diagnostic menu INFINITI QX56 2010 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2010, Model line: QX56, Model: INFINITI QX56 2010Pages: 4210, PDF Size: 81.91 MB

Page 42 of 4210

ADP-28

< FUNCTION DIAGNOSIS >

DIAGNOSIS SYSTEM (DRIVER SEAT C/U)

DIAGNOSIS SYSTEM (DRIVER SEAT C/U)

Diagnosis DescriptionINFOID:0000000005147445

The auto drive positioner system can be checked and diagnosed for component operation with CONSULT-III.

DIAGNOSTIC MODE

CONSULT-III FunctionINFOID:0000000005147446

SELF-DIAGNOSIS RESULTS

Refer to ADP-134, "DTCIndex".

DATA MONITOR

Diagnostic mode

[AUTO DRIVE POS.] Description

WORK SUPPORT Changes the setting of each function.

SELF-DIAG RESULTS Performs self-diagnosis for the auto drive positioner system and displays the results.

DATA MONITOR Displays input signals transmitted from various switches and sensors to driver seat con-

trol unit in real time.

CAN DIAG SUPPORT MNTR The result of transmit/receive diagnosis of CAN communication can be read.

ACTIVE TEST Drive each output device.

ECU PART NUMBER Displays part numbers of driver seat control unit parts.

Monitor ItemUnitMain

Signals Selection

From

Menu Contents

SET SW “ON/OFF”×× ON/OFF status judged from the setting switch signal.

MEMORY SW1 “ON/OFF”×× ON/OFF status judged from the seat memory switch 1 sig-

nal.

MEMORY SW2 “ON/OFF”×× ON/OFF status judged from the seat memory switch 2 sig-

nal.

SLIDE SW–FR “ON/OFF”×× ON/OFF status judged from the sliding switch (forward) sig-

nal.

SLIDE SW–RR “ON/OFF”×× ON/OFF status judged from the sliding switch (backward)

signal.

RECLN SW–FR “ON/OFF”×× ON/OFF status judged from the reclining switch (forward)

signal.

RECLN SW–RR “ON/OFF”×× ON/OFF status judged from the reclining switch (backward)

signal.

LIFT FR SW–UP “ON/OFF” ××ON/OFF status judged from the lifting switch front (up) sig-

nal.

LIFT FR SW–DN “ON/OFF” ××ON/OFF status judged from the lifting switch front (down)

signal.

LIFT RR SW–UP “ON/OFF” ××ON/OFF status judged from the lifting switch rear (up) sig-

nal.

LIFT RR SW–DN “ON/OFF” ××ON/OFF status judged from the lifting switch rear (down)

signal.

MIR CON SW–UP “ON/OFF” ××ON/OFF status judged from the mirror switch (up) signal.

MIR CON SW–DN “ON/OFF” ××ON/OFF status judged from the mirror switch (down) signal.

MIR CON SW–RH “ON/OFF” ××ON/OFF status judged from the door mirror remote control

switch (passenger side) signal.

MIR CON SW–LH “ON/OFF” ××ON/OFF status judged from the door mirror remote control

switch (driver

side) signal.

Revision: April 20092010 QX56

Page 515 of 4210

![INFINITI QX56 2010 Factory Service Manual DIAGNOSIS SYSTEM [ABS ACTUATOR AND ELECTRIC UNIT (CONTROL

UNIT)]

BRC-23

< FUNCTION DIAGNOSIS > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

DIAGNOSIS SYSTEM [ABS ACTUATOR AND ELECTRIC UNIT (CONTR INFINITI QX56 2010 Factory Service Manual DIAGNOSIS SYSTEM [ABS ACTUATOR AND ELECTRIC UNIT (CONTROL

UNIT)]

BRC-23

< FUNCTION DIAGNOSIS > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

DIAGNOSIS SYSTEM [ABS ACTUATOR AND ELECTRIC UNIT (CONTR](/img/42/57032/w960_57032-514.png)

DIAGNOSIS SYSTEM [ABS ACTUATOR AND ELECTRIC UNIT (CONTROL

UNIT)]

BRC-23

< FUNCTION DIAGNOSIS > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

DIAGNOSIS SYSTEM [ABS ACTUATOR AND ELECTRIC UNIT (CONTROL

UNIT)]

CONSULT-III Function (ABS)INFOID:0000000005147962

FUNCTION

CONSULT-III can display each diagnostic item using the diagnostic test modes shown following.

