ECU INFINITI QX56 2010 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2010, Model line: QX56, Model: INFINITI QX56 2010Pages: 4210, PDF Size: 81.91 MB

Page 3850 of 4210

STALL TESTTM-155

< ON-VEHICLE MAINTENANCE >

CEF

G H

I

J

K L

M A

B

TM

N

O P

STALL TEST

Inspection and JudgmentINFOID:0000000005148726

A/T FLUID CHECK

Fluid Leakage and Fluid Level Check

• Inspect for fluid leakage and check the fluid level. Refer to TM-148, "Checking the A/T Fluid (ATF)".

Fluid Condition Check

Inspect the fluid condition.

STALL TEST

Stall Test Procedure

1. Inspect the amount of engine oil. Replenish the engine oil if necessary.

2. Drive for about 10 minutes to warm up the vehicle so that the A/

T fluid temperature is 50 to 80 °C (122 to 176 °F). Inspect the

amount of ATF. Replenish if necessary.

3. Securely engage the parking brake so that the tires do not turn.

Fluid condition Conceivable Cause Required Operation

Varnished (viscous

varnish state) Clutch, brake

scorchedReplace the ATF and check the A/T

main unit and the vehicle for mal-

functions (wire harnesses, cooler

pipes, etc.)

Milky white or

cloudy Water in the fluidReplace the ATF and check for plac-

es where water is getting in.

Large amount of

metal powder mixed

in Unusual wear of

sliding parts within

A/T

Replace the ATF and check for im-

proper operation of the A/T.

SAT638A

SAT647B

SCIA1224E

Revision: April 20092010 QX56

Page 3852 of 4210

LINE PRESSURE TESTTM-157

< ON-VEHICLE MAINTENANCE >

CEF

G H

I

J

K L

M A

B

TM

N

O P

LINE PRESSURE TEST

Inspection and JudgmentINFOID:0000000005148727

LINE PRESSURE TEST

Line Pressure Test Port

Line Pressure Test Procedure

1. Inspect the amount of engine oil and replenish if necessary.

2. Drive the car for about 10 minutes to warm it up so that the ATF reaches in range of 50 to 80 °C (122 to

176° F), then inspect the amount of ATF and replenish if necessary.

NOTE:

The automatic fluid temperature rises in range of 50 to 80 °C (122 to 176° F) during 10 minutes of

driving.

3. After warming up remove the oil pressure detection plug and install the Tool.

CAUTION:

When using the oil pressure ga uge, be sure to use the O-

ring attached to the oil pressure detection plug.

4. Securely engage the parking brake so that the tires do not turn.

SCIA2187E

SCIA5309E

SCIA1224E

Revision: April 20092010 QX56

Page 3861 of 4210

TM-166

< ON-VEHICLE REPAIR >

AIR BREATHER HOSE

AIR BREATHER HOSE

Removal and InstallationINFOID:0000000005402587

REMOVAL and INSTALLATION

2WD

CAUTION:

• Install air breather hose with paint mark at upper side.

• When installing the air breather hose, do not crush or block by folding or bending the hose.

• When inserting the hose to the tran smission tube, be sure to insert it fully until its end reaches the

tube bend portion.

• Make sure clip is securely installed to bracket.

REMOVAL

AWDIA0554GB

A. Set air breather hose with

paint mark at upper side B. Clip (set securely to bracket)

Revision: April 20092010 QX56

Page 3873 of 4210

TM-178

< ON-VEHICLE REPAIR >

CONTROL VALVE WITH TCM

i. Install new O-ring (1) in plug (2).CAUTION:

• Do not reuse O-ring.

• Apply ATF to O-ring.

• O-ring should be free of contamination.

ii. Install plug (2) to bracket (1).

iii. Install plug (1) [with bracket (2)] to control valve with TCM. Tighten plug bolt ( ) to the specified torque.

CAUTION:

Adjust bolt hole of bracket to bolt hole of control valve with

TCM.

6. Install control valve with TCM in transmission case. CAUTION:

• Make sure that input speed sensor is securely installedinto input speed sensor hole (A).

• Hang down output speed sen sor harness toward outside

so as not to disturb installati on of control valve with TCM.

