engine INFINITI QX56 2011 Factory Owner's Guide

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 502 of 5598

BR-32

< REMOVAL AND INSTALLATION >

HYDRAULIC BOOSTER ASSEMBLY

Apply new brake fluid to grommet of between reservoir tank and grommet and ABS actuator and electric unit

(control unit).

Inspection and AdjustmentINFOID:0000000006222486

ADJUSTMENT BEFORE INSTALLATION

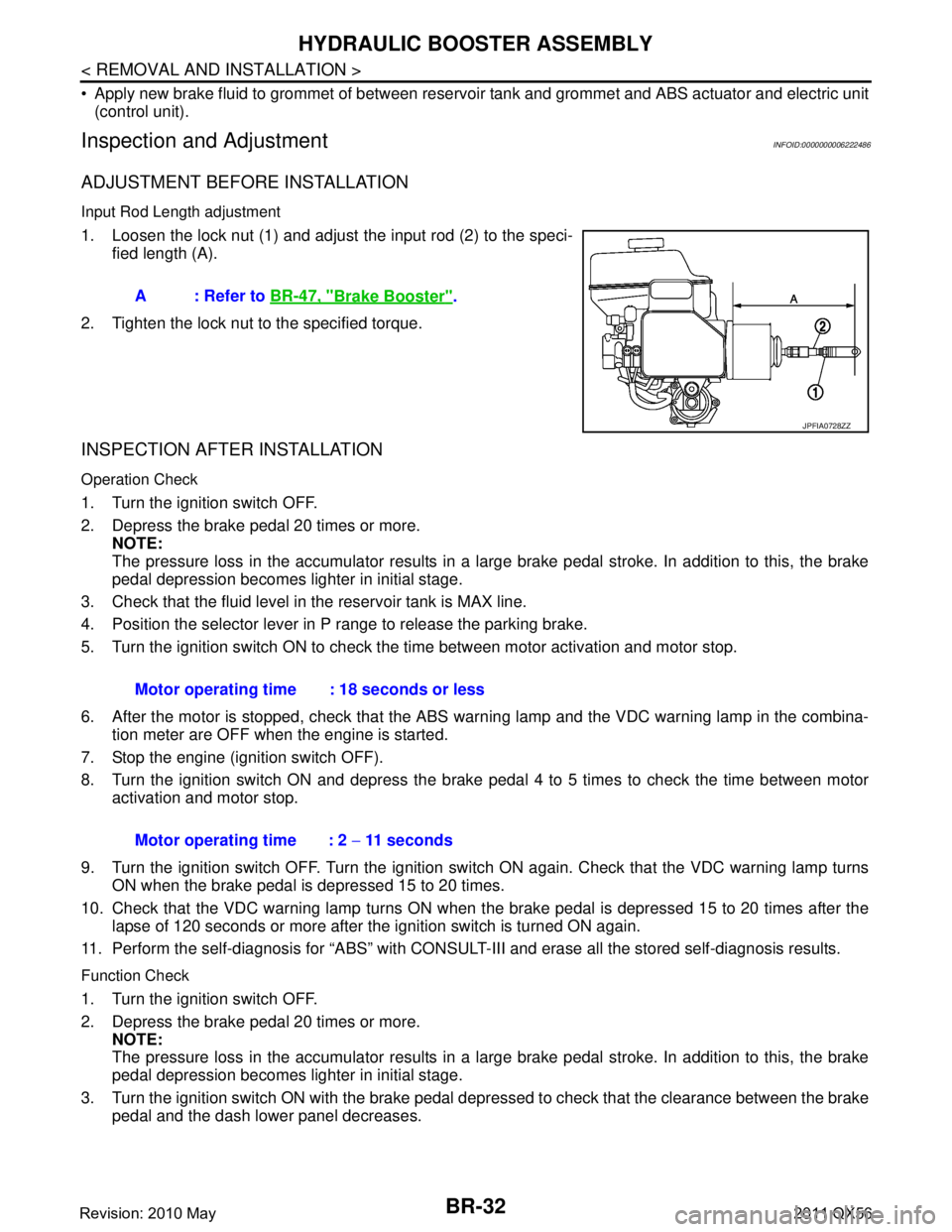

Input Rod Length adjustment

1. Loosen the lock nut (1) and adjust the input rod (2) to the speci-

fied length (A).