SELF DIAGNOSTIC RESULT MODE

Operation Procedure

1. Before performing the self-diagnosis, start engine and drive vehicle at 30 km/h (19 MPH) or more for

approximately 1 minute.

How to Erase Self-diagnosis Results

1. After erasing DTC memory, start engine and drive vehicle at 30 km/h (19 MPH) or more for approximately 1 minute as the final inspection, and make sure t hat the ABS warning lamp, VDC OFF indicator lamp,

SLIP indicator lamp and brake warning lamp turn OFF.

CAUTION:

If memory cannot be erased, perform applicable diagnosis.

NOTE:

• When the wheel sensor malfunctions, after inspecting the wheel sensor system, the ABS warning lamp,

VDC OFF indicator lamp, SLIP indicator lamp and brake warning lamp will not turn OFF even when the

system is normal unless the vehicle is driving at approximately 30 km/h (19 MPH) or more for approxi-

mately 1 minute.

• Brake warning lamp will turn ON in case of parking brake operation (when switch is ON) or of brake fluid level switch operation (when brake fluid is insufficient).

• VDC OFF switch should not stay “ON” position.

Display Item List

Refer to BRC-100, "DTC No. Index".

DATA MONITOR MODE

Display Item List

Diagnostic test mode Function

Work support This mode enables a technician to adjust some devices faster and more accurately by following

the indications on CONSULT-III.

Data Monitor Input/Output data in the ABS actuator and electric uni t (control unit) can be read.

Active Test Diagnostic test mode is which CONSULT-III driv

es some actuators apart from the ABS actuator

and electric unit (control unit) and also shifts some parameters in a specified range.

Self Diagnostic Result Self-diagnostic results can be read and erased quickly.

CAN diag support monitor The results of transmit/receive diagnosis of CAN communication can be read.

ECU Identification ABS actuator and electric unit (control unit) part number can be read.

Item

(Unit) Data monitor item selection

Remarks

ECU INPUT

SIGNALS MAIN

SIGNALS SELECTION

FROM MENU

FR LH SENSOR

(km/h, mph) ×× × Wheel speed (km/h, mph) calculated by front LH

wheel sensor signal is displayed.

FR RH SENSOR

(km/h, mph) ×× ×

Wheel speed (km/h, mph) calculated by front RH

wheel sensor signal is displayed.

RR LH SENSOR

(km/h, mph) ×× × Wheel speed (km/h, mph) calculated by rear LH

wheel sensor signal is displayed.

RR RH SENSOR

(km/h, mph) ×× × Wheel speed (km/h, mph) calculated by rear RH

wheel sensor signal is displayed.

Revision: April 20092010 QX56

Page 688 of 4210

CCS

DIAGNOSIS SYSTEM (ICC SENSOR INTEGRATED UNIT)

CCS-19

< FUNCTION DIAGNOSIS >

C

D E

F

G H

I

J

K L

M B

N P A

• Last five cancel (system cancel) causes are displayed.

• “CAUSE OF AUTO-CANCEL” displays times of ignition switch ON/OFF up to 254 maximum. 254 is kept though the number exceeds 254. The num ber returns to 0 when detecting the same cancellation causes.

SELF DIAGNOSTIC RESULT

For details, refer to CCS-56, "Diagnostic Trouble Code (DTC) Chart".

NOTE:

“DTC RESULTS” and “TIME” are indicated on “Self Diagnostic Result”. “TIME” is used as a reference data of

diagnosis. It shows when malfunction is detected.

“TIME” shows the following.

• 0: malfunction is detected at present (from malfunction detection to ignition switch OFF).

CAN communication ([U1000], [U1010])

• 1 ~ 39: Displays when it is normal at present and finds malfunction in the past. It increases like

0→ 1→ 2...38→ 39 after returning to the normal condition whenever IGN OFF→ ON. If it is over 39, it is fixed to

39 until the self-diagnostic results are erased. It retu rns to 0 when malfunction is detected again in the pro-

cess.

