lock INFINITI QX56 2011 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 2682 of 5598

EM-120

< UNIT DISASSEMBLY AND ASSEMBLY >

CYLINDER BLOCK

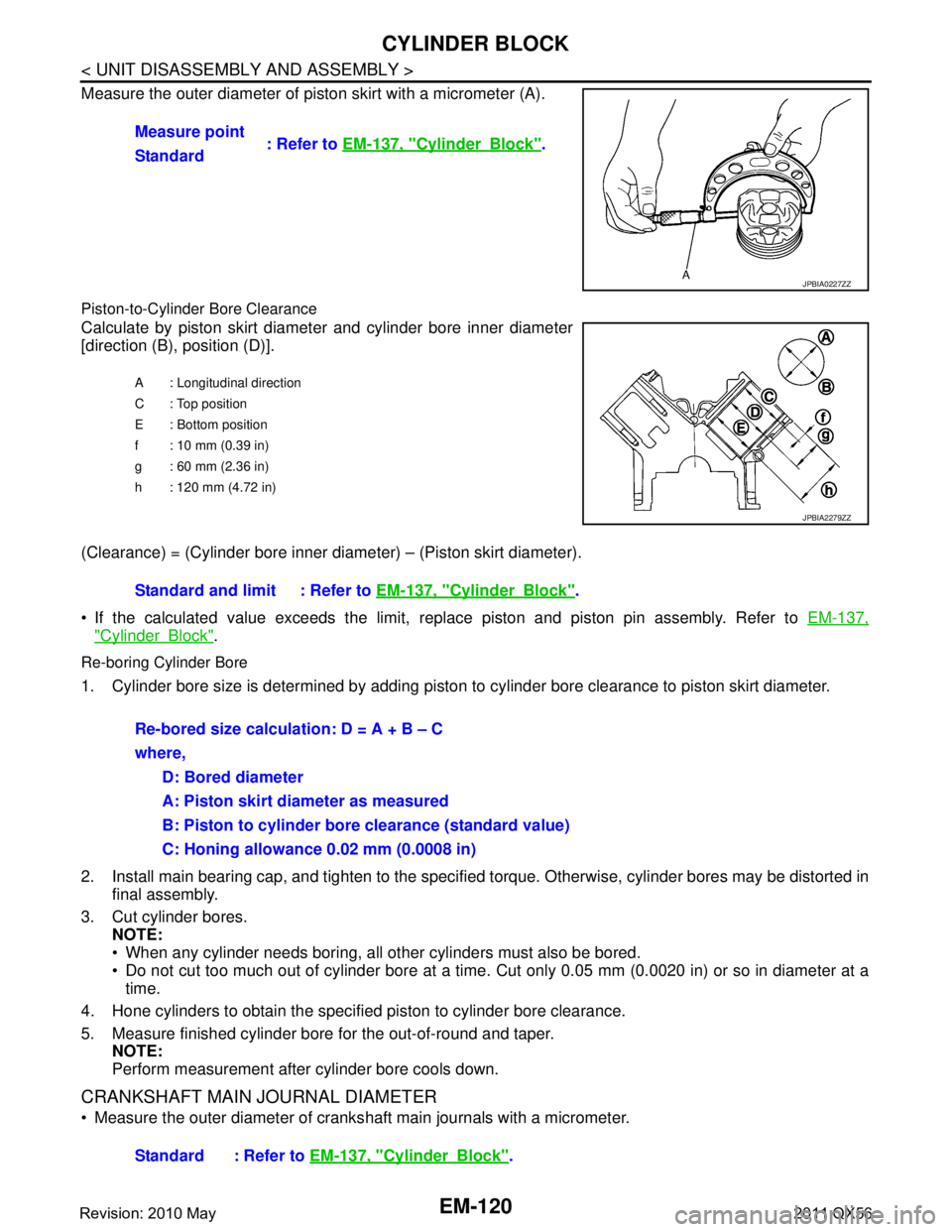

Measure the outer diameter of piston skirt with a micrometer (A).

Piston-to-Cylinder Bore Clearance

Calculate by piston skirt diameter and cylinder bore inner diameter

[direction (B), position (D)].

