turn signal INFINITI QX56 2010 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2010, Model line: QX56, Model: INFINITI QX56 2010Pages: 4210, PDF Size: 81.91 MB

Page 2090 of 4210

EXL-114

< ECU DIAGNOSIS >

BCM (BODY CONTROL MODULE)

58 W/R Optical sensorInput ONWhen optical sensor is illumi-

nated

3.1V or more

When optical sensor is not illu-

minated 0.6V or less

59 G Front door lock as-

sembly LH actuator

(unlock) Output OFF

OFF (neutral)

0V

ON (unlock) Battery voltage

60 G/B Turn signal (left) Output ON Turn left ON

61 G/Y Turn signal (right) Output ON Turn right ON

62 R/W Step lamp LH and RH Output OFF ON (any door open)

0V

OFF (all doors closed) Battery voltage

63 L Interior room/map

lamp Output OFFAny door

switchON (open)

0V

OFF (closed) Battery voltage

65 V All door lock actuators

(lock) Output OFFOFF (neutral)

0V

ON (lock) Battery voltage

66 G/Y Front door lock actua-

tor RH, rear door lock

actuators LH/RH and

back door lock actua-

tor (unlock) Output OFF

OFF (neutral)

0V

ON (unlock) Battery voltage

67 B Ground Input ON—0V

68 W/L Power window power

supply (RAP) Output —Ignition switch ON

Battery voltage

Within 45 seconds after igni-

tion switch OFF Battery voltage

More than 45 seconds after ig-

nition switch OFF 0V

When front door LH or RH is

open or power window timer

operates 0V

69 W/R Power window power

supply

Output —

—Battery voltage

70 W/B Battery power supply Input OFF —Battery voltage

Te r m i n a l

Wire

color Signal name Signal

input/

output Measuring condition

Reference value or waveform

(Approx.)

Ignition

switch Operation or condition

SKIA3009J

SKIA3009J

Revision: April 20092010 QX56

Page 2096 of 4210

EXL-120

< ECU DIAGNOSIS >

BCM (BODY CONTROL MODULE)

DTC Inspection Priority Chart

INFOID:0000000005369895

If some DTCs are displayed at the same time, perform inspections one by one based on the following priority

chart.

DTC IndexINFOID:0000000005369896

NOTE: Details of time display

• CRNT: Displays when there is a malfunction now or after returning to the normal condition until turning igni- tion switch OFF → ON again.

• 1 - 39: Displayed if any previous malfunction is present when current condition is normal. It increases like 1

→ 2 → 3...38 → 39 after returning to the normal condition whenever ignition switch OFF → ON. The counter

remains at 39 even if the number of cycles exceeds it. It is counted from 1 again when turning ignition switch

OFF → ON after returning to the normal condition if the malfunction is detected again.

Display contents of CONS ULTFail-safe Cancellation

U1000: CAN COMM CIRCUIT I nhibit engine crankingWhen the BCM re-establishes communication with the other mod-

ules.

Priority

DTC

1 • U1000: CAN COMM CIRCUIT

2 • B2190: NATS ANTENNA AMP

• B2191: DIFFERENCE OF KEY

• B2192: ID DISCORD BCM-ECM

• B2193: CHAIN OF BCM-ECM

• B2013: STRG COMM 1

• B2552: INTELLIGENT KEY

• B2590: NATS MALFUNCTION

3 • C1729: VHCL SPEED SIG ERR

• C1735: IGNITION SIGNAL

4 • C1708: [NO DATA] FL

• C1709: [NO DATA] FR

• C1710: [NO DATA] RR

• C1711: [NO DATA] RL

• C1712: [CHECKSUM ERR] FL

• C1713: [CHECKSUM ERR] FR

• C1714: [CHECKSUM ERR] RR

• C1715: [CHECKSUM ERR] RL

• C1716: [PRESSDATA ERR] FL

• C1717: [PRESSDATA ERR] FR

• C1718: [PRESSDATA ERR] RR

• C1719: [PRESSDATA ERR] RL

• C1720: [CODE ERR] FL

• C1721: [CODE ERR] FR

• C1722: [CODE ERR] RR

• C1723: [CODE ERR] RL

• C1724: [BATT VOLT LOW] FL

• C1725: [BATT VOLT LOW] FR

• C1726: [BATT VOLT LOW] RR

• C1727: [BATT VOLT LOW] RL

CONSULT display

Fail-safeIntelligent Key

warning lamp ON Tire pressure

monitor warning lamp ON Reference page

No DTC is detected.

