engine INFINITI QX56 2011 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 1495 of 5598

PRECAUTIONSDEF-3

< PRECAUTION >

C

DE

F

G H

I

J

K

M A

B

DEF

N

O P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000006349779

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the “SRS AIR BAG” and “SEAT BELT” of this

Service Manual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision that would result in air ba g inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the “SRS AIR BAG”.

Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

When working near the Air Bag Diagnosis Sensor Unit or other Air Bag System sensors with the

ignition ON or engine running, DO NOT use air or electric power tools or strike near the sensor(s)

with a hammer. Heavy vibration could activate the sensor(s) and deploy the air bag(s), possibly

causing serious injury.

When using air or electric power tools or hammers , always switch the ignition OFF, disconnect the

battery, and wait at least 3 minutes before performing any service.

Precaution Necessary for Steering Wh eel Rotation after Battery Disconnect

INFOID:0000000006299422

NOTE:

Before removing and installing any control units, first tu rn the push-button ignition switch to the LOCK posi-

tion, then disconnect both battery cables.

After finishing work, confirm that all control unit connectors are connected properly, then re-connect both

battery cables.

Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If a DTC is detected, perform trouble diagnos is according to self-diagnosis results.

This vehicle is equipped with a push-button ignition switch and a steering lock unit.

If the battery is disconnect ed or discharged, the steering wheel will lock and cannot be turned.

If turning the steering wheel is required with the battery disconnected or discharged, follow the procedure

below before starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Turn the push-button ignition switch to ACC position. (At this time, the steering lock will be released.)

3. Disconnect both battery cables. The steering lock wil l remain released with both battery cables discon-

nected and the steering wheel can be turned.

4. Perform the necessary repair operation.

Revision: 2010 May2011 QX56

Page 1499 of 5598

DIAGNOSIS SYSTEM (BCM)DEF-7

< SYSTEM DESCRIPTION >

C

DE

F

G H

I

J

K

M A

B

DEF

N

O P

DIAGNOSIS SYSTEM (BCM)

COMMON ITEM

COMMON ITEM : CONSULT-III Fu nction (BCM - COMMON ITEM)INFOID:0000000006349773

APPLICATION ITEM

CONSULT-III performs the following functions via CAN communication with BCM.

SYSTEM APPLICATION

BCM can perform the following functions for each system.

NOTE:

It can perform the diagnosis modes except the following for all sub system selection items.

×: Applicable item

*: This item is indicated, but not used.

FREEZE FRAME DATA (FFD)

The BCM records the following vehicle condition at the time a particular DTC is detected, and displays on

CONSULT-III.

Diagnosis mode Function Description

Work Support Changes the setting for each system function.

Self Diagnostic Result Displays the diagnosis results judged by BCM. Refer to BCS-57, "

DTCIndex".

CAN Diag Support Monitor Monitors the reception status of CAN communication viewed from BCM. Refer to CONSULT-III opera-

tion manual.

Data Monitor The BCM input/output signals are displayed.

Active Test The signals used to activate each device are forcibly supplied from BCM.

Ecu Identification The BCM part number is displayed.

Configuration Read and save the vehicle specification.

Write the vehicle specification when replacing BCM.

System Sub system selection item Diagnosis mode

Work Support Data Monitor Active Test

Door lock DOOR LOCK ×××

Rear window defo gger REAR DEFOGGER ××

Warning chime BUZZER ××

Interior room lamp timer INT LAMP ×××

Exterior lamp HEAD LAMP ×××

Wiper and washer WIPER ×××

Turn signal and hazard warning lamps FLASHER ×××

— AIR CONDITONER* ××

Intelligent Key system

Engine start system INTELLIGENT KEY

×××

Combination switch COMB SW ×

Body control system BCM ×

IVIS IMMU ×××

Interior room lamp battery saver BATTERY SAVER ×××

Back door TRUNK ×

Vehicle security system THEFT ALM ×××

RAP system RETAINED PWR ×

Signal buffer system SIGNAL BUFFER ××

Revision: 2010 May2011 QX56

Page 1500 of 5598

DEF-8

< SYSTEM DESCRIPTION >

DIAGNOSIS SYSTEM (BCM)

REAR WINDOW DEFOGGER

REAR WINDOW DEFOGGER : CONSULT-III Function (BCM - REAR DEFOGGER)

INFOID:0000000006299428

Data monitor

ACTIVE TEST

CONSULT screen item Indication/Unit Description

Vehicle Speed km/h Vehicle speed of the moment a particular DTC is detected

Odo/Trip Meter km Total mileage (Odometer value) of the moment a particular DTC is detected

Vehicle Condition SLEEP>LOCK

Power position status of

the moment a particular

DTC is detected While turning BCM status from low power consumption mode to

normal mode (Power supply position is “LOCK”)

SLEEP>OFF While turning BCM status from low power consumption mode to

normal mode (Power supply position is “OFF”.)