Other than CAN communication (other than [U1000], [U1010])

• 1 ~ 49: Displays when it is normal at present and finds malfunction in the past. It increases like 0→ 1→ 2...48→ 49 after returning to the normal condition whenever IGN OFF→ ON. If it is over 49, it is fixed to

49 until the self-diagnostic results are erased. It retu rns to 0 when malfunction is detected again in the pro-

cess.

DATA MONITOR

× : Applicable

VDC/TCS OFF SW ×VDC OFF switch was pressed.

WHEEL SPD UNMATCH ××Wheel speed became different from A/T vehicle speed.

TIRE SLIP ××Wheel slipped.

IGN LOW VOLT ××Power supply voltage became low.

NO RECORD ××—

Monitored Item [unit]MAIN

SIGNALS SELECTION

FROM

MENU Description

VHCL SPEED SE

[km/h] or [mph] ××Indicates vehicle speed calculated from ICC sensor integrated unit through

CAN communication [ABS actuator and electric unit (control unit) transmits

vehicle speed signal (wheel speed) through CAN communication].

SET VHCL SPD

[km/h] or [mph] ××

Indicates set vehicle speed memorized in ICC sensor integrated unit.

THRTL OPENING

[%] ××Indicates throttle position read from ICC sensor integrated unit through CAN

communication (ECM transmits accelerator pedal position signal through

CAN communication).

SET DISTANCE

[SHOR/MID/LONG] ××

Indicates set distance memorized in ICC sensor integrated unit.

MAIN SW

[On/Off] ××Indicates [On/Off] status as judged from ICC steering switch signal (ECM

transmits ICC steering switch signal through CAN communication).

SET/COAST SW

[On/Off] ××

Indicates [On/Off] status as judged from ICC steering switch signal (ECM

transmits ICC steering switch signal through CAN communication).

CANCEL SW

[On/Off] ××Indicates [On/Off] status as judged from ICC steering switch signal (ECM

transmits ICC steering switch signal through CAN communication).

RESUME/ACC SW

[On/Off] ××Indicates [On/Off] status as judged from ICC steering switch signal (ECM

transmits ICC steering switch signal through CAN communication).

DISTANCE SW

[On/Off] ×

Indicates [On/Off] status as judged from ICC steering switch signal (ECM

transmits ICC steering switch signal through CAN communication).

CRUISE OPE

[On/Off] ××

Indicates whether controlling or not (ON means “controlling”).

BRAKE SW

[On/Off] ××Indicates [On/Off] status as judged from ICC brake switch signal (ECM trans-

mits ICC brake switch signal through CAN communication).

Revision: April 20092010 QX56

Page 1101 of 4210

![INFINITI QX56 2010 Factory Service Manual DIAGNOSIS SYSTEM (TRANSFER CONTROL UNIT)DLN-19

< FUNCTION DIAGNOSIS > [ATX14B]

C

EF

G H

I

J

K L

M A

B

DLN

N

O P

12. Move A/T selector lever to N position.

13. Turn 4WD shift switch to AUTO position.

1 INFINITI QX56 2010 Factory Service Manual DIAGNOSIS SYSTEM (TRANSFER CONTROL UNIT)DLN-19

< FUNCTION DIAGNOSIS > [ATX14B]

C

EF

G H

I

J

K L

M A

B

DLN

N

O P

12. Move A/T selector lever to N position.

13. Turn 4WD shift switch to AUTO position.

1](/img/42/57032/w960_57032-1100.png)

DIAGNOSIS SYSTEM (TRANSFER CONTROL UNIT)DLN-19

< FUNCTION DIAGNOSIS > [ATX14B]

C

EF

G H

I

J

K L

M A

B

DLN

N

O P

12. Move A/T selector lever to N position.

13. Turn 4WD shift switch to AUTO position.

14. Move A/T selector lever to P position.

15. Read the flickering of 4WD warning lamp.

Self-diagnosis example

ERASE SELF-DIAGNOSIS

• In order to make it easier to find the cause of hard-to-duplicate malfunctions, malfunction information is

stored into the control unit as necessary during use by the user. This memory is not erased no matter how

many times the ignition switch is turned ON and OFF.

