Back door INFINITI QX56 2011 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 3617 of 5598

![INFINITI QX56 2011 Factory Service Manual

LAN

MAIN LINE BETWEEN ADP AND PWBD CIRCUIT

LAN-197

< DTC/CIRCUIT DIAGNOSIS > [CAN SYSTEM (TYPE 4)]

C

D

E

F

G H

I

J

K L

B A

O P

N

MAIN LINE BETWEEN ADP AND PWBD CIRCUIT

Diagnosis ProcedureINFOID:00000 INFINITI QX56 2011 Factory Service Manual

LAN

MAIN LINE BETWEEN ADP AND PWBD CIRCUIT

LAN-197

< DTC/CIRCUIT DIAGNOSIS > [CAN SYSTEM (TYPE 4)]

C

D

E

F

G H

I

J

K L

B A

O P

N

MAIN LINE BETWEEN ADP AND PWBD CIRCUIT

Diagnosis ProcedureINFOID:00000](/img/42/57033/w960_57033-3616.png)

LAN

MAIN LINE BETWEEN ADP AND PWBD CIRCUIT

LAN-197

< DTC/CIRCUIT DIAGNOSIS > [CAN SYSTEM (TYPE 4)]

C

D

E

F

G H

I

J

K L

B A

O P

N

MAIN LINE BETWEEN ADP AND PWBD CIRCUIT

Diagnosis ProcedureINFOID:0000000006256369

1.CHECK HARNESS CONTI

NUITY (OPEN CIRCUIT)

1. Turn the ignition switch OFF.

2. Disconnect the battery cabl e from the negative terminal.

3. Disconnect the following harness connectors.

- CAN gateway

- Harness connectors B460 and B24

- Automatic back door control module

4. Check the continuity between the harness connecto r and the automatic back door control module harness

connector.

Is the inspection result normal?

YES (Present error)>>Check CA N system type decision again.

YES (Past error)>>Error was detected in the main li ne between the driver seat control unit and the automatic

back door control module.

NO >> Repair the main line between the harness c onnector B24 and the automatic back door control

module.

Harness connector Automatic back door control module

harness connector Continuity

Connector No. Terminal No. Connector No. Terminal No.

B24 13

B26 7 Existed

12 6 Existed

Revision: 2010 May2011 QX56

Page 3642 of 5598

![INFINITI QX56 2011 Factory Service Manual

LAN-222

< DTC/CIRCUIT DIAGNOSIS >[CAN SYSTEM (TYPE 4)]

PWBD BRANCH LINE CIRCUIT

PWBD BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000006256393

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

INFINITI QX56 2011 Factory Service Manual

LAN-222

< DTC/CIRCUIT DIAGNOSIS >[CAN SYSTEM (TYPE 4)]

PWBD BRANCH LINE CIRCUIT

PWBD BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000006256393

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.](/img/42/57033/w960_57033-3641.png)

LAN-222

< DTC/CIRCUIT DIAGNOSIS >[CAN SYSTEM (TYPE 4)]

PWBD BRANCH LINE CIRCUIT

PWBD BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000006256393

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. Disconnect the battery cable from the negative terminal.

3. Check the following terminals and connectors fo r damage, bend and loose connection (unit side and con-

nector side).

- Automatic back door control module

- CAN gateway (With ICC system)

Is the inspection result normal?

YES (With ICC system)>>GO TO 2.

YES (Without ICC sy stem)>>GO TO 3.

NO >> Repair the terminal and connector.

2.CHECK HARNESS CONTI NUITY (OPEN CIRCUIT)

1. Disconnect the connector of CAN gateway.

2. Check the continuity between the CA N gateway harness connector terminals.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Check the harness and repair the root cause (CAN communication circuit 2). Refer to LAN-57,

"System Diagram".

3.CHECK HARNESS FOR OPEN CIRCUIT

1. Connect the connector of CAN gateway. (With ICC system)

2. Disconnect the connector of automatic back door control module.

3. Check the resistance between the automatic ba ck door control module harness connector terminals.

Is the measurement value within the specification?