2. Tighten the lock nut to the specified torque.

INSPECTION AFTER INSTALLATION

Operation Check

1. Turn the ignition switch OFF.

2. Depress the brake pedal 20 times or more. NOTE:

The pressure loss in the accumulator results in a large brake pedal stroke. In addition to this, the brake

pedal depression becomes lighter in initial stage.

3. Check that the fluid level in the reservoir tank is MAX line.

4. Position the selector lever in P range to release the parking brake.

5. Turn the ignition switch ON to check the time between motor activation and motor stop.

6. After the motor is stopped, check that the ABS warn ing lamp and the VDC warning lamp in the combina-

tion meter are OFF when the engine is started.

7. Stop the engine (ignition switch OFF).

8. Turn the ignition switch ON and depress the brake pedal 4 to 5 times to check the time between motor activation and motor stop.

9. Turn the ignition switch OFF. Turn the ignition swit ch ON again. Check that the VDC warning lamp turns

ON when the brake pedal is depressed 15 to 20 times.

10. Check that the VDC warning lamp turns ON when the brake pedal is depressed 15 to 20 times after the lapse of 120 seconds or more after the ignition switch is turned ON again.

11. Perform the self-diagnosis for “ABS” with CONSULT- III and erase all the stored self-diagnosis results.

Function Check

1. Turn the ignition switch OFF.

2. Depress the brake pedal 20 times or more.

NOTE:

The pressure loss in the accumulator results in a large brake pedal stroke. In addition to this, the brake

pedal depression becomes lighter in initial stage.

3. Turn the ignition switch ON with the brake pedal depr essed to check that the clearance between the brake

pedal and the dash lower panel decreases. A : Refer to

BR-47, "

Brake Booster".

JPFIA0728ZZ

Motor operating time : 18 seconds or less

Motor operating time : 2 − 11 seconds

Revision: 2010 May2011 QX56

Page 517 of 5598

SERVICE DATA AND SPECIFICATIONS (SDS)

BR-47

< SERVICE DATA AND SPECIFICATIONS (SDS)

C

D E

G H

I

J

K L

M A

B

BR

N

O P

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

General SpecificationINFOID:0000000006222502

Unit: mm (in)

Brake PedalINFOID:0000000006222503

Unit: mm (in)

Brake BoosterINFOID:0000000006222504

Unit: mm (in)

Front Disc BrakeINFOID:0000000006222505

Unit: mm (in)

Rear Disc BrakeINFOID:0000000006222506

Unit: mm (in)

Front brake Cylinder bore diameter 50.8 (2.000)

× 2

Pad length × width × thickness 151.6 (5.97) × 56.5 (2.224) × 12.0 (0.472)

Rotor outer diameter × thickness 350 (13.78) × 30.0 (1.181)

Rear brake Cylinder bore diameter 48.1 (10894)

Pad length

× width × thickness 110.0 (4.43) × 41.0 (1.614) × 9.0 (0.354)

Rotor outer diameter × thickness 350 (13.78) × 20.0 (0.787)

Control valve Valve type Electric brake force distribution

Recommended brake fluid Refer to MA-10, "

Fluids and Lubricants".