(Clearance) = (Cylinder bore inner diameter) – (Piston skirt diameter).

If the calculated value exceeds the limit, r eplace piston and piston pin assembly. Refer to EM-137,

"CylinderBlock".

Re-boring Cylinder Bore

1. Cylinder bore size is determined by adding piston to cylinder bore clearance to piston skirt diameter.

2. Install main bearing cap, and tighten to the specifi ed torque. Otherwise, cylinder bores may be distorted in

final assembly.

3. Cut cylinder bores. NOTE:

When any cylinder needs boring, all other cylinders must also be bored.

Do not cut too much out of cylinder bore at a time. Cut only 0.05 mm (0.0020 in) or so in diameter at a

time.

4. Hone cylinders to obtain the specified piston to cylinder bore clearance.

5. Measure finished cylinder bore for the out-of-round and taper. NOTE:

Perform measurement after cylinder bore cools down.

CRANKSHAFT MAIN JOURNAL DIAMETER

Measure the outer diameter of cranks haft main journals with a micrometer.

Measure point

: Refer to EM-137, "

CylinderBlock".

Standard

JPBIA0227ZZ

A : Longitudinal direction

C : Top position

E : Bottom position

f : 10 mm (0.39 in)

g : 60 mm (2.36 in)

h : 120 mm (4.72 in)

JPBIA2279ZZ

Standard and limit : Refer to EM-137, "CylinderBlock".

Re-bored size calculation: D = A + B – C

where, D: Bored diameter

A: Piston skirt diameter as measured

B: Piston to cylinder bore clearance (standard value)

C: Honing allowance 0.02 mm (0.0008 in)

Standard : Refer to EM-137, "

CylinderBlock".

Revision: 2010 May2011 QX56

Page 2683 of 5598

CYLINDER BLOCKEM-121

< UNIT DISASSEMBLY AND ASSEMBLY >

C

DE

F

G H

I

J

K L

M A

EM

NP

O

If out of the standard, measure the main bearing

oil clearance. Then use undersize bearing. Refer to EM-

128, "MainBearing".