LOCK>ACC While turning power supply position from “LOCK” to “ACC”

ACC>ON While turning power supply position from “ACC” to “IGN”

RUN>ACC While turning power supp

ly position from “RUN” to “ACC” (Vehicle

is stopping and selector lever is except P position.)

CRANK>RUN While turning power su

pply position from “CRANKING” to “RUN”

(From cranking up the engine to run it)

RUN>URGENT While turning power supply positi

on from “RUN“ to “ACC” (Emer-

gency stop operation)

ACC>OFF While turning power supply position from “ACC” to “OFF”

OFF>LOCK While turning power supply position from “OFF” to “LOCK”

OFF>ACC While turning power supply position from “OFF” to “ACC”

ON>CRANK While turning power supply position from “IGN” to “CRANKING”

OFF>SLEEP While turning BCM status from normal mode (Power supply posi-

tion is “OFF”.) to low power consumption mode

LOCK>SLEEP While turning BCM status from normal mode (Power supply posi-

tion is “LOCK”.) to low power consumption mode

LOCK Power supply position is “LOCK”

(Ignition switch OFF with steer-

ing is locked.)

OFF Power supply position is “OFF” (Ignition switch OFF with steering

is unlocked.)

ACC Power supply position is “ACC” (Ignition switch ACC)

ON Power supply position is “IGN” (Ignition switch ON with engine

stopped)

ENGINE RUN Power supply position is “RUN” (Ignition switch ON with engine

running)

CRANKING Power supply position is “CRANKING” (At engine cranking)

IGN Counter 0 - 39 The number of times that ignition switch is turned ON after DTC is detected

The number is 0 when a malfunction is detected now.

The number increases like 1

→ 2 → 3...38 → 39 after returning to the normal condition

whenever ignition switch OFF → ON.

The number is fixed to 39 until the self-diagnosis results are erased if it is over 39.

Monitor Item Description

REAR DEF SW Displays “Press (ON)/other (OFF)” status determined with the rear window defogger switch.

PUSH SW Indicates [ON/OFF] condition of push switch.

Revision: 2010 May2011 QX56

Page 1502 of 5598

DEF-10

< SYSTEM DESCRIPTION >

DIAGNOSIS SYSTEM (IPDM E/R)

DIAGNOSIS SYSTEM (IPDM E/R)

Diagnosis DescriptionINFOID:0000000006349776

AUTO ACTIVE TEST

Description

In auto active test, the IPDM E/R sends a drive signal to the following systems to check their operation.

Oil pressure warning lamp

Rear window defogger

Front wiper (LO, HI)

Parking lamp

License plate lamp

Tail lamp

Side marker lamp

Front fog lamp

Headlamp (LO, HI)

A/C compressor (magnet clutch)

Operation Procedure

CAUTION:

Never perform auto active test in the following conditions.

Engine is running.

CONSULT-III is connected.

1. Close the hood and lift the wiper arms from the windshield. (Prevent windshield damage due to wiper

operation)

NOTE:

When auto active test is performed with hood opened, sprinkle water on windshield beforehand.

2. Turn the ignition switch OFF.

3. Turn the ignition switch ON, and within 20 seconds, pr ess the driver door switch 10 times. Then turn the

ignition switch OFF.

CAUTION:

Close passenger door.

4. Turn the ignition switch ON within 10 seconds. Af ter that the horn sounds once and the auto active test

starts.

CAUTION:

Engine starts when igniti on switch is turned ON while brake pedal is depressed.

5. The oil pressure warning lamp starts blinking when the auto active test starts.

6. After a series of the following operations is repeated 3 times, auto active test is completed.

NOTE:

When auto active test has to be cancelled halfway through test, turn the ignition switch OFF.

