warning INFINITI QX56 2010 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2010, Model line: QX56, Model: INFINITI QX56 2010Pages: 4210, PDF Size: 81.91 MB

Page 3408 of 4210

![INFINITI QX56 2010 Factory Service Manual HORN FUNCTIONSEC-57

< COMPONENT DIAGNOSIS > [WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

SEC

N

O P

HORN FUNCTION

Symptom TableINFOID:0000000005147125

HAZARD AND HORN REMINDER FUNCTION MALFUNC INFINITI QX56 2010 Factory Service Manual HORN FUNCTIONSEC-57

< COMPONENT DIAGNOSIS > [WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

SEC

N

O P

HORN FUNCTION

Symptom TableINFOID:0000000005147125

HAZARD AND HORN REMINDER FUNCTION MALFUNC](/img/42/57032/w960_57032-3407.png)

HORN FUNCTIONSEC-57

< COMPONENT DIAGNOSIS > [WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

SEC

N

O P

HORN FUNCTION

Symptom TableINFOID:0000000005147125

HAZARD AND HORN REMINDER FUNCTION MALFUNCTION

NOTE:

• Before performing the diagnosis in the following table, check “Work flow”. Refer to SEC-4, "

Work Flow".

• If the following symptoms” are detected, check systems shown in the “Diagnosis/service procedure” column in this order.

Conditions of Vehicle (Operating Conditions)

• “ANSWER BACK FUNCTION” is ON when setting on CONSULT-III.

• Ignition switch is in OFF position.

• All doors are closed.

Symptom Diagnosis/service procedureReference

page

Hazard reminder does not operate by request switch.

(Horn reminder operate.) 1.

Check “HAZARD ANSWER BACK” setting in “WORK

SUPPORT”. DLK-53

2. Check hazard function.

DLK-112

3. Check Intermittent Incident. GI-38

Hazard reminder does not operate by Intelligent Key.

(Horn reminder operate.)1.

Check “HAZARD ANSWER BACK” setting in “WORK

SUPPORT”. DLK-53

2. Check hazard function.

DLK-112

3. Check Intelligent Key battery inspection.DLK-106

Horn reminder does not operate by request switch.

(Hazard reminder operate.)1.

Check “ANSWER BACK WITH I-KEY LOCK” or “AN-

SWER BACK WITH I-KEY UNLOCK” setting in “WORK

SUPPORT”. DLK-53

2. Check Intelligent Key warning buzzer.

DLK-95

3. Check Intermittent Incident. GI-38

Horn reminder does not operate by Intelligent Key.

(Hazard reminder operate.)1.

Check “HORN WITH KEYLESS LOCK” setting in

“WORK SUPPORT”. DLK-53

2. Check horn function.

SEC-57

3. Check Intermittent Incident. GI-38

Revision: April 20092010 QX56

Page 3415 of 4210

![INFINITI QX56 2010 Factory Service Manual SEC-64

< ECU DIAGNOSIS >[WITH INTELLIGENT KEY SYSTEM]

BCM (BODY CONTROL MODULE)

Te r m i n a lWire

color Signal name Signal

input/

output Measuring condition

Reference value or waveform

(Approx.)

Ig INFINITI QX56 2010 Factory Service Manual SEC-64

< ECU DIAGNOSIS >[WITH INTELLIGENT KEY SYSTEM]

BCM (BODY CONTROL MODULE)

Te r m i n a lWire

color Signal name Signal

input/

output Measuring condition

Reference value or waveform

(Approx.)

Ig](/img/42/57032/w960_57032-3414.png)

SEC-64

< ECU DIAGNOSIS >[WITH INTELLIGENT KEY SYSTEM]

BCM (BODY CONTROL MODULE)

Te r m i n a lWire

color Signal name Signal

input/

output Measuring condition

Reference value or waveform

(Approx.)

