lock INFINITI QX56 2011 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 2564 of 5598

EM-2

Removal and Installation ........................................30

ROCKER COVER ..............................................33

Exploded View ..................................................... ...33

Removal and Installation ........................................33

VVEL ACTUATOR ASSEMBLY ........................36

Exploded View ..................................................... ...36

Removal and Installation ........................................36

Inspection ...............................................................39

EXHAUST MANIFOLD AND THREE WAY

CATALYST ........................................................

40

Exploded View ..................................................... ...40

Removal and Installation ........................................40

Inspection ...............................................................42

HIGH PRESSURE FUEL PUMP AND FUEL

HOSE .................................................................

43

Exploded View ..................................................... ...43

Removal and Installation ........................................43

Inspection ...............................................................46

FUEL INJECTOR AND FUEL TUBE .................48

Exploded View ..................................................... ...48

Removal and Installation ........................................49

Inspection ...............................................................53

OIL PAN (LOWER) AND OIL STRAINER .........54

Exploded View ..................................................... ...54

Removal and Installation ........................................55

Inspection ...............................................................56

OIL PAN (UPPER) .......................................... ...57

Exploded View ..................................................... ...57

Removal and Installation ........................................58

Inspection ...............................................................60

TIMING CHAIN ............................................... ...61

Exploded View ..................................................... ...61

Removal and Installation ........................................62

Inspection ...............................................................72

CAMSHAFT .......................................................74

Exploded View ..................................................... ...74

Removal and Installation ........................................75

Inspection ...............................................................77

CYLINDER HEAD ..............................................86

Exploded View ..................................................... ...86

Removal and Installation ........................................87

Disassembly and Assembly ....................................89

Inspection ............................................................. ...92

OIL SEAL ...........................................................96

FRONT OIL SEAL .................................................. ...96

FRONT OIL SEAL : Removal and Installation ........96

REAR OIL SEAL .................................................... ...96

REAR OIL SEAL : Removal and Installation ...........97

UNIT REMOVAL AND INSTALLATION ....98

ENGINE ASSEMBL Y ..................................... ...98

Exploded View ..................................................... ...98

Removal and Installation .........................................99

Inspection ..............................................................102

UNIT DISASSEMBLY AND ASSEMBLY ..103

ENGINE STAND SETTING ..............................103

Setting .................................................................. .103

ENGINE UNIT ...................................................105

Disassembly ......................................................... .105

Assembly ..............................................................105

CYLINDER BLOCK ..........................................106

Exploded View ..................................................... .106

Disassembly and Assembly ..................................107

Inspection ..............................................................115

HOW TO SELECT PISTON AND BEARING ...125

Description ........................................................... .125

Piston ....................................................................125

Connecting Rod Bearing .....................................126

Main Bearing ........................................................128

SERVICE DATA AND SPECIFICATIONS

(SDS) ........ .................................................

132

SERVICE DATA AND SPECIFICATIONS

(SDS) .............................................................. ..

132

General Specification .......................................... .132

Drive Belts .............................................................132

Spark Plug ............................................................132

Exhaust Manifold ..................................................133

Camshaft ...............................................................133

Cylinder Head ......................................................135

Cylinder Block ......................................................137

Main Bearing ........................................................141

Connecting Rod Bearing .....................................142

Revision: 2010 May2011 QX56

Page 2565 of 5598

PRECAUTIONSEM-3

< PRECAUTION >

C

DE

F

G H

I

J

K L

M A

EM

NP

O

PRECAUTION

PRECAUTIONS

Precaution for Procedur

e without Cowl Top CoverINFOID:0000000006289506

When performing the procedure after removing cowl top cover, cover

the lower end of windshield with urethane, etc.

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000006417202

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the “SRS AIR BAG” and “SEAT BELT” of this

Service Manual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision that would result in air ba g inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the “SRS AIR BAG”.

Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

When working near the Air Bag Diagnosis Sensor Unit or other Air Bag System sensors with the

ignition ON or engine running, DO NOT use air or electric power tools or strike near the sensor(s)

with a hammer. Heavy vibration could activate the sensor(s) and deploy the air bag(s), possibly

causing serious injury.

When using air or electric power tools or hammers , always switch the ignition OFF, disconnect the

battery, and wait at least 3 minutes before performing any service.

Precaution Necessary for Steering Wh eel Rotation after Battery Disconnect

INFOID:0000000006289508

NOTE:

Before removing and installing any control units, first tu rn the push-button ignition switch to the LOCK posi-

tion, then disconnect both battery cables.

After finishing work, confirm that all control unit connectors are connected properly, then re-connect both

battery cables.

Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If a DTC is detected, perform trouble diagnos is according to self-diagnosis results.

For vehicle with steering lock unit, if the battery is disconnected or discharged, the steering wheel will lock and

cannot be turned.

