ecm location INFINITI QX56 2010 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2010, Model line: QX56, Model: INFINITI QX56 2010Pages: 4210, PDF Size: 81.91 MB

Page 670 of 4210

CCS-1

CRUISE CONTROL

C

DE

F

G H

I

J

K L

M B

CCS

SECTION CCS

N

P A

CONTENTS

CRUISE CONTROL SYSTEM

BASIC INSPECTION ....... .............................3

DIAGNOSIS AND REPAIR WORKFLOW ..... .....3

Work Flow ........................................................... ......3

INSPECTION AND ADJUSTMENT .....................5

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT .................................................... ......

5

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT : Description ..................................

5

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT : Special Repair Requirement .......

5

LASER BEAM AIMING ADJUSTMENT ................ ......5

LASER BEAM AIMING ADJUSTMENT : Outline

of Laser Beam Aiming Adjustment Procedure ..........

5

LASER BEAM AIMING ADJUSTMENT : Prepara-

tion ...................................................................... ......

5

LASER BEAM AIMING ADJUSTMENT : Setting

up the ICC Target Board ...........................................

6

LASER BEAM AIMING ADJUSTMENT : Sensor

Adjustment ................................................................

7

ACTION TEST ....................................................... ......8

ACTION TEST : ICC System Running Test ..............8

FUNCTION DIAGNOSIS ..............................12

AUTOMATIC SPEED CONTROL DEVICE

(ASCD) ........................................................... ....

12

System Description ............................................. ....12

INTELLIGENT CRUISE CONTROL SYSTEM ....13

System Diagram .................................................. ....13

System Description .................................................13

Component Parts Location ......................................15

Component Description ...........................................16

DIAGNOSIS SYSTEM (ICC SENSOR INTE-

GRATED UNIT) ..................................................

17

Diagnosis Description ......................................... ....17

CONSULT-III Function (ICC) ............................... ....18

COMPONENT DIAGNOSIS .........................22

DTC 11 CONTROL UNIT ..................................22

DTC 11 CONTROL UNIT .................................... ....22

DTC 12 VDC CONTROL UNIT ..........................23

DTC 12 VDC CONTROL UNIT ................................23

DTC 20 CAN COMM CIRCUIT ..........................24

DTC 20 CAN COMM CIRCUIT ................................24

DTC 31 POWER SUPPLY CIR1, DTC 34

POWER SUPPLY CIR2 .....................................

25

DTC 31 POWER SUPPLY CIR1, DTC 34 POWER

SUPPLY CIR2 .........................................................

25

DTC 41 VHCL SPEED SE CIRC .......................26

DTC 41 VHCL SPEED SE CIRC .............................26

DTC 43 VDC/TCS/ABS CIRC ...........................27

DTC 43 VDC/TCS/ABS CIRC .................................27

DTC 45 BRAKE SW/STOP L SW .....................28

DTC 45 BRAKE SW/STOP L SW ............................28

DTC 46 OPERATION SW CIRC .......................30

DTC 46 OPERATION SW CIRC ......................... ....30

DTC 74 LASER BEAM OFF CNTR ..................32

DTC 74 LASER BEAM OFF CNTR .........................32

DTC 90 STOP LAMP RLY FIX ..........................33

DTC 90 STOP LAMP RLY FIX ................................33

DTC 92 ECM CIRCUIT ......................................38

DTC 92 ECM CIRCUIT ............................................38

DTC 96 NP RANGE ..........................................39

DTC 96 NP RANGE ............................................ ....39

DTC 97 AT CIRCUIT .........................................40

DTC 97 AT CIRCUIT ...............................................40

Revision: April 20092010 QX56

Page 687 of 4210

CCS-18

< FUNCTION DIAGNOSIS >

DIAGNOSIS SYSTEM (ICC SENSOR INTEGRATED UNIT)

ERASING ON BOARD SELF-DIAGNOSIS

1. Stop the vehicle and turn ignition switch OFF.

2. Start engine and start on board self-diagnosis.

3. During on board self-diagnosis, press CANCEL switch 5 times,

and DISTANCE switch 5 times in this order.

NOTE:

• Press them within 10 seconds after pressing CANCEL switch

at first.

• When operation is not completed within 10 seconds, start again from step 2 above.

4. DTC 55 will be shown. NOTE:

DTC of an existing malfunction will not be erased.