Ignition

switch Operation or condition

1BR/W Ignition keyhole illumi-

nation Output OFFDoor is locked (SW OFF)

Battery voltage

Door is unlocked (SW ON) 0V

2SB Combination switch

input 5 Input ON

Lighting, turn, wiper OFF

Wiper dial position 4

3G/Y Combination switch

input 4 Input ONLighting, turn, wiper OFF

Wiper dial position 4

4Y Combination switch

input 3 Input ON

Lighting, turn, wiper OFF

Wiper dial position 4

5G/B Combination switch

input 2

Input ONLighting, turn, wiper OFF

Wiper dial position 4

6V Combination switch

input 1

9GR/R Rear window defogger

switch

Input ONRear window defogger switch

ON

0V

Rear window defogger switch

OFF 5V

10 G Hazard lamp flash Input OFF ON (opening or closing)

0V

OFF (other than above) Battery voltage

11 O Ignition switch (ACC

or ON)

InputACC or

ON Ignition switch ACC or ON

Battery voltage

12 R/L Front door switch RH Input OFF ON (open)

0V

OFF (closed) Battery voltage

13 GR Rear door switch RH Input OFF ON (open)

0V

OFF (closed) Battery voltage

15 L/W Tire pressure warning

check connector

Input OFF

—5V

18 P Remote keyless entry

receiver and optical

sensor (ground)

Output OFF

—0V

SKIA5291E

SKIA5292E

SKIA5291E

SKIA5292E

Revision: April 20092010 QX56

Page 3439 of 4210

![INFINITI QX56 2010 Factory Service Manual SEC-88

< ECU DIAGNOSIS >[WITH INTELLIGENT KEY SYSTEM]

BCM (BODY CONTROL MODULE)

DTC Inspection Priority Chart

INFOID:0000000005405117

If some DTCs are displayed at the same time, perform inspections o INFINITI QX56 2010 Factory Service Manual SEC-88

< ECU DIAGNOSIS >[WITH INTELLIGENT KEY SYSTEM]

BCM (BODY CONTROL MODULE)

DTC Inspection Priority Chart

INFOID:0000000005405117

If some DTCs are displayed at the same time, perform inspections o](/img/42/57032/w960_57032-3438.png)

SEC-88

< ECU DIAGNOSIS >[WITH INTELLIGENT KEY SYSTEM]

BCM (BODY CONTROL MODULE)

DTC Inspection Priority Chart

INFOID:0000000005405117

If some DTCs are displayed at the same time, perform inspections one by one based on the following priority

chart.

DTC IndexINFOID:0000000005405118

NOTE: Details of time display

• CRNT: Displays when there is a malfunction now or after returning to the normal condition until turning igni- tion switch OFF → ON again.

• 1 - 39: Displayed if any previous malfunction is present when current condition is normal. It increases like 1

→ 2 → 3...38 → 39 after returning to the normal condition whenever ignition switch OFF → ON. The counter

remains at 39 even if the number of cycles exceeds it. It is counted from 1 again when turning ignition switch

OFF → ON after returning to the normal condition if the malfunction is detected again.

Display contents of CONS ULTFail-safe Cancellation

U1000: CAN COMM CIRCUIT I nhibit engine crankingWhen the BCM re-establishes communication with the other mod-

ules.

Priority

DTC

1 • U1000: CAN COMM CIRCUIT

2 • B2190: NATS ANTENNA AMP

• B2191: DIFFERENCE OF KEY

• B2192: ID DISCORD BCM-ECM

• B2193: CHAIN OF BCM-ECM

• B2013: STRG COMM 1

• B2552: INTELLIGENT KEY

• B2590: NATS MALFUNCTION

3 • C1729: VHCL SPEED SIG ERR

• C1735: IGNITION SIGNAL

4 • C1708: [NO DATA] FL

• C1709: [NO DATA] FR

• C1710: [NO DATA] RR

• C1711: [NO DATA] RL

• C1712: [CHECKSUM ERR] FL

• C1713: [CHECKSUM ERR] FR

• C1714: [CHECKSUM ERR] RR

• C1715: [CHECKSUM ERR] RL

• C1716: [PRESSDATA ERR] FL

• C1717: [PRESSDATA ERR] FR

• C1718: [PRESSDATA ERR] RR

• C1719: [PRESSDATA ERR] RL

• C1720: [CODE ERR] FL

• C1721: [CODE ERR] FR

• C1722: [CODE ERR] RR

• C1723: [CODE ERR] RL

• C1724: [BATT VOLT LOW] FL

• C1725: [BATT VOLT LOW] FR

• C1726: [BATT VOLT LOW] RR

• C1727: [BATT VOLT LOW] RL

CONSULT display

Fail-safeIntelligent Key

warning lamp ON Tire pressure

monitor warning lamp ON Reference page

No DTC is detected.

