control arm INFINITI QX56 2010 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2010, Model line: QX56, Model: INFINITI QX56 2010Pages: 4210, PDF Size: 81.91 MB

Page 172 of 4210

ADP-158

< ECU DIAGNOSIS >

BCM (BODY CONTROL MODULE)

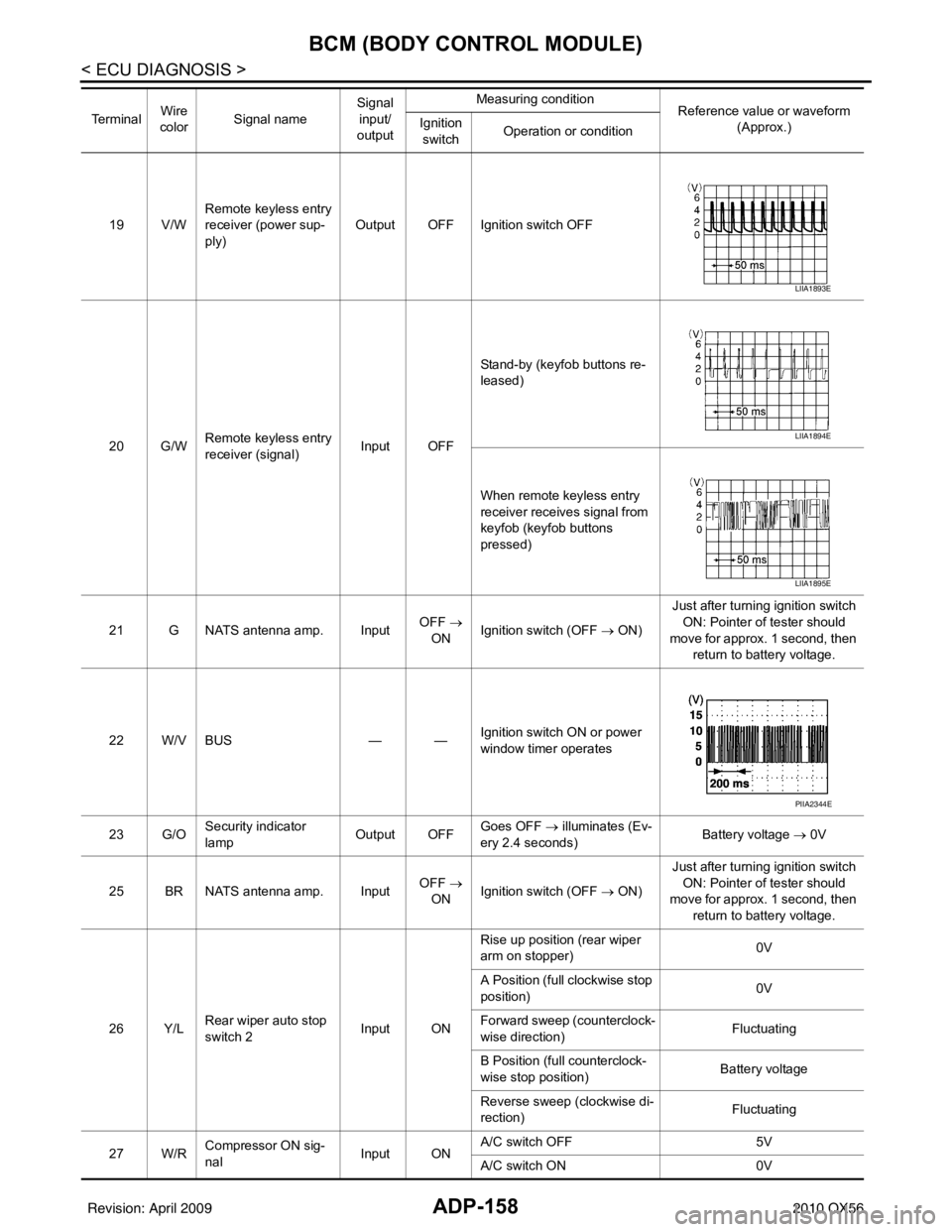

19 V/WRemote keyless entry

receiver (power sup-

ply) Output OFF Ignition switch OFF

20 G/W Remote keyless entry

receiver (signal) Input OFFStand-by (keyfob buttons re-

leased)

When remote keyless entry

receiver receives signal from

keyfob (keyfob buttons

pressed)

21 G NATS antenna amp. Input OFF

→

ON Ignition switch (OFF

→ ON)Just after turning ignition switch

ON: Pointer of tester should

move for approx. 1 second, then return to battery voltage.