5. Turn ignition switch OFF to exit the diagnosis.

CONSULT-III Function (ICC)INFOID:0000000005145984

DESCRIPTION

CONSULT-III can display each diagnostic item us ing the diagnostic test modes shown following.

WORK SUPPORT

Cause of Auto-Cancel Display Item List

×: Applicable

PKIB8373E

Test mode Function

Work Support • Monitors aiming direction to facilitate laser beam aiming operation.

• Indicates causes of automatic cancellation of the ICC system.

Self Diagnostic Result Displays malfunctioning system memorized in ICC sensor integrated unit.

Data Monitor Displays real-time input/output data of ICC sensor integrated unit.

Active Test Enables operation check of electrical loads by sending driving signal to them.

ECU Identification Displays part number of ICC sensor integrated unit.

Work support item Function

CAUSE OF AUTO-CANCEL Indicates causes of automatic cancellation of the ICC system.

LASER BEAM ADJUST Outputs laser beam, calculates dislocation of the beam, and indicates adjustment direction.

For the adjustment procedure, refer to

CCS-5, "

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT : Special Repair Requirement".

Cause of cancellationVehicle-to-vehi-

cle distance

control modeConventional

(fixed speed)

cruise control

mode

Description

OPERATING WIPER ×Windshield wipers were operated at HI or LO speed operation.

OPERATING ABS ×ABS function was operated.

OPERATING TCS ××TCS function was operated.

OPERATING VDC ××VDC function was operated.

OPE SW VOLT CIRC ××Outside the standard control switch input voltage was detected.

ECM CIRCUIT ××ECM did not permit ICC operation.

LASER SUN BEAM ×Intense light such as sunlight entered ICC sensor integrated unit

light sensing part.

LASER TEMP ×Temperature around ICC sensor integrated unit became low.

OP SW DOUBLE TOUCH ××ICC steering switches were pressed at the same time.

WHL SPD ELEC NOISE ××Wheel speed sensor signal caught electromagnetic noise.

Revision: April 20092010 QX56

Page 1354 of 4210

EC-1

ENGINE

C

DE

F

G H

I

J

K L

M

SECTION EC

A

EC

N

O P

CONTENTS

ENGINE CONTROL SYSTEM

VK56DE

BASIC INSPECTION ....... .............................

8

DIAGNOSIS AND REPAIR WORKFLOW ..... .....8

Trouble Diagnosis Introduction ........................... ......8

INSPECTION AND ADJUSTMENT ....................13

Basic Inspection .................................................. ....13

Idle Speed and Ignition Timing Check ....................17

Procedure After Replacing ECM .............................17

VIN Registration ......................................................17

Accelerator Pedal Released Position Learning .......18

Throttle Valve Closed Position Learning .................18

Idle Air Volume Learning .........................................18

FUNCTION DIAGNOSIS ..............................21

ENGINE CONTROL SYSTEM ........................ ....21

System Diagram .................................................. ....21

Engine Control Component Parts Location .............22

MULTIPORT FUEL INJECTION SYSTEM ..... ....28

System Description ............................................. ....28

ELECTRIC IGNITION SYSTEM ..................... ....31

System Description ............................................. ....31

AIR CONDITIONING CUT CONTROL ...............32

Input/Output Signal Chart .................................... ....32

System Description .................................................32

AUTOMATIC SPEED CONTROL DEVICE

(ASCD) ...............................................................

33

System Description ............................................. ....33

Component Description ...........................................34

CAN COMMUNICATION ....................................35

System Description ............................................. ....35

COOLING FAN CONTROL ................................36

Description ..............................................................36

EVAPORATIVE EMISSION SYSTEM ...............37

Description ........................................................... ....37

INTAKE VALVE TIMING CONTROL ................40

Description ...............................................................40

ON BOARD DIAGNOSTIC (OBD) SYSTEM ....41

Introduction ..............................................................41

Two Trip Detection Logic .........................................41

Emission-related Diagnostic Information .................42

Malfunction Indicator Lamp (MIL) ............................55

OBD System Operation Chart .................................58

CONSULT-III Function (ENGINE) ...........................63

Generic Scan Tool (GST) Function .........................72

COMPONENT DIAGNOSIS .........................74

TROUBLE DIAGNOSIS - SPECIFICATION

VALUE ...............................................................