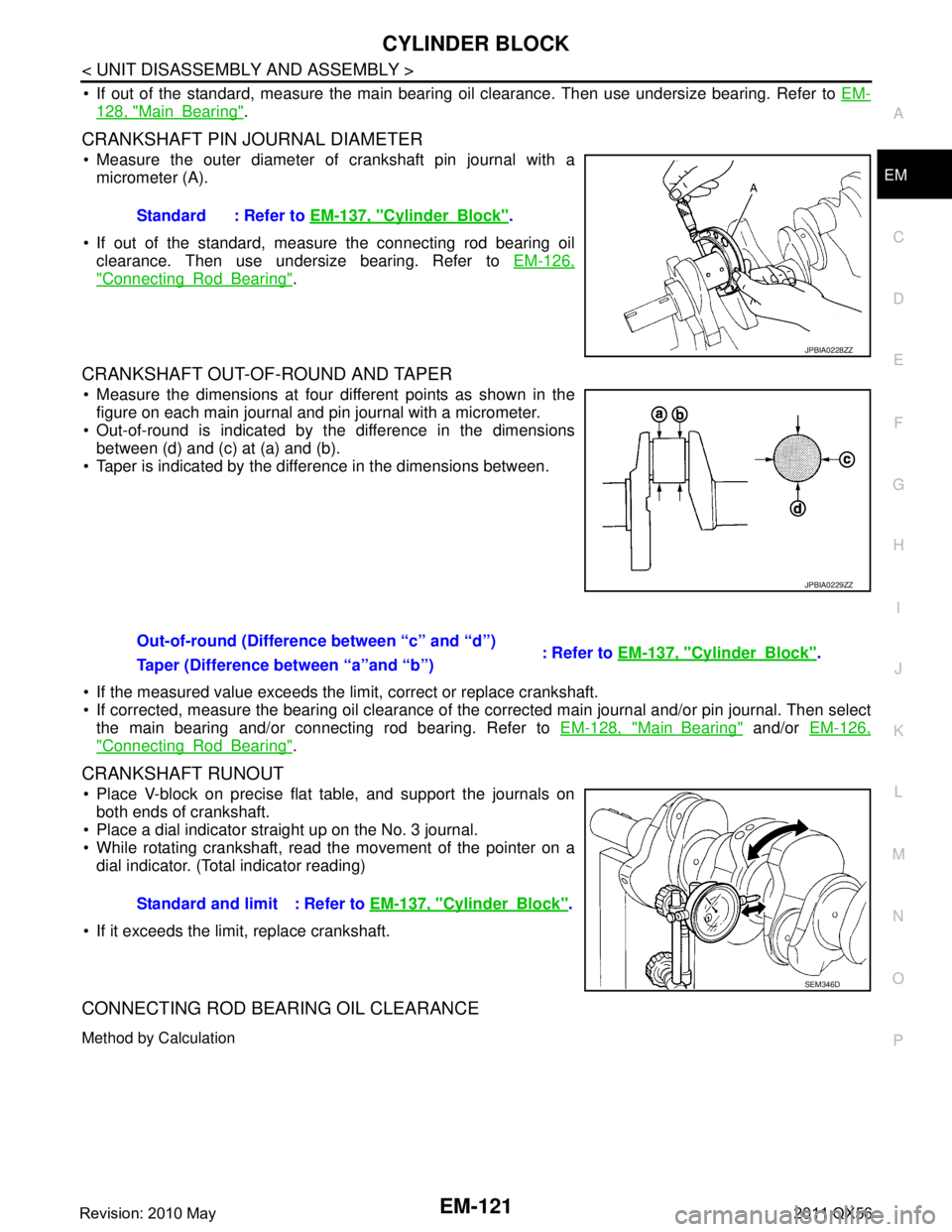

CRANKSHAFT PIN JOURNAL DIAMETER

Measure the outer diameter of crankshaft pin journal with a

micrometer (A).

If out of the standard, measure the connecting rod bearing oil clearance. Then use undersize bearing. Refer to EM-126,

"ConnectingRodBearing".

CRANKSHAFT OUT-OF-ROUND AND TAPER

Measure the dimensions at four different points as shown in the

figure on each main journal and pin journal with a micrometer.

Out-of-round is indicated by t he difference in the dimensions

between (d) and (c) at (a) and (b).

Taper is indicated by the difference in the dimensions between.

If the measured value exceeds the li mit, correct or replace crankshaft.

If corrected, measure the bearing oil clearance of the corrected main journal and/or pin journal. Then select

the main bearing and/or connecting rod bearing. Refer to EM-128, "

MainBearing" and/or EM-126,

"ConnectingRodBearing".

CRANKSHAFT RUNOUT

Place V-block on precise flat table, and support the journals on

both ends of crankshaft.

Place a dial indicator straight up on the No. 3 journal.

While rotating crankshaft, read the movement of the pointer on a

dial indicator. (Total indicator reading)

If it exceeds the limit, replace crankshaft.

CONNECTING ROD BEARING OIL CLEARANCE

Method by Calculation

Standard : Refer to EM-137, "CylinderBlock".

JPBIA0228ZZ

JPBIA0229ZZ

Out-of-round (Difference between “c” and “d”)

: Refer to EM-137, "CylinderBlock".

Taper (Difference between “a”and “b”)

Standard and limit : Refer to EM-137, "

CylinderBlock".

SEM346D

Revision: 2010 May2011 QX56

Page 2684 of 5598

EM-122

< UNIT DISASSEMBLY AND ASSEMBLY >

CYLINDER BLOCK

Install connecting rod bearings (1) to connecting rod (2) and con-necting rod cap, and tighten connecting rod bolts to the specified

torque. Refer to EM-107, "

Disassembly and Assembly" for the

tightening procedure.

Measure the inner diameter of connecting rod bearing with an inside micrometer.

(Oil clearance) = (Connecting rod bearing inner di ameter) – (Crankshaft pin journal diameter)

If the calculated value exceeds the limit, select proper connecting rod bearing according to connecting rod

big end diameter and crankshaft pin journal diameter to obtain the specified bearing oil clearance. Refer to

EM-125, "

Description".

Method of Using Plastigage

Remove oil and dust on crankshaft pin journal and the surfaces of each bearing completely.

