weight INFINITI QX56 2010 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2010, Model line: QX56, Model: INFINITI QX56 2010Pages: 4210, PDF Size: 81.91 MB

Page 649 of 4210

BRM-38

< SERVICE INFORMATION >

BODY REPAIR

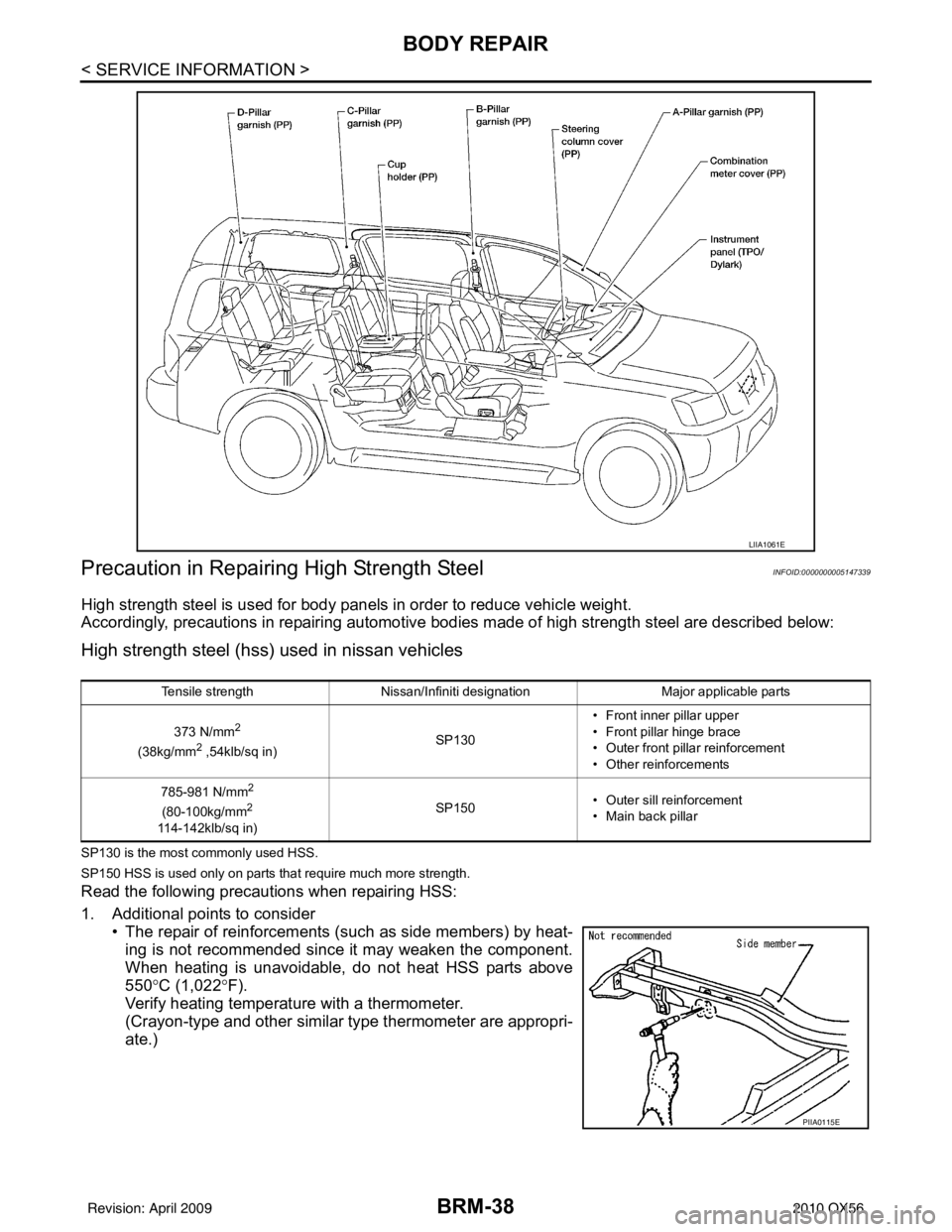

Precaution in Repairing High Strength Steel

INFOID:0000000005147339

High strength steel is used for body panels in order to reduce vehicle weight.

Accordingly, precautions in repairing automotive bodies made of high strength steel are described below:

High strength steel (hss) used in nissan vehicles

SP130 is the most commonly used HSS.

SP150 HSS is used only on parts that require much more strength.

Read the following precautions when repairing HSS:

1. Additional points to consider • The repair of reinforcements (such as side members) by heat-ing is not recommended since it may weaken the component.