74

Description ........................................................... ....74

Testing Condition .....................................................74

Inspection Procedure ...............................................74

Diagnosis Procedure ...............................................75

POWER SUPPLY AND GROUND CIRCUIT ....82

Diagnosis Procedure ...............................................82

Ground Inspection ...................................................85

U0101 CAN COMM CIRCUIT ...........................86

Description ...............................................................86

On Board Diagnosis Logic .......................................86

DTC Confirmation Procedure ..................................86

Diagnosis Procedure ...............................................86

U1001 CAN COMM CIRCUIT ...........................87

Description ...............................................................87

On Board Diagnosis Logic .......................................87

DTC Confirmation Procedure ..................................87

Diagnosis Procedure ...............................................87

P0011, P0021 IVT CONTROL ...........................88

On Board Diagnosis Logic .......................................88

Revision: April 20092010 QX56

Page 1375 of 4210

![INFINITI QX56 2010 Factory Service Manual EC-22

< FUNCTION DIAGNOSIS >[VK56DE]

ENGINE CONTROL SYSTEM

Engine Control Comp onent Parts Location

INFOID:0000000005149063

1. ECM 2. Battery current sensor 3. Power steering pressure sensor

4. Igniti INFINITI QX56 2010 Factory Service Manual EC-22

< FUNCTION DIAGNOSIS >[VK56DE]