Item Standard

Brake pedal height 168.5 (6.63) – 178.5 (7.03)

Depressed brake pedal height

[Depressing 490 N (50 kg, 110 lb) while turning the engine ON] 100 (3.94) or more

Clearance between stop lamp switch and brake switch threaded end and the

brake pedal bracket 0.2 (0.008) – 1.96 (0.0772)

Brake pedal play 3 (0.12) – 11 (0.43)

Item Standard

Input rod length 202.2 (7.96)

Item Limit

Brake pad Wear thickness 1.5 (0.059)

Disc rotor Wear thickness 28.5 (1.122)

Thickness variation (measured at 8 positions) 0.015 (0.0006)

Runout (with it attached to the vehicle) 0.053 (0.0021)

Item Limit

Brake pad Wear thickness 2.0 (0.079)

Disc rotor Wear thickness 18.0 (0.709)

Thickness variation (measured at 8 positions) 0.015 (0.0006)

Runout (with it attached to the vehicle) 0.05 (0.0020)

Revision: 2010 May2011 QX56

Page 519 of 5598

BRC-2

ADDITIONAL SERVICE WHEN REPLACING

ABS ACTUATOR AND ELECTRIC UNIT

(CONTROL UNIT) ..............................................

63

Description ........................................................... ...63

ADJUSTMENT OF STEERING ANGLE SEN-

SOR NEUTRAL POSITION ...............................

64

Description ........................................................... ...64

Work Procedure ......................................................64

CALIBRATION OF DECEL G SENSOR ...........66

Description ........................................................... ...66

Work Procedure ......................................................66

DTC/CIRCUIT DIAGNOSIS ...................... ...68

C1101, C1102, C1103, C1104 WHEEL SEN-

SOR ................................................................. ...

68

DTC Logic ............................................................ ...68

Diagnosis Procedure ..............................................68

C1105, C1106, C1107, C1108 WHEEL SEN-

SOR ....................................................................

70

DTC Logic ............................................................ ...70

Diagnosis Procedure ..............................................70

C1109 POWER AND GROUND SYSTEM .........72

Description ........................................................... ...72

DTC Logic ...............................................................72

Diagnosis Procedure ..............................................72

C1111 PUMP MOTOR .......................................75

DTC Logic ............................................................ ...75

Diagnosis Procedure ..............................................75

C1115 WHEEL SENSOR ...................................77

DTC Logic ............................................................ ...77

Diagnosis Procedure ..............................................77

C1116 STOP LAMP SWITCH ............................79

DTC Logic ............................................................ ...79

Diagnosis Procedure ..............................................79

Component Inspection (Stop lamp Switch) ............85

Component Inspection (Stop Lamp Relay) .............86

C1118 TRANSFER CONTROL UNIT ................87

DTC Logic ............................................................ ...87

Diagnosis Procedure ..............................................87

C1120, C1122, C1124, C1126 ABS IN VALVE

SYSTEM .......................................................... ...

88

DTC Logic ............................................................ ...88

Diagnosis Procedure ..............................................88

C1121, C1123, C1125, C1127 ABS OUT

VALVE SYSTEM ................................................

90

DTC Logic ............................................................ ...90

Diagnosis Procedure ..............................................90

C1130 ENGINE SIGNAL ...................................92

DTC Logic ............................................................ ...92

Diagnosis Procedure ............................................ ...92

C1140 ACTUATOR RELAY SYSTEM ..............93

DTC Logic ............................................................ ...93

Diagnosis Procedure ...............................................93

C1142 PRESS SENSOR ...................................95

DTC Logic ............................................................ ...95

Diagnosis Procedure ...............................................95

C1143 STEERING ANGLE SENSOR ...............97

DTC Logic ............................................................ ...97

Diagnosis Procedure ...............................................97

C1144 INCOMPLETE STEERING ANGLE

SENSOR ADJUSTMENT ..................................

99

DTC Logic ............................................................ ...99

Diagnosis Procedure ...............................................99

C1145, C1146 YAW RATE/SIDE/DECEL G

SENSOR ...........................................................