When heating is unavoidable, do not heat HSS parts above

550° C (1,022° F).

Verify heating temperature with a thermometer.

(Crayon-type and other similar type thermometer are appropri-

ate.)

LIIA1061E

Tensile strength Nissan/Infiniti designation Major applicable parts

373 N/mm

2

(38kg/mm2 ,54klb/sq in) SP130• Front inner pillar upper

• Front pillar hinge brace

• Outer front pillar reinforcement

• Other reinforcements

785-981 N/mm

2

(80-100kg/mm2

114-142klb/sq in) SP150

• Outer sill reinforcement

• Main back pillar

PIIA0115E

Revision: April 20092010 QX56

Page 675 of 4210

CCS-6

< BASIC INSPECTION >

INSPECTION AND ADJUSTMENT

LASER BEAM AIMING ADJUSTMENT : Setting up the ICC Target Board

INFOID:0000000005145975

CAUTION:

Accuracy in setting up the ICC target board is essential for the laser beam aiming adjustment.

For details, refer to T echnical Service Bulletin.

ADJUSTING HEIGHT OF THE TARGET

1. Attach a triangle scale as shown.

2. Adjust the height of the target stand so that the point of the trian-

gle aims above the center of the ICC sensor.

ADJUSTING THE POSITION OF THE TARGET BOARD STRING

1. Attach a scale or straightedge (at least 350 mm [14 in] orlonger).

2. Suspend a string with a weight on the end 218 mm (8.6 in) to the left side of the target board center.

POSITIONING THE TARGET

1. Suspend a string with weights on each end over the cent erline of the vehicle. The string should lay over

the center of the front and bac k bumpers. Mark these centerpoi nts on the ground at each weight.

WKIA1849E

WKIA2039E

SKIA1211E

WKIA2040E

Revision: April 20092010 QX56

Page 676 of 4210

CCS

INSPECTION AND ADJUSTMENTCCS-7

< BASIC INSPECTION >

C

DE

F

G H

I

J

K L

M B

N P A

2. Connect the two center points using a string. Extend the string an additional 5 m (16 ft) beyond the front centerpoint and mark

the floor. Position the target board weight on this mark.

3. Relocate the suspended string from the left side of the target board to the center of the target board. Mark this point on the ground.

4. Pivot the target board on its center mark 20 ° to either side.

NOTE:

Approx. 50 mm (1.97 in) shift will produce a 20 ° movement.

5. Remove any items in the shaded space shown in the figure.

NOTE:

In case the background space shown in the illustration is not available, or if the background is light col-

ored, place a 400 mm (15.75 in) long frosted black board or black cloth to both sides of the target board.

LASER BEAM AIMING ADJUST MENT : Sensor AdjustmentINFOID:0000000005145976

CAUTION:

Never view ICC sensor unit bod y window directly during laser beam aiming adjustment.

NOTE:

Complete all necessary steps for laser beam adjustm ent until the CONSULT-III indicates "COMPLETED". If

the procedure does not complete , the ICC system is inoperable.

1.SET CONSULT-III TO THE LASER BEAM AIMING ADJUSTMENT MODE

1. Connect CONSULT-III and select "Work Support" of "ICC".

2. Select "LASER BEAM ADJUST".

3. Touch "START".

WKIA1851E

PKIA2589E

WKIA1858E

Revision: April 20092010 QX56

Page 1068 of 4210

![INFINITI QX56 2010 Factory Service Manual DLK-234

< ON-VEHICLE REPAIR >[WITH INTELLIGENT KEY SYSTEM]

HOOD

CLEARANCE AND SURFACE HEIGHT ADJUSTMENT

1. Remove the front grille. Refer to

EXT-17, "Removal and Installation".

2. Remove the hood loc INFINITI QX56 2010 Factory Service Manual DLK-234

< ON-VEHICLE REPAIR >[WITH INTELLIGENT KEY SYSTEM]

HOOD

CLEARANCE AND SURFACE HEIGHT ADJUSTMENT

1. Remove the front grille. Refer to

EXT-17, "Removal and Installation".

2. Remove the hood loc](/img/42/57032/w960_57032-1067.png)

DLK-234

< ON-VEHICLE REPAIR >[WITH INTELLIGENT KEY SYSTEM]

HOOD

CLEARANCE AND SURFACE HEIGHT ADJUSTMENT

1. Remove the front grille. Refer to

EXT-17, "Removal and Installation".