22 W/V BUS — —Ignition switch ON or power

window timer operates

23 G/O Security indicator

lamp Output OFF

Goes OFF

→ illuminates (Ev-

ery 2.4 seconds) Battery voltage

→ 0V

25 BR NATS antenna amp. Input OFF

→

ON Ignition switch (OFF

→ ON)Just after turning ignition switch

ON: Pointer of tester should

move for approx. 1 second, then return to battery voltage.

26 Y/L Rear wiper auto stop

switch 2 Input ONRise up position (rear wiper

arm on stopper)

0V

A Position (full clockwise stop

position) 0V

Forward sweep (counterclock-

wise direction) Fluctuating

B Position (full counterclock-

wise stop position) Battery voltage

Reverse sweep (clockwise di-

rection) Fluctuating

27 W/R Compressor ON sig-

nal Input ONA/C switch OFF

5V

A/C switch ON 0V

Te r m i n a l

Wire

color Signal name Signal

input/

output Measuring condition

Reference value or waveform

(Approx.)

Ignition

switch Operation or condition

LIIA1893E

LIIA1894E

LIIA1895E

PIIA2344E

Revision: April 20092010 QX56

Page 174 of 4210

ADP-160

< ECU DIAGNOSIS >

BCM (BODY CONTROL MODULE)