YES >> GO TO 4.

NO >> Repair the automatic back door control module branch line.

4.CHECK POWER SUPPLY AND GROUND CIRCUIT

Check the power supply and the ground circuit of t he automatic back door control module. Refer to DLK-116,

"AUTOMATIC BACK DOOR CONTROL UNIT : Diagnosis Procedure".

Is the inspection result normal?

YES (Present error)>>Replace the automat ic back door control module. Refer to DLK-262, "Removal and

Installation".

YES (Past error)>>Error was detected in the automatic back door control module branch line.

NO >> Repair the power supply and the ground circuit.

CAN gateway harness connector Continuity

Connector No. Terminal No.

M125 46Existed

10 12 Existed

Automatic back door control module harness connector Resistance (Ω)

Connector No. Terminal No.

B26 7 6 Approx. 54 – 66

Revision: 2010 May2011 QX56

Page 3674 of 5598

MA-4

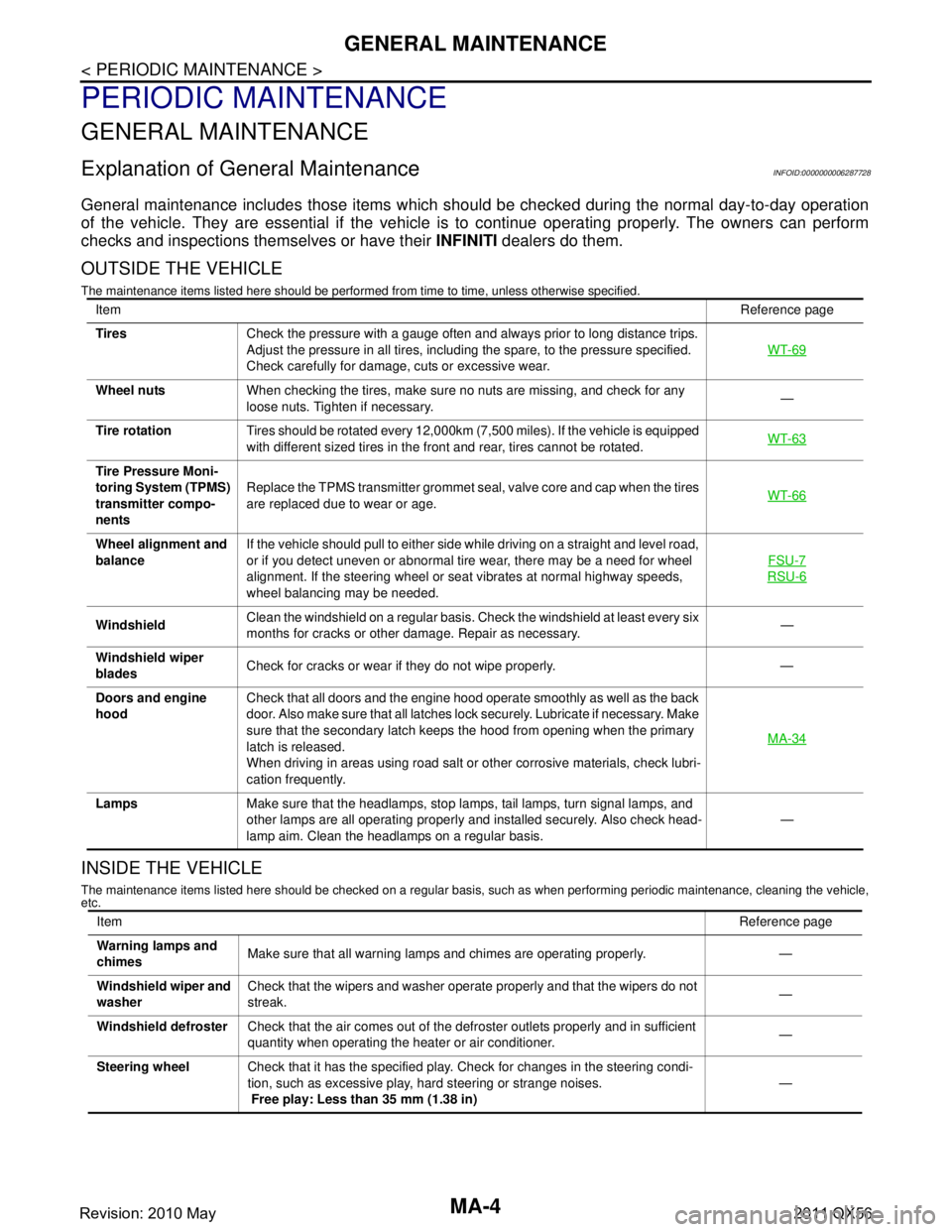

< PERIODIC MAINTENANCE >

GENERAL MAINTENANCE

PERIODIC MAINTENANCE

GENERAL MAINTENANCE

Explanation of General MaintenanceINFOID:0000000006287728

General maintenance includes those items which shoul d be checked during the normal day-to-day operation

of the vehicle. They are essential if the vehicle is to continue operating properly. The owners can perform

checks and inspections themselves or have their INFINITI dealers do them.

OUTSIDE THE VEHICLE

The maintenance items listed here should be performed fr om time to time, unless otherwise specified.

INSIDE THE VEHICLE

The maintenance items listed here should be checked on a regular basis, such as when performing periodic maintenance, cleaning the vehicle,

etc.

Item Reference page

Tires Check the pressure with a gauge often and always prior to long distance trips.

Adjust the pressure in all tires, including the spare, to the pressure specified.

Check carefully for damage, cuts or excessive wear. WT-69

Wheel nuts

When checking the tires, make sure no nuts are missing, and check for any

loose nuts. Tighten if necessary. —

Tire rotation Tires should be rotated every 12,000km (7,500 miles). If the vehicle is equipped

with different sized tires in the front and rear, tires cannot be rotated. WT-63

Tire Pressure Moni-

toring System (TPMS)

