weight INFINITI QX56 2010 Factory User Guide

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2010, Model line: QX56, Model: INFINITI QX56 2010Pages: 4210, PDF Size: 81.91 MB

Page 1619 of 4210

![INFINITI QX56 2010 Factory User Guide EC-266

< COMPONENT DIAGNOSIS >[VK56DE]

P0456 EVAP CONTROL SYSTEM

2. Does water drain from the EVAP canister?

Ye s o r N o

Yes >> GO TO 10.

No (With CONSULT-III)>>GO TO 12.

No (Without CONSULT-III)>> INFINITI QX56 2010 Factory User Guide EC-266

< COMPONENT DIAGNOSIS >[VK56DE]

P0456 EVAP CONTROL SYSTEM

2. Does water drain from the EVAP canister?

Ye s o r N o

Yes >> GO TO 10.

No (With CONSULT-III)>>GO TO 12.

No (Without CONSULT-III)>>](/img/42/57032/w960_57032-1618.png)

EC-266

< COMPONENT DIAGNOSIS >[VK56DE]

P0456 EVAP CONTROL SYSTEM

2. Does water drain from the EVAP canister?

Ye s o r N o

Yes >> GO TO 10.

No (With CONSULT-III)>>GO TO 12.

No (Without CONSULT-III)>>GO TO 13.

10.CHECK EVAP CANISTER

Weigh the EVAP canister with the EVAP canister vent control valve and EVAP control system pressure sensor

attached.

The weight should be less than 3.2 kg (7.1 lb).

OK or NG

OK (With CONSULT-III)>>GO TO 12.

OK (Without CONSULT-III)>>GO TO 13.

NG >> GO TO 11.

11 .DETECT MALFUNCTIONING PART

Check the following.

• EVAP canister for damage

• EVAP hose between EVAP canister and vehicle frame for clogging or poor connection

>> Repair hose or replace EVAP canister.

12.CHECK EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE OPERATION

With CONSULT-III

1. Disconnect vacuum hose to EVAP canister purge volume control solenoid valve at EVAP service port.

2. Start engine.

3. Perform “PURG VOL CONT/V ” in “ACTIVE TEST” mode.

4. Touch “Qu” on CONSULT-III screen to increase “PURG VOL CONT/V” opening to 100%.

5. Check vacuum hose for vacuum when revving engine up to 2,000 rpm.

OK or NG

OK >> GO TO 15.

NG >> GO TO 14.

13.CHECK EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE OPERATION

Without CONSULT-III

1. Start engine and warm it up to normal operating temperature.

2. Stop engine.

3. Disconnect vacuum hose to EVAP canister purge volume control solenoid valve at EVAP service port.

4. Start engine and let it idle for at least 80 seconds.

5. Check vacuum hose for vacuum when revving engine up to 2,000 rpm.

OK or NG

OK >> GO TO 16.

NG >> GO TO 14.

14.CHECK VACUUM HOSE

Check vacuum hoses for clogging or disconnection. Refer to EC-37, "

Description".

OK or NG

BBIA0351E

Vacuum should exist.

Vacuum should exist.

Revision: April 20092010 QX56

Page 1765 of 4210

![INFINITI QX56 2010 Factory User Guide EC-412

< COMPONENT DIAGNOSIS >[VK56DE]

ON BOARD REFUELING VAPOR RECOVERY (ORVR)

ON BOARD REFUELING VAPOR RECOVERY (ORVR)

System DescriptionINFOID:0000000005149485

From the beginning of refueling, the INFINITI QX56 2010 Factory User Guide EC-412

< COMPONENT DIAGNOSIS >[VK56DE]

ON BOARD REFUELING VAPOR RECOVERY (ORVR)

ON BOARD REFUELING VAPOR RECOVERY (ORVR)

System DescriptionINFOID:0000000005149485

From the beginning of refueling, the](/img/42/57032/w960_57032-1764.png)

EC-412

< COMPONENT DIAGNOSIS >[VK56DE]

ON BOARD REFUELING VAPOR RECOVERY (ORVR)

ON BOARD REFUELING VAPOR RECOVERY (ORVR)

System DescriptionINFOID:0000000005149485

From the beginning of refueling, the air and vapor insi

de the fuel tank go through refueling EVAP vapor cut

valve and EVAP/ORVR line to the EVAP canister. The vapor is absorbed by the EVAP canister and the air is

released to the atmosphere.

When the refueling has reached the full level of the fuel tank, the refueling EVAP vapor cut valve is closed and

refueling is stopped because of auto shut-off. The vapor which was absorbed by the EVAP canister is purged

during driving.