100

DTC Logic ............................................................ .100

Diagnosis Procedure .............................................100

C1155 BRAKE FLUID LEVEL SWITCH ..........103

DTC Logic ............................................................ .103

Diagnosis Procedure .............................................103

Component Inspection ..........................................104

C1160 DECEL G SEN SET ..............................105

DTC Logic ............................................................ .105

Diagnosis Procedure .............................................105

C1164, C1165 CV SYSTEM .............................106

DTC Logic ............................................................ .106

Diagnosis Procedure .............................................106

C1166, C1167 SV SYSTEM .............................108

DTC Logic ............................................................ .108

Diagnosis Procedure .............................................108

C1170 VARIANT CODING ...............................110

DTC Logic ............................................................ .110

Diagnosis Procedure .............................................110

C118E ACCUMULATOR ..................................111

DTC Logic ............................................................ .111

Diagnosis Procedure .............................................111

U1000 CAN COMM CIRCUIT ...........................112

Description ........................................................... .112

DTC Logic .............................................................112

Diagnosis Procedure .............................................112

POWER SUPPLY AND GROUND CIRCUIT ....113

Description ........................................................... .113

Diagnosis Procedure .............................................113

PARKING BRAKE SWITCH .............................117

Component Function Check ................................ .117

Diagnosis Procedure .............................................117

Component Inspection ..........................................118

Revision: 2010 May2011 QX56

Page 522 of 5598

![INFINITI QX56 2011 Factory Owners Guide

PRECAUTIONSBRC-5

< PRECAUTION > [WITH VDC]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID INFINITI QX56 2011 Factory Owners Guide

PRECAUTIONSBRC-5

< PRECAUTION > [WITH VDC]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID](/img/42/57033/w960_57033-521.png)

PRECAUTIONSBRC-5

< PRECAUTION > [WITH VDC]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000006228174

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the “SRS AIR BAG” and “SEAT BELT” of this

Service Manual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision that would result in air ba g inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the “SRS AIR BAG”.

Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

When working near the Air Bag Diagnosis Sensor Unit or other Air Bag System sensors with the

ignition ON or engine running, DO NOT use air or electric power tools or strike near the sensor(s)

with a hammer. Heavy vibration could activate the sensor(s) and deploy the air bag(s), possibly

causing serious injury.

When using air or electric power tools or hammers , always switch the ignition OFF, disconnect the

battery, and wait at least 3 minutes before performing any service.

Precaution Necessary for Steering Wh eel Rotation after Battery Disconnect

INFOID:0000000006228175

NOTE:

Before removing and installing any control units, first tu rn the push-button ignition switch to the LOCK posi-

tion, then disconnect both battery cables.

After finishing work, confirm that all control unit connectors are connected properly, then re-connect both

battery cables.

Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If a DTC is detected, perform trouble diagnos is according to self-diagnosis results.

For vehicle with steering lock unit, if the battery is disconnected or discharged, the steering wheel will lock and

cannot be turned.

If turning the steering wheel is required with the batte ry disconnected or discharged, follow the operation pro-

cedure below before starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Turn the push-button ignition switch to ACC position. (At this time, the steering lock will be released.)

3. Disconnect both battery cables. The steering lock wil l remain released with both battery cables discon-

nected and the steering wheel can be turned.

4. Perform the necessary repair operation.

Revision: 2010 May2011 QX56

Page 523 of 5598

![INFINITI QX56 2011 Factory Owners Guide

BRC-6

< PRECAUTION >[WITH VDC]

PRECAUTIONS

5. When the repair work is completed, re-connect bot

h battery cables. With the brake pedal released, turn

the push-button ignition switch from ACC position INFINITI QX56 2011 Factory Owners Guide

BRC-6

< PRECAUTION >[WITH VDC]

PRECAUTIONS

5. When the repair work is completed, re-connect bot

h battery cables. With the brake pedal released, turn

the push-button ignition switch from ACC position](/img/42/57033/w960_57033-522.png)

BRC-6

< PRECAUTION >[WITH VDC]

PRECAUTIONS

5. When the repair work is completed, re-connect bot

h battery cables. With the brake pedal released, turn

the push-button ignition switch from ACC position to ON position, then to LOCK position. (The steering

wheel will lock when the push-button igniti on switch is turned to LOCK position.)