further testing

may be required. ————

U1000: CAN COMM CIRCUIT ———BCS-32

B2190: NATS ANTENNA AMP ———SEC-31

Revision: April 20092010 QX56

Page 2110 of 4210

EXL-134

< ECU DIAGNOSIS >

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

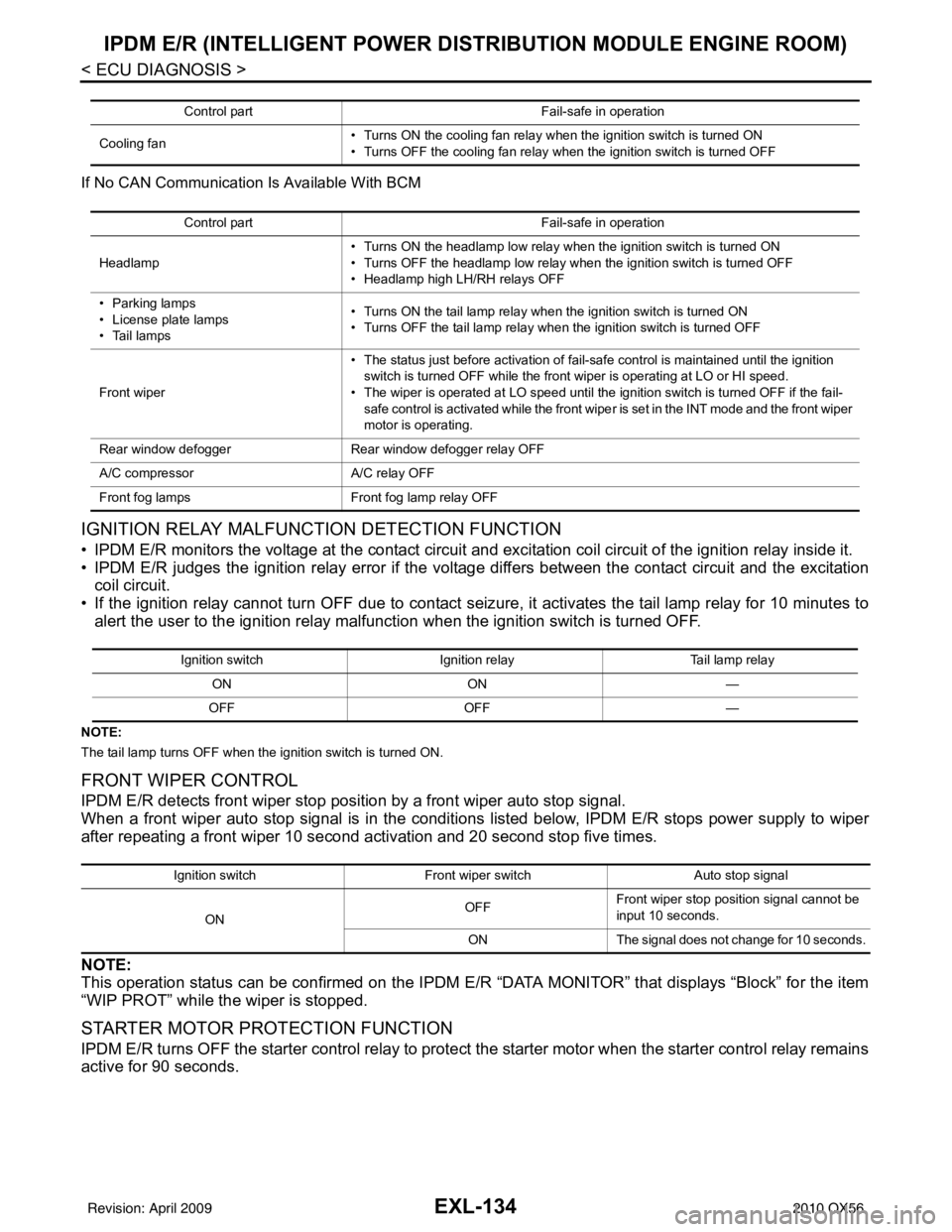

If No CAN Communication Is Available With BCM

IGNITION RELAY MALFUNCTION DETECTION FUNCTION

• IPDM E/R monitors the voltage at the contact circuit and excitation coil circuit of the ignition relay inside it.

• IPDM E/R judges the ignition relay error if the voltage differs between the contact circuit and the excitation

coil circuit.

• If the ignition relay cannot turn OFF due to contact seizure, it activates the tail lamp relay for 10 minutes to alert the user to the ignition relay malfunction when the ignition switch is turned OFF.

NOTE:

The tail lamp turns OFF when the ignition switch is turned ON.

FRONT WIPER CONTROL

IPDM E/R detects front wiper stop posit ion by a front wiper auto stop signal.

When a front wiper auto stop signal is in the conditions listed below, IPDM E/R stops power supply to wiper

after repeating a front wiper 10 second activation and 20 second stop five times.

NOTE:

This operation status can be confirmed on the IPDM E/R “DATA MONITOR” that displays “Block” for the item

“WIP PROT” while the wiper is stopped.

STARTER MOTOR PROTECTION FUNCTION

IPDM E/R turns OFF the starter control relay to protect the starter motor when the starter control relay remains

active for 90 seconds.

Control part Fail-safe in operation

Cooling fan • Turns ON the cooling fan relay when the ignition switch is turned ON

• Turns OFF the cooling fan relay when the ignition switch is turned OFF

Control part

Fail-safe in operation

Headlamp • Turns ON the headlamp low relay when the ignition switch is turned ON