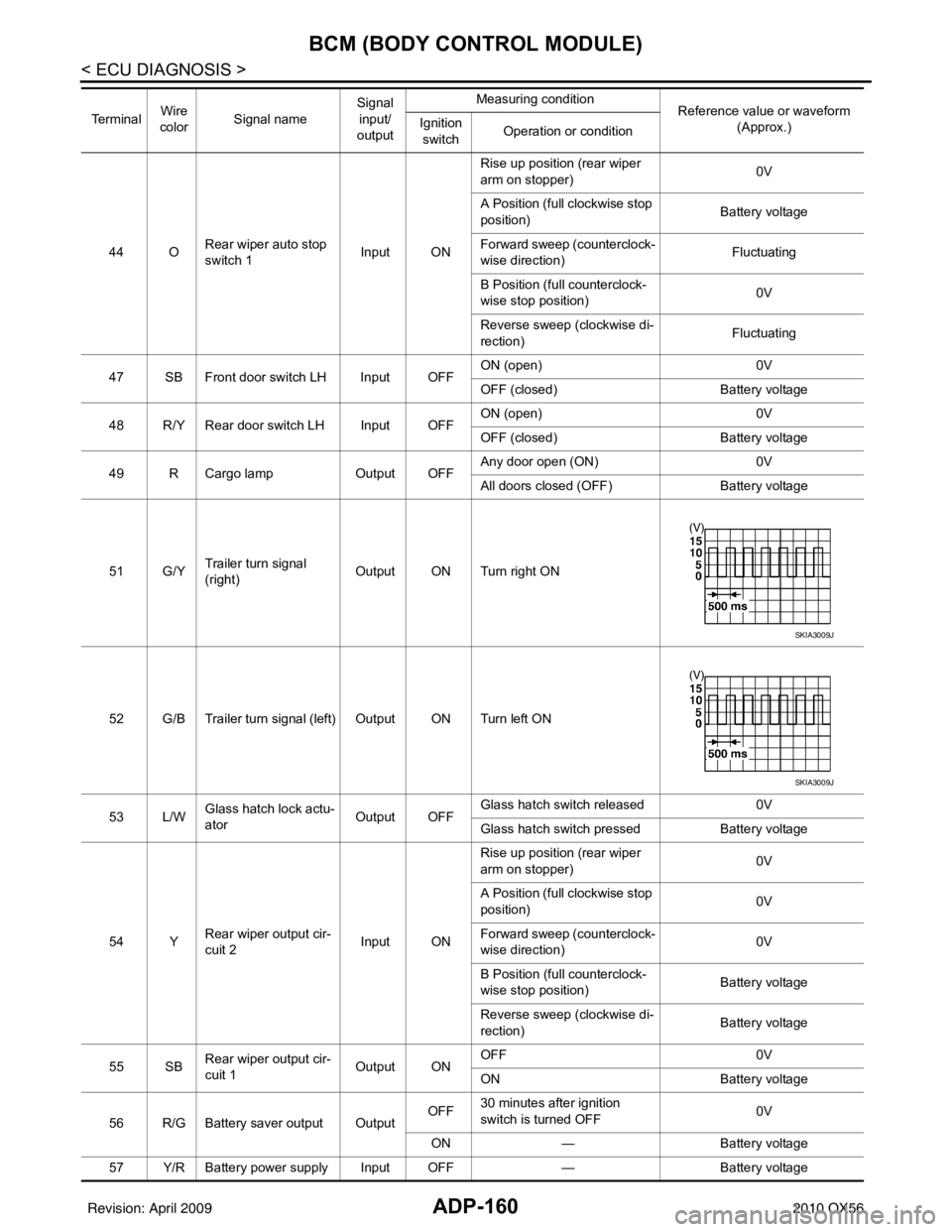

44 ORear wiper auto stop

switch 1 Input ONRise up position (rear wiper

arm on stopper)

0V

A Position (full clockwise stop

position) Battery voltage

Forward sweep (counterclock-

wise direction) Fluctuating

B Position (full counterclock-

wise stop position) 0V

Reverse sweep (clockwise di-

rection) Fluctuating

47 SB Front door switch LH Input OFF ON (open)

0V

OFF (closed) Battery voltage

48 R/Y Rear door switch LH Input OFF ON (open)

0V

OFF (closed) Battery voltage

49 R Cargo lamp Output OFFAny door open (ON)

0V

All doors closed (OFF) Battery voltage

51 G/Y Trailer turn signal

(right) Output ON Turn right ON

52 G/B Trailer turn signal (l eft) Output ON Turn left ON

53 L/W Glass hatch lock actu-

ator

Output OFFGlass hatch switch released

0V

Glass hatch switch pressed Battery voltage

54 Y Rear wiper output cir-

cuit 2 Input ONRise up position (rear wiper

arm on stopper)

0V

A Position (full clockwise stop

position) 0V

Forward sweep (counterclock-

wise direction) 0V

B Position (full counterclock-

wise stop position) Battery voltage

Reverse sweep (clockwise di-

rection) Battery voltage

55 SB Rear wiper output cir-

cuit 1 Output ONOFF

0V

ON Battery voltage

56 R/G Battery saver output Output OFF

30 minutes after ignition

switch is turned OFF 0V

ON — Battery voltage

57 Y/R Battery power supply Input OFF —Battery voltage

Te r m i n a l

Wire

color Signal name Signal

input/

output Measuring condition

Reference value or waveform

(Approx.)

Ignition

switch Operation or condition

SKIA3009J

SKIA3009J

Revision: April 20092010 QX56

Page 187 of 4210

PRECAUTIONSADP-173

< PRECAUTION >

C

DE

F

G H

I

K L

M A

B

ADP

N

O P

5. When the repair work is completed, return the ignition switch to the ″LOCK ″ position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of al l control units using CONSULT-III.

Precaution for WorkINFOID:0000000005147589

• When removing or disassembling each component, be ca reful not to damage or deform it. If a component

may be subject to interference, be sure to protect it with a shop cloth.