ENGINE CONTROL SYSTEM

Engine Control Comp onent Parts Location

INFOID:0000000005149063

1. ECM 2. Battery current sensor 3. Power steering pressure sensor

4. Igniti](/img/42/57032/w960_57032-1374.png)

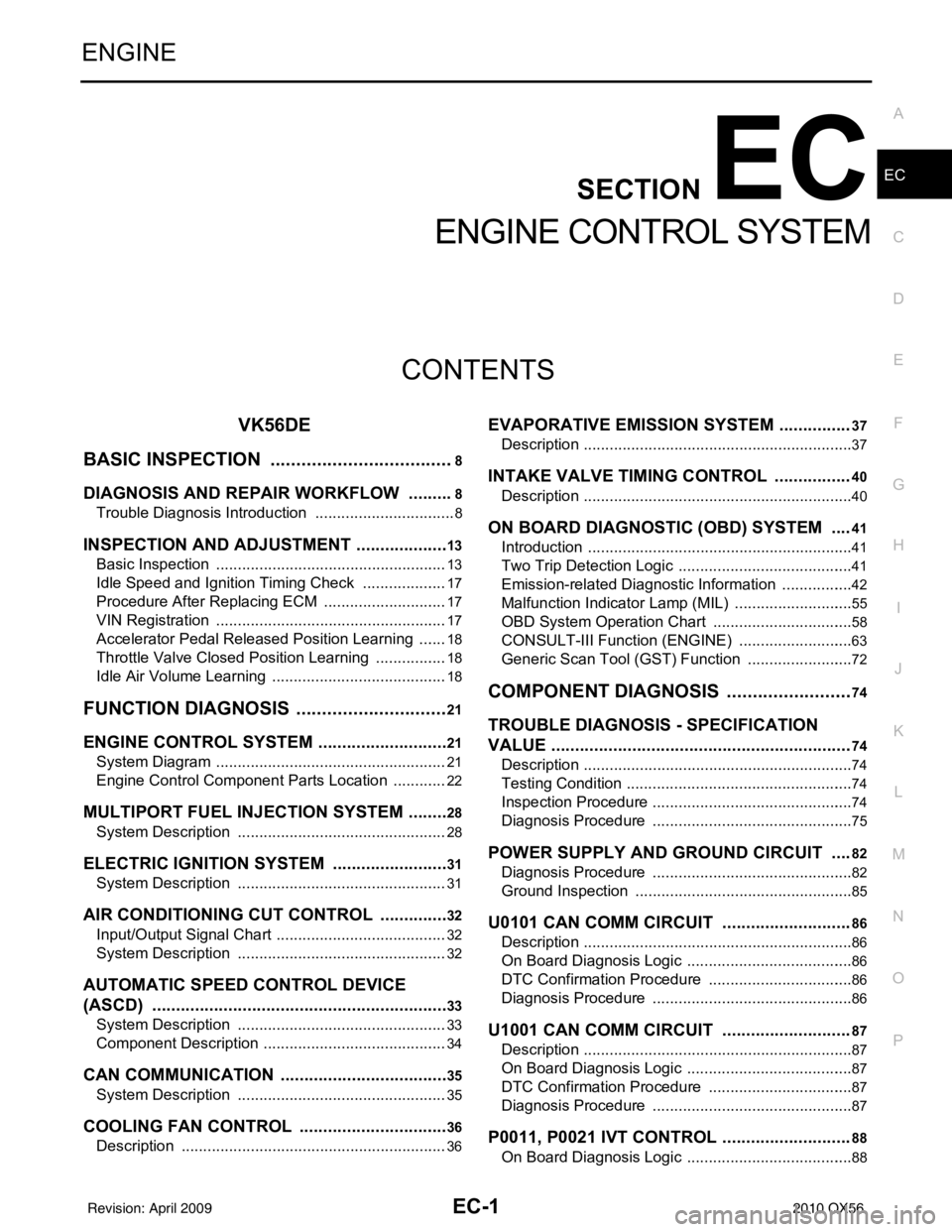

EC-22

< FUNCTION DIAGNOSIS >[VK56DE]

ENGINE CONTROL SYSTEM

Engine Control Comp onent Parts Location

INFOID:0000000005149063

1. ECM 2. Battery current sensor 3. Power steering pressure sensor

4. Ignition coil (with power transistor) and spark plug (bank 2) 5. Refrigerant pressure sensor 6. Intake valve timing control position

sensor (bank 2)

7. Intake valve timing control solenoid valve (bank 2) 8. Engine coolant temperature sensor 9. Electric throttle control actuator

10. Intake valve timing control position sensor (bank 1) 11. Intake valve timing control solenoid

valve (bank 1) 12. Cooling fan motor

13. Camshaft position sensor (PHASE) 14. I gnition coil (with power transistor)

and spark plug (bank 1) 15. Mass air flow sensor (with intake air

temperature sensor)

16. A/F sensor 1 (bank 1) 17. EVAP service port 18. Fuel injector (bank 1)

19. Knock sensor (bank 1) 20. EVAP canister purge volume control

solenoid valve 21. Knock sensor (bank 2)

22. Fuel injector (bank 2) 23. A/F sensor 1 (bank 2) 24. IPDM E/R

BBIA0743E

Revision: April 20092010 QX56

Page 1630 of 4210

![INFINITI QX56 2010 Factory Service Manual P0506 ISC SYSTEMEC-277

< COMPONENT DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

P0506 ISC SYSTEM

DescriptionINFOID:0000000005149303

NOTE:

If DTC P0506 is displayed with ot

her DTC, first perfo INFINITI QX56 2010 Factory Service Manual P0506 ISC SYSTEMEC-277

< COMPONENT DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

P0506 ISC SYSTEM

DescriptionINFOID:0000000005149303

NOTE:

If DTC P0506 is displayed with ot

her DTC, first perfo](/img/42/57032/w960_57032-1629.png)

P0506 ISC SYSTEMEC-277

< COMPONENT DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

P0506 ISC SYSTEM

DescriptionINFOID:0000000005149303

NOTE:

If DTC P0506 is displayed with ot

her DTC, first perform the trouble diagnosis for the other DTC.

The ECM controls the engine idle speed to a specified level through the fine adjustment of the air, which is let

into the intake manifold, by operating the electric thrott le control actuator. The operating of the throttle valve is

varied to allow for optimum control of the engine idli ng speed. The crankshaft position sensor (POS) detects

the actual engine speed and sends a signal to the ECM.

The ECM controls the electric throttle control actuator so that the engine speed coincides with the target value

memorized in the ECM. The target engine speed is the lowest speed at which the engine can operate steadily.

The optimum value stored in the ECM is determined by taking into consideration various engine conditions,

such as during warming up, deceleration, and engine load (air conditioner, power steering and cooling fan

operation, etc.).

On Board Diagnosis LogicINFOID:0000000005149304

DTC Confirmation ProcedureINFOID:0000000005149305

NOTE:

• If DTC Confirmation Procedure has been previously conducted, always perform the following procedure before conducting the next step.

1. Turn ignition switch OFF and wait at least 10 seconds.

2. Turn ignition switch ON.

3. Turn ignition switch OFF and wait at least 10 seconds.

• If the target idle speed is ou t of the specified value, perform EC-18, "

Idle Air Volume Learning",

before conducting DTC Confirmation Procedure. For the target idle speed, refer to the EC-497, "

Idle

Speed and Ignition Timing".

TESTING CONDITION:

• Before performing the following procedure, confirm that battery voltage is more than 11V at idle.