WARNING:

When conducting inspections below, be sure to observe the following:

• Put a “CAUTION: FLAMMABLE” sign in workshop.

• Do not smoke while servicing fuel system. Keep open flames and sparks away from work area.

• Be sure to furnish the workshop with a CO

2 fire extinguisher.

CAUTION:

• Before removing fuel line parts, carry out the following procedures:

- Put drained fuel in an explosion-pr oof container and put lid on securely.

- Release fuel pressure from fuel line. Refer to EC-489, "

Fuel Pressure Check".

- Disconnect battery ground cable.

• Always replace O-ring when the fu el gauge retainer is removed.

• Do not kink or twist hose and tube when they are installed.

• Do not tighten hose and clamps excessively to avoid damaging hoses.

• After installation, run engine and check for fuel leaks at connection.

• Do not attempt to top off the fuel tank afte r the fuel pump nozzle shuts off automatically.

Continued refueling may cause fuel overflow, r esulting in fuel spray and possibly a fire.

Diagnosis ProcedureINFOID:0000000005149486

SYMPTOM: FUEL ODOR FROM EVAP CANISTER IS STRONG.

1.CHECK EVAP CANISTER

1. Remove EVAP canister with EVAP canister vent control valve and EVAP control system pressure sensor attached.

2. Weigh the EVAP canister with EVAP canister vent control valve and EVAP control system pressure sensor

attached.

The weight should be l ess than 3.2 kg (7.1 lb).

OK or NG

OK >> GO TO 2.

NG >> GO TO 3.

2.CHECK IF EVAP CANISTER SATURATED WITH WATER

PBIB1068E

Revision: April 20092010 QX56

Page 1766 of 4210

![INFINITI QX56 2010 Factory User Guide ON BOARD REFUELING VAPOR RECOVERY (ORVR)EC-413

< COMPONENT DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

Does water drain from

the EVAP canister?

Ye s o r N o

Yes >> GO TO 3.

No >> GO TO 5.

INFINITI QX56 2010 Factory User Guide ON BOARD REFUELING VAPOR RECOVERY (ORVR)EC-413

< COMPONENT DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

Does water drain from

the EVAP canister?

Ye s o r N o

Yes >> GO TO 3.

No >> GO TO 5.](/img/42/57032/w960_57032-1765.png)

ON BOARD REFUELING VAPOR RECOVERY (ORVR)EC-413

< COMPONENT DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

Does water drain from

the EVAP canister?

Ye s o r N o

Yes >> GO TO 3.

No >> GO TO 5.

3.REPLACE EVAP CANISTER

Replace EVAP canister with a new one.

>> GO TO 4.

4.DETECT MALFUNCTIONING PART

Check the EVAP hose between EVAP canister and vehicle frame for clogging or poor connection.

>> Repair or replace EVAP hose.

5.CHECK REFUELING EVAP VAPOR CUT VALVE

Refer to EC-414, "

Component Inspection".

OK or NG

OK >> INSPECTION END

NG >> Replace refueling EVAP vapor cut valve with fuel tank.

SYMPTOM: CANNOT REFUEL/FUEL ODOR FROM THE FUEL FILLER OPENING IS STRONG

WHILE REFUELING.

1.CHECK EVAP CANISTER

1. Remove EVAP canister with EVAP canister vent c ontrol valve and EVAP control system pressure sensor

attached.

2. Weigh the EVAP canister with EVAP canister vent control valve and EVAP control system pressure sensor

attached.

The weight should be l ess than 3.2 kg (7.1 lb).

OK or NG

OK >> GO TO 2.

NG >> GO TO 3.

2.CHECK IF EVAP CANISTER SATURATED WITH WATER

Does water drain from the EVAP canister?

Ye s o r N o

Yes >> GO TO 3.

No >> GO TO 5.

3.REPLACE EVAP CANISTER

Replace EVAP canister with a new one.

>> GO TO 4.

BBIA0351E

BBIA0351E

Revision: April 20092010 QX56

Page 1828 of 4210

![INFINITI QX56 2010 Factory User Guide ECM

EC-475

< ECU DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

HOW TO ERASE EMISSION-RELATED DIAGNOSTIC INFORMATION

How to Erase DTC

WITH CONSULT-III

The emission related diagnostic informatio INFINITI QX56 2010 Factory User Guide ECM

EC-475

< ECU DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

HOW TO ERASE EMISSION-RELATED DIAGNOSTIC INFORMATION

How to Erase DTC

WITH CONSULT-III

The emission related diagnostic informatio](/img/42/57032/w960_57032-1827.png)

ECM

EC-475

< ECU DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

HOW TO ERASE EMISSION-RELATED DIAGNOSTIC INFORMATION

How to Erase DTC

WITH CONSULT-III

The emission related diagnostic information in the ECM can be erased by selecting “All Erase” in the “Descrip-

tion” of “FINAL CHECK” mode with CONSULT-III.