6. Perform self-diagnosis check of all control units using CONSULT-III.

Precaution for Procedure without Cowl Top CoverINFOID:0000000006228176

When performing the procedure after removing cowl top cover, cover

the lower end of windshield with urethane, etc.

Precaution for Brake SystemINFOID:0000000006222556

WARNING:

Clean any dust from the front brake and rear brake using a vacuum dust collector. Never blow by com-

pressed air.

Brake fluid use refer to MA-10, "

Fluids and Lubricants".

Never reuse drained brake fluid.

Never spill or splash brake fluid on painted surfaces. Brake fluid may seriously damage paint. Wipe it off

immediately and wash with water if it gets on a painted surface.

Always confirm the specified tightening torque when installing the brake pipes.

After pressing the brake pedal more deeply or harder t han normal driving, such as air bleeding, check each

item of brake pedal. Adjust brake pedal if it is outside the standard value.

Never use mineral oils such as gasoline or light oil to clean. They may damage rubber parts and cause

improper operation.

Always loosen the brake tube flar e nut with a flare nut wrench.

Tighten the brake tube flare nut to the specified torque with a crow-

foot (A) and torque wrench (B).

Always connect the battery terminal when moving the vehicle.

Turn the ignition switch OFF and disconnect the ABS actuator and

electric unit (control unit) harness connector or the battery negative

terminal before performing the work.

Check that no brake fluid leakage is present after replacing the parts.

Precaution for Brak e Control SystemINFOID:0000000006222557

Slight vibrations are felt on the brake pedal and the operation noises occur, when VDC function, TCS func-

tion, ABS function, EBD function, hill start assist function or brake limited slip differential (BLSD) function

operates. This is not a malfunction because it is caus ed by VDC function, TCS function, ABS function, EBD

function, hill start assist function or brake limited sl ip differential (BLSD) function that is normally operated.

When starting engine or when starting vehicle just after starting engine, brake pedal may vibrate or motor

operating noise may be heard from engine compartment. This is normal condition.

Brake stopping distance may become longer than models without ABS function depending on the road con-

ditions, when ABS function is operated on slippery r oad like rough road, gravel road or snowy road.

When a malfunction is indicated, always collect info rmation from the customer about conditions of occur-

rence, estimate cause and perform operation. Check brake booster operation, brake fluid level and brake

fluid leakage, as well as electrical system.

The optimum performance is achieved by control for V DC function, TCS function, ABS function, EBD func-

tion, hill start assist function or brake limited slip di fferential (BLSD) function when all of brakes, suspensions

PIIB3706J

JPFIA0001ZZ

Revision: 2010 May2011 QX56

Page 524 of 5598

![INFINITI QX56 2011 Factory Owners Guide

PRECAUTIONSBRC-7

< PRECAUTION > [WITH VDC]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

and tires installed on the vehicle are the specified si ze and parts. Brake performance and controllability may

be negativ INFINITI QX56 2011 Factory Owners Guide

PRECAUTIONSBRC-7

< PRECAUTION > [WITH VDC]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

and tires installed on the vehicle are the specified si ze and parts. Brake performance and controllability may

be negativ](/img/42/57033/w960_57033-523.png)

PRECAUTIONSBRC-7

< PRECAUTION > [WITH VDC]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

and tires installed on the vehicle are the specified si ze and parts. Brake performance and controllability may

be negatively affected when other parts than the specified are installed.

Brake stopping distance may become longer and steering stability may be negatively affected, when tires in

different size and combination or other parts than the specified are used.

When a radio (including wiring), antenna and antenna lead line are located near ABS actuator and electric

unit (control unit), a malfunction or improper operation ma y occur for the control of VDC function, TCS func-

tion, ABS function, EBD function, hill start assist func tion or brake limited slip differential (BLSD) function.

When the following items are replaced by other parts than genuine parts or modified, ABS warning lamp, brake warning lamp and VDC warning lamp may turn ON, and the control may not operate normally for VDC

function, TCS function, ABS function, EB D function, hill start assist function or brake limited slip differential

(BLSD) function.