• However, this information is erased by turning igni tion switch OFF after performing self-diagnostics or by

erasing the memory using the CONSULT-III.

DATA MONITOR MODE

Operation Procedure

1. Connect CONSULT-III.

2. Touch DATA MONITOR.

3. Select from SELECT MONITOR ITEM, screen of data monitor mode is displayed.

NOTE:

When malfunction is detected, CONSUL T-III performs REAL-TIME DIAGNOSIS.

Also, any malfunction detected while in th is mode will be displayed at real time.

Display Item List

×: Standard –: Not applicable

PDIA0227E

Monitored item (Unit) Monitor item selection

Remarks

ECU INPUT

SIGNALS MAIN

SIGNALS SELEC-

TION FROM MENU

VHCL/S SEN·FR [km/h] or [mph] ×–×Wheel speed calculated by ABS actuator and

electric unit (control unit).

Signal input with CAN communication line.

VHCL/S SEN·RR [km/h] or [mph] ×–×Wheel speed calculated by TCM.

Signal input with CAN communication line.

ENGINE SPEED [rpm] ×–×Engine speed calculated by ECM.

Signal input with CAN communication line.

THRTL POS SEN [V] ×–×Accelerator peda

l position (APP) sensor sig-

nal voltage is displayed.

Signal input with CAN communication line.

FLUID TEMP SE [V] ×–×Transfer fluid temperature sensor signal volt-

age is displayed.

BATTERY VOLT [V] ×–×Power supply voltage for transfer control unit.

2WD SWITCH [On/Off] ×–×4WD shift switch status is displayed.

AUTO SWITCH [On/Off] ×–×4WD shift switch status is displayed.

LOCK SWITCH [On/Off] ×–×4WD shift switch status is displayed.

(LOCK means 4H of 4WD shift switch.)

Revision: April 20092010 QX56

Page 3239 of 4210

DIAGNOSIS SYSTEM (SUSPENSION CONTROL UNIT)

SCS-7

< FUNCTION DIAGNOSIS >

C

D F

G H

I

J

K L

M A

B

SCS

N

O P

DIAGNOSIS SYSTEM (SUS PENSION CONTROL UNIT)

CONSULT-III FunctionINFOID:0000000005148150

CONSULT-III can display each diagnostic item using the diagnostic test modes shown following.

WORK SUPPORT

Display Item List

DATA MONITOR

Display Item List

ACTIVE TEST

CAUTION:

Do not perform active test while driving.

Display Item List

AIR LEVELIZER diagnosis mode Description

WORK SUPPORT Supports inspection and adjustment. Commands are transmitted to the suspension control

unit for setting the status suitable for required operation, input/output signals are received

from the suspension control unit and received data is displayed.

SELF-DIAG RESULTS Displays suspension control unit self-diagnosis results.

DATA MONITOR Displays suspension control unit input/output data in real time.

ACTIVE TEST Operation of electrical loads can be checked by sending drive signal to them.

ECU PART NUMBER The part number of suspension control unit can be checked.

ItemDescription Condition

STANDARD HEIGHT LEVEL Resets the vehicle height to the initialization flag

setting stored in the suspension control unit. Vehicle unladen, set in a horizontal position and

not moving.

NOTE:

Do not take your eyes off the vehicle while CON-

SULT-III is processing.

ADJUST HEIGHT INI Sets the height initialization flag in the suspen-

sion control unit when the control unit has been

replaced or when the initialization flag has been

cleared using the "CLEAR HEIGHT INI" proce-

dure. Vehicle unladen, move vehicle forward and back-

ward approx. 5 m (16.4 ft) and rock vehicle side

to side.

NOTE:

Do not move vehicle wh

ile CONSULT-III is pro-

cessing.

CLEAR HEIGHT INI Clears the initialization flag in the suspension

control unit. Vehicle unladen.