2. Remove the hood lock assembly and adjust the height by rotating the bumper rubber until the hood clear- ance of hood and fender becomes 1 mm (0.04 in) lower than fitting standard dimension.

3. Temporarily tighten the hood lock, and position it by engaging it with the hood striker. Check the lock and striker for looseness, and tighten the lock mounting bolt to the specified torque.

4. Adjust the clearance and surface height of hood and fender according to \

the fitting standard dimension by rotating right and left bumper rubbers.

CAUTION:

Adjust right/left gap between hood and each part to the following specification.

5. Install the front grille. Refer to EXT-17, "

Removal and Installation".

HOOD LOCK ADJUSTMENT

1. Remove the front grille. Refer to EXT-17, "Removal and Installation".

2. Move the hood lock to the left or right so that striker center is vertically aligned with hood lock center (when viewed from vehicle front).

3. Make sure the secondary latch is properly engaged with the sec- ondary striker with hood's own weight by dropping it from

approx. 200 mm (7.87 in) height or by pressing it lightly approx.

3 kg (29 N, 7lb).

CAUTION:

Do not drop the hood from 300 mm (11.81 in) height or

higher.

4. After adjusting hood lock, tighten the lock bolts.

5. Install the front grille. Refer to EXT-17, "

Removal and Installa-

tion".

Removal and Installation of Hood AssemblyINFOID:0000000005147051

1. Support the hood striker with proper material to prevent it from falling.

WARNING:

Body injury may occur if no supporting rod is holding the

hood open when removing the damper stay.

2. Remove the hinge nuts from the hood to remove the hood assembly.

CAUTION:

Operate with two workers, because of its heavy weight.

Installation is in the reverse order of removal. Hood and headlamp (B–B) : 2.0 mm or less

PIIA3806E

LIIA1443E

Revision: April 20092010 QX56

Page 1070 of 4210

![INFINITI QX56 2010 Factory Service Manual DLK-236

< ON-VEHICLE REPAIR >[WITH INTELLIGENT KEY SYSTEM]

HOOD

4. Install the primary and secondary cables securely to the hood

lock assembly.

5. Install the hood lock and the secondary hood lock rel INFINITI QX56 2010 Factory Service Manual DLK-236

< ON-VEHICLE REPAIR >[WITH INTELLIGENT KEY SYSTEM]

HOOD

4. Install the primary and secondary cables securely to the hood

lock assembly.

5. Install the hood lock and the secondary hood lock rel](/img/42/57032/w960_57032-1069.png)

DLK-236

< ON-VEHICLE REPAIR >[WITH INTELLIGENT KEY SYSTEM]

HOOD

4. Install the primary and secondary cables securely to the hood

lock assembly.

5. Install the hood lock and the secondary hood lock release assemblies.

6. Check the hood lock adjustment and hood opener operation. Refer to DLK-233, "

Fitting Adjustment".

7. Install the remaining components in the reverse order of removal.

Hood Lock Control InspectionINFOID:0000000005147053

CAUTION:

If the hood lock cable is bent or deformed, replace it.

1. Remove the front grille. Refer to EXT-17, "

Removal and Installation".

2. Make sure the secondary latch is properly engaged with the sec- ondary striker with hood's own weight by dropping it from

approx. 200 mm (7.87 in) height.

3. While operating the hood opener, carefully make sure the front end of the hood is raised by approx. 20 mm (0.79 in). Also make

sure the hood opener returns to the original position.

4. Check the hood lock lubrication condition. If necessary, apply “body grease” to the points shown in the figure.

5. Install the front grille. Refer to EXT-17, "

Removal and Installa-

tion".

Hood Stay DisposalINFOID:0000000005356855

1. Fix hood stay (1) using a vise (C).

2. Using hacksaw (A) slowly make 2 holes in the hood stay, in numerical order as shown in the figure.

CAUTION:

• When cutting a hole on hood stay, always cover a hack-saw using a shop cloth (B) to avoid scattering metal frag-

ments or oil.

• Wear eye protection (safety glasses).

• Wear gloves.

