Back door INFINITI QX56 2011 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 4633 of 5598

![INFINITI QX56 2011 Factory Service Manual

SEC-26

< SYSTEM DESCRIPTION >[WITH INTELLIGENT KEY SYSTEM]

DIAGNOSIS SYSTEM (BCM)

THEFT ALM

THEFT ALM : CONSULT-III Function (BCM - THEFT)INFOID:0000000006226189

DATA MONITOR

WORK SUPPORT

LOCK INDICA INFINITI QX56 2011 Factory Service Manual

SEC-26

< SYSTEM DESCRIPTION >[WITH INTELLIGENT KEY SYSTEM]

DIAGNOSIS SYSTEM (BCM)

THEFT ALM

THEFT ALM : CONSULT-III Function (BCM - THEFT)INFOID:0000000006226189

DATA MONITOR

WORK SUPPORT

LOCK INDICA](/img/42/57033/w960_57033-4632.png)

SEC-26

< SYSTEM DESCRIPTION >[WITH INTELLIGENT KEY SYSTEM]

DIAGNOSIS SYSTEM (BCM)

THEFT ALM

THEFT ALM : CONSULT-III Function (BCM - THEFT)INFOID:0000000006226189

DATA MONITOR

WORK SUPPORT

LOCK INDICATORThis test is able to check LOCK indicato

r (push-button ignition switch) operation

On: Operate

Off: Non-operation

ACC INDICATOR This test is able to check ACC indicator (push-button ignition switch) operation

On: Operate

Off: Non-operation

IGNITION ON IND This test is able to check ON indicator (push-button ignition switch) operation

On: Operate

Off: Non-operation

HORN This test is able to check horn operation

On: Operate

Off: Non-operation

TRUNK/BACK DOOR NOTE:

This item is displayed, but cannot be used

Test item Description

Monitored Item Description

REQ SW -DR Indicates [ON/OFF] condition of door request switch (driver side).

REQ SW -AS Indicates [ON/OFF] condition of door request switch (passenger side).

REQ SW -RR NOTE:

This item is displayed, but cannot be monitored.

REQ SW -RL NOTE:

This item is displayed, but cannot be monitored.

REQ SW -BD/TR Indicates [ON/OFF] condition of back door request switch.

PUSH SW Indicates [ON/OFF] condition of push-button ignition switch

UNLK SEN -DR Indicates [ON/OFF] condition of driver door UNLOCK status.

DOOR SW-DR Indicates [ON/OFF] condition of front door switch (driver side).

DOOR SW-AS Indicates [ON/OFF] condition of front door switch (passenger side).

DOOR SW-RR Indicates [ON/OFF] condition of rear door switch RH.

DOOR SW-RL Indicates [ON/OFF] condition of rear door switch LH.

DOOR SW-BK Indicates [ON/OFF] condition of back door switch.

CDL LOCK SW Indicates [ON/OFF] condition of lock signal from door lock/unlock switch LH and RH.

CDL UNLOCK SW Indicates [ON/OFF] condition of unlock signal from door lock/unlock switch LH and RH.

KEY CYL LK-SW Indicates [ON/OFF] condition of lock signal from door key cylinder.

KEY CYL UN-SW Indicates [ON/OFF] condition of unlock signal from door key cylinder.

TR/BD OPEN SW Indicates [ON/OFF] condition of back door opener switch.

TRNK/HAT MNTR NOTE:

This item is displayed, but cannot be monitored.

RKE-LOCK Indicates [ON/OFF] condition of LOCK signal from Intelligent Key.

RKE-UNLOCK Indicates [ON/OFF] condition of UNLOCK signal from Intelligent Key.

RKE-TR/BD NOTE:

This item is displayed, but cannot be monitored.