• Always perform the test at a temperature above −10° C (14° F).

1. Open engine hood.

2. Start engine and warm it up to normal operating temperature.

3. Turn ignition switch OFF and wait at least 10 seconds.

4. Start engine and run it for at least 1 minute at idle speed.

5. Check 1st trip DTC.

6. If 1st trip DTC is detected, go to EC-277, "

Diagnosis Procedure".

Diagnosis ProcedureINFOID:0000000005149306

1.CHECK INTAKE AIR LEAK

1. Start engine and let it idle.

2. Listen for an intake air leak after the mass air flow sensor.

OK or NG

OK >> GO TO 2.

NG >> Discover air leak location and repair.

2.REPLACE ECM

1. Stop engine.

2. Replace ECM.

3. Perform initialization of IVIS(NATS) system and registration of all IVIS(NATS) ignition key IDs. Refer to SEC-9, "

ECM RE-COMMUNICATING FUNCTION : Special Repair Requirement".

4. Perform EC-17, "

VIN Registration".

5. Perform EC-18, "

Accelerator Pedal Released Position Learning".

DTC No. Trouble diagnosis name DTC detecting conditionPossible cause

P0506

0506 Idle speed control system

RPM lower than expected The idle speed is less than the target idle speed

by 100 rpm or more. • Electric throttle control actuator

• Intake air leak

Revision: April 20092010 QX56

Page 1632 of 4210

![INFINITI QX56 2010 Factory Service Manual P0507 ISC SYSTEMEC-279

< COMPONENT DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

P0507 ISC SYSTEM

DescriptionINFOID:0000000005149307

NOTE:

If DTC P0507 is displayed with ot

her DTC, first perfo INFINITI QX56 2010 Factory Service Manual P0507 ISC SYSTEMEC-279

< COMPONENT DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

P0507 ISC SYSTEM

DescriptionINFOID:0000000005149307

NOTE:

If DTC P0507 is displayed with ot

her DTC, first perfo](/img/42/57032/w960_57032-1631.png)

P0507 ISC SYSTEMEC-279

< COMPONENT DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

P0507 ISC SYSTEM

DescriptionINFOID:0000000005149307

NOTE:

If DTC P0507 is displayed with ot

her DTC, first perform the trouble diagnosis for the other DTC.

The ECM controls the engine idle speed to a specified level through the fine adjustment of the air, which is let

into the intake manifold, by operating the electric thrott le control actuator. The operating of the throttle valve is

varied to allow for optimum control of the engine idli ng speed. The crankshaft position sensor (POS) detects

the actual engine speed and sends a signal to the ECM.

The ECM controls the electric throttle control actuator so that the engine speed coincides with the target value

memorized in the ECM. The target engine speed is the lowest speed at which the engine can operate steadily.

The optimum value stored in the ECM is determined by taking into consideration various engine conditions,

such as during warming up, deceleration, and engine load (air conditioner, power steering and cooling fan

operation, etc.).

On Board Diagnosis LogicINFOID:0000000005149308

DTC Confirmation ProcedureINFOID:0000000005149309

NOTE:

• If DTC Confirmation Procedure has been previously conducted, always perform the following procedure before conducting the next step.

1. Turn ignition switch OFF and wait at least 10 seconds.

2. Turn ignition switch ON.

3. Turn ignition switch OFF and wait at least 10 seconds.

• If the target idle speed is ou t of the specified value, perform EC-18, "

Idle Air Volume Learning",

before conducting DTC Confirmation Procedure. For the target idle speed, refer to the EC-497, "

Idle

Speed and Ignition Timing".

TESTING CONDITION:

• Before performing the following procedure, confirm that battery voltage is more than 11V at idle.

• Always perform the test at a temperature above −10° C (14° F).

1. Open engine hood.

2. Start engine and warm it up to normal operating temperature.

3. Turn ignition switch OFF and wait at least 10 seconds.

4. Start engine and run it for at least 1 minute at idle speed.

5. Check 1st trip DTC.

6. If 1st trip DTC is detected, go to EC-279, "

Diagnosis Procedure".

Diagnosis ProcedureINFOID:0000000005149310

1.CHECK PCV HOSE CONNECTION

Confirm that PCV hose is connected correctly.

OK or NG

OK >> GO TO 2.

NG >> Repair or replace.