PIIB3706J

Revision: 2010 May2011 QX56

Page 2566 of 5598

EM-4

< PRECAUTION >

PRECAUTIONS

If turning the steering wheel is required with the battery disconnected or discharged, follow the operation pro-

cedure below before starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables.

NOTE:

Supply power using jumper cables if battery is discharged.

2. Turn the push-button ignition switch to ACC position. (At this time, the steering lock will be released.)

3. Disconnect both battery cables. The steering lock wi ll remain released with both battery cables discon-

nected and the steering wheel can be turned.

4. Perform the necessary repair operation.

5. When the repair work is completed, re-connect bot h battery cables. With the brake pedal released, turn

the push-button ignition switch from ACC position to ON position, then to LOCK position. (The steering

wheel will lock when the push-button igniti on switch is turned to LOCK position.)

6. Perform self-diagnosis check of all control units using CONSULT-III.

Precaution for Drain Engine Coolant and Engine OilINFOID:0000000006289509

Drain engine coolant and engine oil when engine is cooled.

Precaution for Disconnecting Fuel PipingINFOID:0000000006289510

Before starting work, check no fire or sp ark producing items are in the work area.

Release fuel pressure before disconnecting and disassembly.

After disconnecting pipes, plug openings to stop fuel leakage.

Precaution for Handling High Pressure Fuel SystemINFOID:0000000006289511

High pressure fuel system components are betw een high pressure fuel pump and fuel injector.

Always release fuel pressure and never start the engine when performing removal and installation.

When removing or installing parts without releasing fuel pressure, fuel may be splashed and, if fuel contacts

skin or eyes, it may cause inflammation.

Precaution for Removal and DisassemblyINFOID:0000000006289512

When instructed to use SST, use specified tools. Always be careful to work safely, avoid forceful or unin-

structed operations.

Exercise maximum care to avoid damage to mating or sliding surfaces.

Cover openings of engine system with tape or the equival ent, if necessary, to seal out foreign materials.

Mark and arrange disassembly parts in an organi zed way for easy troubleshooting and assembly.

When loosening nuts and bolts, as a basic rule, star t with the one furthest outside, then the one diagonally

opposite, and so on. If the order of loosening is specified, do exactly as specified. Power tools may be used

where noted in the step.

Precaution for Inspection, Repair and ReplacementINFOID:0000000006289513

Before repairing or replacing, thoroughly inspect parts. Inspect new replacement parts in the same way, and

replace if necessary.

Precaution for Assembly and InstallationINFOID:0000000006289514

Use torque wrench to tighten bolts or nuts to specification.

When tightening nuts and bolts, as a basic rule, equally tighten in several different steps starting with the

ones in center, then ones on inside and outside diagonally in this order. If the order of tightening is specified,

do exactly as specified.

Replace with new gasket, packing, oil seal or O-ring.

Thoroughly wash, clean, and air-blow each part. Carefully check engine oil or engine coolant passages for

any restriction and blockage.

Dowel pins are used for several parts alignment. When replacing and reassembling parts with dowel pins,

check that dowel pins are installed in the original position.