Cut a plastigage slightly shorter than the bearing width, and place it in crankshaft axial direction, avoiding oil

holes.

Install connecting rod bearings to connecting rod and connecting rod bearing cap, and tighten connecting

rod bolts to the specified torque. Refer to EM-107, "

Disassembly and Assembly" for the tightening proce-

dure.

CAUTION:

Never rotate crankshaft.

Remove connecting rod bearing cap and bearings, and using the

scale on the plastigage bag, measure the plastigage width.

NOTE:

The procedure when the measured va lue exceeds the limit is the

same as that described in the “Method by Calculation”.

MAIN BEARING OIL CLEARANCE

Method by Calculation

Install main bearings (3) to cylinder block (1) and main bearing cap (2), and tighten main bearing cap bolts to the specified torque.

Refer to EM-107, "

Disassembly and Assembly" for the tightening

procedure.

Measure the inner diameter of main bearing with a bore gauge.

(Oil clearance) = (Main bearing inner diameter) – (Crankshaft main

journal diameter)

If the calculated value exceeds t he limit, select proper main bear-

ing according to main bearing inner diameter and crankshaft main

journal diameter to obtain the specified bearing oil clearance.

Refer to EM-125, "

Description".

Method of Using Plastigage

Remove engine oil and dust on crankshaft journal and the surfaces of each bearing completely.

JPBIA0230ZZ

Standard and limit : Refer to EM-142, "ConnectingRodBearing".

JPBIA0231ZZ

Standard and limit : Refer to EM-141, "MainBearing".

JPBIA0232ZZ

Revision: 2010 May2011 QX56

Page 2685 of 5598

CYLINDER BLOCKEM-123

< UNIT DISASSEMBLY AND ASSEMBLY >

C

DE

F

G H

I

J

K L

M A

EM

NP

O

Cut a plastigage slightly shorter than the bearing width,

and place it in crankshaft axial direction, avoiding oil

holes.

Install main bearing to cylinder block and main bearing cap, and tighten main bearing cap bolts with main

bearing cap to the specified torque. Refer to EM-107, "

Disassembly and Assembly" for the tightening proce-

dure.

CAUTION:

Never rotate crankshaft.

Remove main bearing cap and bearings, and using the scale on the plastigage bag, measure the plastigage width.

NOTE:

The procedure when the measured value exceeds the limit is the

same as that described in the “Method by Calculation”.

MAIN BEARING CRUSH HEIGHT

When main bearing cap is removed after being tightened to thespecified torque with main bearings (1) installed, the tip end of

bearing must protrude. Refer to EM-107, "

Disassembly and

Assembly" for the tightening procedure.

If the standard is not met, replace main bearings.

CONNECTING ROD BEARING CRUSH HEIGHT

When connecting rod bearing cap is removed after being tightened to the specified torque with connecting rod bearings (1) installed,

the tip end of bearing must protrude. Refer to EM-107, "

Disassem-

bly and Assembly" for the tightening procedure.

If the standard is not met, replace connecting rod bearings.

MAIN BEARING CAP BOLT OUTER DIAMETER

Measure the outer diameters (A), (B) at two positions as shown in

the figure.

If reduction appears in (A) range, regard it (B).

If it exceeds the limit (large difference in dimensions), replace main bearing cap bolts with new one.

MAIN BEARING CAP SUB BOLT OUTER DIAMETER

JPBIA0231ZZ

A : Crush height

Standard : There must be crush height.

JPBIA0233ZZ

A : Crush height

Standard : There must be crush height.

JPBIA0233ZZ

c : 20 mm (0.79 in)

d : 55 mm (2.17 in)

e : 12 mm (0.47 in)

Limit [(B) – (A)] : 0.15 mm (0.0059 in)