2.CHECK INTAKE AIR LEAK

1. Start engine and let it idle.

2. Listen for an intake air leak after the mass air flow sensor.

OK or NG

OK >> GO TO 3.

NG >> Discover air leak location and repair.

DTC No. Trouble diagnosis name DTC detecting conditionPossible cause

P0507

0507 Idle speed control system

RPM higher than expected The idle speed is more than the target idle

speed by 200 rpm or more. • Electric throttle control actuator

• Intake air leak

• PCV system

Revision: April 20092010 QX56

Page 1691 of 4210

![INFINITI QX56 2010 Factory Service Manual EC-338

< COMPONENT DIAGNOSIS >[VK56DE]

P1572 ICC BRAKE SWITCH

4. Check 1st trip DTC.

5. If 1st trip DTC is detected, go to

EC-338, "

Diagnosis Procedure".

If 1st trip DTC is not detec ted, go to the INFINITI QX56 2010 Factory Service Manual EC-338

< COMPONENT DIAGNOSIS >[VK56DE]

P1572 ICC BRAKE SWITCH

4. Check 1st trip DTC.

5. If 1st trip DTC is detected, go to

EC-338, "

Diagnosis Procedure".

If 1st trip DTC is not detec ted, go to the](/img/42/57032/w960_57032-1690.png)

EC-338

< COMPONENT DIAGNOSIS >[VK56DE]

P1572 ICC BRAKE SWITCH

4. Check 1st trip DTC.

5. If 1st trip DTC is detected, go to

EC-338, "

Diagnosis Procedure".

If 1st trip DTC is not detec ted, go to the following step.

6. Drive the vehicle for at least 5 consecutive seconds under the following conditions.

7. Check 1st trip DTC.

8. If 1st trip DTC is detected, go to EC-338, "

Diagnosis Procedure".

Diagnosis ProcedureINFOID:0000000005149402

1.CHECK OVERALL FUNCTION-I

With CONSULT-III

1. Turn ignition switch ON.

2. Select “BRAKE SW1” in “DAT A MONITOR” mode with CONSULT-III.

3. Check “BRAKE SW1” indication under the following conditions.

Without CONSULT-III

1. Turn ignition switch ON.

2. Check voltage between ECM terminal 108 and ground under the following conditions.

OK or NG

OK >> GO TO 2.

NG >> GO TO 3.

2.CHECK OVERALL FUNCTION-II

With CONSULT-III

Check “BRAKE SW2” indication in “DATA MONITOR” mode.

Without CONSULT-III

VHCL SPEED SE More than 30 km/h (19 MPH)

Selector lever Suitable position

VHCL SPEED SE More than 30 km/h (19 MPH)

Selector lever Suitable position

Driving location Depress the brake pedal for more than

five seconds so as not to come off from

the above-mentioned vehicle speed.

CONDITION

INDICATION

Brake pedal: Slightly depressed OFF

Brake pedal: Fully released ON

CONDITIONVOLTAGE

Brake pedal: Slightly depressed Approximately 0V

Brake pedal: Fully released Battery voltage

MBIB0061E

CONDITIONINDICATION

Brake pedal: Fully released OFF

Brake pedal: Slightly depressed ON

Revision: April 20092010 QX56

Page 1698 of 4210

![INFINITI QX56 2010 Factory Service Manual P1572 ASCD BRAKE SWITCHEC-345

< COMPONENT DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O4. Check 1st trip DTC.

5. If 1st trip DTC is detected, go to

EC-345, "

Diagnosis Procedure".

If 1st trip INFINITI QX56 2010 Factory Service Manual P1572 ASCD BRAKE SWITCHEC-345

< COMPONENT DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O4. Check 1st trip DTC.

5. If 1st trip DTC is detected, go to

EC-345, "

Diagnosis Procedure".

If 1st trip](/img/42/57032/w960_57032-1697.png)

P1572 ASCD BRAKE SWITCHEC-345

< COMPONENT DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O4. Check 1st trip DTC.

5. If 1st trip DTC is detected, go to

EC-345, "

Diagnosis Procedure".

If 1st trip DTC is not detected, go to the following step.

6. Drive the vehicle for at least 5 consecutive seconds under the following condition.

7. Check 1st trip DTC.

8. If 1st trip DTC is detected, go to EC-345, "

Diagnosis Procedure".