further testing

may be required. ————

U1000: CAN COMM CIRCUIT ———BCS-32

B2190: NATS ANTENNA AMP ———SEC-31

Revision: April 20092010 QX56

Page 3440 of 4210

![INFINITI QX56 2010 Factory Service Manual BCM (BODY CONTROL MODULE)SEC-89

< ECU DIAGNOSIS > [WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

SEC

N

O P

B2191: DIFFERENCE OF KEY ———SEC-34

B2192: ID DISCORD BCM-ECM ———SEC-35

B21 INFINITI QX56 2010 Factory Service Manual BCM (BODY CONTROL MODULE)SEC-89

< ECU DIAGNOSIS > [WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

SEC

N

O P

B2191: DIFFERENCE OF KEY ———SEC-34

B2192: ID DISCORD BCM-ECM ———SEC-35

B21](/img/42/57032/w960_57032-3439.png)

BCM (BODY CONTROL MODULE)SEC-89

< ECU DIAGNOSIS > [WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

SEC

N

O P

B2191: DIFFERENCE OF KEY ———SEC-34

B2192: ID DISCORD BCM-ECM ———SEC-35

B2193: CHAIN OF BCM-ECM ———SEC-37

B2552: INTELLIGENT KEY ———SEC-39

B2590: NATS MALFUNCTION ———SEC-40

C1708: [NO DATA] FL ———WT-14

C1709: [NO DATA] FR ———WT-14

C1710: [NO DATA] RR ———WT-14

C1711: [NO DATA] RL ———WT-14

C1712: [CHECKSUM ERR] FL ———WT-16

C1713: [CHECKSUM ERR] FR ———WT-16

C1714: [CHECKSUM ERR] RR ———WT-16

C1715: [CHECKSUM ERR] RL ———WT-16

C1716: [PRESSDATA ERR] FL ———WT-18

C1717: [PRESSDATA ERR] FR ———WT-18

C1718: [PRESSDATA ERR] RR ———WT-18

C1719: [PRESSDATA ERR] RL ———WT-18

C1720: [CODE ERR] FL ———WT-16

C1721: [CODE ERR] FR ———WT-16

C1722: [CODE ERR] RR ———WT-16

C1723: [CODE ERR] RL ———WT-16

C1724: [BATT VOLT LOW] FL ———WT-16

C1725: [BATT VOLT LOW] FR ———WT-16

C1726: [BATT VOLT LOW] RR ———WT-16

C1727: [BATT VOLT LOW] RL ———WT-16

C1729: VHCL SPEED SIG ERR ———WT-19

C1735: IGNITION SIGNAL ———WT-20

CONSULT display Fail-safeIntelligent Key

warning lamp ON Tire pressure

monitor warning

lamp ON Reference page

Revision: April 20092010 QX56

Page 3458 of 4210

![INFINITI QX56 2010 Factory Service Manual IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

SEC-107

< ECU DIAGNOSIS > [WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

SEC

N

O P

THFT HRN REQ Not operated

OFF

• Panic alarm is INFINITI QX56 2010 Factory Service Manual IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

SEC-107

< ECU DIAGNOSIS > [WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

SEC

N

O P

THFT HRN REQ Not operated

OFF

• Panic alarm is](/img/42/57032/w960_57032-3457.png)

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

SEC-107

< ECU DIAGNOSIS > [WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

SEC

N

O P

THFT HRN REQ Not operated

OFF

• Panic alarm is activated

• Horn is activated with VEHICLE SECURITY (THEFT WARNING) SYS-

TEM ON

HORN CHIRP Not operated

OFF

Door locking with Intelligent Key (horn chirp mode) ON

Monitor Item

ConditionValue/Status

Revision: April 20092010 QX56

Page 3469 of 4210

![INFINITI QX56 2010 Factory Service Manual SEC-118

< PRECAUTION >[WITH INTELLIGENT KEY SYSTEM]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint Syst

em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005199 INFINITI QX56 2010 Factory Service Manual SEC-118