PIIA0174E

PIIA1086E

PIIA0176E

JMKIA3336ZZ

Revision: April 20092010 QX56

Page 1407 of 4210

![INFINITI QX56 2010 Factory Service Manual EC-54

< FUNCTION DIAGNOSIS >[VK56DE]

ON BOARD DIAGNOSTIC (OBD) SYSTEM

HOW TO ERASE EMISSION-RELATED DIAGNOSTIC INFORMATION

How to Erase DTC

WITH CONSULT-III

• If the ignition switch stays ON after INFINITI QX56 2010 Factory Service Manual EC-54

< FUNCTION DIAGNOSIS >[VK56DE]

ON BOARD DIAGNOSTIC (OBD) SYSTEM

HOW TO ERASE EMISSION-RELATED DIAGNOSTIC INFORMATION

How to Erase DTC

WITH CONSULT-III

• If the ignition switch stays ON after](/img/42/57032/w960_57032-1406.png)

EC-54

< FUNCTION DIAGNOSIS >[VK56DE]

ON BOARD DIAGNOSTIC (OBD) SYSTEM

HOW TO ERASE EMISSION-RELATED DIAGNOSTIC INFORMATION

How to Erase DTC

WITH CONSULT-III

• If the ignition switch stays ON after repair wo rk, be sure to turn ignition switch OFF once.

Wait at least 10 seconds and then tu rn it on (engine stopped) again.

• If the DTC is not for A/T related items (see EC-459, "

DTC Index"), skip step 1.

1. Perform “HOW TO ERASE DTC” in TM-30, "

OBD-II Diagnostic Trouble Code (DTC)". (The DTC in TCM

will be erased)

2. Select “ENGINE” with CONSULT-III.

3. Select “SELF DIAGNOSTIC RESULT”.

MISFIRE A2H No.1 Cylinder Misfire

P0301 0BH 24H

EWMA (Exponential Weighted Moving

Average) misfire counts for last 10 driv-

ing cycles

P0301 0CH 24H Misfire counts for last/current driving cy-

cles

A3H No.2 Cylinder Misfire P0302 0BH 24H

EWMA (Exponential Weighted Moving

Average) misfire counts for last 10 driv-

ing cycles

P0302 0CH 24H Misfire counts for last/current driving cy-

cles

A4H No.3 Cylinder Misfire P0303 0BH 24H

EWMA (Exponential Weighted Moving

Average) misfire counts for last 10 driv-

ing cycles

P0303 0CH 24H Misfire counts for last/current driving cy-

cles

A5H No.4 Cylinder Misfire P0304 0BH 24H

EWMA (Exponential Weighted Moving

Average) misfire counts for last 10 driv-

ing cycles

P0304 0CH 24H Misfire counts for last/current driving cy-

cles

A6H No.5 Cylinder Misfire P0305 0BH 24H

EWMA (Exponential Weighted Moving

Average) misfire counts for last 10 driv-

ing cycles

P0305 0CH 24H Misfire counts for last/current driving cy-

cles

A7H No.6 Cylinder Misfire P0306 0BH 24H

EWMA (Exponential Weighted Moving

Average) misfire counts for last 10 driv-

ing cycles

P0306 0CH 24H Misfire counts for last/current driving cy-

cles

A8H No.7 Cylinder Misfire P0307 0BH 24H

EWMA (Exponential Weighted Moving

Average) misfire counts for last 10 driv-

ing cycles

P0307 0CH 24H Misfire counts for last/current driving cy-

cles

A9H No.8 Cylinder Misfire P0308 0BH 24H

EWMA (Exponential Weighted Moving

Average) misfire counts for last 10 driv-

ing cycles

P0308 0CH 24H Misfire counts for last/current driving cy-

cles

Item

OBD-

MID Self-diagnostic test item

DTCTest value and Test

limit

(GST display) Description

TID Unit and

Scaling ID

Revision: April 20092010 QX56

Page 1575 of 4210

![INFINITI QX56 2010 Factory Service Manual EC-222

< COMPONENT DIAGNOSIS >[VK56DE]

P0442 EVAP CONTROL SYSTEM

2. Does water drain from the EVAP canister?

Ye s o r N o

Yes >> GO TO 10.

No (With CONSULT-III)>>GO TO 12.

No (Without CONSULT-III)>> INFINITI QX56 2010 Factory Service Manual EC-222

< COMPONENT DIAGNOSIS >[VK56DE]

P0442 EVAP CONTROL SYSTEM

2. Does water drain from the EVAP canister?

Ye s o r N o

Yes >> GO TO 10.

No (With CONSULT-III)>>GO TO 12.

No (Without CONSULT-III)>>](/img/42/57032/w960_57032-1574.png)

EC-222

< COMPONENT DIAGNOSIS >[VK56DE]

P0442 EVAP CONTROL SYSTEM

2. Does water drain from the EVAP canister?

Ye s o r N o

Yes >> GO TO 10.