• When removing (disengaging) components with a screwdriver or similar tool, be sure to wrap the component

with a shop cloth or vinyl tape to protect it.

• Protect the removed parts with a shop cloth and keep them.

• Replace a deformed or damaged clip.

• If a part is specified as a non-reusable part, always replace it with new one.

• Be sure to tighten bolts and nuts securely to the specified torque.

• After re-installation is completed, be sure to check that each part works normally.

• Follow the steps below to clean components.

- Water soluble foul: Dip a soft cloth into lukewarm water, and wring the water out of the cloth to wipe the fouled area.

Then rub with a soft and dry cloth.

- Oily foul: Dip a soft cloth into lukewarm water with mild detergent (concentration: within 2 to 3%), and wipe the fouled area.

Then dip a cloth into fresh water, and wring the water out of the cloth to wipe the detergent off. Then rub with

a soft and dry cloth.

• Do not use organic solvent such as thinner, benzene, alcohol, or gasoline.

• For genuine leather seats, use a genuine leather seat cleaner.

Revision: April 20092010 QX56

Page 388 of 4210

BCS-2

COMB SW .................................................................25

COMB SW : CONSULT-III Function (BCM -

COMB SW) .............................................................

25

IMMU ...................................................................... ...26

IMMU : CONSULT-III Function (BCM - IMMU) .......26

BATTERY SAVER ................................................. ...26

BATTERY SAVER : CONSULT-III Function (BCM

- BATTERY SAVER) ........................................... ...

26

TRUNK ................................................................... ...27

TRUNK : CONSULT-III Function (BCM - TRUNK) ...27

RETAINED PWR .................................................... ...27

RETAINED PWR : CONSULT-III Function (BCM -

RETAINED PWR) ...................................................

27

SIGNAL BUFFER ................................................... ...27

SIGNAL BUFFER : CONSULT-III Function (BCM

- SIGNAL BUFFER) ................................................

28

AIR PRESSURE MONITOR ................................... ...28

AIR PRESSURE MONITOR : Diagnosis Descrip-

tion ..........................................................................

28

AIR PRESSURE MONITOR : CONSULT-III Func-

tion ....................................................................... ...

30

THEFT ALM ........................................................... ...30

THEFT ALM : CONSULT-III Function (BCM -

THEFT ALM) ..........................................................

30

PANIC ALARM ....................................................... ...31

PANIC ALARM : CONSULT-III Function (BCM -

PANIC ALARM) ................................................... ...

31

COMPONENT DIAGNOSIS ........................32

U1000 CAN COMM CIRCUIT ......................... ...32

Description ........................................................... ...32

DTC Logic ...............................................................32

Diagnosis Procedure ..............................................32

POWER SUPPLY AND GROUND CIRCUIT .....33

Diagnosis Procedure ........................................... ...33

COMBINATION SWITCH INPUT CIRCUIT .......35

Diagnosis Procedure ............................................ ...35

Special Repair Requirement ...................................36

COMBINATION SWITCH OUTPUT CIRCUIT ...37

Diagnosis Procedure ...............................................37

Special Repair Requirement ...................................37

COMBINATION SWITCH ..................................38

Description ........................................................... ...38

Diagnosis Procedure ...............................................38

ECU DIAGNOSIS .......................................40

BCM (BODY CONTROL MODULE) ............... ...40

Reference Value .................................................. ...40

Terminal Layout ......................................................43

Physical Values .......................................................43

Wiring Diagram .......................................................49

Fail Safe .................................................................53

DTC Inspection Priority Chart ...............................54

DTC Index ..............................................................54

SYMPTOM DIAGNOSIS ............................56

COMBINATION SWITCH SYSTEM SYMP-

TOMS .............................................................. ...

56

Symptom Table .................................................... ...56

PRECAUTION ............................................57

PRECAUTIONS .............................................. ...57

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" .............................................................. ...

57

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ..................................