• Adjust A/T assembly harness co nnector of control valve

with TCM to terminal hole of transmission case.

• Assemble it so that manual valve cutout is engaged with manual plate projection.

JSDIA1313ZZ

JSDIA1312ZZ

JSDIA1311ZZ

1 : Brake band

JSDIA1318ZZ

SCIA5142E

Revision: April 20092010 QX56

Page 3874 of 4210

CONTROL VALVE WITH TCMTM-179

< ON-VEHICLE REPAIR >

CEF

G H

I

J

K L

M A

B

TM

N

O P

7. Install bolts (A), (B) and (C) in control valve with TCM. • : Front

8. Tighten bolt (1), (2) and (3) temporarily to prevent dislocation. After that tighten them in order (1 → 2 → 3). Then tighten other

bolts.

• : Front

9. Tighten control valve with TCM bolts to the specified torque.

10. After installing the A/T fluid temperature sensor 2, connect the A/T fluid temperature sensor 2 connector

as shown below.

a. Connect A/T fluid temperature sensor 2 connector (A).

b. Securely fasten terminal cord assembly and A/T fluid tempera- ture sensor 2 harness with terminal clips ( ).

11. Connect output speed sensor connector (1).

Bolt symbol Length mm (in) Number of bolts

A 42 (1.65) 5

B 55 (2.17) 6

C 40 (1.57) 1

SCIA8074E

Bolt symbolAB C

Number of bolts 56 1

Length mm (in) 42 (1.65) 55 (2.17)40 (1.57)

Tightening torque

N·m (km-g, in-lb) 7.9 (0.81, 70)With ATF applied

7.9 (0.81, 70)

SCIA8075E

SCIA8124E

JSDIA1319ZZ

Revision: April 20092010 QX56

Page 3875 of 4210

TM-180

< ON-VEHICLE REPAIR >

CONTROL VALVE WITH TCM

12. Securely fasten output speed sensor (1) harness with terminalclip ( ).

13. Install oil pan to transmission case. Refer to TM-170, "

Oil Pan".

14. Pull up A/T assembly harness connector. CAUTION:

Do not damage connector.

15. Install snap ring to A/T assembly harness connector.

16. Connect A/T assembly harness connector.

17. Connect the negative battery terminal.

18. Refill the A/T with fluid and check the fluid level and for fluid leakage. Refer to TM-148, "

Checking the A/T Fluid (ATF)".

REMOVAL AND INSTALLATION OF A/T FLUID TEMPERATURE SENSOR 2

Removal

1. Disconnect negative battery terminal.

2. Remove oil pan and oil pan gasket. Refer to TM-170, "

Oil Pan".

3. Disconnect A/T fluid temperat ure sensor 2 connector (A).

CAUTION:

Do not damage connector.

4. Straighten terminal clip ( ) to free A/T fluid temperature sensor 2 harness.

JSDIA1316ZZ

SCIA5038E

SCIA5039E

SCIA8125E

Revision: April 20092010 QX56

Page 3877 of 4210

TM-182

< ON-VEHICLE REPAIR >

CONTROL VALVE WITH TCM

3. Connect A/T fluid temperature sensor 2 connector (A).

4. Securely fasten A/T fluid temperature sensor 2 harness with ter-minal clip .

5. Install oil pan to transmission case. Refer to TM-170, "

Oil Pan".

6. Connect the negative battery terminal.

7. Refill the A/T with fluid and check the fluid level and for fluid leakage. Refer to TM-148, "

Checking the A/T

Fluid (ATF)".

REMOVAL AND INSTALLATION OF PLUG

Removal

1. Disconnect negative battery terminal.

2. Remove oil pan and oil pan gasket. Refer to TM-170, "

Oil Pan".