Revision: 2010 May2011 QX56

Page 2575 of 5598

CAMSHAFT VALVE CLEARANCEEM-13

< BASIC INSPECTION >

C

DE

F

G H

I

J

K L

M A

EM

NP

O

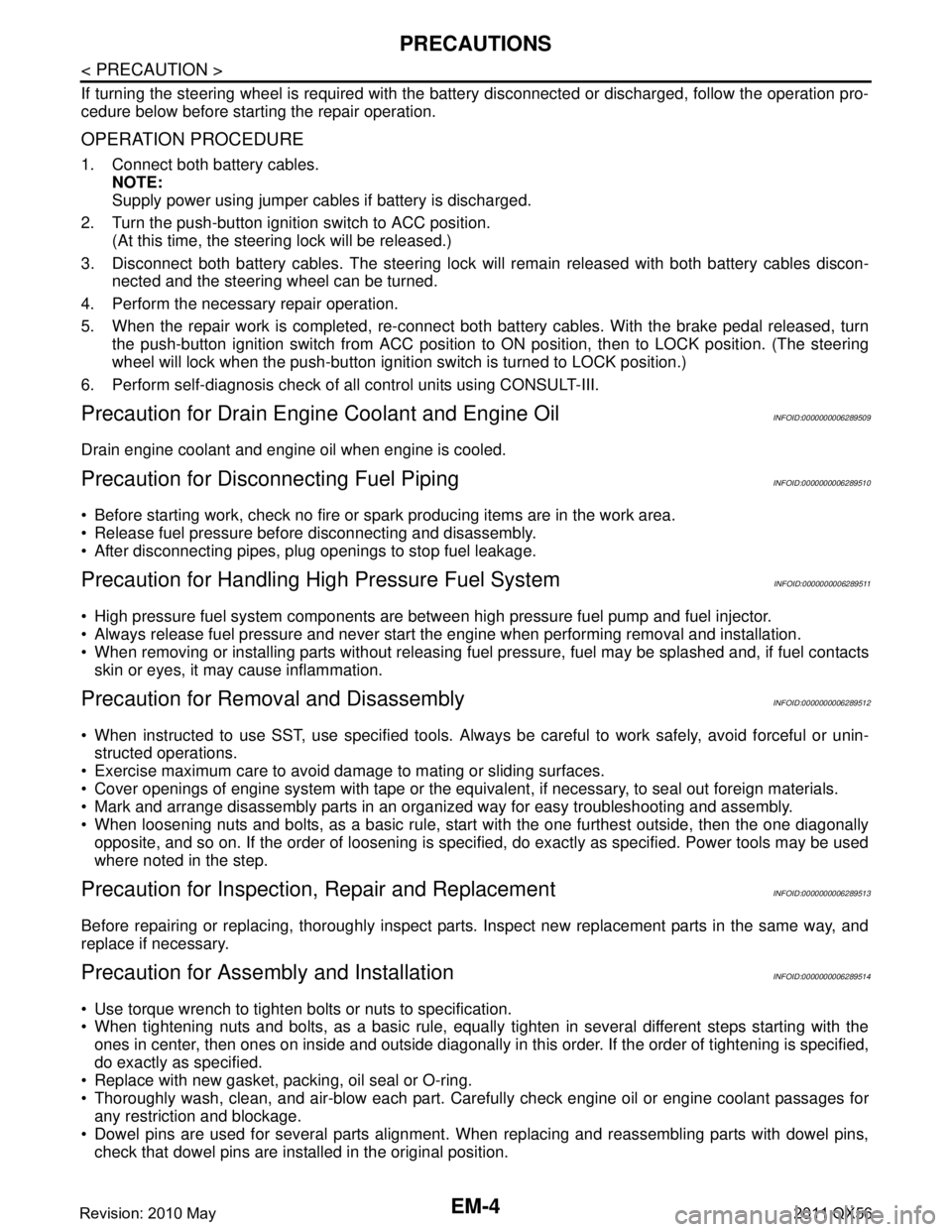

a. Set No. 1 cylinder at TDC of its compression stroke.

Rotate crankshaft pulley clockwise to align timing mark

(grooved line without color) (B) with timing indicator (A).

Check that exhaust cam nose on No. 1 cylinder (engine front side of bank 1) is located as shown in the figure.

If not, turn crankshaft one revolution (360 degrees) and align as shown in the figure.

By referring to the figure, measure the valve clearances at locations marked “ ×” as shown in the table below (locations

indicated in the figure).

No. 1 cylinder at compression TDC

NOTE:

JPBIA2070ZZ

1 : Exhaust camshaft (bank 1) : Engine front

JPBIA2071ZZ

: Engine front

Measuring position [bank 2 (A)] No. 2

CYL. No. 4

CYL. No. 6

CYL. No. 8

CYL.

No. 1 cylinder at com- pression TDC EXH

× (C)

INT × (D) × (E)

Measuring position [bank 1 (B)] No. 1

CYL. No. 3

CYL. No. 5

CYL. No. 7

CYL.

No. 1 cylinder at com- pression TDC INT

× (F) × (G)

EXH × (H) × (I)