Display item [unit] ALL

SIGNALS SELECTION FROM MENU

HEIGT SEN [V] XX

HEIGT CALC [mm] XX

SEN FIX TIME [HR] XX

HEIGT INI VAL [V] XX

COMPRESSOR [ON/OFF] XX

EXH SOLENOID [ON/OFF] XX

ACG L [ON/OFF] XX

Test Item Description

COMPRESSOR ON/OFF

Revision: April 20092010 QX56

Page 3732 of 4210

DIAGNOSIS SYSTEM (TCM)TM-37

< FUNCTION DIAGNOSIS >

CEF

G H

I

J

K L

M A

B

TM

N

O P

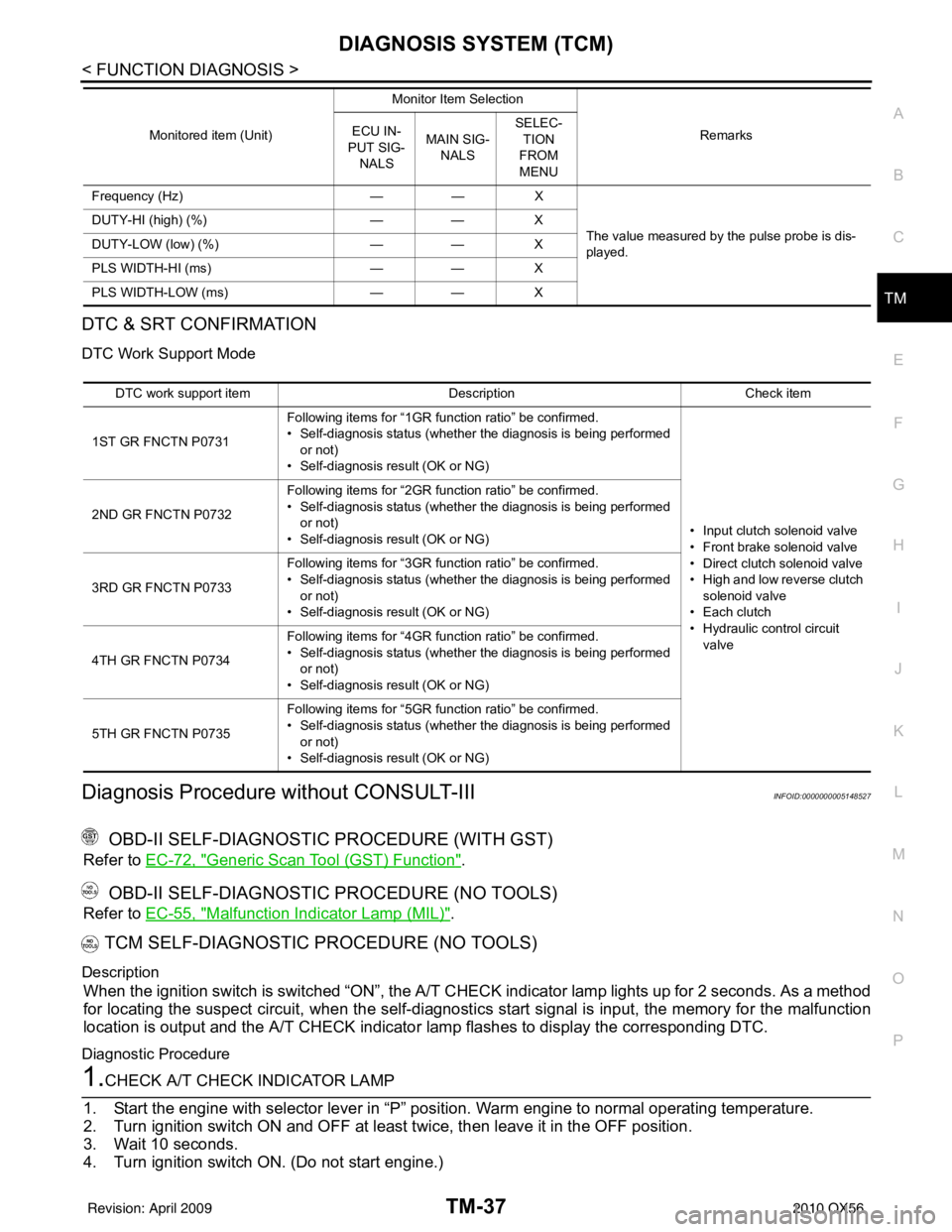

DTC & SRT CONFIRMATION

DTC Work Support Mode

Diagnosis Procedure without CONSULT-IIIINFOID:0000000005148527

OBD-II SELF-DIAGNOSTIC PROCEDURE (WITH GST)

Refer to EC-72, "Generic Scan Tool (GST) Function".