transmitter compo-

nentsReplace the TPMS transmitter grommet seal, valve core and cap when the tires

are replaced due to wear or age.

WT-66

Wheel alignment and

balanceIf the vehicle should pull to either side while driving on a straight and level road,

or if you detect uneven or abnormal tire wear, there may be a need for wheel

alignment. If the steering wheel or seat vibrates at normal highway speeds,

wheel balancing may be needed. FSU-7

RSU-6

Windshield

Clean the windshield on a regular basis. Check the windshield at least every six

months for cracks or other damage. Repair as necessary. —

Windshield wiper

blades Check for cracks or wear if they do not wipe properly. —

Doors and engine

hood Check that all doors and the engine hood operate smoothly as well as the back

door. Also make sure that all latches lock securely. Lubricate if necessary. Make

sure that the secondary latch keeps the hood from opening when the primary

latch is released.

When driving in areas using road salt or other corrosive materials, check lubri-

cation frequently. MA-34

Lamps

Make sure that the headlamps, stop lamps, tail lamps, turn signal lamps, and

other lamps are all operating properly and installed securely. Also check head-

lamp aim. Clean the headlamps on a regular basis. —

Item

Reference page

Warning lamps and

chimes Make sure that all warning lamps and chimes are operating properly. —

Windshield wiper and

washer Check that the wipers and washer operate properly and that the wipers do not

streak.

—

Windshield defroster Check that the air comes out of the defroster outlets properly and in sufficient

quantity when operating the heater or air conditioner. —

Steering wheel Check that it has the specified play. Check for changes in the steering condi-

tion, such as excessive play, hard steering or strange noises.

Free play: Less than 35 mm (1.38 in) —

Revision: 2010 May2011 QX56

Page 3704 of 5598

MA-34

< PERIODIC MAINTENANCE >

BODY MAINTENANCE

BODY MAINTENANCE

LOCKS, HINGES AND HOOD LATCH

LOCKS, HINGES AND HOOD LATCH : LubricatingINFOID:0000000006220949

For hood and hood lock illustration.

Hood: Refer to DLK-215, "

Exploded View".

Hood lock: Refer to DLK-238, "

Exploded View".