• Turns OFF the headlamp low relay when the ignition switch is turned OFF

• Headlamp high LH/RH relays OFF

•Parking lamps

• License plate lamps

• Tail lamps • Turns ON the tail lamp relay when the ignition switch is turned ON

• Turns OFF the tail lamp relay when the ignition switch is turned OFF

Front wiper • The status just before activation of fail-safe control is maintained until the ignition

switch is turned OFF while the front wiper is operating at LO or HI speed.

• The wiper is operated at LO speed until the ignition switch is turned OFF if the fail- safe control is activated while the front wipe r is set in the INT mode and the front wiper

motor is operating.

Rear window defogger Rear window defogger relay OFF

A/C compressor A/C relay OFF

Front fog lamps Front fog lamp relay OFF

Ignition switch Ignition relayTail lamp relay

ON ON —

OFF OFF —

Ignition switchFront wiper switch Auto stop signal

ON OFF

Front wiper stop position signal cannot be

input 10 seconds.

ON The signal does not change for 10 seconds.

Revision: April 20092010 QX56

Page 2112 of 4210

EXL-136

< SYMPTOM DIAGNOSIS >

EXTERIOR LIGHTING SYSTEM SYMPTOMS

SYMPTOM DIAGNOSIS

EXTERIOR LIGHTING SYSTEM SYMPTOMS

Symptom TableINFOID:0000000005146686

CAUTION:

Perform the self-diagnosis with CONSULT-III before the symptom diagnosis. Perform the trouble diag-

nosis if any DTC is detected.

Symptom Possible causeInspection item

Headlamp does not

switch to the high beam. One side•Fuse

• Harness between IPDM E/R

and the front combination lamp

• Front combination lamp

(High beam relay)

• IPDM E/R Headlamp (HI) circuit

Refer to EXL-30, "

Description".

Both sides Symptom diagnosis

"BOTH SIDE HEADLAMPS DO NOT SWITCH TO HIGH BEAM"

Refer to

EXL-139

.

High beam indicator lamp is not turned ON.