57

ON-VEHICLE REPAIR ...............................59

BCM (BODY CONTROL MODULE) ............... ...59

Removal and Installation .........................................59

Revision: April 20092010 QX56

Page 400 of 4210

![INFINITI QX56 2010 Factory Service Manual BCS-14

< FUNCTION DIAGNOSIS >[BCM]

POWER CONSUMPTION CONTROL SYSTEM

Sleep condition

Wake-up operation

• BCM transmits sleep wake up signal (wake up) to each unit when any condition listed below is e INFINITI QX56 2010 Factory Service Manual BCS-14

< FUNCTION DIAGNOSIS >[BCM]

POWER CONSUMPTION CONTROL SYSTEM

Sleep condition

Wake-up operation

• BCM transmits sleep wake up signal (wake up) to each unit when any condition listed below is e](/img/42/57032/w960_57032-399.png)

BCS-14

< FUNCTION DIAGNOSIS >[BCM]

POWER CONSUMPTION CONTROL SYSTEM

Sleep condition

Wake-up operation

• BCM transmits sleep wake up signal (wake up) to each unit when any condition listed below is established,

and then goes into normal mode from low power consumption mode.

• Each unit starts transmissions with CAN communication by receiving sleep wake up signals. Each unit trans- mits wake up signals to BCM with CAN communication to convey the start of CAN communication.

Wake-up condition

CAN sleep condition BCM sleep condition

• Receiving the sleep-ready signal (ready) from all units

• Ignition switch: OFF

• Vehicle security system alarm: No operation

• Warning lamp: No operation

• Warning chime: No operation

• Stop lamp switch: OFF

• Key switch status: No change for 2 seconds

• Hazard warning lamp: No operation

•Exterior lamp: OFF

• Door lock status: No change for 2 seconds

• CONSULT-III communication status: No communication

• Door switch status: No change for 2 seconds The controls only BCM are completed.

(Interior room lamp battery saver: Time out etc.)

BCM wake-up condition

• Ignition switch: OFF → ACC or ON

• Stop lamp switch: ON (Depress brake pedal)

• Any door switch: OFF → ON

• Lighting switch: OFF → 1ST or PASS

• Hazard switch: OFF → ON

• Back door opener switch OFF → ON

• Remote keyless entry receiver: Receiving

• Intelligent Key unit: Receiving

Revision: April 20092010 QX56

Page 406 of 4210

![INFINITI QX56 2010 Factory Service Manual BCS-20

< FUNCTION DIAGNOSIS >[BCM]

DIAGNOSIS SYSTEM (BCM)

ACTIVE TEST

MULTIREMOTE ENT

MULTIREMOTE ENT : CONSULT-III Function (BCM - MULTIREMOTE ENT)

INFOID:0000000005146400

WORK SUPPORT

Hazard and hor INFINITI QX56 2010 Factory Service Manual BCS-20

< FUNCTION DIAGNOSIS >[BCM]

DIAGNOSIS SYSTEM (BCM)

ACTIVE TEST

MULTIREMOTE ENT

MULTIREMOTE ENT : CONSULT-III Function (BCM - MULTIREMOTE ENT)

INFOID:0000000005146400

WORK SUPPORT

Hazard and hor](/img/42/57032/w960_57032-405.png)

BCS-20

< FUNCTION DIAGNOSIS >[BCM]

DIAGNOSIS SYSTEM (BCM)

ACTIVE TEST

MULTIREMOTE ENT

MULTIREMOTE ENT : CONSULT-III Function (BCM - MULTIREMOTE ENT)

INFOID:0000000005146400

WORK SUPPORT

Hazard and horn reminder mode

CDL LOCK SW [ON/OFF]

Lock switch status input from door lock and unlock switch

CDL UNLOCK SW [ON/OFF] Unlock switch status input from door lock and unlock switch

I-KEY LOCK [ON/OFF] Lock signal status received from Intelligent Key unit by CAN communication

I-KEY UNLOCK [ON/OFF] Unlock signal status received from Intelligen t Key unit by CAN communication

Monitor Item

[Unit] Description

Test Item

Operation Description

IGN ILLUM ON

Outputs the ignition keyhole illumination control signal to turn the ignition keyhole il-

lumination lamp ON.