JPBIA2280ZZ

Revision: 2010 May2011 QX56

Page 2686 of 5598

EM-124

< UNIT DISASSEMBLY AND ASSEMBLY >

CYLINDER BLOCK

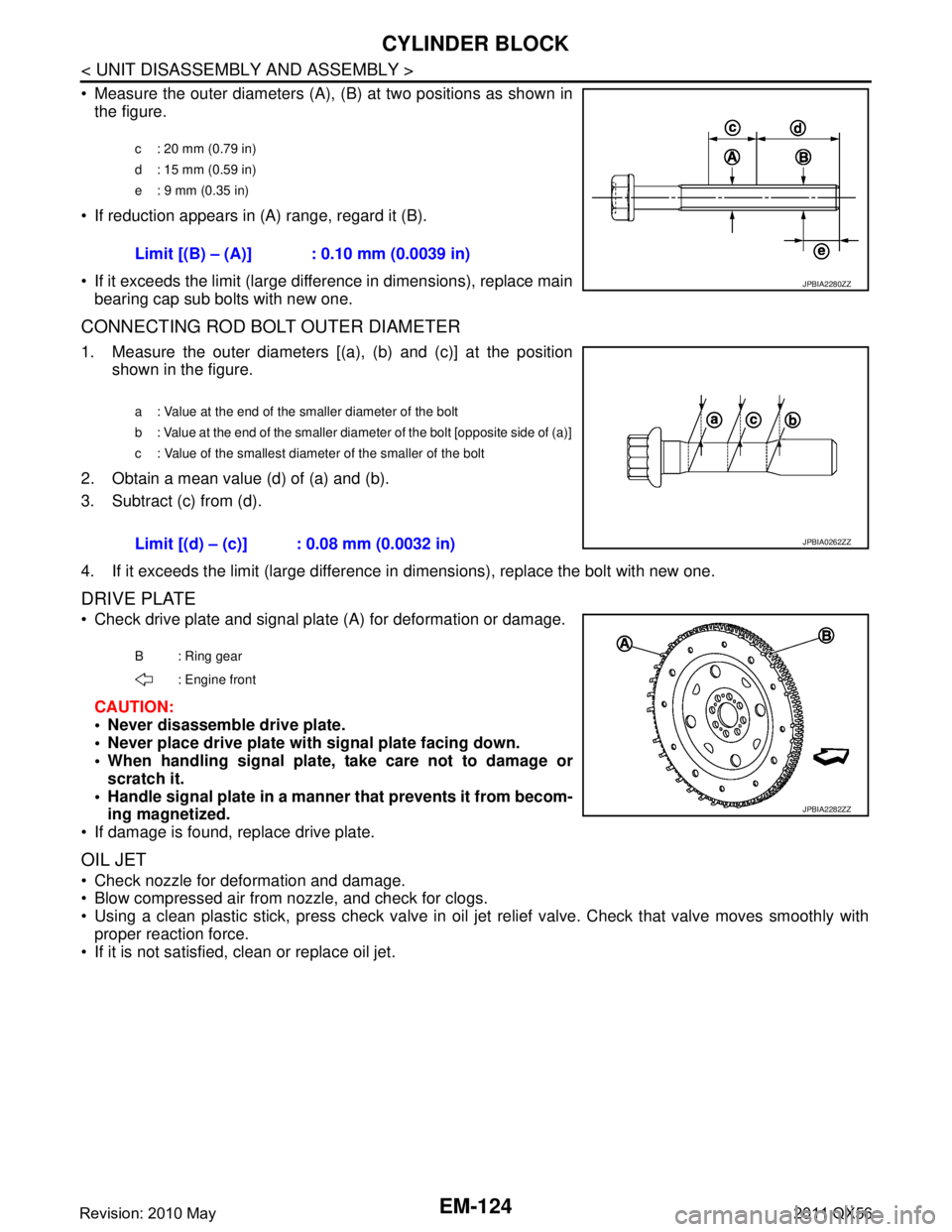

Measure the outer diameters (A), (B) at two positions as shown in

the figure.

If reduction appears in (A) range, regard it (B).

If it exceeds the limit (large difference in dimensions), replace main bearing cap sub bolts with new one.

CONNECTING ROD BOLT OUTER DIAMETER

1. Measure the outer diameters [(a), (b) and (c)] at the position shown in the figure.

2. Obtain a mean value (d) of (a) and (b).

3. Subtract (c) from (d).

4. If it exceeds the limit (large difference in dimensions), replace the bolt with new one.

DRIVE PLATE

Check drive plate and signal plate (A) for deformation or damage.

CAUTION:

Never disassemble drive plate.