< PRECAUTION >[WITH INTELLIGENT KEY SYSTEM]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint Syst

em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005199](/img/42/57032/w960_57032-3468.png)

SEC-118

< PRECAUTION >[WITH INTELLIGENT KEY SYSTEM]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint Syst

em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005199685

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SR and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution Necessary for Steering W heel Rotation After Battery Disconnect

INFOID:0000000005369244

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecting both battery cables with the ignition knob in the

″LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS, an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be rotated.

4. Perform the necessary repair operation.

Revision: April 20092010 QX56

Page 3518 of 4210

SN-46

< PRECAUTION >

PRECAUTION

PRECAUTION

PRECAUTION

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005403331

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SR and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution Necessary for Steering W heel Rotation After Battery Disconnect

INFOID:0000000005403332

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecting both battery cables with the ignition knob in the

″LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS, an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be rotated.

4. Perform the necessary repair operation.

Revision: April 20092010 QX56

Page 3525 of 4210

SR-2

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005250379

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SR and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution for SRS "AIR BAG" and "S EAT BELT PRE-TENSIONER" Service

INFOID:0000000005147754

• Do not use electrical test equipment to check SRS ci rcuits unless instructed to in this Service Manual.

• Before servicing the SRS, turn ignition switch OFF, disconnect both battery terminals and wait at least 3 min- utes.

For approximately 3 minutes after the terminals are remov ed, it is still possible for the air bags and seat belt

pre-tensioners to deploy. Therefore, do not work on any SRS connectors or wires until at least 3 minutes

have passed.

• The air bag diagnosis sensor unit must always be installed with the arrow mark “ ⇐” pointing toward the front

of the vehicle for proper operation. Also check air bag diagnosis sensor unit for cracks, deformities or rust

before installation and replace as required.

• The spiral cable must be aligned with the neutral position since its rotations are limited. Do not attempt to

turn steering wheel or column after removal of steering gear.

• Handle air bag module carefully. Always place driver and front passenger air bag modules with the pad side facing upward and seat mounted front side air bag module standing with the stud bolt side facing down.

• Conduct self-diagnosis to check entire SRS for proper function after replacing any components.

• After air bag inflates, the front instrument panel assembly should be replaced if damaged.

Precaution Necessary for Steering Wheel Rotation After Battery Disconnect

INFOID:0000000005256816

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecting both battery cables with the ignition knob in the ″LOCK ″ position.