OBD-II SELF-DIAGNOSTIC PROCEDURE (NO TOOLS)

Refer to EC-55, "Malfunction Indicator Lamp (MIL)".

TCM SELF-DIAGNOSTIC PROCEDURE (NO TOOLS)

Description

When the ignition switch is switched “ON”, the A/T CHECK indicator lamp lights up for 2 seconds. As a method

for locating the suspect circuit, when the self-diagnosti cs start signal is input, the memory for the malfunction

location is output and the A/T CHECK indicator lamp flashes to display the corresponding DTC.

Diagnostic Procedure

1.CHECK A/T CHECK INDICATOR LAMP

1. Start the engine with selector lever in “P” pos ition. Warm engine to normal operating temperature.

2. Turn ignition switch ON and OFF at least twice, then leave it in the OFF position.

3. Wait 10 seconds.

4. Turn ignition switch ON. (Do not start engine.)

Frequency (Hz) —— X

The value measured by the pulse probe is dis-

played.

DUTY-HI (high) (%)

—— X

DUTY-LOW (low) (%) —— X

PLS WIDTH-HI (ms) —— X

PLS WIDTH-LOW (ms) —— X

Monitored item (Unit)

Monitor Item Selection

Remarks

ECU IN-

PUT SIG- NALS MAIN SIG-

NALS SELEC-

TION

FROM

MENU

DTC work support item DescriptionCheck item

1ST GR FNCTN P0731 Following items for “1GR function ratio” be confirmed.

• Self-diagnosis status (whether the diagnosis is being performed

or not)

• Self-diagnosis result (OK or NG)

• Input clutch solenoid valve

• Front brake solenoid valve

• Direct clutch solenoid valve

• High and low reverse clutch solenoid valve

• Each clutch

• Hydraulic co ntrol circuit

valve

2ND GR FNCTN P0732

Following items for “2GR function ratio” be confirmed.

• Self-diagnosis status (whether the diagnosis is being performed

or not)

• Self-diagnosis result (OK or NG)

3RD GR FNCTN P0733 Following items for “3GR function ratio” be confirmed.

• Self-diagnosis status (whether the diagnosis is being performed

or not)

• Self-diagnosis result (OK or NG)

4TH GR FNCTN P0734 Following items for “4GR function ratio” be confirmed.

• Self-diagnosis status (whether the diagnosis is being performed

or not)

• Self-diagnosis result (OK or NG)

5TH GR FNCTN P0735 Following items for “5GR function ratio” be confirmed.

• Self-diagnosis status (whether the diagnosis is being performed

or not)

• Self-diagnosis result (OK or NG)

Revision: April 20092010 QX56

Page 3736 of 4210

P0615 STARTER RELAYTM-41

< COMPONENT DIAGNOSIS >

CEF

G H

I

J

K L

M A

B

TM

N

O P

P0615 STARTER RELAY

DescriptionINFOID:0000000005148533

TCM prohibits cranking other than at “P” or “N” position.

CONSULT-III Reference Value in Data Monitor ModeINFOID:0000000005148534

On Board Diagnosis LogicINFOID:0000000005148535

• This is not an OBD-II self-diagnostic item.

• Diagnostic trouble code “P0615 STARTER RELAY” with CONSULT-III is detected when starter relay is

switched “ON” other than at “P” or “N” position. (Or when switched “OFF” at “P” or “N” position).

Possible CauseINFOID:0000000005148536

• Harness or connectors

(The starter relay and TCM circuit is open or shorted.)

• Sarter relay

DTC Confirmation ProcedureINFOID:0000000005148537

NOTE:

If “DTC Confirmation Procedure” has been previously performed, always turn ignition switch “OFF”

and wait at least 10 seconds before performing the next test.

After the repair, perform the following procedure to confirm the malfunction is eliminated.

WITH CONSULT-III

1. Turn ignition switch “ON”. (Do not start engine.)

2. Select “DATA MONITOR” mode for “TRANSMISSION” with CONSULT-III.

3. Start engine.

4. Drive vehicle for at least 2 consecutive seconds.

5. If DTC is detected, go to TM-41, "

Diagnosis Procedure".