JPBIA3488ZZ

Revision: 2010 May2011 QX56

Page 2576 of 5598

EM-14

< BASIC INSPECTION >

CAMSHAFT VALVE CLEARANCE

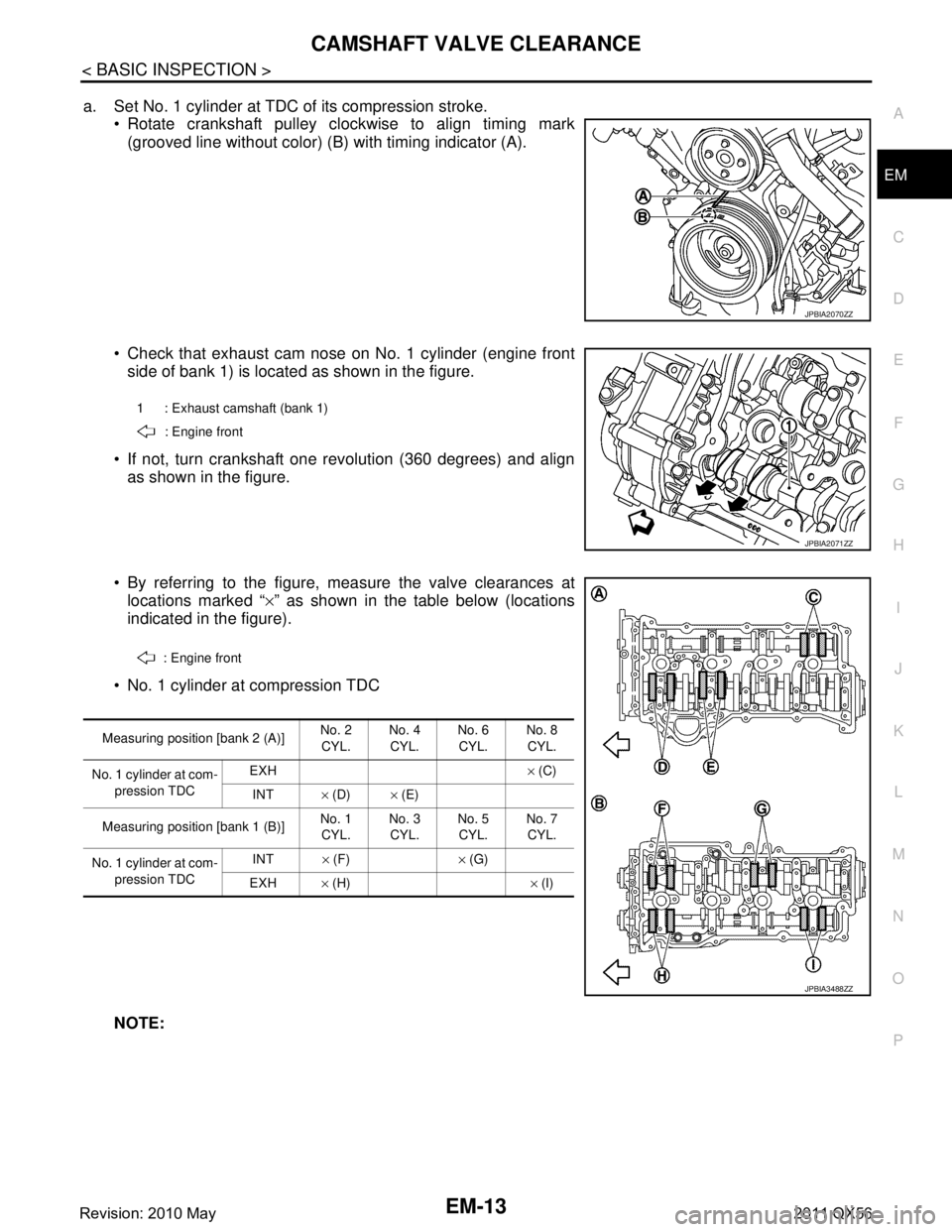

To measure valve clearance of No. 1 cylinder INT valve (front

side), insert feeler gauge (A) (commercial service tool) as shown

in the figure.

b. Rotate crankshaft 270 degrees clockwise (when viewed from engine front) to align No. 3 cylinder at TDC its compression stroke.

NOTE:

Crankshaft pulley mounting bolt flange has an angle mark (B)

every 90 degrees (c). They can be used as a guide to rotation

angle.

By referring to the figure, measure the valve clearances atlocations marked “ ×” as shown in the table below (locations

indicated in the figure).

No. 3 cylinder at compression TDC

c. Rotate crankshaft 90 degrees clockwise (when viewed from engine front) to align No. 6 cylinder at TDC of compression stroke.

NOTE:

: Engine front

JPBIA3489ZZ

A : Paint mark

JPBIA2066ZZ

: Engine front

Measuring position [bank 2 (A)] No. 2

CYL. No. 4

CYL. No. 6

CYL. No. 8

CYL.

No. 3 cylinder at com- pression TDC EXH

× (C)

INT × (D)

Measuring position [bank 1 (B)] No. 1

CYL. No. 3

CYL. No. 5

CYL. No. 7

CYL.

No. 3 cylinder at com- pression TDC INT

× (E) × (F)

EXH × (G) × (H)