- Suspension component parts (shock absorber, spring, bushing and others)

- Tire and wheel (other than the specified size)

- Brake component parts (brake pad, disc rotor, brake caliper and others)

- Engine component parts (ECM, muffler and others)

- Body reinforcement component parts (rollover bar, tower bar and others)

When suspension, tire and brake component parts are excessively worn or deteriorated and the vehicle is

driven, ABS warning lamp, brake warning lamp and VDC warning lamp may tu\

rn ON, and the control may

not operate normally for VDC function, TCS function, ABS function, EBD function, hill start assist function or

brake limited slip differential (BLSD) function.

ABS warning lamp, brake warning lamp and VDC warning lamp may turn ON, when only front wheel or rear wheel is rotated using a free roller. This is not a ma lfunction, because it is caused by wheel speed difference

between wheel that is rotated and wheel that is not rota ted. In this case, perform self-diagnosis, check self-

diagnosis results, and erase memory.

When power supply voltage is not normal, ABS warning lamp, brake warning lamp and VDC warning lamp

turn ON. ABS actuator and electric unit (control unit) st ops control for VDC function, TCS function, ABS func-

tion, EBD function, hill start assist function or brake limited slip differential (BLSD) function. Ordinary brake

operates. After power supply returns to normal, ABS warning lamp, brake warning lamp and VDC warning

lamp turn OFF. The control becomes operative for VD C function, TCS function, ABS function, EBD function,

hill start assist function or brake li mited slip differential (BLSD) function.

VDC warning lamp may turn ON and VDC function or TCS function may not normally operate, when driving

on a special road the is extremely slanted (bank in a circ uit course). This is not a malfunction if the status

returns to normal for VDC function or TCS function after the engine is started again. In this case, perform

self-diagnosis, check self-diagnosis results, and erase memory.

A malfunction in yaw rate/side/decel G sensor syste m may be detected when the vehicle sharply turns dur-

ing a spin turn, acceleration turn or drift driving while VDC function or TCS function are OFF (VDC OFF

switch is pressed and VDC OFF indicator lamp is in ON st atus). This is not a malfunction if the status returns

to normal for VDC function or TCS function after the engine is started again. In this case, perform self-diag-

nosis, check self-diagnosis results, and erase memory

Precaution for Harness RepairINFOID:0000000006222558

Solder the repair part, and wrap it with tape. [Twisted wire fray must be 110 mm (4.33 in) or less.]

SKIB8766E

Revision: 2010 May2011 QX56

Page 528 of 5598

![INFINITI QX56 2011 Factory Owners Guide

COMPONENT PARTSBRC-11

< SYSTEM DESCRIPTION > [WITH VDC]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

4WD

1. ECM Refer to EC-16, "

Component Parts

Location". 2. Control valve & TCM

Refer to TM-10, "

A/T CONTR INFINITI QX56 2011 Factory Owners Guide

COMPONENT PARTSBRC-11

< SYSTEM DESCRIPTION > [WITH VDC]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

4WD

1. ECM Refer to EC-16, "

Component Parts

Location". 2. Control valve & TCM

Refer to TM-10, "

A/T CONTR](/img/42/57033/w960_57033-527.png)

COMPONENT PARTSBRC-11

< SYSTEM DESCRIPTION > [WITH VDC]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

4WD

1. ECM Refer to EC-16, "

Component Parts

Location". 2. Control valve & TCM

Refer to TM-10, "