For front door and front door lock illustration.

Front door: Refer to DLK-224, "

Exploded View".

Front door lock: Refer to DLK-240, "

Exploded View".

For rear door and rear door lock illustration.

Rear door: Refer to DLK-228, "

Exploded View".

Rear door lock: Refer to DLK-243, "

Exploded View".

For back door and back door lock illustration.

Back door: Refer to DLK-232, "

Exploded View".

Back door lock: Refer to DLK-246, "

Exploded View".

SEAT BELT, BUCKLES, RETRACTORS, ANCHORS AND ADJUSTERS

SEAT BELT, BUCKLES, RETRACTORS, ANCHORS AND ADJUSTERS : Inspection

INFOID:0000000006220950

For front seat belt illustration. Refer to SB-6, "SEAT BELT RETRACTOR : Exploded View".

For second seat belt illustration. Refer to SB-11, "

SEAT BELT RETRACTOR : Exploded View".

For third seat belt illustration. Refer to SB-19, "

SEAT BELT RETRACTOR : Exploded View".

CAUTION:

After any collision, inspect all seat belt assembli es, including retractors and other attached hard-

wares (I.e. anchor bolt, guide ra il set). Nissan recommends to replace all seat belt assemblies in use

during a collision, unless not damaged and pr operly operating after minor collision.

Also inspect seat belt assemblies not in use during a collision, and replace if damaged or improperly

operating.

Seat belt pre-tensioner should be replaced even if th e seat belts are not in use during a frontal colli-

sion where the driver and passenger air bags are deployed.

If any component of seat belt assembl y is questionable, do not repair.

Replace as seat belt assembly.

If webbing is cut, frayed, or damaged, replace belt assembly.

Never oil tongue and buckle.

Use a genuine NISSAN seat belt assembly.

For details, refer to SB-4, "

SEAT BELT RETRACTOR : Inspection", SB-10, "SEAT BELT RETRACTOR :

Inspection", SB-17, "SEAT BELT RETRACTOR : Inspection" in SB section.

Check anchors for loose mounting

Check belts for damage

Check retractor for smooth operation

Check function of buckles and tongues when buckled and released

Revision: 2010 May2011 QX56

Page 3740 of 5598

OUTSIDE MIRRORMIR-35

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

K

M A

B

MIR

N

O P

9. Remove fixing screws (A), (B) and then remove power fold unit (2) from bracket (1).

ASSEMBLY

Assemble in the reverse order of disassembly.

GLASS MIRROR

GLASS MIRROR : Removal and InstallationINFOID:0000000006257239

REMOVAL

1. Remove door mirror assembly from front door. Refer to MIR-32, "DOOR MIRROR ASSEMBLY : Removal

and Installation".

2. Remove glass mirror. 1. Place the glass mirror upward.

2. Put a strip of protective tape (B) on housing assembly.

3. As shown in the figure, insert a small flat-bladed screwdriver (A) between glass mirror (1) and actuator (2). Push up both

pawls simultaneously to remove glass mirror lower half side.

NOTE:

Insert flat-bladed screwdriver into recesses, and push up

while rotating (twisting) to make work easier.

4. Remove terminals (A) of mi rror heater attachment from

glass mirror (1) if equipped.

3. Lightly lift up lower side of glass mirror, and detach both pawls of upper side as if pulling it out to disas- semble glass mirror from actuator.

NOTE:

Be careful not to allow grease on sealing agent in center of mirror or back side of glass mirror.

INSTALLATION

Note the following item, and then install in the reverse order n the reverse order of disassembly.

CAUTION:

After installation, visually check that pawls are securely engaged.