When auto active test is not activated, door swit ch may be the cause. Check door switch. Refer to DLK-117,

"ComponentFunctionCheck".

Inspection in Auto Active Test

When auto active test is actuated, the following operation sequence is repeated 3 times.

Operation

sequence Inspection location Operation

1 Oil pressure warning lamp Blinks continuously during operation of auto active test

2 Rear window defogger 10 seconds

3 Front wiper LO for 5 seconds → HI for 5 seconds

4 Parking lamp

License plate lamp

Tail lamp

Side marker lamp

Front fog lamp 10 seconds

Revision: 2010 May2011 QX56

Page 1506 of 5598

DEF-14

< SYSTEM DESCRIPTION >

DIAGNOSIS SYSTEM (IPDM E/R)

*: Operates while the engine is running.EXTERNAL LAMPS

Off OFF

TAIL Operates the tail lamp relay.

Lo Operates the headlamp low relay.

Hi

Operates the headlamp low relay and ON/OFF the headlamp high relay at 1 sec-

ond intervals.

Fog Operates the front fog lamp relay.

Test item Operation Description

Revision: 2010 May2011 QX56

Page 1544 of 5598

DLK-8

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000006225828

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the “SRS AIR BAG” and “SEAT BELT” of this

Service Manual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision that would result in air bag inflation, all maintenance must be performed by

an authorized NISS AN/INFINITI dealer.

Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the “SRS AIR BAG”.

Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

When working near the Air Bag Diagnosis Sensor Unit or other Air Bag System sensors with the ignition ON or engine running, DO NOT use air or electric power tools or strike near the sensor(s)

with a hammer. Heavy vibration could activate the sensor(s) and deploy the air bag(s), possibly

causing serious injury.

When using air or electric power tools or hammers , always switch the ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution Necessary for Steering W heel Rotation after Battery Disconnect

INFOID:0000000006225829

NOTE:

Before removing and installing any control units, first tu rn the push-button ignition switch to the LOCK posi-

tion, then disconnect bot h battery cables.

After finishing work, confirm that all control unit connectors are connected properly, then re-connect both

battery cables.

Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If a DTC is detected, perform trouble diagnos is according to self-diagnosis results.

For vehicle with steering lock unit, if the battery is disconnected or discharged, the steering wheel will lock and

cannot be turned.

If turning the steering wheel is required with the bat tery disconnected or discharged, follow the operation pro-

cedure below before starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Turn the push-button ignition switch to ACC position. (At this time, the steering lock will be released.)

3. Disconnect both battery cables. The steering lock wi ll remain released with both battery cables discon-

nected and the steering wheel can be turned.