Diagnosis ProcedureINFOID:0000000005149407

1.CHECK OVERALL FUNCTION-I

With CONSULT-III

1. Turn ignition switch ON.

2. Select “BRAKE SW1” in “DATA MONITOR” mode with CONSULT-III.

3. Check “BRAKE SW1” indication under the following conditions.

Without CONSULT-III

1. Turn ignition switch ON.

2. Check voltage between ECM terminal 108 and ground under the

following conditions.

OK or NG

OK >> GO TO 2.

NG >> GO TO 3.

2.CHECK OVERALL FUNCTION-II

With CONSULT-III

Check “BRAKE SW2” indication in “DATA MONITOR” mode.

VHCL SPEED SE More than 30 km/h (19 MPH)

Selector lever Suitable position

VHCL SPEED SE More than 30 km/h (19 MPH)

Selector lever Suitable position

Driving location Depress the brake pedal for more than

five seconds so as not to come off from

the above-mentioned condition.

CONDITION

INDICATION

Brake pedal: Slightly depressed OFF

Brake pedal: Fully released ON

CONDITIONVOLTAGE

Brake pedal: Slightly depressed Approximately 0V

Brake pedal: Fully released Battery voltage

MBIB0061E

CONDITIONINDICATION

Brake pedal: Fully released OFF

Brake pedal: Slightly depressed ON

Revision: April 20092010 QX56

Page 1999 of 4210

DIAGNOSIS SYSTEM (IPDM E/R)EXL-23

< FUNCTION DIAGNOSIS >

C

DE

F

G H

I

J

K

M A

B

EXL

N

O P

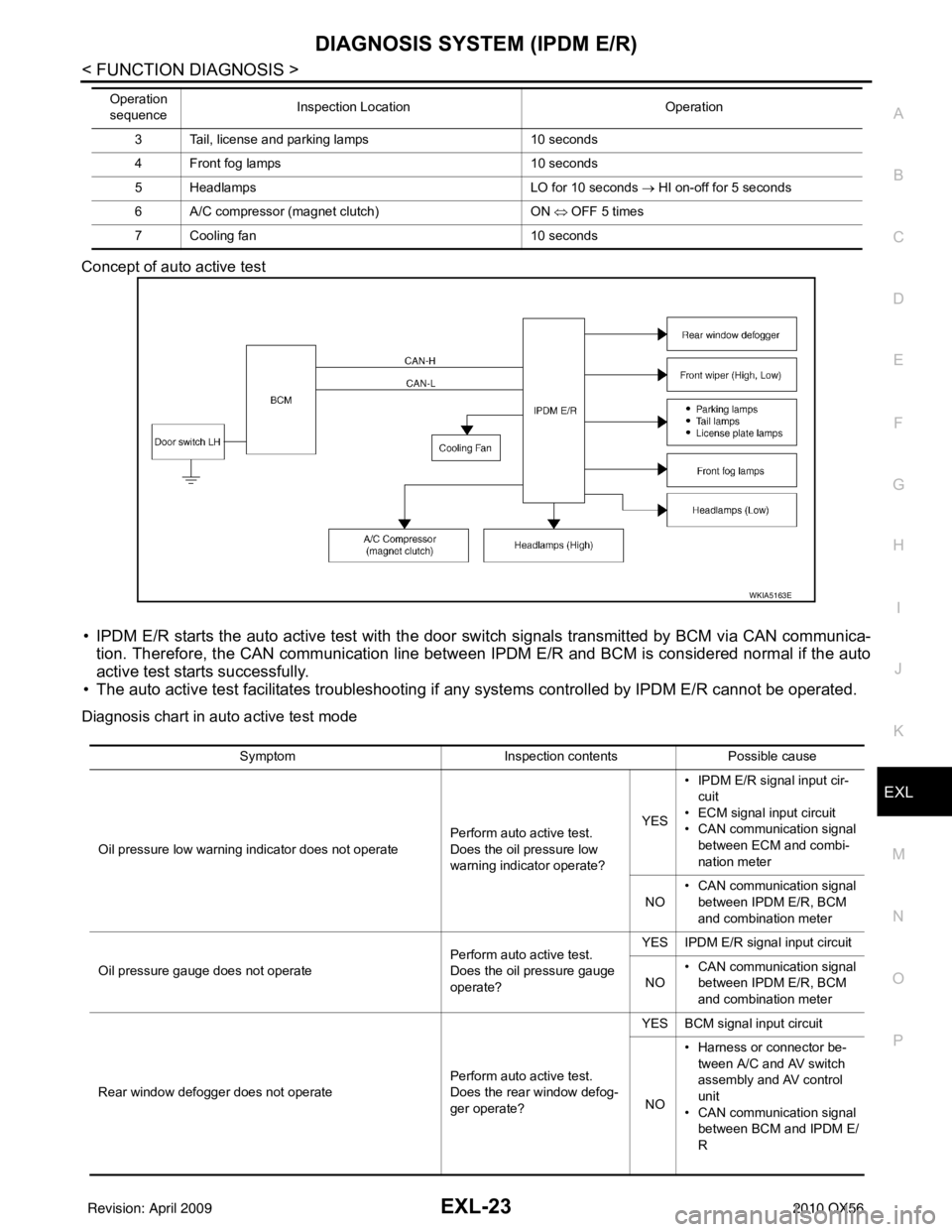

Concept of auto active test

• IPDM E/R starts the auto active test with the door

switch signals transmitted by BCM via CAN communica-

tion. Therefore, the CAN communication line between IPDM E/R and BCM is considered normal if the auto

active test starts successfully.

• The auto active test facilitates troubleshooting if any systems controlled by IPDM E/R cannot be operated.

Diagnosis chart in auto active test mode

3 Tail, license and parking lamps 10 seconds

4 Front fog lamps 10 seconds

5 Headlamps LO for 10 seconds → HI on-off for 5 seconds

6 A/C compressor (magnet clutch) ON ⇔ OFF 5 times

7 Cooling fan 10 seconds

Operation

sequence Inspection Location

Operation

WKIA5163E

SymptomInspection contentsPossible cause

Oil pressure low warning indicator does not operate Perform auto active test.

Does the oil pressure low

warning indicator operate?YES

• IPDM E/R signal input cir-

cuit

• ECM signal input circuit

• CAN communication signal

between ECM and combi-

nation meter

NO • CAN communication signal

between IPDM E/R, BCM

and combination meter

Oil pressure gauge does not operate Perform auto active test.

Does the oil pressure gauge

operate?YES IPDM E/R signal input circuit