Revision: 2010 May2011 QX56

Page 4770 of 5598

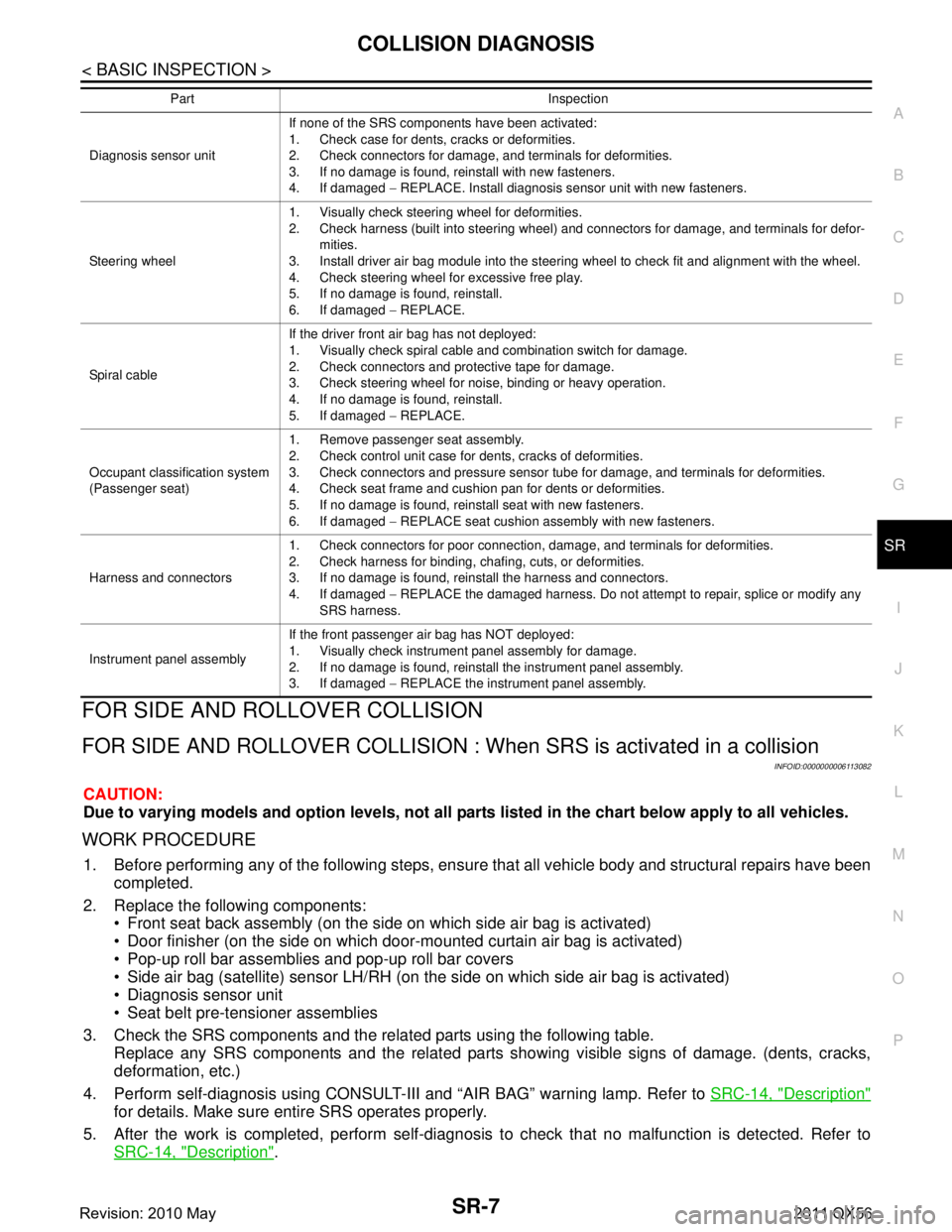

COLLISION DIAGNOSISSR-7

< BASIC INSPECTION >

C

DE

F

G

I

J

K L

M A

B

SR

N

O P

FOR SIDE AND ROLLOVER COLLISION

FOR SIDE AND ROLLOVER CO LLISION : When SRS is activated in a collision

INFOID:0000000006113082

CAUTION:

Due to varying models and option levels, not all parts listed in the chart below apply to all vehicles.

WORK PROCEDURE

1. Before performing any of the following steps, ensur e that all vehicle body and structural repairs have been

completed.

2. Replace the following components: Front seat back assembly (on the side on which side air bag is activated)

Door finisher (on the side on which door-mounted curtain air bag is activated)

Pop-up roll bar assemblies and pop-up roll bar covers

Side air bag (satellite) sensor LH/RH (on the side on which side air bag is activated)

Diagnosis sensor unit

Seat belt pre-tensioner assemblies

3. Check the SRS components and the related parts using the following table. Replace any SRS components and the related parts s howing visible signs of damage. (dents, cracks,

deformation, etc.)

4. Perform self-diagnosis using CONSULT-III and “AIR BAG” warning lamp. Refer to SRC-14, "

Description"

for details. Make sure entire SRS operates properly.