Diagnosis ProcedureINFOID:0000000005148538

1.CHECK STARTER RELAY

With CONSULT-III

1. Turn ignition switch “ON”. (Do not start engine.)

2. Select “SELECTION FROM MENU” in “DATA MONI TOR” mode for “TRANSMISSION” with CONSULT-III

and check monitor “STARTER RELAY” ON/OFF.

Without CONSULT-III

Item name Condition Display value

STARTER RELAY Selector lever in “N”,“P” position.

ON

Selector lever in other position. OFF

Item nameCondition Display value

STARTER RELAY Selector lever in "N'', "P'' positions.

ON

Selector lever in other positions. OFF

Revision: April 20092010 QX56

Page 3740 of 4210

P0705 TRANSMISSION RANGE SWITCH A

TM-45

< COMPONENT DIAGNOSIS >

C EF

G H

I

J

K L

M A

B

TM

N

O P

P0705 TRANSMISSION RANGE SWITCH A

DescriptionINFOID:0000000005148544

The transmission range switch detects the select or lever position and sends a signal to the TCM.

CONSULT-III Reference Value in Data Monitor ModeINFOID:0000000005148545

On Board Diagnosis LogicINFOID:0000000005148546

• This is an OBD-II self-diagnostic item.

• Diagnostic trouble code “P0705 T/M RANGE SWITCH A” wi th CONSULT-III is detected under the following

conditions.

- When TCM does not receive the correct voltage signal from the transmission range switch 1, 2, 3, 4 based

on the gear position.

- When no other position but “P” positi on is detected from “N” positions.

Possible CauseINFOID:0000000005148547

• Harness or connectors

(The transmission range switch 1, 2, 3, 4 and TCM circuit is open or shorted.)

• Transmission range switch 1, 2, 3, 4

DTC Confirmation ProcedureINFOID:0000000005148548

CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If “DTC Confirmation Procedure” has been previously performed, always turn ignition switch “OFF”

and wait at least 10 seconds before performing the next test.

After the repair, perform the following procedure to confirm the malfunction is eliminated.

WITH CONSULT-III

1. Turn ignition switch “ON”. (Do not start engine.)

2. Select “DATA MONITOR” mode for “ENGINE” with CONSULT-III.

3. Start engine.

4. Drive vehicle and maintain the following conditions for at least 2 consecutive seconds. THRTL POS SEN: More than 1.2V

5. If DTC is detected, go to TM-45, "

Diagnosis Procedure".

WITH GST

Follow the procedure “With CONSULT-III”.

Diagnosis ProcedureINFOID:0000000005148549

1.CHECK TRANSMISSION RANGE SW CIRCUIT

With CONSULT-III

1. Turn ignition switch “ON”. (Do not start engine.)

2. Select “SELECTION FROM MENU” in “DATA MONI TOR” mode for “TRANSMISSION” with CONSULT-III.

Item nameCondition Display value

SLCTLVR POSI Selector lever in “N”,“P” positions.

N/P

Selector lever in “R” position. R

Selector lever in “D” position. D

Selector lever in “4” position. 4

Selector lever in “3” position. 3

Selector lever in “2” position. 2

Selector lever in “1” position. 1

Revision: April 20092010 QX56

Page 3775 of 4210

TM-80

< COMPONENT DIAGNOSIS >

P1731 1ST ENGINE BRAKING

P1731 1ST ENGINE BRAKING

DescriptionINFOID:0000000005148636

Fail-safe function to prevent sudden decrease in speed by engine brake other than at "1" position.

CONSULT-III Reference Value in Data Monitor ModeINFOID:0000000005148637

On Board Diagnosis LogicINFOID:0000000005148638

• This is not an OBD-II self-diagnostic item.

• Diagnostic trouble code “P1731 1GR E/BRAKING” with CO NSULT-III is detected under the following condi-

tions.

- When TCM does not receive the proper voltage signal from the sensor.

- When TCM monitors ATF pressure switch 2 and solenoid monitor value, and detects as irregular when

engine brake of 1GR acts other than at 1 position.

Possible CauseINFOID:0000000005148639

• Harness or connectors(The sensor circuit is open or shorted.)