4. Perform the necessary repair operation.

Revision: 2010 May2011 QX56

Page 1546 of 5598

DLK-10

< PREPARATION >

PREPARATION

PREPARATION

PREPARATION

Commercial Service ToolsINFOID:0000000006225832

Tool name Description

Engine ear Locates the noise

Remover tool Removes the clips, pawls, and metal clips

Power tool

Hook and pick tool Press tumbler stopper

SIIA0995E

JMKIA3050ZZ

PIIB1407E

JMJIA0490ZZ

Revision: 2010 May2011 QX56

Page 1548 of 5598

DLK-12

< SYSTEM DESCRIPTION >

COMPONENT PARTS

DOOR LOCK SYSTEM : Component Description

INFOID:0000000006225834

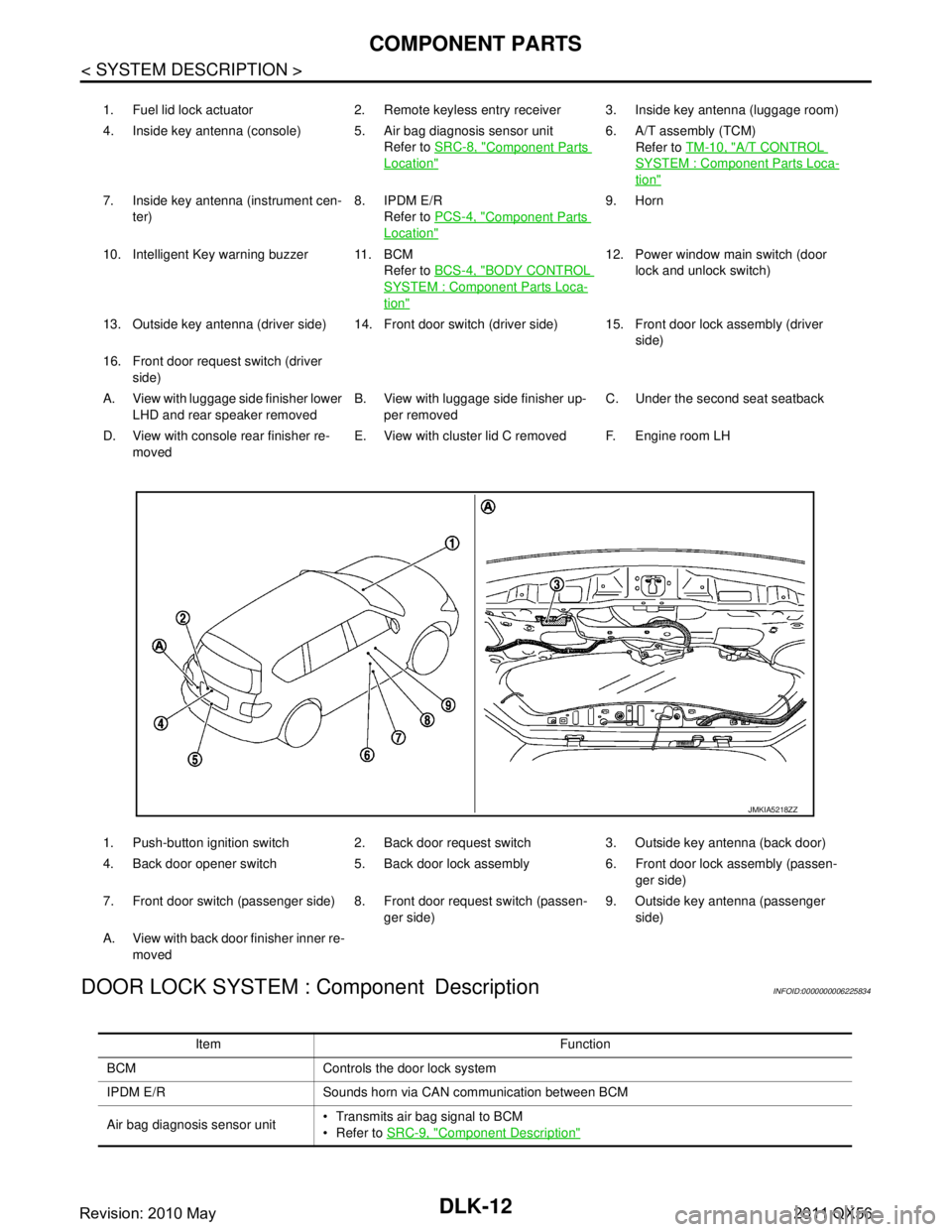

1. Fuel lid lock actuator 2. Remote keyless entry receiver 3. Inside key antenna (luggage room)

4. Inside key antenna (console) 5. Air bag diagnosis sensor unit Refer to SRC-8, "

Component Parts

Location"

6. A/T assembly (TCM)

Refer to TM-10, "

A/T CONTROL

SYSTEM : Component Parts Loca-

tion"

7. Inside key antenna (instrument cen-

ter) 8. IPDM E/R

Refer to PCS-4, "

Component Parts

Location"

9. Horn

10. Intelligent Key warning buzzer 11. BCM Refer to BCS-4, "

BODY CONTROL

SYSTEM : Component Parts Loca-

tion"

12. Power window main switch (door

lock and unlock switch)

13. Outside key antenna (driver side) 14. Front door switch (driver side) 15. Front door lock assembly (driver side)

16. Front door request switch (driver side)

A. View with luggage side finisher lower LHD and rear speaker removed B. View with luggage side finisher up-

per removed C. Under the second seat seatback

D. View with console rear finisher re- moved E. View with cluster lid C removed F. Engine room LH

1. Push-button ignition switch 2. Back door request switch 3. Outside key antenna (back door)

4. Back door opener switch 5. Back door lock assembly 6. Front door lock assembly (passen- ger side)

7. Front door switch (passenger side) 8. Front door request switch (passen- ger side)9. Outside key antenna (passenger

side)

