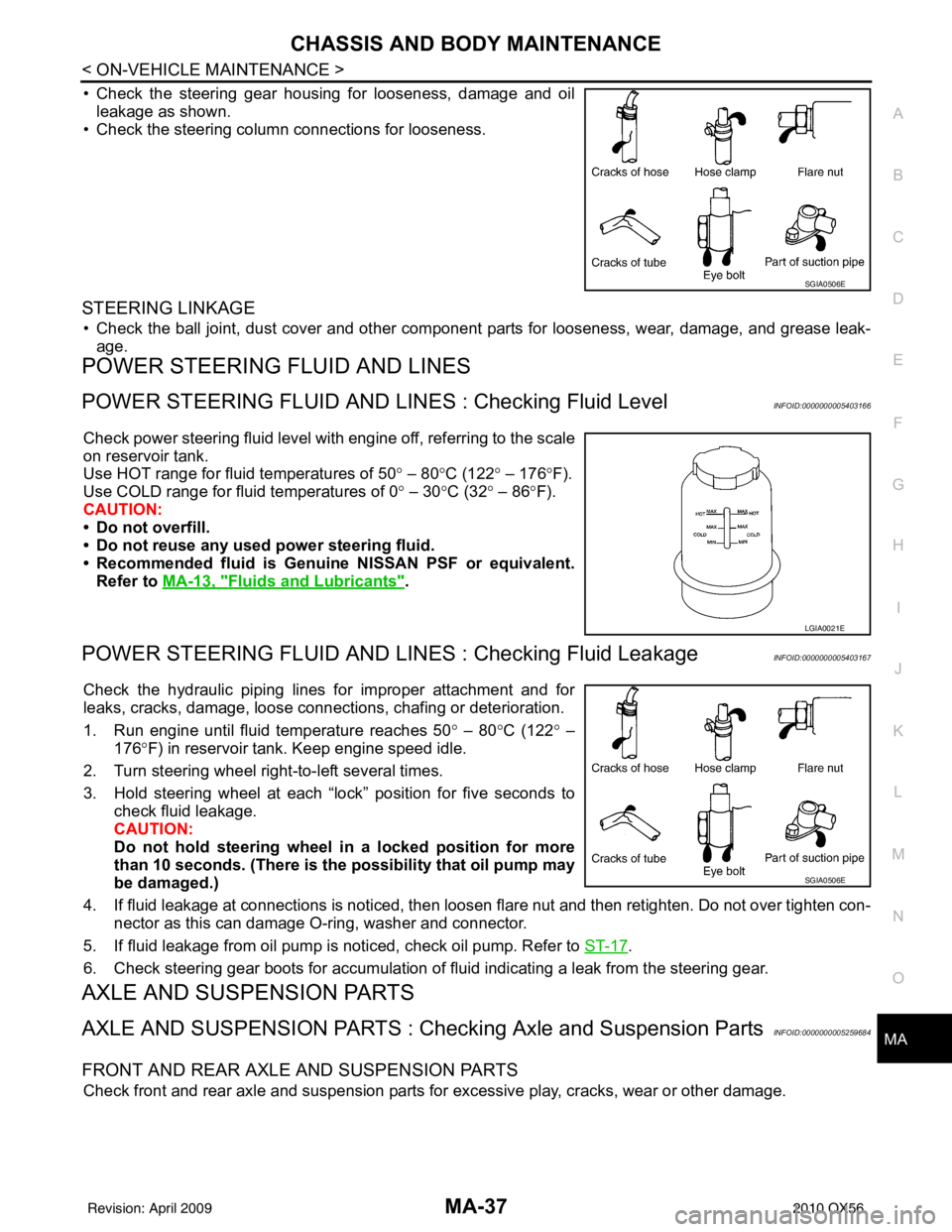

Check power steering fluid level with engine off, referring to the scale

on reservoir tank.

Use HOT range for fluid temperatures of 50 ° – 80 °C (122 ° – 176 °F).

Use COLD range for fluid temperatures of 0 ° – 30 °C (32° – 86°F).

CAUTION:

• Do not overfill.

• Do not reuse any used power steering fluid.

• Recommended fluid is Genuine NISSAN PSF or equivalent.

Refer to MA-13, "

Fluids and Lubricants".

POWER STEERING FLUID AND LINES : Checking Fluid LeakageINFOID:0000000005403167

Check the hydraulic piping lines for improper attachment and for

leaks, cracks, damage, loose connec tions, chafing or deterioration.

1. Run engine until fluid temperature reaches 50 ° – 80° C (122° –

176° F) in reservoir tank. Keep engine speed idle.

2. Turn steering wheel right-to-left several times.

3. Hold steering wheel at each “lock” position for five seconds to check fluid leakage.

CAUTION:

Do not hold steering wheel in a locked position for more

than 10 seconds. (There is the possibility that oil pump may

be damaged.)

4. If fluid leakage at connections is noticed, then loosen flare nut and then retighten. Do not over tighten con- nector as this can damage O-ring, washer and connector.

5. If fluid leakage from oil pump is noticed, check oil pump. Refer to ST-17

.

6. Check steering gear boots for accumulation of fluid indicating a leak from the steering gear.

AXLE AND SUSPENSION PARTS

AXLE AND SUSPENSION PARTS : Chec king Axle and Suspension PartsINFOID:0000000005259684

FRONT AND REAR AXLE AND SUSPENSION PARTS

Check front and rear axle and suspension parts for excessive play, cracks, wear or other damage.