5. After the work is completed, perform self-diagnosis to check that no malfunction is detected. Refer to

SRC-14, "

Description".

Diagnosis sensor unit If none of the SRS components have been activated:

1. Check case for dents, cracks or deformities.

2. Check connectors for damage, and terminals for deformities.

3. If no damage is found, reinstall with new fasteners.

4. If damaged

− REPLACE. Install diagnosis sensor unit with new fasteners.

Steering wheel 1. Visually check steering wheel for deformities.

2. Check harness (built into steering wheel) and connectors for damage, and terminals for defor-

mities.

3. Install driver air bag module into the steering wheel to check fit and alignment with the wheel.

4. Check steering wheel for excessive free play.

5. If no damage is found, reinstall.

6. If damaged − REPLACE.

Spiral cable If the driver front air bag has not deployed:

1. Visually check spiral cable and combination switch for damage.

2. Check connectors and protective tape for damage.

3. Check steering wheel for noise, binding or heavy operation.

4. If no damage is found, reinstall.

5. If damaged

− REPLACE.

Occupant classification system

(Passenger seat) 1. Remove passenger seat assembly.

2. Check control unit case for dents, cracks of deformities.

3. Check connectors and pressure sensor tube for damage, and terminals for deformities.

4. Check seat frame and cushion pan for dents or deformities.

5. If no damage is found, reinstall seat with new fasteners.

6. If damaged

− REPLACE seat cushion assembly with new fasteners.

Harness and connectors 1. Check connectors for poor connection, damage, and terminals for deformities.

2. Check harness for binding, chafing, cuts, or deformities.

3. If no damage is found, reinstall the harness and connectors.

4. If damaged

− REPLACE the damaged harness. Do not attempt to repair, splice or modify any

SRS harness.

Instrument panel assembly If the front passenger air bag has NOT deployed:

1. Visually check instrument panel assembly for damage.

2. If no damage is found, reinstall the instrument panel assembly.

3. If damaged

− REPLACE the instrument panel assembly.

Part Inspection

Revision: 2010 May2011 QX56

Page 4771 of 5598

SR-8

< BASIC INSPECTION >

COLLISION DIAGNOSIS

SRS INSPECTION (FOR SIDE AND ROLLOVER COLLISION)

FOR SIDE AND ROLLOVER COLLISION : When SRS is not activated in a collision

INFOID:0000000006113083

CAUTION:

Due to varying models and option levels, not all part s listed in the chart below apply to all vehicles.

WORK PROCEDURE

1. Before performing any of the following steps, ensur e that all vehicle body and structural repairs have been

completed.

2. Check the SRS components and the related parts using the following table. If the front seat back assembly is damaged, t he front seat back assembly must be replaced.

If the door finisher assembly is damaged, the door finisher assembly and door-mounted curtain air bag

module must be replaced.

3. Perform self-diagnosis using CONSULT-III and “AIR BAG” warning lamp. Refer to SRC-14, "

Description"

for details. Make sure entire SRS operates properly.

4. After the work is completed, perform self-diagnosis to check that no malfunction is detected. Refer to

SRC-14, "

Description".

SRS INSPECTION (FOR SIDE AND ROLLOVER COLLISION)

Part Inspection

Side curtain air bag module LH If the side curtain air bag LH has deployed:

REPLACE the side curtain air bag module LH.

Install with new fasteners.

Side curtain air bag module RH If the side curtain air bag RH has deployed:

REPLACE the side curtain air bag module RH.

Install with new fasteners.

Front side air bag module LH If the front side air bag LH has deployed:

REPLACE front seatback assembly LH.

Front side air bag module RH If the front side air bag RH has deployed:

REPLACE front seatback assembly RH.

Side air bag (satellite) sensor

(LH or RH) If any of the SRS components have deployed:

REPLACE the side air bag (satellite) sensor on the collision side with new fasteners.

Diagnosis sensor unit If any of the SRS components have deployed:

REPLACE the diagnosis sensor unit with new fasteners.

Seat belt pre-tensioner assem-

blies

(All applicable locations: buckle,

retractor, lap outer) If either the driver or passenger seat belt pre-tensioner* has been activated:

REPLACE all seat belt pre-tensioner assemblies with new fasteners.

*: Confirm seat belt pre-tensioner activation using CONSULT-III only.