JPBIA3490ZZ

Revision: 2010 May2011 QX56

Page 2581 of 5598

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTINGEM-19

< SYMPTOM DIAGNOSIS >

C

DE

F

G H

I

J

K L

M A

EM

NP

O

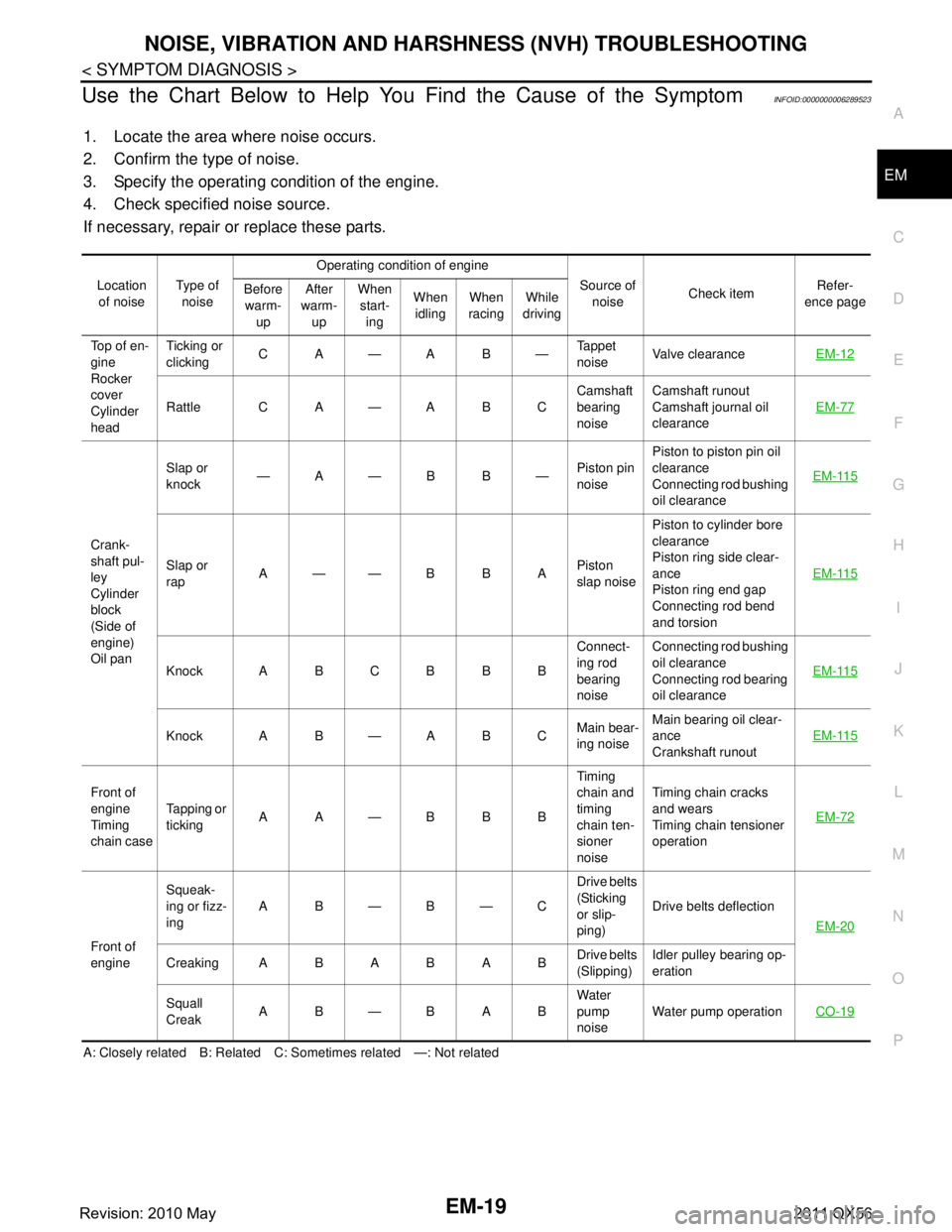

Use the Chart Below to Help You Find the Cause of the SymptomINFOID:0000000006289523

1. Locate the area where noise occurs.

2. Confirm the type of noise.

3. Specify the operating condition of the engine.

4. Check specified noise source.

If necessary, repair or replace these parts.

A: Closely related B: Related C: Sometimes related —: Not related Location

of noise Type of

noise Operating condition of engine

Source of noise Check item Refer-

ence page

Before

warm- up After

warm- up When

start- ing When

idling When

racing While

driving

Top of en-

gine

Rocker

cover

Cylinder

head Ticking or

clicking

CA—AB— Tappet

noiseValve clearance

EM-12

Rattle C A — A B C Camshaft

bearing

noiseCamshaft runout

Camshaft journal oil

clearance

EM-77

Crank-

shaft pul-

ley

Cylinder

block

(Side of

engine)