SGIA0506E

LGIA0021E

SGIA0506E

Revision: April 20092010 QX56

Page 2742 of 4210

MA-38

< ON-VEHICLE MAINTENANCE >

CHASSIS AND BODY MAINTENANCE

• Shake each wheel to check for excessive play.

• Rotate each wheel to check for abnormal noise.

• Check the axle and suspension nuts and bolts for looseness.

• Check the strut and shock absorber for oil leakage or other damage.

• Check the suspension ball joints for grease leakage and ball joint dust cover for cracks or other damage.

LOCKS AND HINGES

LOCKS AND HINGES : Lubricating Locks, Hinges and Hood LatchesINFOID:0000000005259685

Lubricate the locations shown with a suitable multi-purpose grease.

SMA525A

WLIA0024E

Revision: April 20092010 QX56

Page 2743 of 4210

CHASSIS AND BODY MAINTENANCEMA-39

< ON-VEHICLE MAINTENANCE >

C

DE

F

G H

I

J

K L

M B

MA

N

O A

SEAT BELT, BUCKLES, RETRAC

TORS, ANCHORS AND ADJUSTERS

SEAT BELT, BUCKLES, RETRACTORS, ANCHORS AND ADJUSTERS : Checking

Seat Belts, Buckles, Retrac tors, Anchors and Adjusters

INFOID:0000000005259686

Check the seat belt buckles, webbing, retractors, anc hors and adjusters. Replace any seat belt assembly as

necessary. Refer to SB-11, "

Seat Belt Inspection".

• Check the seat belt anchors for loose mounting bolts, damage, or excessive wear.

• Check the seat belt webbing for any damage, cuts, fraying, or excessive wear.

• Check the retractor for smooth operation.

• Check the function of the buckles by inserting the seat belt tongue and checking for proper engagement of

the buckle and press the button on the buckle to c heck for proper release of the seat belt tongue.

CAUTION:

• After any collision, inspect al l seat belt assemblies, including retractors and other attached compo-

nents, such as the guide rail set. NISSAN recomme nds replacing all seat belt assemblies in use dur-

ing a collision, unless they are not damaged an d are inspected to confirm they are operating

properly after a minor collision.

Also inspect all seat belt assemblies that are not in use during a collision, and replace any compo-

nents if damaged or not operating properly. The seat belt pre-tensioner should be replaced even if

the seat belts are not in use during a frontal collision where the driver and passenger air bags have

been deployed.

• If any component of the seat belt assembly is susp ected of being damaged or not operating prop-

erly, do not repair the component. Replace the components as an assembly.

• If the seat belt webbing is cut, frayed, or damaged then replace the seat belt assembly.

• Never lubricate the seat belt buckle or tongue.

• When replacing any seat belt assembly alw ays use a Genuine NISSAN seat belt assembly.

Revision: April 20092010 QX56

Page 2744 of 4210

MIR-1

DRIVER CONTROLS

C

DE

F

G H

I

J

K

M

SECTION MIR

A

B

MIR

N

O P

CONTENTS

MIRRORS

COMPONENT DIAGNOSIS ..........................2

DOOR MIRROR .............................................. .....2

Wiring Diagram ................................................... ......2

INSIDE MIRROR .................................................5

Wiring Diagram ................................................... ......5

PRECAUTION ...............................................8

PRECAUTIONS .............................................. .....8

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

8

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

8

Handling for Adhesive and Primer ............................9

PREPARATION ...........................................10

PREPARATION .............................................. ....10

Special Service Tool ............................................ ....10

Commercial Service Tool ........................................10

REMOVAL AND INSTALLATION ...............11

INSIDE MIRROR ...............................................11

Wiring Diagram - I/MIRR - ................................... ....11

Removal and Installation .........................................12

DOOR MIRROR ................................................13

Wiring Diagram - MIRROR -Without Power Fold-

ing Mirrors ................................................................

13

Wiring Diagram - H/MIRR - ......................................15

Door Mirror Assembly ..............................................17

Door Mirror Glass ....................................................17

DISASSEMBLY AND ASSEMBLY ..............19

DOOR MIRROR ................................................19

Mirror Actuator ..................................................... ....19

Revision: April 20092010 QX56

Page 2745 of 4210

MIR-2

< COMPONENT DIAGNOSIS >

DOOR MIRROR

COMPONENT DIAGNOSIS

DOOR MIRROR

Wiring DiagramINFOID:0000000005146590

ABLWA0538GB

Revision: April 20092010 QX56

Page 2746 of 4210

DOOR MIRRORMIR-3

< COMPONENT DIAGNOSIS >

C

DE

F

G H

I

J

K

M A

B

MIR

N

O P

ABLIA0133GB

Revision: April 20092010 QX56

Page 2747 of 4210

MIR-4

< COMPONENT DIAGNOSIS >

DOOR MIRROR

ABLIA1330GB

Revision: April 20092010 QX56

Page 2748 of 4210

INSIDE MIRRORMIR-5

< COMPONENT DIAGNOSIS >

C

DE

F

G H

I

J

K

M A

B

MIR

N

O P

INSIDE MIRROR

Wiring DiagramINFOID:0000000005146591

ABLWA0042GB

Revision: April 20092010 QX56

Page 2749 of 4210

MIR-6

< COMPONENT DIAGNOSIS >

INSIDE MIRROR

ABLIA0134GB

Revision: April 20092010 QX56

Page 2750 of 4210

INSIDE MIRRORMIR-7

< COMPONENT DIAGNOSIS >

C

DE

F

G H

I

J

K

M A

B

MIR

N

O P

ABLIA0135GB

Revision: April 20092010 QX56

Trending: wipers, bluetooth, clock reset, service schedule, brake sensor, ignition, open gas tank