OFF Stops the ignition keyhole illumination control signal to turn the ignition keyhole illu-

mination lamp OFF.

INT LAMP ON Outputs the interior room lamp control signal to turn the interior room lamps ON.

OFF Stops the interior room lamp control signal to turn the interior room lamps OFF.

STEP LAMP TEST ON Outputs the step lamp control signal to turn the step lamps ON.

OFF Stops the step lamp control signal to turn the step lamps OFF.

LUGGAGE LAMP TEST ON Outputs the luggage lamp control signal to turn the luggage lamp ON.

OFF Stops the luggage lamp control signal to turn the luggage lamp OFF.

Te s t I t e m D e s c r i p t i o n

REMO CONT ID REGIST Keyfob ID code can be registered.

REMO CONT ID ERASUR Keyfob ID code can be erased.

REMO CONT ID CONFIR It can be checked whether keyfob ID code is registered or not in this mode.

HORN CHIRP SET Horn chirp function mode can be changed in this mode. The function mode will be changed when

"CHANG SETT" on CONSULT- III screen is touched.

HAZARD LAMP SET Hazard lamp function mode can be changed in this mode. The function mode will be changed when

"CHANG SETT" on CONSULT- III screen is touched.

MULTI ANSWER BACK SET Hazard and horn reminder mode can be changed in this mode. The reminder mode will be changed

when “CHANG SETT” on CONSULT-III screen is touched.

AUTO LOCK SET Auto locking function mode can be changed in this mode. The function mode will be changed when

"CHANG SETT" on CONSULT-

III screen is touched.

PANIC ALRM SET Panic alarm operation mode can be changed in this mode. The operation mode will be changed when

"CHANG SETT" on CONSULT-

III screen is touched.

PW DOWN SET Keyless power window down (open) operation mode can be changed in this mode. The operation

mode will be changed when "CHANG SETT" on CONSULT-III screen is touched.

MODE 1

(C mode) MODE 2

(S mode) MODE 3MODE 4MODE 5MODE 6

Keyfob

operation Lock Unlock Lock Unlock Lock Unlock Lock Unlock Lock Unlock Lock Unlock

Hazard warning

lamp flash TwiceOnceTwice — — — TwiceOnceTwice — — Once

Horn sound Once———————Once—Once—

Revision: April 20092010 QX56

Page 431 of 4210

![INFINITI QX56 2010 Factory Service Manual BCS

BCM (BODY CONTROL MODULE)BCS-45

< ECU DIAGNOSIS > [BCM]

C

D

E

F

G H

I

J

K L

B A

O P

N19 V/W

Remote keyless entry

receiver (power sup-

ply) Output OFF Ignition switch OFF

20 G/W Remote keyless ent INFINITI QX56 2010 Factory Service Manual BCS

BCM (BODY CONTROL MODULE)BCS-45

< ECU DIAGNOSIS > [BCM]

C

D

E

F

G H

I

J

K L

B A

O P

N19 V/W

Remote keyless entry

receiver (power sup-

ply) Output OFF Ignition switch OFF

20 G/W Remote keyless ent](/img/42/57032/w960_57032-430.png)

BCS

BCM (BODY CONTROL MODULE)BCS-45

< ECU DIAGNOSIS > [BCM]

C

D

E

F

G H

I

J

K L

B A

O P

N19 V/W

Remote keyless entry

receiver (power sup-

ply) Output OFF Ignition switch OFF

20 G/W Remote keyless entry

receiver (signal) Input OFFStand-by (keyfob buttons re-

leased)

When remote keyless entry

receiver receives signal from

keyfob (keyfob buttons

pressed)

21 G NATS antenna amp. Input OFF

→

ON Ignition switch (OFF → ON) Just after turning ignition switch

ON: Pointer of tester should

move for approx. 1 second, then return to battery voltage.