DOOR MIRROR COVER

JMLIA0924ZZ

JMLIA0158ZZ

JMLIA0908ZZ

Revision: 2010 May2011 QX56

Page 3878 of 5598

![INFINITI QX56 2011 Factory Service Manual

PCS

SYSTEMPCS-37

< SYSTEM DESCRIPTION > [POWER DISTRIBUTION SYSTEM]

C

D

E

F

G H

I

J

K L

B A

O P

N

SYSTEM

POWER DISTRIBUTION SYSTEM

POWER DISTRIBUTION SYSTEM : System DiagramINFOID:0000000006220196

PO INFINITI QX56 2011 Factory Service Manual

PCS

SYSTEMPCS-37

< SYSTEM DESCRIPTION > [POWER DISTRIBUTION SYSTEM]

C

D

E

F

G H

I

J

K L

B A

O P

N

SYSTEM

POWER DISTRIBUTION SYSTEM

POWER DISTRIBUTION SYSTEM : System DiagramINFOID:0000000006220196

PO](/img/42/57033/w960_57033-3877.png)

PCS

SYSTEMPCS-37

< SYSTEM DESCRIPTION > [POWER DISTRIBUTION SYSTEM]

C

D

E

F

G H

I

J

K L

B A

O P

N

SYSTEM

POWER DISTRIBUTION SYSTEM

POWER DISTRIBUTION SYSTEM : System DiagramINFOID:0000000006220196

POWER DISTRIBUTION SYST

EM : System DescriptionINFOID:0000000006220197

SYSTEM DESCRIPTION

PDS (POWER DISTRIBUTION SYSTEM) is the system that BCM controls with the operation of the push-

button ignition switch and performs the power distributi on to each power circuit. This system is used instead

of the mechanical power supply changing mechanism wit h the operation of the conventional key cylinder.

The push-button ignition switch can be operated when Intelligent Key is in the following condition. Refer to Engine Start Function for details.

- Intelligent Key is in the detection area of the inside key antenna.

- Intelligent Key backside is contact ed to push-button ignition switch.

The push-button ignition switch operation is input to BCM as a signal. BCM changes the power supply posi-

tion according to the status and operates the follo wing relays to supply power to each power circuit.

- Ignition relay (inside IPDM E/R)

- Ignition relay-1

- ACC relay

- Blower relay

NOTE:

The engine switch operation changes due to the conditions of brake pedal, selector lever and vehicle speed.

The power supply position can be confirmed with the light ing of the indicators near the push-button ignition

switch.

BATTERY SAVER SYSTEM

When all the following conditions are met for 60 minutes, the battery saver system will cut off the power supply

to prevent battery discharge.

The ignition switch is in the ACC position

All doors are closed

Selector lever is in the P position

Reset Condition of Battery Saver System

In order to prevent the battery from discharging, the battery saver system will cut off the power supply when all

doors are closed, the selector lever is on P position and t he ignition switch is left on ACC position for 1 hour. If

any of the following conditions are met the battery saver system is released and the steering will change auto-

matically to lock position from OFF position.

Opening any door

Operating with door request switch on door lock

Operating with Intelligent Key on door lock

Press push-button ignition switch and ignition swit ch will change to ACC position from OFF position.

JMMIA0444GB

Revision: 2010 May2011 QX56

Page 3879 of 5598

![INFINITI QX56 2011 Factory Service Manual

PCS-38

< SYSTEM DESCRIPTION >[POWER DISTRIBUTION SYSTEM]

SYSTEM

STEERING LOCK OPERATION

Steering is locked by steering lock unit when ignition switch

is in the OFF position, selector lever is in the INFINITI QX56 2011 Factory Service Manual

PCS-38

< SYSTEM DESCRIPTION >[POWER DISTRIBUTION SYSTEM]

SYSTEM

STEERING LOCK OPERATION

Steering is locked by steering lock unit when ignition switch

is in the OFF position, selector lever is in the](/img/42/57033/w960_57033-3878.png)

PCS-38

< SYSTEM DESCRIPTION >[POWER DISTRIBUTION SYSTEM]

SYSTEM

STEERING LOCK OPERATION

Steering is locked by steering lock unit when ignition switch

is in the OFF position, selector lever is in the P

position and any of the following conditions are met.

Opening door

Closing door

Door is locked with door request switch

Door is locked with Intelligent Key

POWER SUPPLY POSITION CHANGE TABLE BY PUSH-BUTTON IGNITION SWITCH OPERA-

TION

The power supply position changing operation can be performed with the following operations.