Revision: April 20092010 QX56

Page 3540 of 4210

DIAGNOSIS SENSOR UNITSR-17

< ON-VEHICLE REPAIR >

C

DE

F

G

I

J

K L

M A

B

SR

N

O P

DIAGNOSIS SENSOR UNIT

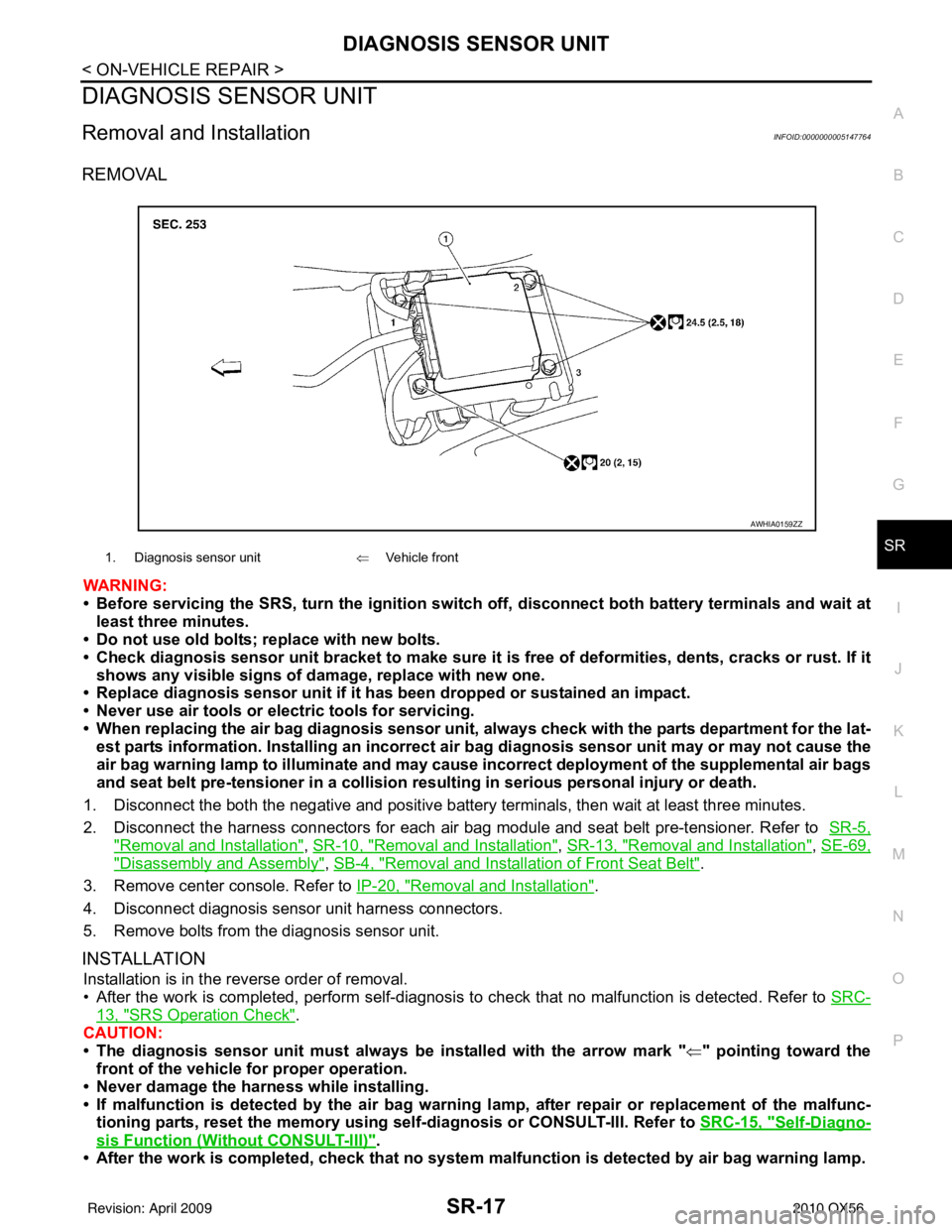

Removal and InstallationINFOID:0000000005147764

REMOVAL

WARNING:

• Before servicing the SRS, turn the ignition switch off, disconnect both battery terminals and wait at

least three minutes.

• Do not use old bolts; replace with new bolts.

• Check diagnosis sensor unit bracket to make sure it is free of deformities, dents, cracks or rust. If it

shows any visible signs of damage, replace with new one.

• Replace diagnosis sensor unit if it has been dropped or sustained an impact.

• Never use air tools or el ectric tools for servicing.

• When replacing the air bag diagnosis sensor unit, always check with the parts department for the lat-

est parts information. Installing an incorrect air bag diagnosis sensor unit may or may not cause the

air bag warning lamp to illuminate and may cause incorrect deployment of the supplemental air bags

and seat belt pre-tensioner in a collision r esulting in serious personal injury or death.

1. Disconnect the both the negative and positive battery terminals, then wait at least three minutes.

2. Disconnect the harness connectors for each air bag module and seat belt pre-tensioner. Refer to SR-5,

"Removal and Installation", SR-10, "Removal and Installation", SR-13, "Removal and Installation", SE-69,

"Disassembly and Assembly", SB-4, "Removal and Installation of Front Seat Belt".

3. Remove center console. Refer to IP-20, "

Removal and Installation".

4. Disconnect diagnosis sensor unit harness connectors.

5. Remove bolts from the diagnosis sensor unit.

INSTALLATION

Installation is in the reverse order of removal.