22 W/V BUS — —Ignition switch ON or power

window timer operates

23 G/O Security indicator

lamp Output OFF

Goes OFF

→ illuminates (Ev-

ery 2.4 seconds) Battery voltage

→ 0V

25 BR NATS antenna amp. Input OFF

→

ON Ignition switch (OFF → ON) Just after turning ignition switch

ON: Pointer of tester should

move for approx. 1 second, then return to battery voltage.

26 Y/L Rear wiper auto stop

switch 2 Input ONRise up position (rear wiper

arm on stopper)

0V

A Position (full clockwise stop

position) 0V

Forward sweep (counterclock-

wise direction) Fluctuating

B Position (full counterclock-

wise stop position) Battery voltage

Reverse sweep (clockwise di-

rection) Fluctuating

27 W/R Compressor ON sig-

nal Input ONA/C switch OFF

5V

A/C switch ON 0V

Te r m i n a l

Wire

color Signal name Signal

input/

output Measuring condition

Reference value or waveform

(Approx.)

Ignition

switch Operation or condition

LIIA1893E

LIIA1894E

LIIA1895E

PIIA2344E

Revision: April 20092010 QX56

Page 433 of 4210

![INFINITI QX56 2010 Factory Service Manual BCS

BCM (BODY CONTROL MODULE)BCS-47

< ECU DIAGNOSIS > [BCM]

C

D

E

F

G H

I

J

K L

B A

O P

N44 O

Rear wiper auto stop

switch 1 Input ONRise up position (rear wiper

arm on stopper)

0V

A Position (full c INFINITI QX56 2010 Factory Service Manual BCS

BCM (BODY CONTROL MODULE)BCS-47

< ECU DIAGNOSIS > [BCM]

C

D

E

F

G H

I

J

K L

B A

O P

N44 O

Rear wiper auto stop

switch 1 Input ONRise up position (rear wiper

arm on stopper)

0V

A Position (full c](/img/42/57032/w960_57032-432.png)

BCS

BCM (BODY CONTROL MODULE)BCS-47

< ECU DIAGNOSIS > [BCM]

C

D

E

F

G H

I

J

K L

B A

O P

N44 O

Rear wiper auto stop

switch 1 Input ONRise up position (rear wiper

arm on stopper)

0V

A Position (full clockwise stop

position) Battery voltage

Forward sweep (counterclock-

wise direction) Fluctuating

B Position (full counterclock-

wise stop position) 0V

Reverse sweep (clockwise di-

rection) Fluctuating

47 SB Front door switch LH Input OFF ON (open)

0V

OFF (closed) Battery voltage

48 R/Y Rear door switch LH Input OFF ON (open)

0V

OFF (closed) Battery voltage

49 R Cargo lamp Output OFFAny door open (ON)

0V

All doors closed (OFF) Battery voltage

51 G/Y Trailer turn signal

(right) Output ON Turn right ON

52 G/B Trailer turn signal (left) Output ON Turn left ON

53 L/W Glass hatch lock actu-

ator

Output OFFGlass hatch switch released

0V

Glass hatch switch pressed Battery voltage

54 Y Rear wiper output cir-

cuit 2 Input ONRise up position (rear wiper

arm on stopper)

0V

A Position (full clockwise stop

position) 0V

Forward sweep (counterclock-

wise direction) 0V

B Position (full counterclock-

wise stop position) Battery voltage

Reverse sweep (clockwise di-

rection) Battery voltage

55 SB Rear wiper output cir-

cuit 1 Output ONOFF

0V

ON Battery voltage

56 R/G Battery saver output Output OFF

30 minutes after ignition

switch is turned OFF 0V

ON — Battery voltage

57 Y/R Battery power supply Input OFF —Battery voltage

Te r m i n a l

Wire

color Signal name Signal

input/

output Measuring condition

Reference value or waveform

(Approx.)