3. Remove plug (1) with bracket (2) from control valve with TCM.

4. Remove bracket (1) from plug (2).

5. Remove O-ring (1) from plug (2).

Installation

CAUTION:

SCIA8125E

: Bolt

JSDIA1311ZZ

JSDIA1312ZZ

JSDIA1313ZZ

Revision: April 20092010 QX56

Page 3882 of 4210

TRANSMISSION ASSEMBLYTM-187

< REMOVAL AND INSTALLATION >

CEF

G H

I

J

K L

M A

B

TM

N

O P

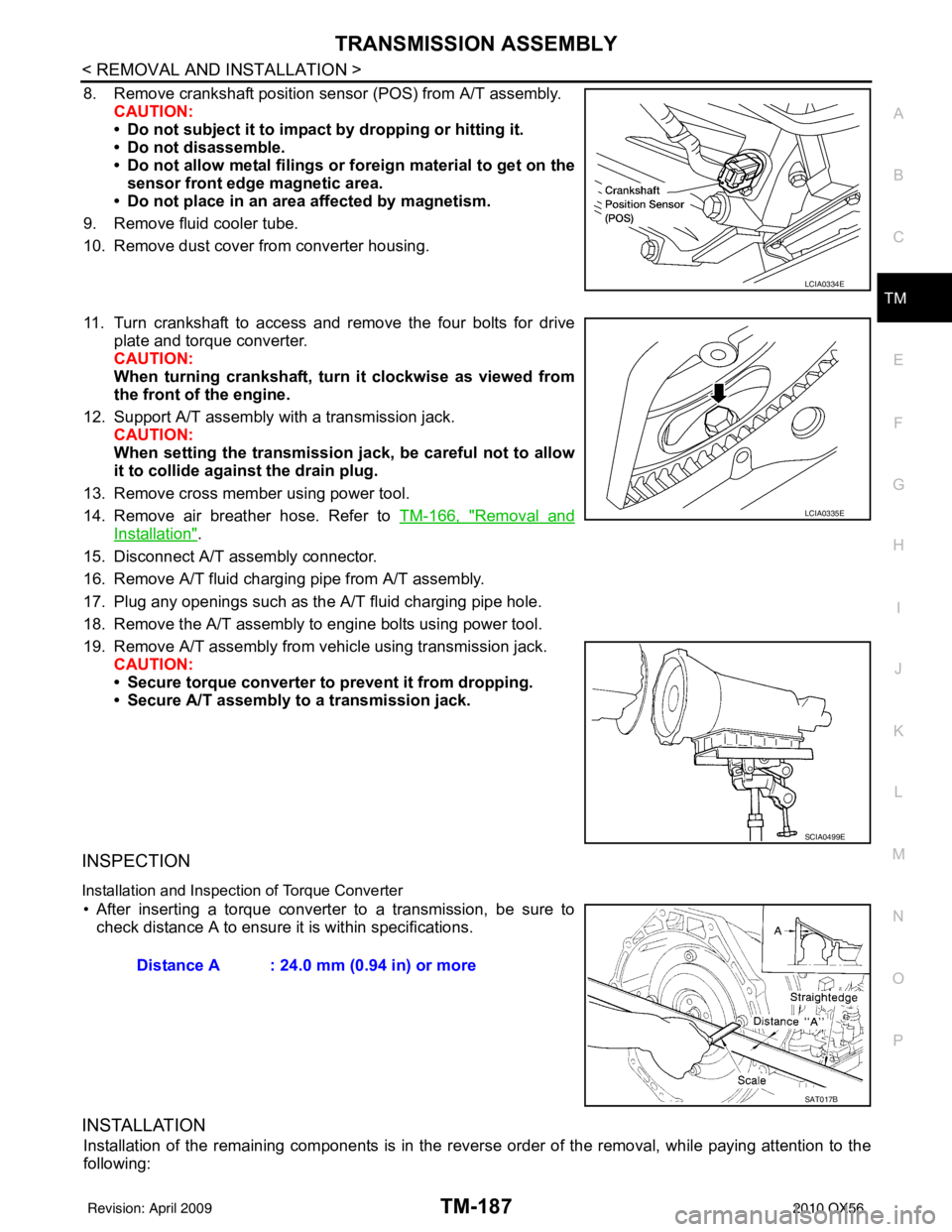

8. Remove crankshaft position sens or (POS) from A/T assembly.

CAUTION:

• Do not subject it to impact by dropping or hitting it.

• Do not disassemble.

• Do not allow metal filings or foreign material to get on the

sensor front edge magnetic area.

• Do not place in an area affected by magnetism.