(Headlamp switches to the high beam.) • Combination meter

•BCM• Combination meter.

Data monitor "HI-BEAM IND".

• BCM (HEAD LAMP) Active test "HEADLAMP".

Headlamp does not

switch to the low beam. One side

Front combination lamp (Low

beam relay)

—

Both sides • Combination switch (lighting

and turn signal switch)

• Harness between the combina-

tion switch and BCM

•BCM Combination switch

Refer to BCS-38

.

High beam request signal

•BCM

• IPDM E/R IPDM E/R

Data monitor "HL HI REQ".

IPDM E/R —

Headlamp does not turn

ON. One side•Fuse

•Bulb

• Harness between IPDM E/R

and the front combination lamp

• Front combination lamp

• IPDM E/R Headlamp (L

O) circuit

Refer to EXL-33

.

Both sides Symptom diagnosis

"BOTH SIDE HEADLAMPS (LO) ARE NOT TURNED ON"

Refer to

EXL-140, "

Description".

Headlamp does not turn

OFF. When the ignition

switch is turned ON•BCM

• Combination switch (lighting

and turn signal switch) Combination switch (lighting and

turn signal switch)

Refer to BCS-38

.

Headlamp is not turned ON/OFF with the lighting

switch AUTO. • Combination switch (lighting

and turn signal switch)

• Harness between the combina-

tion switch and BCM

•BCM Combination switch (lighting and

turn signal switch)

Refer to BCS-38

.

• Optical sensor

• Harness between the optical sensor and BCM

•BCM Optical sensor

Refer to EXL-47

.

Revision: April 20092010 QX56

Page 2113 of 4210

EXTERIOR LIGHTING SYSTEM SYMPTOMSEXL-137

< SYMPTOM DIAGNOSIS >

C

DE

F

G H

I

J

K

M A

B

EXL

N

O P

Daytime light system does not activate. • Either high beam bulb

• Parking brake switch

• Combination switch (lighting

and turn signal switch)

•BCM

• IPDM E/R

• Daytime light relay

• Harness between IPDM E/R

and daytime light relay. Daytime light system description.

Refer to

EXL-9, "System Descrip-

tion".

Front fog lamp is not

turned ON. One side

• Front fog lamp bulb

• Harness between IPDM E/R

and the front combination lamp

• Front combination lamp

• IPDM E/R Front fog lamp circuit

Refer to

EXL-36

.

Both sides Symptom diagnosis

"BOTH SIDE FRONT FOG LAMPS ARE NOT TURNED ON"

Refer to EXL-142

.

Parking lamp is not turned

ON. One side•Fuse

• Parking lamp bulb

• Harness between IPDM E/R

and the front/rear combination

lamp

• Front/rear combination lamp

• IPDM E/R Parking lamp circuit

Refer to

EXL-38

.

Both sides Symptom diagnosis

"PARKING, LICENSE PLATE AND TAIL LAMPS ARE NOT TURNED

ON"

Refer to EXL-141

.

Turn signal lamp does not

blink. Indicator lamp is nor-

mal.

(The applicable side

performs the high flash-

er activation).• Harness between BCM and

each turn signal lamp

• Turn signal lamp bulb

• Door mirror Turn signal lamp circuit

Refer to

EXL-44

.

Turn signal indicator lamp

does not blink. One side

Combination meter —

Both sides

(Always) • Turn signal indicator lamp sig-

nal

• Combination meter

•BCM • Combination meter.

Data monitor "TURN IND".

• BCM (FLASHER) Active test "FLASHER".

Both sides

(Does blink when acti-

vating the hazard warn-

ing lamp with the

ignition switch OFF) • The combination meter power

supply and the ground circuit

• Combination meter Combination meter

Power supply and the ground circuit

Refer to

MWI-28

.