Never place drive plate with signal plate facing down.

When handling signal plate, take care not to damage or scratch it.

Handle signal plate in a manner that prevents it from becom-

ing magnetized.

If damage is found, replace drive plate.

OIL JET

Check nozzle for deformation and damage.

Blow compressed air from nozzle, and check for clogs.

Using a clean plastic stick, press check valve in oil je t relief valve. Check that valve moves smoothly with

proper reaction force.

If it is not satisfied, clean or replace oil jet.

c : 20 mm (0.79 in)

d : 15 mm (0.59 in)

e : 9 mm (0.35 in)

Limit [(B) – (A)] : 0.10 mm (0.0039 in)

JPBIA2280ZZ

a : Value at the end of the smaller diameter of the bolt

b : Value at the end of the smaller diameter of the bolt [opposite side of (a)]

c : Value of the smallest diameter of the smaller of the bolt

Limit [(d) – (c)] : 0.08 mm (0.0032 in)JPBIA0262ZZ

B : Ring gear

: Engine front

JPBIA2282ZZ

Revision: 2010 May2011 QX56

Page 2687 of 5598

HOW TO SELECT PISTON AND BEARINGEM-125

< UNIT DISASSEMBLY AND ASSEMBLY >

C

DE

F

G H

I

J

K L

M A

EM

NP

O

HOW TO SELECT PISTON AND BEARING

DescriptionINFOID:0000000006289585

The identification grade stamped on each part is the

grade for the dimension measured in new condition.

This grade cannot apply to reused parts.

For reused or repaired parts, measure the dimens ion accurately. Determine the grade by comparing the

measurement with the values of each selection table.

For details of the measurement method of each part , the reuse standards and the selection method of the

selective fitting parts, refer to the text.

PistonINFOID:0000000006289586

WHEN NEW CYLINDER BLOCK IS USED

Check the cylinder bore grade on the bottom face of the cylinder

block, and select the piston of the same grade.

NOTE:

Piston is available with piston pin as a set for the service part.

WHEN NEW CYLINDER BLOCK IS REUSED

1. Measure the cylinder bore inner diameter. Refer to EM-137, "CylinderBlock".

Selection points Selection parts Selection items Selection methods

Between cylinder block and

crankshaft Main bearing Main bearing grade

(bearing thickness)Determined by match of cylin-

der block bearing housing

grade (inner diameter of hous-

ing) and crankshaft journal

grade (outer diameter of jour-

nal)

Between crankshaft and con-

necting rod Connecting rod bearing Connecting rod bearing grade

(bearing thickness)Determined by match of con-

necting rod big end diameter

grade (inner diameter of hous-

ing) and crankshaft pin outer di-

ameter.

Between cylinder block and pis-

ton Piston and piston pin assembly

(Piston is available together

with piston pin as assembly.) Piston grade

(piston skirt diameter)

Piston grade = cylinder bore

grade (inner diameter of bore)

KBIA2495E

Revision: 2010 May2011 QX56

Page 2690 of 5598

![INFINITI QX56 2011 Factory Service Manual

EM-128

< UNIT DISASSEMBLY AND ASSEMBLY >

HOW TO SELECT PISTON AND BEARING

In grinding crankshaft pin to use undersize bearings, keep the

fillet R (A) [1.5 - 1.7 mm (0.059 - 0.067 in)].

Main BearingIN INFINITI QX56 2011 Factory Service Manual

EM-128

< UNIT DISASSEMBLY AND ASSEMBLY >

HOW TO SELECT PISTON AND BEARING

In grinding crankshaft pin to use undersize bearings, keep the

fillet R (A) [1.5 - 1.7 mm (0.059 - 0.067 in)].

Main BearingIN](/img/42/57033/w960_57033-2689.png)

EM-128

< UNIT DISASSEMBLY AND ASSEMBLY >

HOW TO SELECT PISTON AND BEARING

In grinding crankshaft pin to use undersize bearings, keep the

fillet R (A) [1.5 - 1.7 mm (0.059 - 0.067 in)].