Oil panSlap or

knock

—A—B B—

Piston pin

noisePiston to piston pin oil

clearance

Connecting rod bushing

oil clearance

EM-115

Slap or

rap

A——B B A

Piston

slap noisePiston to cylinder bore

clearance

Piston ring side clear-

ance

Piston ring end gap

Connecting rod bend

and torsion

EM-115

Knock A B C B B B

Connect-

ing rod

bearing

noiseConnecting rod bushing

oil clearance

Connecting rod bearing

oil clearance

EM-115

Knock A B — A B C

Main bear-

ing noiseMain bearing oil clear-

ance

Crankshaft runout

EM-115

Front of

engine

Timing

chain caseTapping or

ticking

AA—BBB Timing

chain and

timing

chain ten-

sioner

noiseTiming chain cracks

and wears

Timing chain tensioner

operation

EM-72

Front of

engineSqueak-

ing or fizz-

ing

AB—B—C Drive belts

(Sticking

or slip-

ping)Drive belts deflection

EM-20

CreakingABABAB Drive belts

(Slipping)Idler pulley bearing op-

eration

Squall

Creak AB—BAB Water

pump

noiseWater pump operation

CO-19

Revision: 2010 May2011 QX56

Page 2583 of 5598

DRIVE BELTSEM-21

< PERIODIC MAINTENANCE >

C

DE

F

G H

I

J

K L

M A

EM

NP

O

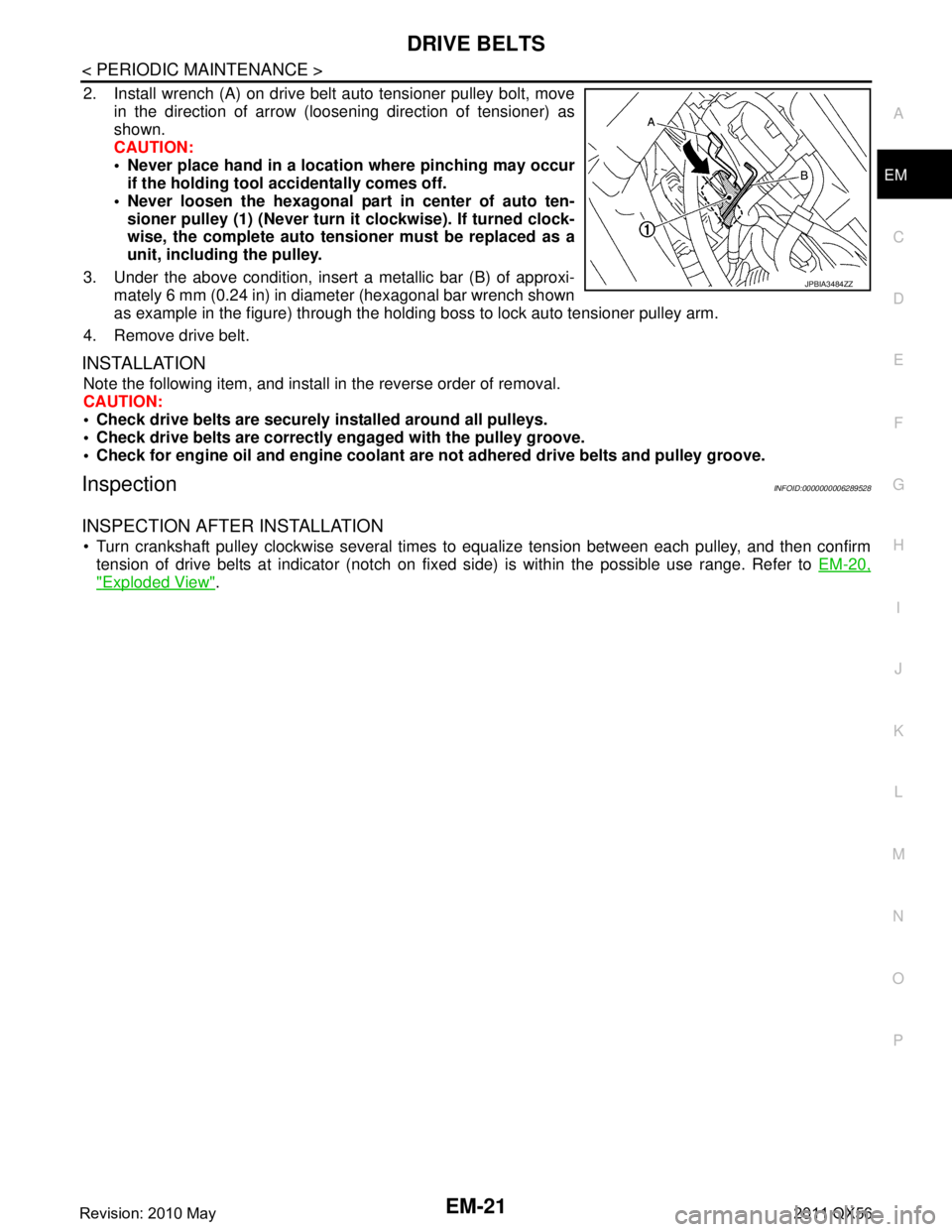

2. Install wrench (A) on drive belt auto tensioner pulley bolt, move

in the direction of arrow (loosening direction of tensioner) as

shown.

CAUTION:

Never place hand in a location where pinching may occurif the holding tool accidentally comes off.

Never loosen the hexagonal part in center of auto ten- sioner pulley (1) (Never turn it clockwise). If turned clock-

wise, the complete auto tensioner must be replaced as a

unit, including the pulley.