Symptom

Possible causeInspection item

Revision: April 20092010 QX56

Page 2115 of 4210

BOTH SIDE HEADLAMPS DO NOT SWITCH TO HIGH BEAM

EXL-139

< SYMPTOM DIAGNOSIS >

C

D E

F

G H

I

J

K

M A

B

EXL

N

O P

BOTH SIDE HEADLAMPS DO NOT SWITCH TO HIGH BEAM

DescriptionINFOID:0000000005146688

The headlamps (both sides) do not switch to high beam when the combination switch (lighting and turn signal

switch) is in the HI or PASS setting.

Diagnosis ProcedureINFOID:0000000005146689

1.COMBINATION SWITCH (LIGHTING AND TURN SIGNAL SWITCH) INSPECTION

Check the combination switch (lighting and turn signal switch). Refer to BCS-38, "

Diagnosis Procedure".

Is the combination switch (lighting and turn signal switch) normal?

YES >> GO TO 2.

NO >> Repair or replace the malfunctioning part.

2.CHECK HEADLAMP (HI) REQUEST SIGNAL INPUT

CONSULT-III DATA MONITOR

1. Select "HL HI REQ" of IPDM E/R DATA MONITOR item.

2. With operating the combination switch (lighting and turn signal switch), check the monitor status.

Is the item status normal?

YES >> GO TO 3.

NO >> Replace BCM. Refer to BCS-59, "

Removal and Installation" .

3.HEADLAMP (HI) CIRCUIT INSPECTION

Check the headlamp (HI) circuit. Refer to EXL-30, "

Description".

Is the headlamp (HI) circuit normal?

YES >> Replace IPDM E/R. Refer to PCS-35, "Removal and Installation of IPDM E/R" .

NO >> Repair or replace the malfunctioning part.

Monitor item ConditionMonitor status

HL HI REQ Combination switch (lighting and

turn signal switch)

(2ND) HI or PASS

ON

Except for HI or

PASS OFF

Revision: April 20092010 QX56

Page 2116 of 4210

EXL-140

< SYMPTOM DIAGNOSIS >

BOTH SIDE HEADLAMPS (LO) ARE NOT TURNED ON

BOTH SIDE HEADLAMPS (LO) ARE NOT TURNED ON

DescriptionINFOID:0000000005146690

The headlamps (both sides) do not turn ON in any combination switch (lighting and turn signal switch) setting.

Diagnosis ProcedureINFOID:0000000005146691

1.COMBINATION SWITCH (LIGHTING AND TURN SIGNAL SWITCH) INSPECTION

Check the combination switch (lighting and turn signal switch). Refer to BCS-38, "

Diagnosis Procedure".

Is the combination switch (lighting and turn signal switch) normal?

YES >> GO TO 2.

NO >> Repair or replace the malfunctioning part.

2.CHECK HEADLAMP (LO) REQUEST SIGNAL INPUT

CONSULT-III DATA MONITOR

1. Select "HL LO REQ" of IPDM E/R DATA MONITOR item.

2. With operating the combination switch (lighting and turn signal switch), check the monitor status.

Is the item status normal?

YES >> GO TO 3.

NO >> Replace BCM. Refer to BCS-59, "

Removal and Installation" .

3.HEADLAMP (LO) CIRCUIT INSPECTION

Check the headlamp (LO) circuit. Refer to EXL-33, "

Description".

Is the headlamp (LO) circuit normal?

YES >> Replace IPDM E/R. Refer to PCS-35, "Removal and Installation of IPDM E/R" .

NO >> Repair or replace the malfunctioning part.

Monitor item ConditionMonitor status

HL LO REQ Combination switch

(lighting and turn signal

switch) 2ND

ON

OFF OFF

Revision: April 20092010 QX56

Page 2117 of 4210

PARKING, LICENSE PLATE AND TAIL LAMPS ARE NOT TURNED ON

EXL-141

< SYMPTOM DIAGNOSIS >

C

D E

F

G H

I

J

K

M A

B

EXL

N

O P

PARKING, LICENSE PLATE AND TA IL LAMPS ARE NOT TURNED ON

DescriptionINFOID:0000000005146692

The parking, license plate and tail lamps do not turn ON in with any combination switch (lighting and turn sig-

nal switch) setting.