Ignition

switch Operation or condition

SKIA3009J

SKIA3009J

Revision: April 20092010 QX56

Page 614 of 4210

PRECAUTIONSBRM-3

< PRECAUTION >

C

DE

F

G H

I

J

L

M A

B

BRM

N

O P

5. When the repair work is completed, return the ignition switch to the ″LOCK ″ position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of al l control units using CONSULT-III.

Handling Precaution For PlasticsINFOID:0000000005370283

PRECAUTIONS FOR PLASTICS

1. When repairing and painting a portion of the body adjacent to plastic parts, consider their characteristics (influence of hea t and sol-

vent) and remove them if necessary or take suitable measures to protect them.

2. Plastic parts should be repaired and painted using methods suiting the materials

, characteristics.

Abbre-

viation Material name Heat resisting

temperature

°C ( °F) Resistance to gasoline and

solvents Other cautions

PE Polyethylene 60 (140)Gasoline and most solvents are

harmless if applied for a very

short time (wipe up quickly).

Flammable

ABS Acrylonitrile Butadiene Styrene 80 (176) Avoid gasoline and solvents. —

EPM/

EPDM Ethylene Propylene (Diene) co-

polymer

80 (176)Gasoline and most solvents are

harmless if applied for a very

short time (wipe up quickly). Flammable

PS Polystyrene 80 (176) Avoid solvents. Flammable

PVC Poly Vinyl Chloride 80 (176)Gasoline and most solvents are

harmless if applied for a very

short time (wipe up quickly). Poison gas is emitted

when burned.

TPO Thermoplastic Olefine 80 (176) Same as above. Flammable

AAS Acrylonitrile Acrylic Styrene 85 (185) Avoid gasoline and solvents. —

PMMA Poly Methyl Methacrylate 85 (185) Same as above. —

EVAC Ethylene Vinyl Acetate 90 (194) Avoid gasoline and solvents. —

PP Polypropylene 90 (194)Gasoline and most solvents are

harmless if applied for a very

short time (wipe up quickly). Flammable, avoid bat-

tery acid.

PUR Polyurethane 90 (194) Avoid gasoline and solvents. —

UP Unsaturated Polyester 90 (194) Same as above. Flammable

ASA Acrylonitrile Styrene Acrylate 100 (212) Same as above. Flammable

PPE Poly Phenylene Ether 110 (230) Same as above. —

TPU Thermoplastic Urethane 110 (230) Same as above. —

PBT+

PC Poly Butylene Terephthalate +

Polycarbonate

120 (248) Same as above.

Flammable

PC Polycarbonate 120 (248) Same as above. —

POM Poly Oxymethylene 120 (248) Same as above. Avoid battery acid.

PA Polyamide 140 (284) Same as above. Avoid immersing in wa-

ter.

PBT Poly Butylene Terephthalate 140 (284) Same as above. —

PAR Polyarylate 180 (356) Same as above. —

PET Polyester 180 (356) Same as above. —

PEI Polyetherimide 200 (392) Same as above. —

Revision: April 20092010 QX56

Page 783 of 4210

ENGINE COOLING FANCO-19

< ON-VEHICLE REPAIR >

C

DE

F

G H

I

J

K L

M A

CO

NP

O

INSTALLATION

Installation is in the reverse order of removal.

• Install cooling fan with its front mark “F” facing front of engine.

INSPECTION AFTER INSTALLATION

• Check for leaks of the engine coolant. Refer to

CO-10, "Inspection".

• Start and warm up the engine. Visually make sure that there are no leaks of the engine coolant.

Removal and Installati on (Motor Driven Type)INFOID:0000000005149048

REMOVAL

1. Remove the front bumper fascia. Refer to EXT-13, "Removal and Installation".

2. Disconnect the secondary hood release cable.

3. Disconnect harness connector (A) from fan motor.

4. Remove the bolt and remove the fan grille and motor assembly.

INSTALLATION

Installation is in the reverse order of removal.

• Cooling fan is controlled by ECM. For details, refer to EC-36, "

Description".

AWBIA0668ZZ

Revision: April 20092010 QX56