A. View with back door finisher inner re- moved

JMKIA5218ZZ

Item Function

BCM Controls the door lock system

IPDM E/R Sounds horn via CAN communication between BCM

Air bag diagnosis sensor unit Transmits air bag signal to BCM

Refer to

SRC-9, "

Component Description"

Revision: 2010 May2011 QX56

Page 1549 of 5598

COMPONENT PARTSDLK-13

< SYSTEM DESCRIPTION >

C

DE

F

G H

I

J

L

M A

B

DLK

N

O P

AUTOMATIC BACK DOOR SYSTEM

Combination meter Displays each operation method guide and warning for system malfunction

Performs operation method guide and warning with buzzer

Transmits vehicle speed signal to CAN communication line

TCM Transmits shift position signal to BCM via CAN communication line

Remote keyless entry receiver Receives Intelligent Key operation and transmits to BCM

Inside key antenna Detects if Intelligent Key is inside the vehicle

Outside key antenna Detects if Intelligent Key is outside the vehicle

Push-button ignition switch Inputs push-button ignition switch ON/OFF condition to BCM

Door switch Inputs door open/close condition to BCM

Door lock and unlock switch Detects if door lock and unlock switch is press/release

Integrated in the power window main switch and front power window switch (passenger

side)

Door request switch Detects if each door request switch is press/release

Integrated in the outside handle (driver side, passenger side) and back door opener

switch assembly

Intelligent Key warning buzzer Warns the user of the lock/unlock condition and inappropriate operations with the buzzer

sound

Intelligent Key The following functions are available when having and carrying electronic ID

Door lock/unlock

Engine start

Remote control entry function is available when operating on button

Hazard warning lamp Warns the user of the lock/unlock condition and inappropriate operations with the lamps

blink

Door lock actuator Output lock/unlock signal from BCM and locks/unlocks each door

Fuel lid lock actuator Output lock/unlock signal from BCM and locks/unlocks fuel filler lid Item Function

Revision: 2010 May2011 QX56

Page 1555 of 5598

SYSTEM (INTELLIGENT KEY SYSTEM)

DLK-19

< SYSTEM DESCRIPTION >

C

D E

F

G H

I

J

L

M A

B

DLK

N

O P

DOOR LOCK FUNCTION

DOOR LOCK FUNCTION : System DiagramINFOID:0000000006225841

DOOR LOCK FUNCTION : System DescriptionINFOID:0000000006225842

Only when pressing the door request switch, it is possi ble to lock and unlock the door by carrying the Intelli-

gent Key.

OPERATION DESCRIPTION

When the BCM detects that each door request switch is pressed, it activates the outside key antenna and

inside key antenna corresponding to the pressed door reques t switch and transmits the request signal to the

Intelligent Key. And then, check that the Intelligent Key is near the door.

If the Intelligent Key is within the outside key ant enna detection area, it receives the request signal and

transmits the key ID signal to the BCM via remote keyless entry receiver.

BCM receives the key ID signal and compares it with the registered key ID.

BCM locks/unlocks each doors (except back door).

BCM sounds Intelligent Key warning buzzer (lock: 2 ti mes, unlock: 1 time) and blinks hazard warning lamps

(lock: 2 times, unlock: 1 time) at the same time as a reminder.

Key reminder The key reminder buzzer sounds a warning if the door is locked with the key left

inside the vehicle DLK-26

Welcome lightWhen the Intelligent Key is carried, and vehicle doors are approached, the BCM

illuminates interior room lamps and operates heart beat operation of the push-

button ignition switch DLK-26

Warning

If an action that does not meet the operating condition of the Intelligent Key sys-

tem is taken, the buzzer sounds to inform the driver DLK-27

Engine start The engine can be turned on while carrying the Intelligent Key

SEC-12

Interior room lamp control Interior room lamp is controlled according to door lock/unlock state INL-6

Power window Power window can be operated by Intelligent Key button operationPWC-8

Automatic drive positioner Automatic drive positioner system can be operated by door unlock operationADP-11

Panic alarm When Intelligent Key panic alarm button is pressed, horn soundsSEC-18

Function Description Refer

JMKIA5068GB

Revision: 2010 May2011 QX56