Diagnosis ProcedureINFOID:0000000005146693

1.COMBINATION SWITCH (LIGHTING AND TURN SIGNAL SWITCH) INSPECTION

Check the combination switch (lighting and turn signal switch). Refer to BCS-38, "

Diagnosis Procedure".

Is the combination switch (lighting and turn signal switch) normal?

YES >> GO TO 2.

NO >> Repair or replace the malfunctioning part.

2.CHECK TAIL LAMP RELAY REQUEST SIGNAL INPUT

CONSULT-III DATA MONITOR

1. Select "TAIL & CLR REQ" of IPDM E/R DATA MONITOR item.

2. With operating the combination switch (lighting and turn signal switch), check the monitor status.

Is the item status normal?

YES >> GO TO 3.

NO >> Replace BCM. Refer to BCS-59, "

Removal and Installation".

3.PARK LAMP CIRCUIT INSPECTION

Check the parking lamp circuit. Refer to EXL-38, "

Description".

Is the tail lamp circuit normal?

YES >> Replace IPDM E/R. Refer to PCS-35, "Removal and Installation of IPDM E/R".

NO >> Repair or replace the malfunctioning part.

Monitor item ConditionMonitor status

TAIL & CLR

REQ combination switch (lighting

and turn signal switch) 1ST

ON

OFF OFF

Revision: April 20092010 QX56

Page 2118 of 4210

EXL-142

< SYMPTOM DIAGNOSIS >

BOTH SIDE FRONT FOG LAMPS ARE NOT TURNED ON

BOTH SIDE FRONT FOG LA MPS ARE NOT TURNED ON

DescriptionINFOID:0000000005146694

The front fog lamps do not turn ON in any setting.

Diagnosis ProcedureINFOID:0000000005146695

1.COMBINATION SWITCH (LIGHTING AND TURN SIGNAL SWITCH) INSPECTION

Check the combination switch (lighting and turn signal switch). Refer to BCS-38, "

Diagnosis Procedure".

Is the combination switch (lighting and turn signal switch) normal?

YES >> GO TO 2.

NO >> Repair or replace the malfunctioning part.

2.CHECK FRONT FOG LAMP REQUEST SIGNAL INPUT

CONSULT-III DATA MONITOR

1. Select "FR FOG REQ" of IPDM E/R DATA MONITOR item.

2. With operating the front fog lamp switch, check the monitor status.

Is the item status normal?

YES >> GO TO 3.

NO >> Replace BCM. Refer to BCS-59, "

Removal and Installation".

3.FRONT FOG LAMP CIRCUIT INSPECTION

Check the front fog lamp circuit. Refer to EXL-36, "

Description".

Is the front fog lamp circuit normal?

YES >> Replace IPDM E/R. Refer to PCS-35, "Removal and Installation of IPDM E/R".

NO >> Repair or replace the malfunctioning part.

Monitor item ConditionMonitor status

FR FOG REQ Front fog lamp switch

(combination switch (lighting

and turn signal switch) 2ND) ON ON

OFF OFF

Revision: April 20092010 QX56

Page 2120 of 4210

EXL-144

< PRECAUTION >

PRECAUTIONS

5. When the repair work is completed, re-connect both battery cables. With the brake pedal released, turn

the push-button ignition switch from ACC position to ON position, then to LOCK position. (The steering

wheel will lock when the push-button igniti on switch is turned to LOCK position.)

6. Perform self-diagnosis check of all control units using CONSULT-III.

General precautions for service operationsINFOID:0000000005369811

• When removing or disassembling any part, be careful not to damage or deform it. Protect parts which may

get in the way with cloth.

• When removing parts with a screw driver or other tool , protect parts by wrapping them with vinyl or tape.

• Keep removed parts protected with cloth.

• If an non-reuseable part is removed, replace it with a new one.

• After re-assembly has been completed, make sure each part functions correctly.

• Never work with wet hands.

• Turn the combination switch (lighting and turn signal switch) OFF before disconnecting and connecting the connector.

• Do not use organic solvent (paint thinner or gasoline) to clean lamps or remove sealant residue.

Revision: April 20092010 QX56