• After the work is completed, perform self-diagnosis to check that no malfunction is detected. Refer to SRC-

13, "SRS Operation Check".

CAUTION:

• The diagnosis sensor unit must always be installed with the arrow mark " ⇐" pointing toward the

front of the vehicle for proper operation.

• Never damage the harness while installing.

• If malfunction is detected by the air bag warnin g lamp, after repair or replacement of the malfunc-

tioning parts, reset the memory using sel f-diagnosis or CONSULT-III. Refer to SRC-15, "

Self-Diagno-

sis Function (Without CONSULT-III)".

• After the work is completed, check that no system malfunction is detected by air bag warning lamp.

1. Diagnosis sensor unit⇐Vehicle front

AWHIA0159ZZ

Revision: April 20092010 QX56

Page 3544 of 4210

COLLISION DIAGNOSISSR-21

< ON-VEHICLE REPAIR >

C

DE

F

G

I

J

K L

M A

B

SR

N

O P

For Side and Rollover CollisionINFOID:0000000005147767

Check the SRS components using the following table.

• After the work is completed, perform self-diagnosis to check that no malfunction is detected. Refer to SRC-

13, "SRS Operation Check".

WHEN SRS IS ACTIVATED IN THE SIDE OR ROLLOVER COLLISION

1. Replace the following components:

- Front seat back assembly (on the side on which side air bag is activated)

- Diagnosis sensor unit

- (LH or RH) side air bag (satellite) sensor (on the side on which side air bag is activated)

2. Check the SRS components and the related parts using the following table.

- Replace any SRS components and the related parts showing visible signs of damage (dents, cracks,

deformation).

3. Conduct self-diagnosis using CONSULT-III and “AIR BAG” warning lamp. Refer to SRC-13, "

SRS Opera-

tion Check" for details. Ensure entire SRS operates properly.

WHEN SRS IS NOT ACTIVATED IN THE SIDE OR ROLLOVER COLLISION

1. Check the SRS components and the related parts using the following table.

- If the front seat back assembly is damaged, t he front seat back assembly must be replaced.

2. Conduct self-diagnosis using CONSULT-III and “AIR BAG” warning lamp. Refer to SRC-13, "

SRS Opera-

tion Check" for details. Ensure entire SRS operates properly.

SRS INSPECTION (FOR SIDE AND ROLLOVER COLLISION)

Steering wheel 1. Visually check steering wheel for deformities.

2. Check harness (built into steering wheel) and connectors for damage, and terminals for deformities.

3. Install driver air bag module into the steering wheel to check fit and alignment with the wheel.

4. Check steering wheel for excessive free play.

5. If no damage is found, reinstall.

6. If damaged—REPLACE.

Spiral cable If the driver front air

bag has deployed:

REPLACE the spiral

cable. If the driver front air bag has not deployed:

1. Visually check spiral cable and combination switch for damage.

2. Check connectors and protective tape for damage.

3. Check steering wheel for noise, binding or heavy operation.

4. If no damage is found, reinstall.

5. If damaged—REPLACE.

Occupant classifica-

tion system (Passen-

ger seat) 1. Remove passenger seat.

2. Check control unit case for dents, cracks of deformities.

3. Check connectors and pressure sensor tube for damage, and terminals for deformities.

4. Check seat frame and cushion pan for dents or deformities.

5. If no damage is found, reinstall seat with new fasteners.

6. If damaged — REPLACE seat cushion assembly with new fasteners.

Harness and connec-

tors 1. Check connectors for poor connection, damage, and terminals for deformities.

2. Check harness for binding, chafing, cuts, or deformities.

3. If no damage is found, reinstall the harness and connectors.

4. If damaged—REPLACE the damaged harness. Do not attempt to repair, splice or modify any SRS har-

ness.

Instrument panel If the passenger front air bag has deployed:

REPLACE the instru-

ment panel assembly.If the passenger front air bag has NOT deployed:

1. Visually check instrument panel for damage.

2. If no damage is found, reinstall the instrument panel.

3. If damaged—REPLACE the instrument panel.

Part

SRS is activated SRS is NOT activated

Revision: April 20092010 QX56