NOTE:

When an Intelligent Key is within the detection area of inside key antenna and when Intelligent Key backside

is contacted to push-button ignition switch, it is equivalent to the operations below.

When starting the engine, the BCM monitors under the engine start conditions,

- Brake pedal operating condition

- Selector lever position

- Vehicle speed

Vehicle speed: less than 4 km/h (2.5 MPH)

Vehicle speed: 4 km/h (2.5 MPH) or more

Emergency stop operation

Press and hold the push-button ignition switch for 2 seconds or more.

Press the push-button ignition switch 3 times or more within 1.5 seconds. Power supply position

Engine start/stop condition

Push-button ignition switch

operation frequency

Selector lever position Brake pedal operation condition

LOCK → ACC — Not depressed 1

LOCK → ACC → ON — Not depressed 2

LOCK → ACC → ON →

OFF — Not depressed 3

LOCK → START

ACC → START

ON → START P or N position Depressed 1

Engine is running → OFF — — 1

Power supply position Engine start/stop condition

Push-button ignition switch

operation frequency

Selector lever position Brake pedal operation condition

Engine is running → ACC — — Emergency stop operation

Engine stall return operation

while driving N position Not depressed 1

Revision: 2010 May2011 QX56

Page 3880 of 5598

![INFINITI QX56 2011 Factory Service Manual

PCS

DIAGNOSIS SYSTEM (BCM)PCS-39

< SYSTEM DESCRIPTION > [POWER DISTRIBUTION SYSTEM]

C

D

E

F

G H

I

J

K L

B A

O P

N

DIAGNOSIS SYSTEM (BCM)

COMMON ITEM

COMMON ITEM : CONSULT-III Fu

nction (BCM - COMMON INFINITI QX56 2011 Factory Service Manual

PCS

DIAGNOSIS SYSTEM (BCM)PCS-39

< SYSTEM DESCRIPTION > [POWER DISTRIBUTION SYSTEM]

C

D

E

F

G H

I

J

K L

B A

O P

N

DIAGNOSIS SYSTEM (BCM)

COMMON ITEM

COMMON ITEM : CONSULT-III Fu

nction (BCM - COMMON](/img/42/57033/w960_57033-3879.png)

PCS

DIAGNOSIS SYSTEM (BCM)PCS-39

< SYSTEM DESCRIPTION > [POWER DISTRIBUTION SYSTEM]

C

D

E

F

G H

I

J

K L

B A

O P

N

DIAGNOSIS SYSTEM (BCM)

COMMON ITEM

COMMON ITEM : CONSULT-III Fu

nction (BCM - COMMON ITEM)INFOID:0000000006376369

APPLICATION ITEM

CONSULT-III performs the following functions via CAN communication with BCM.

SYSTEM APPLICATION

BCM can perform the following functions for each system.

NOTE:

It can perform the diagnosis modes except the following for all sub system selection items.

×: Applicable item

*: This item is indicated, but not used.

FREEZE FRAME DATA (FFD)

The BCM records the following vehicle condition at the time a particular DTC is detected, and displays on

CONSULT-III.

Diagnosis mode Function Description

Work Support Changes the setting for each system function.

Self Diagnostic Result Displays the diagnosis results judged by BCM. Refer to BCS-57, "

DTCIndex".

CAN Diag Support Monitor Monitors the reception status of CAN communication viewed from BCM. Refer to CONSULT-III opera-

tion manual.

Data Monitor The BCM input/output signals are displayed.

Active Test The signals used to activate each device are forcibly supplied from BCM.

Ecu Identification The BCM part number is displayed.

Configuration Read and save the vehicle specification.

Write the vehicle specification when replacing BCM.