Center inner pillar 1. Check the center inner pillar on the collision side for damage (dents, cracks, deformation, etc.).

2. If damaged

− REPAIR the center inner pillar.

Trim/headlining 1. Check for visible signs of damage (dents, cracks, deformation, etc.) of the interior trim on the

collision side.

2. If damaged − REPLACE the damaged trim parts.

Door-mounted curtain air bag

module LH If the door-mounted curtain air bag module LH has deployed:

REPLACE the door finisher LH and door-mounted curtain air bag module.

Install with new fasteners.

Door-mounted curtain air bag

module RH If the door-mounted curtain air bag module RH has deployed:

REPLACE the door finisher RH and door-mounted curtain air bag module.

Install with new fasteners.

Pop-up roll bar assemblies If the pop-up roll bar has deployed:

REPLACE pop-up roll bar assemblies and pop-up roll bar covers.

Install with new fasteners.

Revision: 2010 May2011 QX56

Page 4773 of 5598

SR-10

< BASIC INSPECTION >

COLLISION DIAGNOSIS

Trim/headlining1. Check for visible signs of damage (dents, cracks, deformation, etc.) of the interior trim on the

collision side.

2. If damaged − REPLACE the damaged trim parts.

Door-mounted curtain air bag

module LH If the door-mounted curtain air bag LH has NOT deployed:

1. Check for visible signs of damage (dents, tears, deformation, etc.) of the door finisher on the

collision side.

2. If damaged − REPLACE the door finisher LH with new fasteners.

3. Check for visible signs of damaged (tears etc.) of the door-mounted curtain air bag module LH.

4. Check harness and connectors for damage, and terminals for deformities.

5. If no damage is found, reinstall door finisher. CAUTION:

When removing door-mounted curtain air bag module from door finisher, never reuse

door finisher.

6. If damaged − REPLACE the door finisher LH and door-mounted curtain air bag module LH with

new fasteners.

Door-mounted curtain air bag

module RH If the door-mounted curtain air bag RH has NOT deployed:

1. Check for visible signs of damage (dents, tears, deformation, etc.) of the door finisher on the

collision side.

2. If damaged − REPLACE the door finisher RH with new fasteners.

3. Check for visible signs of damage (tears etc.) of the door-mounted curtain air bag module RH.

4. Check harness and connectors for damage, and terminals for deformities.

5. If no damage is found, reinstall door finisher. CAUTION:

When removing door-mounted curtain air bag module from door finisher, never reuse

door finisher.

6. If damaged − REPLACE the door finisher RH and door-mounted curtain air bag module RH with

new fasteners.

Pop-up roll bar If the pop-up roll bar has NOT deployed:

1. Check for visible signs of damage (dents, tears, deformation, etc.) of the pop-up roll bar.

2. If damaged

− REPLACE the pop-up roll bar with new fasteners.

3. Check harness and connectors for damage, and terminals for deformities.

4. If no damage is found, reinstall the pop-up roll bar with new fasteners.

5. Check for visible signs of damage (dents, cracks, deformation, etc.) of the seatback support brace assembly.

6. If damaged − REPAIR the seatback support brace assembly.

Part Inspection

Revision: 2010 May2011 QX56

Page 4969 of 5598

SRC-176

< DTC/CIRCUIT DIAGNOSIS >

B1211 ROLLOVER DETECTION

B1211 ROLLOVER DETECTION

DescriptionINFOID:0000000006220134

The seat belt pre-tensioner, door-mounted curtain air bag and pop-up roll bar are activated by the air bag diag-

nosis sensor unit signal at the time of rollover.

DTC LogicINFOID:0000000006220135

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.CHECK SELF-DIAG RESULT

With CONSULT-III

1. Turn ignition switch ON.

2. Perform “AIR BAG” Self Diagnostic Result.

Without CONSULT-III

1. Turn ignition switch ON.

2. Check the air bag warning lamp status. Refer to SRC-14, "

On Board Diagnosis Function".

NOTE:

SRS does not enter the diagnosis mode if no malfunction is detected in the user mode.

Is malfunctioning part detected?

YES >> Refer to SRC-176, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis ProcedureINFOID:0000000006220136

WARNING:

Before servicing, turn ignition sw itch OFF, disconnect battery negative terminal, and wait at least 3

minutes or more. (To discharge backup capacitor.)

Never use unspecified tester or other measuring device.