No (With CONSULT-III)>>GO TO 12.

No (Without CONSULT-III)>>GO TO 13.

10.CHECK EVAP CANISTER

Weigh the EVAP canister with the EVAP canister vent control valve and EVAP control system pressure sensor

attached.

The weight should be less than 3.2 kg (7.1 lb).

OK or NG

OK (With CONSULT-III)>>GO TO 12.

OK (Without CONSULT-III)>>GO TO 13.

NG >> GO TO 11.

11 .DETECT MALFUNCTIONING PART

Check the following.

• EVAP canister for damage

• EVAP hose between EVAP canister and vehicle frame for clogging or poor connection

>> Repair hose or replace EVAP canister.

12.CHECK EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE OPERATION

With CONSULT-III

1. Disconnect vacuum hose to EVAP canister purge volume control solenoid valve at EVAP service port.

2. Start engine.

3. Perform “PURG VOL CONT/V ” in “ACTIVE TEST” mode.

4. Touch “Qu” on CONSULT-III screen to increase “PURG VOL CONT/V” opening to 100%.

5. Check vacuum hose for vacuum when revving engine up to 2,000 rpm.

OK or NG

OK >> GO TO 15.

NG >> GO TO 14.

13.CHECK EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE OPERATION

Without CONSULT-III

1. Start engine and warm it up to normal operating temperature.

2. Stop engine.

3. Disconnect vacuum hose to EVAP canister purge volume control solenoid valve at EVAP service port.

4. Start engine and let it idle for at least 80 seconds.

5. Check vacuum hose for vacuum when revving engine up to 2,000 rpm.

OK or NG

OK >> GO TO 16.

NG >> GO TO 14.

14.CHECK VACUUM HOSE

Check vacuum hoses for clogging or disconnection. Refer to EC-37, "

Description".

OK or NG

BBIA0351E

Vacuum should exist.

Vacuum should exist.

Revision: April 20092010 QX56

Page 1582 of 4210

![INFINITI QX56 2010 Factory Service Manual P0443 EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE

EC-229

< COMPONENT DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

2. Check if water will drain from the EVAP canister.

Ye s o r N o

Yes INFINITI QX56 2010 Factory Service Manual P0443 EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE

EC-229

< COMPONENT DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

2. Check if water will drain from the EVAP canister.

Ye s o r N o

Yes](/img/42/57032/w960_57032-1581.png)

P0443 EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE

EC-229

< COMPONENT DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

2. Check if water will drain from the EVAP canister.

Ye s o r N o

Yes >> GO TO 11.

No >> GO TO 13.

11 .CHECK EVAP CANISTER

Weigh the EVAP canister with the EVAP canister vent control valve and EVAP control system pressure sensor

attached.

The weight should be less than 3.2 kg (7.1 lb).

OK or NG

OK >> GO TO 13.

NG >> GO TO 12.

12.DETECT MALFUNCTIONING PART

Check the following.

• EVAP canister for damage

• EVAP hose between EVAP canister and vehi cle frame for clogging or poor connection

>> Repair hose or replace EVAP canister.

13.CHECK INTERMITTENT INCIDENT

Refer to GI-35, "

How to Check Terminal" and GI-38, "Intermittent Incident".

>> INSPECTION END

Component InspectionINFOID:0000000005149246

EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE

With CONSULT-III

Check air passage continuity of EVAP canister purge volume control

solenoid valve under the following conditions.

Without CONSULT-III

BBIA0351E

Condition

(PURG VOL CONT/V value) Air passage continuity

between A and B

100% Yes

0% No

PBIB2058E

Revision: April 20092010 QX56

Page 1593 of 4210

![INFINITI QX56 2010 Factory Service Manual EC-240

< COMPONENT DIAGNOSIS >[VK56DE]

P0448 EVAP CANISTER VENT CONTROL VALVE

Weigh the EVAP canister with the EVAP canister vent

control valve and EVAP control system pressure sensor

attached.

The w INFINITI QX56 2010 Factory Service Manual EC-240

< COMPONENT DIAGNOSIS >[VK56DE]

P0448 EVAP CANISTER VENT CONTROL VALVE

Weigh the EVAP canister with the EVAP canister vent

control valve and EVAP control system pressure sensor

attached.

The w](/img/42/57032/w960_57032-1592.png)

EC-240

< COMPONENT DIAGNOSIS >[VK56DE]

P0448 EVAP CANISTER VENT CONTROL VALVE

Weigh the EVAP canister with the EVAP canister vent

control valve and EVAP control system pressure sensor

attached.