WITH GST

The emission related diagnostic information in the ECM can be erased by selecting Service $04 with GST.

NOTE:

If the DTC is not for A/T related items (see EC-459, "

DTC Index"), skip step 2.

MISFIREA2H No.1 Cylinder Misfire

P0301 0BH 24H

EWMA (Exponential Weighted Moving

Average) misfire counts for last 10 driv-

ing cycles

P0301 0CH 24H Misfire counts for last/current driving cy-

cles

A3H No.2 Cylinder Misfire P0302 0BH 24H

EWMA (Exponential Weighted Moving

Average) misfire counts for last 10 driv-

ing cycles

P0302 0CH 24H Misfire counts for last/current driving cy-

cles

A4H No.3 Cylinder Misfire P0303 0BH 24H

EWMA (Exponential Weighted Moving

Average) misfire counts for last 10 driv-

ing cycles

P0303 0CH 24H Misfire counts for last/current driving cy-

cles

A5H No.4 Cylinder Misfire P0304 0BH 24H

EWMA (Exponential Weighted Moving

Average) misfire counts for last 10 driv-

ing cycles

P0304 0CH 24H Misfire counts for last/current driving cy-

cles

A6H No.5 Cylinder Misfire P0305 0BH 24H

EWMA (Exponential Weighted Moving

Average) misfire counts for last 10 driv-

ing cycles

P0305 0CH 24H Misfire counts for last/current driving cy-

cles

A7H No.6 Cylinder Misfire P0306 0BH 24H

EWMA (Exponential Weighted Moving

Average) misfire counts for last 10 driv-

ing cycles

P0306 0CH 24H Misfire counts for last/current driving cy-

cles

A8H No.7 Cylinder Misfire P0307 0BH 24H

EWMA (Exponential Weighted Moving

Average) misfire counts for last 10 driv-

ing cycles

P0307 0CH 24H Misfire counts for last/current driving cy-

cles

A9H No.8 Cylinder Misfire P0308 0BH 24H

EWMA (Exponential Weighted Moving

Average) misfire counts for last 10 driv-

ing cycles

P0308 0CH 24H Misfire counts for last/current driving cy-

cles

Item

OBD-

MID Self-diagnostic test item

DTCTest value and Test

limit

(GST display) Description

TID Unit and

Scaling ID

Revision: April 20092010 QX56

Page 1832 of 4210

![INFINITI QX56 2010 Factory User Guide ENGINE CONTROL SYSTEM SYMPTOMSEC-479

< SYMPTOM DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

SYMPTOM

Reference

page

HARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

S INFINITI QX56 2010 Factory User Guide ENGINE CONTROL SYSTEM SYMPTOMSEC-479

< SYMPTOM DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

SYMPTOM

Reference

page

HARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

S](/img/42/57032/w960_57032-1831.png)

ENGINE CONTROL SYSTEM SYMPTOMSEC-479

< SYMPTOM DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

SYMPTOM

Reference

page

HARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

SPARK KNOCK/DETONATION

LACK OF POWER/POOR ACCELERATION

HIGH IDLE/LOW IDLE

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEATS/WATER TEMPERATURE HIGH

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

BATTERY DEAD (UNDER CHARGE)

Warranty symptom code AA AB AC AD AE AF AG AH AJ AK AL AM HA

Fuel Fuel tank 5

5 FL-11

Fuel piping

5 5 5 5 55FL-6

Va p o r l o c k —

Valve deposit 5 555 55 5—

Poor fuel (Heavy weight gasoline,

Low octane) —

Air Air duct

55555 5 EM-25

Air cleaner

EM-25

Air leakage from air duct

(Mass air flow sensor — electric

throttle control actuator)

5555 EM-25

Electric throttle control actuator

EM-26

Air leakage from intake manifold/

Collector/GasketEM-26

Cranking Battery

111111

11

PG-74

Generator circuit

CHG-6

Starter circuit3 STR-8

Signal plate6 EM-45

Park/Neutral position (PNP) sig-

nal4

TM-45

Engine Cylinder head

55555 55 5 EM-68

Cylinder head gasket 4 3

Cylinder block

66666 66 64

EM-83

Piston

Piston ring

Connecting rod

Bearing

Crankshaft

Va l v e

mecha-

nism Timing chain

55555 55 5EM-45

Camshaft

EM-53

Intake valve timing controlEM-53

Intake valve

3EM-68

Exhaust valve

Revision: April 20092010 QX56

Page 1931 of 4210

EM-80

< REMOVAL AND INSTALLATION >

ENGINE ASSEMBLY

• Before and during lifting, always check if any harnesses are left connected.