NO • CAN communication signal

between IPDM E/R, BCM

and combination meter

Rear window defogger does not operate Perform auto active test.

Does the rear window defog-

ger operate?YES BCM signal input circuit

NO • Harness or connector be-

tween A/C and AV switch

assembly and AV control

unit

• CAN communication signal between BCM and IPDM E/

R

Revision: April 20092010 QX56

Page 2249 of 4210

GI-26

< PRECAUTION >

PRECAUTIONS

• Before starting repairs which do not require battery power:Turn off ignition switch.

Disconnect the negative battery terminal.

• If the battery terminals are disconnected, recorded memory of radio and each control unit is erased.

• To prevent serious burns: Avoid contact with hot metal parts.

Do not remove the radiator cap when the engine is hot.

• Dispose of drained oil or the solvent used for cleaning parts in an appropriate manner.

• Do not attempt to top off the fuel tank after the fuel pump nozzle

shuts off automatically.

Continued refueling may cause fuel overflow, resulting in fuel spray

and possibly a fire.

• Clean all disassembled parts in the designated liquid or solvent prior to inspection or assembly.

• Replace oil seals, gaskets, packings, O-rings, locking washers,

cotter pins, self-locking nuts, etc. with new ones.

• Replace inner and outer races of tapered roller bearings and needle bearings as a set.

• Arrange the disassembled parts in accordance with their assembled locations and sequence.

• Do not touch the terminals of electrical com ponents which use microcomputers (such as ECM).

Static electricity may damage internal electronic components.

• After disconnecting vacuum or air hoses, atta ch a tag to indicate the proper connection.

• Use only the fluids and lubricants specified in this manual.

• Use approved bonding agent, sealants or their equivalents when required.

• Use hand tools, power tools (disassembly only) and recommended special tools where specified for safe and efficient service repairs.

• When repairing the fuel, oil, water, vacuum or exhaust systems, check all affected lines for leaks.

• Before servicing the vehicle: Protect fenders, upholstery and carpeting with appropriate covers.

Take caution that keys, buckles or buttons do not scratch paint.

WARNING:

To prevent ECM from storing the diagnostic tro uble codes, do not carelessly disconnect the harness

connectors which are related to the engine control system and TCM (transmission control module)

SEF289H

SGI233

PBIC0190E

SGI234

Revision: April 20092010 QX56