1.PERFORM COLLISION DIAGNOSIS

Perform collision diagnosis.Refer to SR-7, "

FOR SIDE AND ROLLOVER COLLISI ON : When SRS is activated

in a collision" or SR-8, "FOR SIDE AND ROLLOVER COLLISION : When SRS is not activated in a collision".

Iscollision diagnosis complete?

YES >> GO TO 2.

NO >> INSPECTION END

2.FINAL INSPECTION

Perform “AIR BAG” Self Diagnostic Result.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Peform diagnosis of applicable DTC.Refer to SRC-22, "

DTCIndex".

DTCDisplay contents of

CONSULT-III DTC detecting condition Possible cause

B1211 ROLLOVER DETECTION Seat belt pre-tensioner and curtain air bag module are

deployed because of rollover detection —

Revision: 2010 May2011 QX56

Page 5423 of 5598

WCS

DIAGNOSIS SYSTEM (BCM)WCS-19

< SYSTEM DESCRIPTION >

C

DE

F

G H

I

J

K L

M B A

O P

DIAGNOSIS SYSTEM (BCM)

COMMON ITEM

COMMON ITEM : CONSULT-III Fu nction (BCM - COMMON ITEM)INFOID:0000000006419721

APPLICATION ITEM

CONSULT-III performs the following functions via CAN communication with BCM.

SYSTEM APPLICATION

BCM can perform the following functions for each system.

NOTE:

It can perform the diagnosis modes except the following for all sub system selection items.

×: Applicable item

*: This item is indicated, but not used.

FREEZE FRAME DATA (FFD)

The BCM records the following vehicle condition at the time a particular DTC is detected, and displays on

CONSULT-III.

Diagnosis mode Function Description

Work Support Changes the setting for each system function.

Self Diagnostic Result Displays the diagnosis results judged by BCM. Refer to BCS-57, "

DTCIndex".

CAN Diag Support Monitor Monitors the reception status of CAN communication viewed from BCM. Refer to CONSULT-III opera-

tion manual.

Data Monitor The BCM input/output signals are displayed.

Active Test The signals used to activate each device are forcibly supplied from BCM.

Ecu Identification The BCM part number is displayed.

Configuration Read and save the vehicle specification.

Write the vehicle specification when replacing BCM.

System Sub system selection item Diagnosis mode

Work Support Data Monitor Active Test

Door lock DOOR LOCK ×××

Rear window defo gger REAR DEFOGGER ××

Warning chime BUZZER ××

Interior room lamp timer INT LAMP ×××

Exterior lamp HEAD LAMP ×××

Wiper and washer WIPER ×××

Turn signal and hazard warning lamps FLASHER ×××

— AIR CONDITONER* ××

Intelligent Key system

Engine start system INTELLIGENT KEY

×××

Combination switch COMB SW ×

Body control system BCM ×

IVIS IMMU ×××

Interior room lamp battery saver BATTERY SAVER ×××

Back door TRUNK ×

Vehicle security system THEFT ALM ×××

RAP system RETAINED PWR ×

Signal buffer system SIGNAL BUFFER ××

Revision: 2010 May2011 QX56

Page 5524 of 5598

COMPONENT PARTSWW-5

< SYSTEM DESCRIPTION >

C

DE

F

G H

I

J

K

M A

B

WW

N

O P

SYSTEM DESCRIPTION

COMPONENT PARTS

Component Parts LocationINFOID:0000000006300448

1. IPDM E/R Refer to PCS-4, "

Component Parts

Location"

2. BCM

Refer to BCS-4, "

BODY CONTROL

SYSTEM : Component Parts Loca-

tion"

3. TCM

Refer to TM-10, "

A/T CONTROL

SYSTEM : Componen t Parts Loca-

tion"

4. Light & rain sensor 5. Combination switch 6. Washer level switch

7. Washer pump 8. Headlamp washer pump 9. Headlamp washer relay

10. Front wiper motor 11. Rear wiper motor

A. Behind front fender protector (RH) B. Engine room (LH) C. Cowl top, left side of engine room

D. Back door finisher inside

JMLIA0976ZZ

Revision: 2010 May2011 QX56

Page 5533 of 5598

WW-14

< SYSTEM DESCRIPTION >

DIAGNOSIS SYSTEM (BCM)

DIAGNOSIS SYSTEM (BCM)

COMMON ITEM

COMMON ITEM : CONSULT-III Function (BCM - COMMON ITEM)INFOID:0000000006349813

APPLICATION ITEM

CONSULT-III performs the following functions via CAN communication with BCM.