3. Under the above condition, insert a metallic bar (B) of approxi- mately 6 mm (0.24 in) in diameter (hexagonal bar wrench shown

as example in the figure) through the holding boss to lock auto tensioner pulley arm.

4. Remove drive belt.

INSTALLATION

Note the following item, and install in the reverse order of removal.

CAUTION:

Check drive belts are securely installed around all pulleys.

Check drive belts are correctly engaged with the pulley groove.

Check for engine oil and engine coolant ar e not adhered drive belts and pulley groove.

InspectionINFOID:0000000006289528

INSPECTION AFTER INSTALLATION

Turn crankshaft pulley clockwise several times to equalize tension between each pulley, and then confirm

tension of drive belts at indicator (notch on fixed side) is within the possible use range. Refer to EM-20,

"Exploded View".

JPBIA3484ZZ

Revision: 2010 May2011 QX56

Page 2588 of 5598

EM-26

< REMOVAL AND INSTALLATION >

DRIVE BELT AUTO TENSIONER AND IDLER PULLEY

DRIVE BELT AUTO TENSI ONER AND IDLER PULLEY

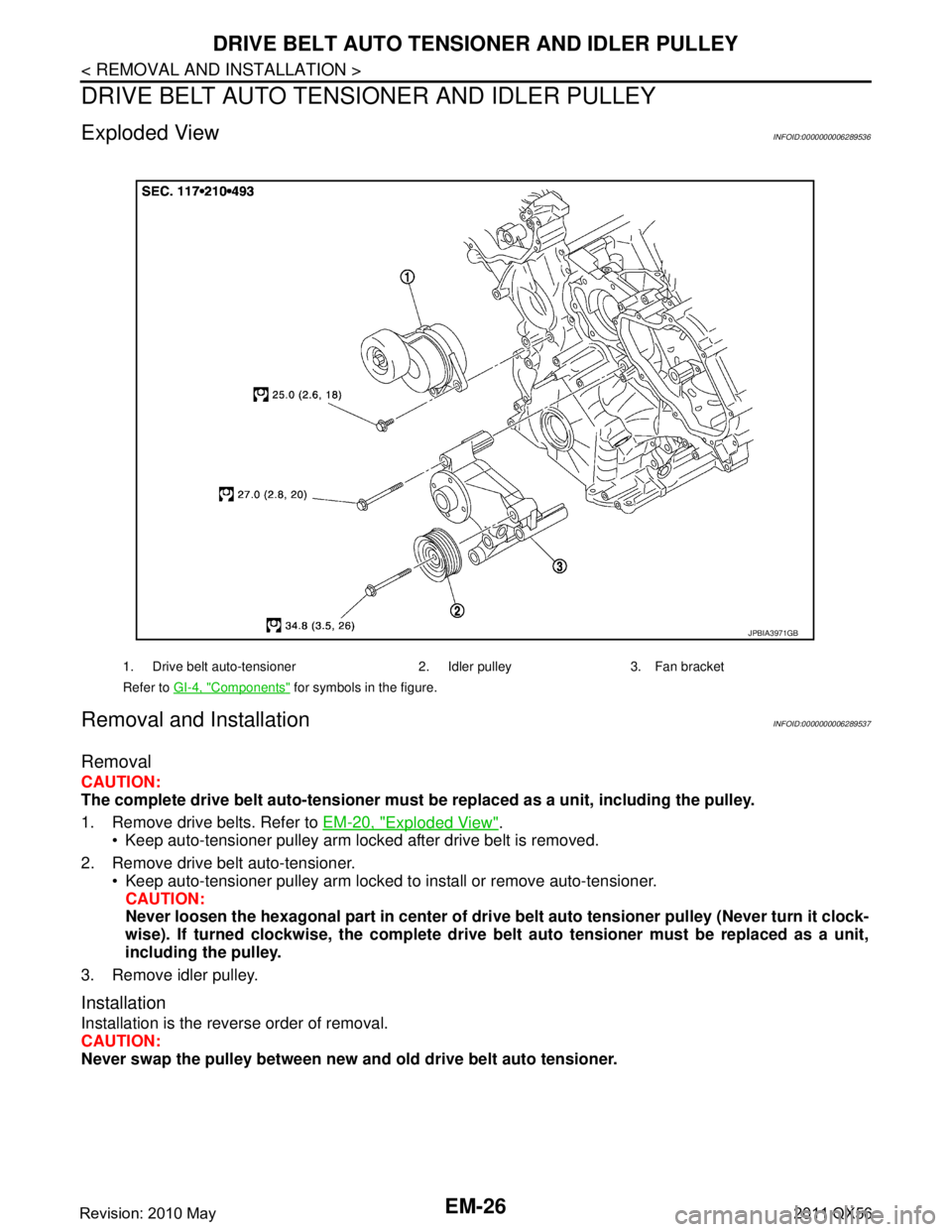

Exploded ViewINFOID:0000000006289536

Removal and InstallationINFOID:0000000006289537

Removal

CAUTION:

The complete drive belt auto-tensioner must be replaced as a unit, including the pulley.