The weight should be less than 3.2 kg (7.1 lb).

OK or NG

OK >> GO TO 6.

NG >> GO TO 5.

5.DETECT MALFUNCTIONING PART

Check the following.

• EVAP canister for damage

• EVAP hose between EVAP canister and vehicle frame for clogging or poor connection

>> Repair hose or replace EVAP canister.

6.CHECK EVAP CONTROL SYSTEM PRESSURE SENSOR CONNECTOR

1. Disconnect EVAP control system pressure sensor harness connector.

2. Check connectors for water.

OK or NG

OK >> GO TO 7.

NG >> Replace EVAP control system pressure sensor.

7.CHECK EVAP CONTROL SY STEM PRESSURE SENSOR

Refer to EC-243, "

Component Inspection".

OK or NG

OK >> GO TO 8.

NG >> Replace EVAP control system pressure sensor.

8.CHECK INTERMITTENT INCIDENT

Refer to GI-35, "

How to Check Terminal" and GI-38, "Intermittent Incident".

>> INSPECTION END

Component InspectionINFOID:0000000005149261

EVAP CANISTER VENT CONTROL VALVE

With CONSULT-III

1. Remove EVAP canister vent control valve from EVAP canister.

2. Check portion B of EVAP canister vent control valve for being

rusted.

If NG, replace EVAP canister vent control valve.

If OK, go to next step.

3. Reconnect harness connectors disconnected.

4. Turn ignition switch ON.

5. Perform “VENT CONTROL/V” in “ACTIVE TEST” mode.

6. Check air passage continuity and operation delay time. Make sure that new O-ring is installed properly.Water should not exist.

PBIB1033E

Revision: April 20092010 QX56

Page 1605 of 4210

![INFINITI QX56 2010 Factory Service Manual EC-252

< COMPONENT DIAGNOSIS >[VK56DE]

P0453 EVAP CONTROL SYSTEM PRESSURE SENSOR

8.DETECT MALFUNCTIONING PART

Check the following.

• Harness connectors C1, E41

• Harness connectors E5, F14

• Har INFINITI QX56 2010 Factory Service Manual EC-252

< COMPONENT DIAGNOSIS >[VK56DE]

P0453 EVAP CONTROL SYSTEM PRESSURE SENSOR

8.DETECT MALFUNCTIONING PART

Check the following.

• Harness connectors C1, E41

• Harness connectors E5, F14

• Har](/img/42/57032/w960_57032-1604.png)

EC-252

< COMPONENT DIAGNOSIS >[VK56DE]

P0453 EVAP CONTROL SYSTEM PRESSURE SENSOR

8.DETECT MALFUNCTIONING PART

Check the following.

• Harness connectors C1, E41

• Harness connectors E5, F14

• Harness for open or short between EVAP control system pressure sensor and ECM

>> Repair open circuit or short to ground or short to power in harness or connectors.

9.CHECK RUBBER TUBE

1. Disconnect rubber tube connected to EV AP canister vent control valve.

2. Check the rubber tube for clogging, vent or kinked.

OK or NG

OK >> GO TO 10.

NG >> Clean the rubber tube using an air blower, repair or replace rubber tube.

10.CHECK EVAP CANISTER VENT CONTROL VALVE

Refer to EC-236, "

Component Inspection".

OK or NG

OK >> GO TO 11.

NG >> Replace EVAP canister vent control valve.

11 .CHECK EVAP CONTROL SYSTEM PRESSURE SENSOR

Refer to EC-253, "

Component Inspection".

OK or NG

OK >> GO TO 12.

NG >> Replace EVAP control system pressure sensor.

12.CHECK IF EVAP CANISTER SATURATED WITH WATER

1. Remove EVAP canister with EVAP canister vent control valve and EVAP control system pressure sensor attached.

2. Check if water will drain from the EVAP canister.

Ye s o r N o

Yes >> GO TO 13.

No >> GO TO 15.

13.CHECK EVAP CANISTER

Weigh the EVAP canister with the EVAP canister vent control valve and EVAP control system pressure sensor

attached.

The weight should be less than 3.2 kg (7.1 lb).

OK or NG

OK >> GO TO 15.

NG >> GO TO 14.

14.DETECT MALFUNCTIONING PART

Check the following.

• EVAP canister for damage

• EVAP hose between EVAP canister and vehicle frame for clogging or poor connection

>> Repair hose or replace EVAP canister.

BBIA0351E

Revision: April 20092010 QX56