System Sub system selection item Diagnosis mode

Work Support Data Monitor Active Test

Door lock DOOR LOCK ×××

Rear window defo gger REAR DEFOGGER ××

Warning chime BUZZER ××

Interior room lamp timer INT LAMP ×××

Exterior lamp HEAD LAMP ×××

Wiper and washer WIPER ×××

Turn signal and hazard warning lamps FLASHER ×××

— AIR CONDITONER* ××

Intelligent Key system

Engine start system INTELLIGENT KEY

×××

Combination switch COMB SW ×

Body control system BCM ×

IVIS IMMU ×××

Interior room lamp battery saver BATTERY SAVER ×××

Back door TRUNK ×

Vehicle security system THEFT ALM ×××

RAP system RETAINED PWR ×

Signal buffer system SIGNAL BUFFER ××

Revision: 2010 May2011 QX56

Page 3882 of 5598

![INFINITI QX56 2011 Factory Service Manual

PCS

DIAGNOSIS SYSTEM (BCM)PCS-41

< SYSTEM DESCRIPTION > [POWER DISTRIBUTION SYSTEM]

C

D

E

F

G H

I

J

K L

B A

O P

N

ENGINE START BY I-KEY

Engine start function mode can be changed to operation with thi INFINITI QX56 2011 Factory Service Manual

PCS

DIAGNOSIS SYSTEM (BCM)PCS-41

< SYSTEM DESCRIPTION > [POWER DISTRIBUTION SYSTEM]

C

D

E

F

G H

I

J

K L

B A

O P

N

ENGINE START BY I-KEY

Engine start function mode can be changed to operation with thi](/img/42/57033/w960_57033-3881.png)

PCS

DIAGNOSIS SYSTEM (BCM)PCS-41

< SYSTEM DESCRIPTION > [POWER DISTRIBUTION SYSTEM]

C

D

E

F

G H

I

J

K L

B A

O P

N

ENGINE START BY I-KEY

Engine start function mode can be changed to operation with this mode

On: Operate

Off: Non-operation

TRUNK/GLASS HATCH OPEN Buzzer reminder function mode by back door opener switch can be changed to operation with

this mode

On: Operate

Off: Non-operation

PANIC ALARM SET Panic alarm button pressing time on Intelligent Key button can be selected from the following

with this mode

MODE 1: 0.5 sec

MODE 2: Non-operation

MODE 3: 1.5 sec

TRUNK OPEN DELAY Back door open button pressing to Intelligent Key button can be selected as per the following

in this mode

MODE 1: Press and hold

MODE 2: Press twice

MODE 3: Press and hold, or press twice

LO- BATT OF KEY FOB WARN Intelligent Key low battery warning mode can be changed to operation with this mode

On: Operate

Off: Non-operation

ANTI KEY LOCK IN FUNCTI Key reminder function mode can be changed to operation with this mode

On: Operate

Off: Non-operation

HAZARD ANSWER BACK Hazard reminder function mode by door request switch and Intelligent Key button can be se-

lected from the following with this mode

Lock Only: Door lock operation only

Unlock Only: Door unlock operation only

Lock/Unlock: Lock and unlock operation

Off: Non-operation

ANS BACK I-KEY LOCK Buzzer reminder function (lock operation) mode by door request switch can be selected from

the following with this mode

Horn Chirp: Sound horn

Buzzer: Sound Intelligent Key warning buzzer

Off: Non-operation

ANS BACK I-KEY UNLOCK Buzzer reminder function (unlock operation) mode by door request switch can be changed to

operation with this mode

On: Operate

Off: Non-operation

SHORT CRANKING OUTPUT Starter motor can operate during the times below

70 msec

100 msec

200 msec

CONFIRM KEY FOB ID It can be checked wh ether Intelligent Key ID code is registered or not in this mode

AUTO LOCK SET Auto door lock operation time can be changed in this mode

MODE 1: OFF

MODE 2: 30 sec

MODE 3: 1 minute

MODE 4: 2 minutes

MODE 5: 3 minutes

MODE 6: 4 minutes

MODE 7: 5 minutes

HORN WITH KEYLESS LOCK Horn reminder function mode by Intelligent Key button can be selected from the following with

this mode

On: Operate

Off: Non-operation

Monitor item Description

Revision: 2010 May2011 QX56

Page 3883 of 5598

![INFINITI QX56 2011 Factory Service Manual

PCS-42

< SYSTEM DESCRIPTION >[POWER DISTRIBUTION SYSTEM]

DIAGNOSIS SYSTEM (BCM)

SELF-DIAG RESULT

Refer to

BCS-57, "DTCIndex".