9. Remove fluid cooler tube.

10. Remove dust cover from converter housing.

11. Turn crankshaft to access and remove the four bolts for drive plate and torque converter.

CAUTION:

When turning crankshaft, turn it clockwise as viewed from

the front of the engine.

12. Support A/T assembly with a transmission jack. CAUTION:

When setting the transmission jack, be careful not to allow

it to collide agai nst the drain plug.

13. Remove cross member using power tool.

14. Remove air breather hose. Refer to TM-166, "

Removal and

Installation".

15. Disconnect A/T assembly connector.

16. Remove A/T fluid charging pipe from A/T assembly.

17. Plug any openings such as the A/T fluid charging pipe hole.

18. Remove the A/T assembly to engine bolts using power tool.

19. Remove A/T assembly from vehicle using transmission jack. CAUTION:

• Secure torque converter to prevent it from dropping.

• Secure A/T assembly to a transmission jack.

INSPECTION

Installation and Inspection of Torque Converter

• After inserting a torque converter to a transmission, be sure to check distance A to ensure it is within specifications.

INSTALLATION

Installation of the remaining components is in the revers e order of the removal, while paying attention to the

following:

LCIA0334E

LCIA0335E

SCIA0499E

Distance A : 24.0 mm (0.94 in) or more

SAT017B

Revision: April 20092010 QX56

Page 3883 of 4210

TM-188

< REMOVAL AND INSTALLATION >

TRANSMISSION ASSEMBLY

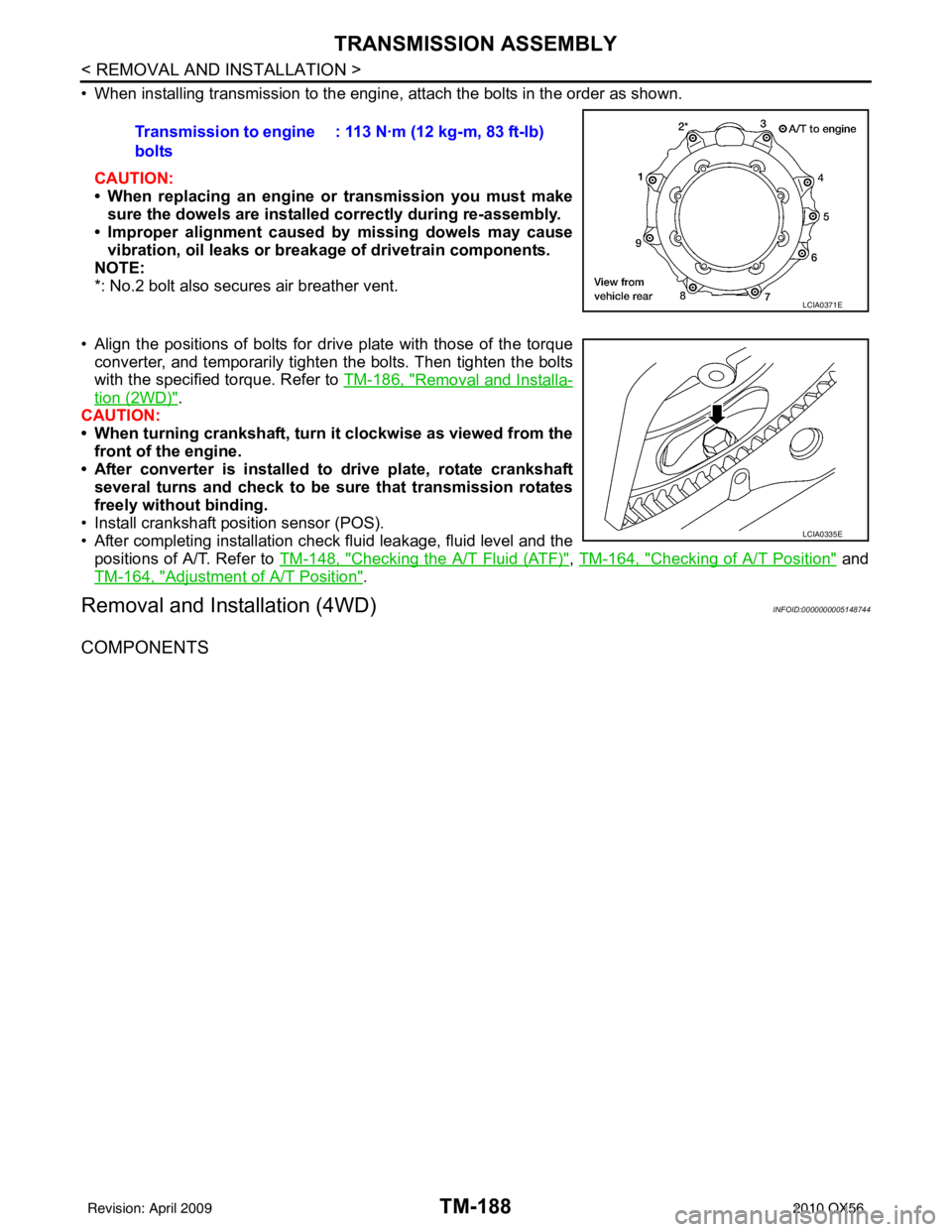

• When installing transmission to the engine, attach the bolts in the order as shown.CAUTION:

• When replacing an engine or transmission you must make

sure the dowels are installe d correctly during re-assembly.

• Improper alignment caused by missing dowels may cause

vibration, oil leaks or breakage of drivetrain components.

NOTE:

*: No.2 bolt also secures air breather vent.

• Align the positions of bolts for drive plate with those of the torque converter, and temporarily tighten the bolts. Then tighten the bolts

with the specified torque. Refer to TM-186, "

Removal and Installa-

tion (2WD)".

CAUTION:

• When turning crankshaft, turn it clockwise as viewed from the front of the engine.

• After converter is installed to drive plate, rotate crankshaft