A/T CONTROL

SYSTEM : Compon ent Parts Loca-

tion". 3. Front wheel sensor

4. ABS actuator and electric unit (con- trol unit) 5. Stop lamp switch 6. Steering angle sensor

7. VDC OFF switch 8. Yaw rate/side/decel G sensor 9. Rear wheel sensor

A. Front wheel hub and bearing assem- bly B. Inside engine room C. Brake pedal

D. ABS warning lamp, brake warning lamp, VDC warning lamp, VDC OFF

indicator lamp E. Back of spiral cable assembly F. Center console assembly

G. Under center console assembly H. Rear wheel hub and bearing assem- bly

Revision: 2010 May2011 QX56

Page 529 of 5598

![INFINITI QX56 2011 Factory Owners Guide

BRC-12

< SYSTEM DESCRIPTION >[WITH VDC]

COMPONENT PARTS

1. Transfer control unit

Refer to DLN-10, "

Component Parts

Location". 2. ECM

Refer to EC-16, "

Component Parts

Location". 3. Control valve INFINITI QX56 2011 Factory Owners Guide

BRC-12

< SYSTEM DESCRIPTION >[WITH VDC]

COMPONENT PARTS

1. Transfer control unit

Refer to DLN-10, "

Component Parts

Location". 2. ECM

Refer to EC-16, "

Component Parts

Location". 3. Control valve](/img/42/57033/w960_57033-528.png)

BRC-12

< SYSTEM DESCRIPTION >[WITH VDC]

COMPONENT PARTS

1. Transfer control unit

Refer to DLN-10, "

Component Parts

Location". 2. ECM

Refer to EC-16, "

Component Parts

Location". 3. Control valve & TCM

Refer to TM-10, "

A/T CONTROL

SYSTEM : Component Parts Loca-

tion".

4. Front wheel sensor 5. ABS actuat or and electric unit (con-

trol unit) 6. Stop lamp switch

7. Steering angle sensor 8. VDC OFF switch 9. Yaw rate/side/decel G sensor

10. Rear wheel sensor

A. Front wheel hub and bearing assem- bly B. Inside engine room C. Brake pedal

JPFIC0186ZZ

Revision: 2010 May2011 QX56

Page 530 of 5598

![INFINITI QX56 2011 Factory Owners Guide

COMPONENT PARTSBRC-13

< SYSTEM DESCRIPTION > [WITH VDC]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

Component DescriptionINFOID:0000000006222560

*1: Models with Advanced Driver Assistance System

*2: Models wit INFINITI QX56 2011 Factory Owners Guide

COMPONENT PARTSBRC-13

< SYSTEM DESCRIPTION > [WITH VDC]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

Component DescriptionINFOID:0000000006222560

*1: Models with Advanced Driver Assistance System

*2: Models wit](/img/42/57033/w960_57033-529.png)

COMPONENT PARTSBRC-13

< SYSTEM DESCRIPTION > [WITH VDC]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

Component DescriptionINFOID:0000000006222560

*1: Models with Advanced Driver Assistance System

*2: Models with 4WD system

D. ABS warning lamp, brake warning lamp, VDC warning lamp, VDC OFF

indicator lamp E. Back of spiral cable assembly F. Center console assembly

G. Under center console assembly H. Rear wheel hub and bearing assem- bly

Component Reference/Function

ABS actuator and electric unit

(control unit) Motor/accumulator assembly

BRC-14, "

ABS Actuator and Electric Unit (Control Unit)"

Motor relay

Actuator relay (main relay)

ABS IN valve

ABS OUT valve

Cut valve 1

Cut valve 2

Suction valve 1

Suction valve 2

Control pressure sensor

*1

Accumulator pressure sensor

Master cylinder pressure sensor

Wheel sensor BRC-14, "

Wheel Sensor and Sensor Rotor"

Stop lamp switchBRC-15, "Stop Lamp Switch"

Steering angle sensorBRC-15, "Steering Angle Sensor"

Yaw rate/side/decel G sensorBRC-15, "Yaw Rate/Side/Decel G sensor"

Brake fluid level switch BRC-15, "Brake Fluid Level Switch"

Parking brake switchBRC-15, "Parking Brake Switch"

VDC OFF switchBRC-15, "VDC OFF Switch"

ECMMainly transmits the

following signals to ABS actuator and elec-

tric unit (control unit) via CAN communication.