33. Remove the parts that may restrict installation of the engine to the engine stand. NOTE:

This procedure is described assuming that you use an engine stand mounting to the surface to which the

transmission mounts.

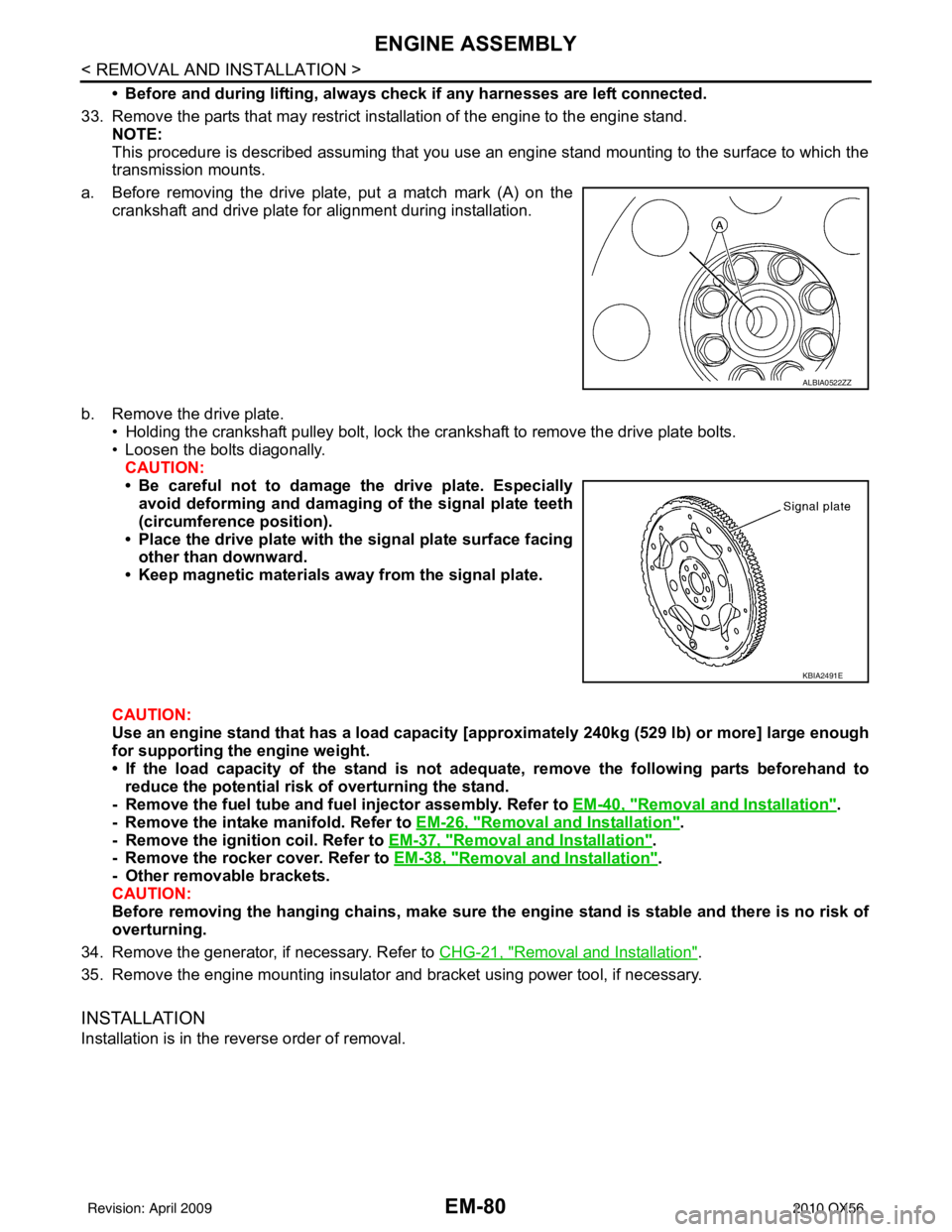

a. Before removing the drive plate, put a match mark (A) on the crankshaft and drive plate for alignment during installation.

b. Remove the drive plate. • Holding the crankshaft pulley bolt, lock the crankshaft to remove the drive plate bolts.