several turns and check to be sure that transmission rotates

freely without binding.

• Install crankshaft pos ition sensor (POS).

• After completing installation check fluid leakage, fluid level and the

positions of A/T. Refer to TM-148, "

Checking the A/T Fluid (ATF)", TM-164, "Checking of A/T Position" and

TM-164, "

Adjustment of A/T Position".

Removal and Installation (4WD)INFOID:0000000005148744

COMPONENTS

Transmission to engine

bolts : 113 N·m (12 kg-m, 83 ft-lb)

LCIA0371E

LCIA0335E

Revision: April 20092010 QX56

Page 3885 of 4210

TM-190

< REMOVAL AND INSTALLATION >

TRANSMISSION ASSEMBLY

8. Remove crankshaft position sensor (POS) from A/T assembly.CAUTION:

• Do not subject it to impact by dropping or hitting it.

• Do not disassemble.

• Do not allow metal filings or fo reign material to get on the

sensor front edge magnetic area.

• Do not place in an area affected by magnetism.

9. Remove A/T fluid cooler tube from A/T assembly.

10. Remove dust cover from converter housing.

11. Turn crankshaft, and remove the four bolts for drive plate and torque converter.

CAUTION:

When turning crankshaft, turn it clockwise as viewed from

the front of the engine.

12. Support A/T assembly using transmission jack and Tool. CAUTION:

When setting the transmission jack, be careful not to allow it to collide against the drain plug.

NOTE:

The actual special service tool may differ from tool shown.

13. Remove cross member using power tool.

14. Tilt the transmission slightly to keep the cl earance between body and transmission, then disconnect air

breather hose from A/T fluid charging pipe.

15. Remove air breather hose. Refer to TM-166, "

Removal and Installation".

16. Disconnect A/T assembly connector and transfer unit connector.

17. Remove A/T fluid charging pipe.

18. Plug any openings such as the fluid charging pipe hole.

19. Remove A/T assembly to engine bolts using power tool.

20. Remove A/T assembly with transfer from vehicle. CAUTION:

• Secure torque converter to prevent it from dropping.

• Secure A/T assembly to transmission jack.

21. Remove transfer from A/T assembly. Refer to TM-188,

"Removal and Installation (4WD)".

INSPECTION

Installation and Inspection of Torque Converter

LCIA0334E

LCIA0335E

Tool number : — (J-47002)

SCIA2203E

Revision: April 20092010 QX56