1. Remove drive belts. Refer to EM-20, "

Exploded View".

Keep auto-tensioner pulley arm locked after drive belt is removed.

2. Remove drive belt auto-tensioner. Keep auto-tensioner pulley arm locked to install or remove auto-tensioner.CAUTION:

Never loosen the hexagonal part in center of dri ve belt auto tensioner pulley (Never turn it clock-

wise). If turned clockwise, the complete drive belt auto tensioner must be replaced as a unit,

including the pulley.

3. Remove idler pulley.

Installation

Installation is the reverse order of removal.

CAUTION:

Never swap the pulley between new an d old drive belt auto tensioner.

1. Drive belt auto-tensioner 2. Idler pulley 3. Fan bracket

Refer to GI-4, "

Components" for symbols in the figure.

JPBIA3971GB

Revision: 2010 May2011 QX56

Page 2612 of 5598

![INFINITI QX56 2011 Factory Service Manual

EM-50

< REMOVAL AND INSTALLATION >

FUEL INJECTOR AND FUEL TUBE

c. Press down body portion (A) of injector remover [SST:KV10119600 (—)] until it contacts cylinder head.

d. Tighten injector remover INFINITI QX56 2011 Factory Service Manual

EM-50

< REMOVAL AND INSTALLATION >

FUEL INJECTOR AND FUEL TUBE

c. Press down body portion (A) of injector remover [SST:KV10119600 (—)] until it contacts cylinder head.

d. Tighten injector remover](/img/42/57033/w960_57033-2611.png)

EM-50

< REMOVAL AND INSTALLATION >

FUEL INJECTOR AND FUEL TUBE

c. Press down body portion (A) of injector remover [SST:KV10119600 (—)] until it contacts cylinder head.

d. Tighten injector remover [SST: KV10119600 (—)] clockwise and remove injector from cylinder head.

e. Cut Teflon seal (1) while pinching it. Be careful not to damage injector.

f. Remove insulator from mounting ho le of fuel injector of cylinder

head.

INSTALLATION

1. Install seal ring to fuel injector as per the following: CAUTION:

Handle seal ring with bare hands. Never wear gloves.

Never apply engine oil to seal ring.

Never clean seal ring with solvent.

JPBIA3747ZZ

JPBIA3748ZZ

JSBIA0346ZZ

Revision: 2010 May2011 QX56

Page 2613 of 5598

![INFINITI QX56 2011 Factory Service Manual

FUEL INJECTOR AND FUEL TUBEEM-51

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

K L

M A

EM

NP

O

a. Install an injector seal drift set [SST: KV101197S0 (—)] (A) to

fuel injector (1).

b. Set seal ring INFINITI QX56 2011 Factory Service Manual

FUEL INJECTOR AND FUEL TUBEEM-51

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

K L

M A

EM

NP

O

a. Install an injector seal drift set [SST: KV101197S0 (—)] (A) to

fuel injector (1).

b. Set seal ring](/img/42/57033/w960_57033-2612.png)

FUEL INJECTOR AND FUEL TUBEEM-51

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

K L

M A

EM

NP

O

a. Install an injector seal drift set [SST: KV101197S0 (—)] (A) to

fuel injector (1).

b. Set seal ring (1) to injector seal drift set [SST: KV101197S0 (—)]

(A).

c. Straightly insert seal ring (1), which is set in step 2, to fuel injec- tor as shown in the figure and install.

CAUTION:

Be careful that seal ring do es not exceed the groove portion

of fuel injector.

d. Insert injector seal drift set [SST: KV101197S0 (—)] (A) to injec- tor and rotate clockwise and counterclockwise by 90 ° while

pressing seal ring to fit it.

NOTE:

Compress seal ring, because this operation is for rectifying

stretch of seal ring caused by installation and for preventing

sticking when inserting injector into cylinder head.

2. Install O-ring and backup ring to fuel injector. When handing new O-ring and backup ring, paying attention to the following caution items:

CAUTION:

Handle O-ring with bare hands. Never wear gloves.

Lubricate O-ring with new engine oil.

Never clean O-ring with solvent.

Check that O-ring and its mating pa rt are free of foreign material.

When installing O-ring, be careful not to scratch it with tool or fingernails. Also be careful not to

twist or stretch O-ring. If O-ring was stretched wh ile it was being attached, never insert it quickly

into fuel tube.

Insert new O-ring straight into fu el rail. Never decenter or twist it.

JSBIA0347ZZ

JSBIA0348ZZ

JSBIA0350ZZ

JSBIA0351ZZ

Revision: 2010 May2011 QX56