• Low coast brake solenoid valve

• ATF pressure switch 2

DTC Confirmation ProcedureINFOID:0000000005148640

NOTE:

If “DTC Confirmation Procedure” has been previously preformed, always turn ignition switch “OFF”

and wait at least 10 seconds before performing the next test.

After the repair, perform the following proc edure to confirm the malfunction is eliminated.

WITH CONSULT-III

1. Turn ignition switch “ON”. (Do not start engine.)

2. Select “DATA MONITOR” mode for “TRANSMISSION” with CONSULT-III.

3. Start engine.

4. Drive vehicle and maintain the following conditions for at least 2 consecutive seconds. ENGINE SPEED: 1,200 rpm

SLCT LVR POSI: “1” position

GEAR: 1st

5. If DTC is detected, go to TM-80, "

Diagnosis Procedure".

Diagnosis ProcedureINFOID:0000000005148641

1.CHECK INPUT SIGNALS

With CONSULT-III

1. Start the engine.

2. Select “SELECTION FROM MENU” in “DATA MONITOR” for "TRANSMISSION" with CONSULT-III"

3. Drive vehicle in the “1” position (1GR), and confir m the ON/OFF actuation of “ATF PRES SW 2” and "ON

OFF SOL".

Item name Condition Display value

ON OFF SOL Low coast brake engaged. Refer to

TM-9

.O N

Low coast brake disengaged. Refer to TM-9

.O FF

ATF PRES SW 2 Low coast brake engaged. Refer to

TM-9

.O N

Low coast brake disengaged. Refer to TM-9

.O FF

Revision: April 20092010 QX56

Page 3785 of 4210

TM-90

< COMPONENT DIAGNOSIS >

P1772 LOW COAST BRAKE SOLENOID

P1772 LOW COAST BRAKE SOLENOID

DescriptionINFOID:0000000005148666

Low coast brake solenoid valve is turned “ON” or “OFF” by the TCM in response to signals sent from the trans-

mission range switch, output speed sensor and accelerator pedal position sensor. Gears will then be shifted to

the optimum position.

CONSULT-III Reference Value in Data Monitor ModeINFOID:0000000005148667

On Board Diagn osis LogicINFOID:0000000005148668

• This is an OBD-II self-diagnostic item.

• Diagnostic trouble code “P1772 L C BRAKE SOLENOID” with CONSULT-III is detected when TCM detects

an improper voltage drop when it tries to operate the solenoid valve.

Possible CauseINFOID:0000000005148669

• Harness or connectors (The solenoid circuit is open or shorted.)

• Low coast brake solenoid valve

DTC Confirmation ProcedureINFOID:0000000005148670

NOTE:

If “DTC Confirmation Procedure” has been previously performed, always turn ignition switch “OFF”

and wait at least 10 seconds before performing the next test.

After the repair, perform the following proc edure to confirm the malfunction is eliminated.

WITH CONSULT-III

1. Turn ignition switch “ON”. (Do not start engine.)

2. Select “DATA MONITOR” mode for “ENGINE” with CONSULT-III.

3. Start engine.

4. Drive vehicle and maintain the following conditions for at least 5 consecutive seconds.

SLCT LVR POSI: “1” or “2”

GEAR: “1st” or “2nd” (LC/B ON/OFF)

5. If DTC is detected, go to TM-90, "

Diagnosis Procedure".

WITH GST

Follow the procedure “With CONSULT-III”.

Diagnosis ProcedureINFOID:0000000005148671

1.CHECK INPUT SIGNAL

With CONSULT-III

1. Turn ignition switch “ON”.

2. Select “SELECTION FROM MENU” in “DATA MONI TOR” mode for “TRANSMISSION” with CONSULT-III.

3. Start the engine.

4. Read out the value of “ON OFF SOL” while driving.

OK or NG

OK >> GO TO 4.

Item name Condition Display value

ON OFF SOL Low coast brake engaged. Refer to

TM-9

.O N

Low coast brake disengaged. Refer to TM-9

.O FF

Item name Condition Display value

ON OFF SOL Low coast brake engaged. Refer to

TM-9

.O N

Low coast brake disengaged. Refer to TM-9

.O FF

Revision: April 20092010 QX56