• Loosen the bolts diagonally.CAUTION:

• Be careful not to damage the drive plate. Especiallyavoid deforming and damaging of the signal plate teeth

(circumference position).

• Place the drive plate with th e signal plate surface facing

other than downward.

• Keep magnetic materials away from the signal plate.

CAUTION:

Use an engine stand that has a load capacity [a pproximately 240kg (529 lb) or more] large enough

for supporting the engine weight.

• If the load capacity of the stand is not adeq uate, remove the following parts beforehand to

reduce the potential risk of overturning the stand.

- Remove the fuel tube and fuel injector assembly. Refer to EM-40, "

Removal and Installation".

- Remove the intake manifold. Refer to EM-26, "

Removal and Installation".

- Remove the ignition coil. Refer to EM-37, "

Removal and Installation".

- Remove the rocker cover. Refer to EM-38, "

Removal and Installation".

- Other removable brackets.

CAUTION:

Before removing the hanging chains, make sure th e engine stand is stable and there is no risk of

overturning.

34. Remove the generator, if necessary. Refer to CHG-21, "

Removal and Installation".

35. Remove the engine mounting insulator and bracket using power tool, if necessary.

INSTALLATION

Installation is in the reverse order of removal.

ALBIA0522ZZ

KBIA2491E

Revision: April 20092010 QX56

Page 2121 of 4210

ADJUSTMENT AND INSPECTIONEXL-145

< ON-VEHICLE REPAIR >

C

DE

F

G H

I

J

K

M A

B

EXL

N

O P

ON-VEHICLE REPAIR

ADJUSTMENT AND INSPECTION

HEADLAMP

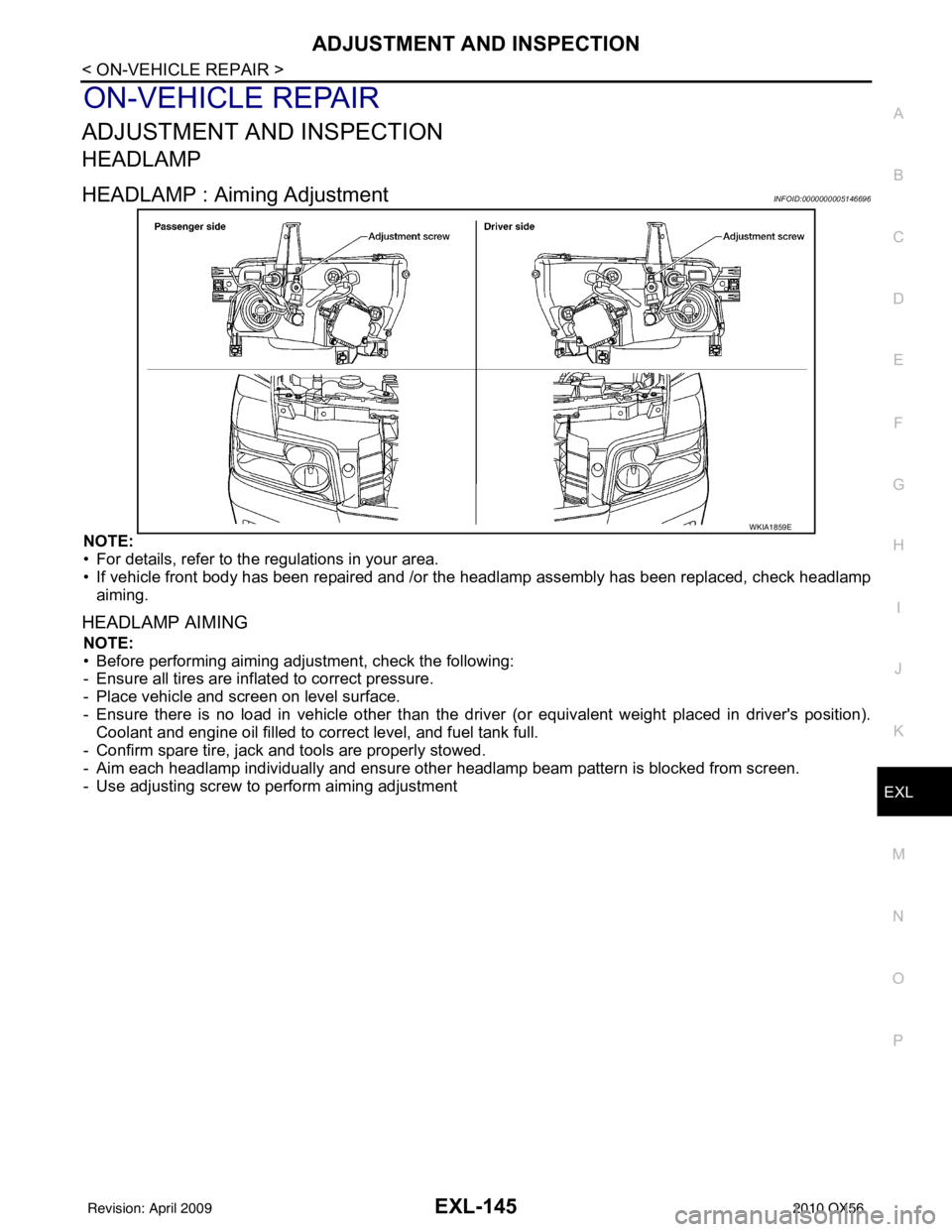

HEADLAMP : Aiming AdjustmentINFOID:0000000005146696

NOTE:

• For details, refer to the regulations in your area.

• If vehicle front body has been repaired and /or the headlamp assembly has been replaced, check headlamp

aiming.

HEADLAMP AIMING

NOTE:

• Before performing aiming adjustment, check the following:

- Ensure all tires are inflated to correct pressure.

- Place vehicle and screen on level surface.

- Ensure there is no load in vehicle other than the driver (or equivalent weight placed in driver's position). Coolant and engine oil filled to correct level, and fuel tank full.

- Confirm spare tire, jack and tools are properly stowed.

- Aim each headlamp individually and ensure other headlamp beam pattern is blocked from screen.

- Use adjusting screw to perform aiming adjustment

WKIA1859E

Revision: April 20092010 QX56

Page 2123 of 4210

ADJUSTMENT AND INSPECTIONEXL-147

< ON-VEHICLE REPAIR >

C

DE

F

G H

I

J

K

M A

B

EXL

N

O P

• See that vehicle is unloaded (except for full levels of coolant, engine oil and fuel, and spare tire, jack, and tools). Have the driver

or equivalent weight placed in driver seat.

Adjust aiming in the vertical direction by turning the adjustment

screw.

NOTE:

Access adjustment screw from underneath front bumper. Turn screw

clockwise to raise pattern and c ounterclockwise to lower pattern.

1. Set the distance between the screen and the center of the fog lamp lens as shown.

2. Turn front fog lamps ON.

3. Adjust front fog lamps using adjusting screw so that the top edge of the high intensity zone is 200 mm (7.9 in) below the height of

the fog lamp centers as shown.

• When performing adjustment, if necessary, cover the head-lamps and opposite fog lamp.