Main BearingINFOID:0000000006289588

WHEN NEW CYLINDER BLOCK AND CRANKSHAFT ARE USED

1. Apply the main bearing housing grade on the bottom face of thecylinder block to the row in “MAIN BEARING SELECTION

TA B L E ” .

2. “MAIN BEARING SELECTION TABLE” columns correspond to

journal diameter grade on front side of crankshaft.

3. Select main bearing grade at the point where selected row and column meet in “MAIN BEARING SELEC- TION TABLE”.

CAUTION:

Initial clearance for No. 1, 5 journal and No. 2, 3, 4 journal is different. Use two different selection

table for each part.

No. 1, 5 journal and No. 2, 3, 4 journal have the same signs but different measures. Never con-

fuse.

4. Apply sign at crossing in above step 3 to “MAIN BEARING GRADE TABLE”.

NOTE:

“MAIN BEARING GRADE TABLE” applies to all journals.

Service parts are available as a set of both upper and lower.

WHEN CYLINDER BLOCK AND CRANKSHAFT ARE REUSED

1. Measure cylinder block main bearing housing inner diameter and crankshaft main journal diameter. Refer to EM-115, "

Inspection".

JPBIA0216ZZ

Bearing undersize table : Refer to EM-142, "ConnectingRodBearing".

KBIA2495E

A : Pin diameter grade No. 1

B : Pin diameter grade No. 2

C : Pin diameter grade No. 3

D : Pin diameter grade No. 4

E : Journal diameter grade No. 1

F : Journal diameter grade No. 2

G : Journal diameter grade No. 3

H : Journal diameter grade No. 4

I : Journal diameter grade No. 5

JPBIA2283ZZ

Revision: 2010 May2011 QX56

Page 2691 of 5598

HOW TO SELECT PISTON AND BEARINGEM-129

< UNIT DISASSEMBLY AND ASSEMBLY >

C

DE

F

G H

I

J

K L

M A

EM

NP

O

2. Correspond the measured dimension in “Cylinder

block main bearing housing inner diameter” row of

“MAIN BEARING SELECTION TABLE”.

3. Correspond the measured dimension in “Crankshaft main journal diameter” column of “MAIN BEARING

SELECTION TABLE”.

4. Follow from step 3 in “When New Cylinder Block and Crankshaft are Used”.

MAIN BEARING SELECTION TABLE (No. 1 and 5 Journal)

JPBIA2285GB

Revision: 2010 May2011 QX56

Page 2699 of 5598

SERVICE DATA AND SPECIFICATIONS (SDS)

EM-137

< SERVICE DATA AND SPECIFICATIONS (SDS)

C

D E

F

G H

I

J

K L

M A

EM

NP

O

*1: Diameter made by intersection point of conic angles “

α1” and “ α2”

*

2: Diameter made by intersection point of conic angles “ α2” and “ α3”

*

3: Machining data

*

4: Parts settings are for exhaust side only

VALVE SPRING

Cylinder BlockINFOID:0000000006289595

CYLINDER BLOCK

Unit: mm (in)

Angle “ α2” 88°75 ′ - 90 °25 ′

Angle “ α3” 11 9 - 1 2 1°

Contacting width “W”*

3Intake 1.0 - 1.4 (0.039 - 0.055)

Exhaust 1.2 - 1.6 (0.047 - 0.063)

Height “h” Intake 5.9 - 6.0 (0.232 - 0.236) —

Exhaust 5.9 - 6.0 (0.232 - 0.236)

4.95 - 5.05 (0.1949 - 0.1988)*

4

Depth “H” 6.0 (0.236)

ItemStandard

Intake Exhaust

Free height 47.28 mm (1.8614 in) 48.06 mm (1.8921 in)

Pressure Installation

166 - 188 N (16.9 - 19.2 kg, 37 - 42 lb)

at 41.0 mm (1.614 in) 166 - 188 N (16.9 - 19.2 kg, 37 - 42 lb)

at 34.45 mm (1.3563 in)

Valve open 541 - 611 N (55.2 - 62.3 kg, 122 - 137 lb)

at 29.6 mm (1.165 in) 320.1 - 360.1 N (32.7 - 36.7 kg, 72 - 81 lb)

at 24.65 mm (0.9705 in)