Accelerator pedal position signal

Engine speed signal

Mainly receives the following signals from ABS actuator and

electric unit (control unit) via CAN communication.

Target throttle position signal

TCM Mainly transmits the

following signals to ABS actuator and elec-

tric unit (control unit) via CAN communication.

Shift position signal

Current gear position signal

Transfer control unit

*2Mainly transmits the following signals to ABS actuator and elec-

tric unit (control unit) via CAN communication.

Current 4WD mode signal

ABS warning lamp

BRC-16, "

System Description"Brake warning lamp

VDC warning lamp

VDC OFF indicator lamp

Revision: 2010 May2011 QX56

Page 531 of 5598

![INFINITI QX56 2011 Factory Owners Guide

BRC-14

< SYSTEM DESCRIPTION >[WITH VDC]

COMPONENT PARTS

ABS Actuator and Electric Unit (Control Unit)

INFOID:0000000006222561

Electric unit (control unit) is in tegrated with actuator and motor/accu INFINITI QX56 2011 Factory Owners Guide

BRC-14

< SYSTEM DESCRIPTION >[WITH VDC]

COMPONENT PARTS

ABS Actuator and Electric Unit (Control Unit)

INFOID:0000000006222561

Electric unit (control unit) is in tegrated with actuator and motor/accu](/img/42/57033/w960_57033-530.png)

BRC-14

< SYSTEM DESCRIPTION >[WITH VDC]

COMPONENT PARTS

ABS Actuator and Electric Unit (Control Unit)

INFOID:0000000006222561

Electric unit (control unit) is in tegrated with actuator and motor/accumulator assembly and comprehensively

controls VDC function, TCS function, AB S function, EBD function, hill start assist function or brake limited slip

differential function.

ELECTRIC UNIT (CONTROL UNIT)

Brake fluid pressure, engine and transmission are controlled according to signals from each sensor.

If malfunction is detected, the system enters fail-safe mode.

ACTUATOR

The following components are integrated with ABS actuator.

Motor/accumulator Assembly

Pump Operates the pump drive according to signals from ABS actuator and electric unit (control unit) by the motor.

Motor Operates the motor drive according to signals fr om ABS actuator and electric unit (control unit).

Accumulator

The accumulator accumulates brake fluid conveyed by the motor and pump.

Motor Relay

Operates the motor ON/OFF according to signals fr om ABS actuator and electric unit (control unit).

Actuator Relay (Main Relay)

Operates each valve ON/OFF according to signals fr om ABS actuator and electric unit (control unit).

ABS IN Valve and ABS OUT Valve

Increases, holds or decreases the fluid pressure of each caliper according to signals from ABS actuator and

electric unit (control unit).

Cut Valve 1, Cut Valve 2

Shuts off the ordinary brake line from master cylinder to signals from ABS actuator and electric unit (control

unit).

Suction Valve 1

Suction Valve 1 switches the brake path to convey accu mulator pressure to the front system, according to a

signal transmitted from the ABS actuat or and electric unit (control unit).

Suction Valve 2

Suction valve 2 releases accumulator pressure, accord ing to a signal transmitted from the ABS actuator and

electric unit (control unit).

Control Pressure Sensor (models with Advanced Driver Assistance System)

Detects the brake fluid pressure of brake caliper side and transmits a signal to ABS actuator and electric unit

(control unit).

Accumulator Pressure Sensor

The accumulator pressure sensor detects brake fluid pressure accumulated in the accumulator and conveys

the detected result to the ABS act uator and electric unit (control unit).

Master cylinder Pressure Sensor

Detects the brake fluid pressure of master cylinder part and transmits a signal to ABS actuator and electric unit

(control unit).

Wheel Sensor and Sensor RotorINFOID:0000000006222562

NOTE:

Wheel sensor and sensor rotor is integrated in wheel hub assembly.

Never measure resistance and voltage value using a tester because sensor is active sensor.

Revision: 2010 May2011 QX56