SEL350X

MEL327G

MEL328GA

Revision: April 20092010 QX56

Page 2244 of 4210

IDENTIFICATION INFORMATIONGI-21

< FEATURES OF NEW MODEL >

C

DE

F

G H

I

J

K L

M B

GI

N

O P

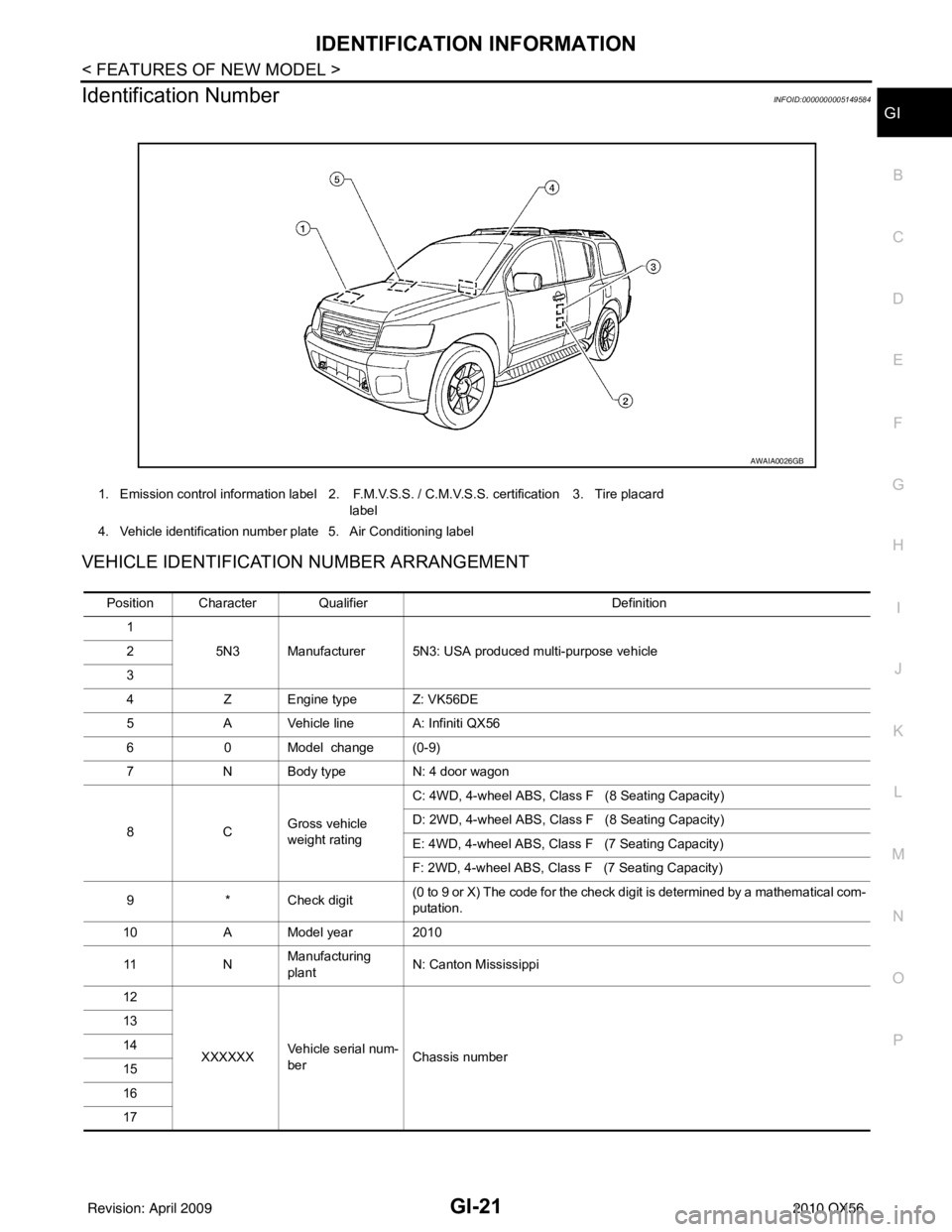

Identification NumberINFOID:0000000005149584

VEHICLE IDENTIFICATION NUMBER ARRANGEMENT

1. Emission control information label 2. F.M.V.S.S. / C.M.V.S.S. certification label3. Tire placard

4. Vehicle identification number plate 5. Air Conditioning label

AWAIA0026GB

Position Character Qualifier Definition

1 5N3 Manufacturer 5N3: USA produced multi-purpose vehicle

2

3

4 Z Engine type Z: VK56DE

5 A Vehicle line A: Infiniti QX56

6 0 Model change (0-9)

7 N Body type N: 4 door wagon

8C Gross vehicle

weight ratingC: 4WD, 4-wheel ABS, Class F (8 Seating Capacity)

D: 2WD, 4-wheel ABS, Class F (8 Seating Capacity)

E: 4WD, 4-wheel ABS, Class F (7 Seating Capacity)

F: 2WD, 4-wheel ABS, Class F (7 Seating Capacity)

9 * Check digit (0 to 9 or X) The code for the check digit is determined by a mathematical com-

putation.

10 A Model year 2010

11 NManufacturing

plant

N: Canton Mississippi

12

XXXXXX Vehicle serial num-

ber Chassis number

13

14

15

16

17

Revision: April 20092010 QX56

Page 2248 of 4210

PRECAUTIONSGI-25

< PRECAUTION >

C

DE

F

G H

I

J

K L

M B

GI

N

O P

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be

rotated.

4. Perform the necessary repair operation.

5. When the repair work is completed, return the ignition switch to the ″LOCK ″ position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of al l control units using CONSULT-III.