DATA MONITOR

PW DOWN SET Unlock button pressing time on Intelligent Key INFINITI QX56 2011 Factory Service Manual

PCS-42

< SYSTEM DESCRIPTION >[POWER DISTRIBUTION SYSTEM]

DIAGNOSIS SYSTEM (BCM)

SELF-DIAG RESULT

Refer to

BCS-57, "DTCIndex".

DATA MONITOR

PW DOWN SET Unlock button pressing time on Intelligent Key](/img/42/57033/w960_57033-3882.png)

PCS-42

< SYSTEM DESCRIPTION >[POWER DISTRIBUTION SYSTEM]

DIAGNOSIS SYSTEM (BCM)

SELF-DIAG RESULT

Refer to

BCS-57, "DTCIndex".

DATA MONITOR

PW DOWN SET Unlock button pressing time on Intelligent Key button can be selected from the following with

this mode

MODE 1: 3 sec

MODE 2: Non-operation

MODE 3: 5 sec

WELCOME LIGHT SELECT Welcome light function mode can be selected from the following with this mode

Puddle/Outside Handle

Room lamp

Head & Tail Lamps (this item is displayed, but cannot be used)

Heart Beat

WELCOME LIGHT OP SET Welcome light function mode can be changed to operation with this mode

On: Operate

Off: Non-operation

Monitor item Description

Monitor Item Condition

REQ SW -DR Indicates [On/Off] condition of door request switch (driver side)

REQ SW -AS Indicates [On/Off] condition of door request switch (passenger side)

REQ SW -BD/TR Indicates [On/Off] condition of back door request switch

PUSH SW Indicates [On/Off] condition of push-button ignition switch

CLUTCH SW NOTE:

This item is displayed, but cannot be monitored

BRAKE SW 1 Indicates [On/Off]* condition of stop lamp switch power supply

BRAKE SW 2 Indicates [On/Off] condition of stop lamp switch

DETE/CANCL SW Indicates [On/Off] condition of P position

SFT PN/N SW Indicates [On/Off] condition of P or N position

S/L -LOCK Indicates [On/Off] condition of steering lock unit (LOCK)

S/L -UNLOCK Indicates [On/Off] condition of steering lock unit (UNLOCK)

S/L RELAY -F/B Indicates [On/Off] condition of steering lock relay

UNLK SEN -DR Indicates [On/Off] condition of driver door UNLOCK status

PUSH SW -IPDM Indicates [On/Off] condition of push-button ignition switch

IGN RLY1 -F/B Indicates [On/Off] condition of ignition relay 1

DETE SW -IPDM Indicates [On/Off] condition of P position

SFT PN -IPDM Indicates [On/Off] condition of P or N position

SFT P -MET Indicates [On/Off] condition of P position

SFT N -MET Indicates [On/Off] condition of N position

ENGINE STATE Indicates [Stop/Stall/Crank/Run] condition of engine states

S/L LOCK-IPDM Indicates [On/Off] condition of steering lock unit (LOCK)

S/L UNLK-IPDM Indicates [On/Off] condition of steering lock unit (UNLOCK)

S/L RELAY-REQ Indicates [On/Off] condition of steering lock relay

VEH SPEED 1 Display the vehicle speed signal received from combination meter by numerical value [Km/h]

VEH SPEED 2 Display the vehi cle speed signal received from ABS or VDC or TCM by numerical value [Km/h]

DOOR STAT-DR Indicates [LOCK/READY/UNLK] condition of unlock sensor

DOOR STAT-AS Indicates [LOCK/READY/UNLK] condition of passenger side door status

ID OK FLAG Indicates [Set/Reset] condition of key ID

PRMT ENG STRT Indicates [Set/Reset] condition of engine start possibility

Revision: 2010 May2011 QX56