SYSTEM APPLICATION

BCM can perform the following functions for each system.

NOTE:

It can perform the diagnosis modes except the following for all sub system selection items.

×: Applicable item

*: This item is indicated, but not used.

FREEZE FRAME DATA (FFD)

The BCM records the following vehicle condition at the time a particular DTC is detected, and displays on

CONSULT-III.

Diagnosis mode Function Description

Work Support Changes the setting for each system function.

Self Diagnostic Result Displays the diagnosis results judged by BCM. Refer to BCS-57, "

DTCIndex".

CAN Diag Support Monitor Monitors the reception status of CAN communication viewed from BCM. Refer to CONSULT-III opera-

tion manual.

Data Monitor The BCM input/output signals are displayed.

Active Test The signals used to activate ea ch device are forcibly supplied from BCM.

Ecu Identification The BCM part number is displayed.

Configuration Read and save the vehicle specification.

Write the vehicle specification when replacing BCM.

System Sub system selection item Diagnosis mode

Work Support Data Monitor Active Test

Door lock DOOR LOCK ×××

Rear window defogger REAR DEFOGGER ××

Warning chime BUZZER ××

Interior room lamp timer INT LAMP ×××

Exterior lamp HEAD LAMP ×××

Wiper and washer WIPER ×××

Turn signal and hazard warning lamps FLASHER ×××

— AIR CONDITONER* ××

Intelligent Key system

Engine start system INTELLIGENT KEY

×××

Combination switch COMB SW ×

Body control system BCM ×

IVIS IMMU ×××

Interior room lamp battery saver BATTERY SAVER ×××

Back door TRUNK ×

Vehicle security system THEFT ALM ×××

RAP system RETAINED PWR ×

Signal buffer system SIGNAL BUFFER ××

Revision: 2010 May2011 QX56

Page 5593 of 5598

WW-74

< REMOVAL AND INSTALLATION >

REAR WIPER ARM

REAR WIPER ARM

Exploded ViewINFOID:0000000006220420

Removal and InstallationINFOID:0000000006220421

REMOVAL

1. Operate rear wiper to the auto stop position.

2. Remove rear wiper arm cover.

3. Remove rear wiper arm mounting nut.

4. Remove wiper arm from the vehicle.

INSTALLATION

1. Clean wiper arm mount as shown in the figure to prevent nutfrom being loosened.

2. Operate the rear wiper motor to the auto stop position.

3. Adjust the rear wiper blade position. Refer to WW-74, "

Adjust-

ment".

4. Install the rear wiper arm by tightening the mounting nut.

5. Inject the washer fluid.

6. Operate the rear wiper to the auto stop position.

7. Check that the rear wiper blades stop at the specified position.

8. Install the rear wiper arm cover.

AdjustmentINFOID:0000000006220422

REAR WIPER BLADE POSITION ADJUSTMENT

Set the wiper blade top on the defrosting wire (A) (c learance between the end of back door glass and the top

of wiper blade center).

1. Rear wiper motor 2. Pivot seal 3. Rear wiper arm

4. Rear wiper arm cover 5. Rear wiper blade

Refer to GI-4, "

Components" for symbols in the figure.

JMLIA0942GB

SKIA0082J

Revision: 2010 May2011 QX56

Page 5595 of 5598

WW-76

< REMOVAL AND INSTALLATION >

REAR WIPER MOTOR

REAR WIPER MOTOR

Exploded ViewINFOID:0000000006220423

Removal and InstallationINFOID:0000000006220424

REMOVAL

1. Remove rear wiper arm. Refer to WW-74, "Removal and Installation".

2. Remove back door finisher inner. Refer to INT-39, "

Removal and Installation".

3. Disconnect rear wiper motor connector.

4. Remove rear wiper motor mounting bolts.

5. Remove rear wiper motor from the vehicle.

6. Remove the pivot seal.

INSTALLATION

Install in the reverse order of removal.

1. Rear wiper motor 2. Pivot seal 3. Rear wiper arm

4. Rear wiper arm cover 5. Rear wiper blade

Refer to GI-4, "

Components" for symbols in the figure.

JMLIA0942GB

Revision: 2010 May2011 QX56