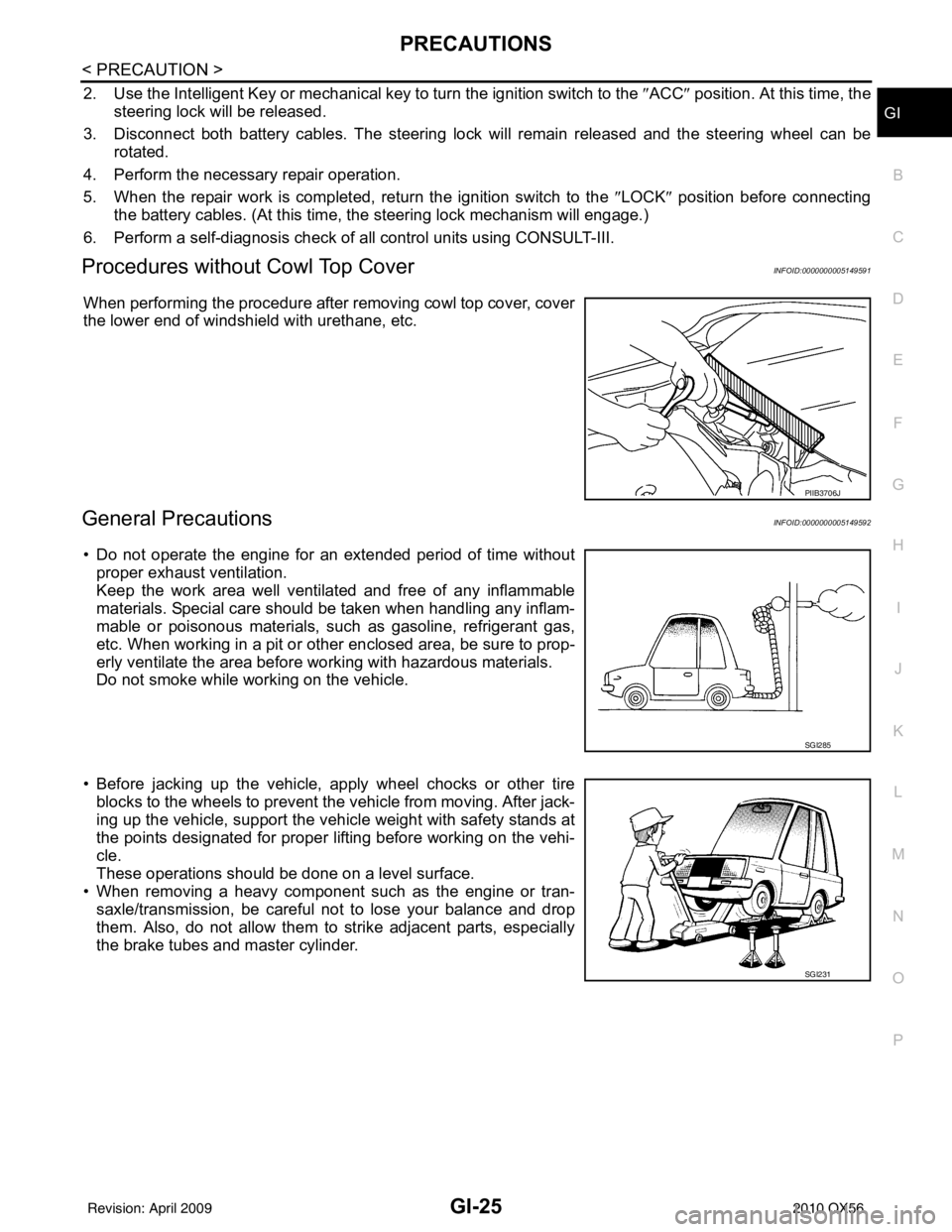

Procedures without Cowl Top CoverINFOID:0000000005149591

When performing the procedure after removing cowl top cover, cover

the lower end of windshield with urethane, etc.

General PrecautionsINFOID:0000000005149592

• Do not operate the engine for an extended period of time without

proper exhaust ventilation.

Keep the work area well ventilated and free of any inflammable

materials. Special care should be taken when handling any inflam-

mable or poisonous materials, such as gasoline, refrigerant gas,

etc. When working in a pit or ot her enclosed area, be sure to prop-

erly ventilate the area before working with hazardous materials.

Do not smoke while working on the vehicle.

• Before jacking up the vehicle, apply wheel chocks or other tire blocks to the wheels to prevent t he vehicle from moving. After jack-

ing up the vehicle, support the vehicle weight with safety stands at

the points designated for proper lifting before working on the vehi-

cle.

These operations should be done on a level surface.

• When removing a heavy component such as the engine or tran-

saxle/transmission, be careful not to lose your balance and drop

them. Also, do not allow them to strike adjacent parts, especially

the brake tubes and master cylinder.

PIIB3706J

SGI285

SGI231

Revision: April 20092010 QX56