Identification color Light green Light blue

Item Limit

Intake Exhaust

Out-of-square 2.1 mm (0.083 in) 2.0 mm (0.079 in)

Surface flatness Limit 0.1 (0.004)

Main bearing housing inner diameter Standard 68.944 - 68.968 (2.7143 - 2.7153)

Cylinder bore Inner diameter StandardGrade No. 1 98.000 - 98.010 (3.8583 - 3.8587)

Grade No. 2 98.010 - 98.020 (3.8587 - 3.8590)

Grade No. 3 98.020 - 98.030 (3.8590 - 3.8594)

Wear limit 0.2 (0.008)

Out-of-round Limit0.015 (0.0006)

Ta p e r 0.010 (0.0004)

Revision: 2010 May2011 QX56

Page 2723 of 5598

![INFINITI QX56 2011 Factory Service Manual

SYSTEMEXL-13

< SYSTEM DESCRIPTION > [XENON TYPE]

C

D

E

F

G H

I

J

K

M A

B

EXL

N

O P

BCM transmits each request signal to IPDM E/R via CAN communication, according to ON/OFF condition by

the auto li INFINITI QX56 2011 Factory Service Manual

SYSTEMEXL-13

< SYSTEM DESCRIPTION > [XENON TYPE]

C

D

E

F

G H

I

J

K

M A

B

EXL

N

O P

BCM transmits each request signal to IPDM E/R via CAN communication, according to ON/OFF condition by

the auto li](/img/42/57033/w960_57033-2722.png)

SYSTEMEXL-13

< SYSTEM DESCRIPTION > [XENON TYPE]

C

D

E

F

G H

I

J

K

M A

B

EXL

N

O P

BCM transmits each request signal to IPDM E/R via CAN communication, according to ON/OFF condition by

the auto light function.

NOTE:

As to ON/OFF timing, the sensitivity depends on sett ings. The settings can be changed with CONSULT-III.

Refer to EXL-23, "

HEADLAMP : CONSULT-III F unction (BCM - HEAD LAMP)".

Auto Lighting Timing Table

When the light switch is in AUTO position and the ignition switch is ON, the exterior lamps turns ON/OFF in the

following condition.

Standard Light ON

BCM turns exterior lamps ON when outside brightness obtained from the optical sensor signal is 1250 lx or

less for 3 seconds or more. And BCM turns exterior lamp OFF when outside brightness from the optical sen-

sor signal is 2500 lx or more for 5 seconds or more.

Twilight Light ON (Twili ght Lighting Function)

BCM detects twilight by filtered brightness.

BCM filters outside brightness to block the impact of the rapid change in brightness, based on the optical

sensor signal, and judges outside brightness.

BCM detects changes in outside brightness, based on outside brightness obtained from the optical sensor

signal and filtered brightness and judges ON/OFF of the exterior lamps.

Filtering chart

BCM starts filtering 0.3 seconds after the ignition swit ch is turned ON and the light switch is turned to AUTO.

BCM filters signals from the optical sensor at intervals of 2 seconds.When the filtered brightness is higher

than outside brightness (signal from the optical sens or), BCM decreases the filtered brightness by 20

lx

*.When the filtered brightness is lower than outside bri ghtness, BCM increases the filtered brightness by 20

lx

*.

BCM turns ON the exterior lamps when filtered brightness reaches 3000 lx and turns OFF when reaching 5000 lx.

*:When vehicle speed is 5 km/h or less, BCM decr eases/increases the filtered brightness by 5 lx.

WIPER LINKED AUTO LIGHTING FUNCTION

BCM turns the exterior lamp ON when detecting 4 operations of the front wiper work the light switch in AUTO

position.

NOTE:

BCM turns OFF the headlamps 3 seconds after the front wiper switch is turned from HI⇒OFF.

Exterior lamps Standard Light ON

(Sudden increase/decrease in brightness) Twilight Light ON

(Gradual increase/decrease in brightness)

ON Outside brightness is 1250 lx or less for 3

seconds or more.Filtered brightness is 3000 lx or less

OFF Outside brightness is 2500 lx or more for 5

seconds or more.

Filtered brightness is 5000 lx or more

JPLIA1827GB

Revision: 2010 May2011 QX56