spare wheel INFINITI QX56 2011 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 4 of 5598

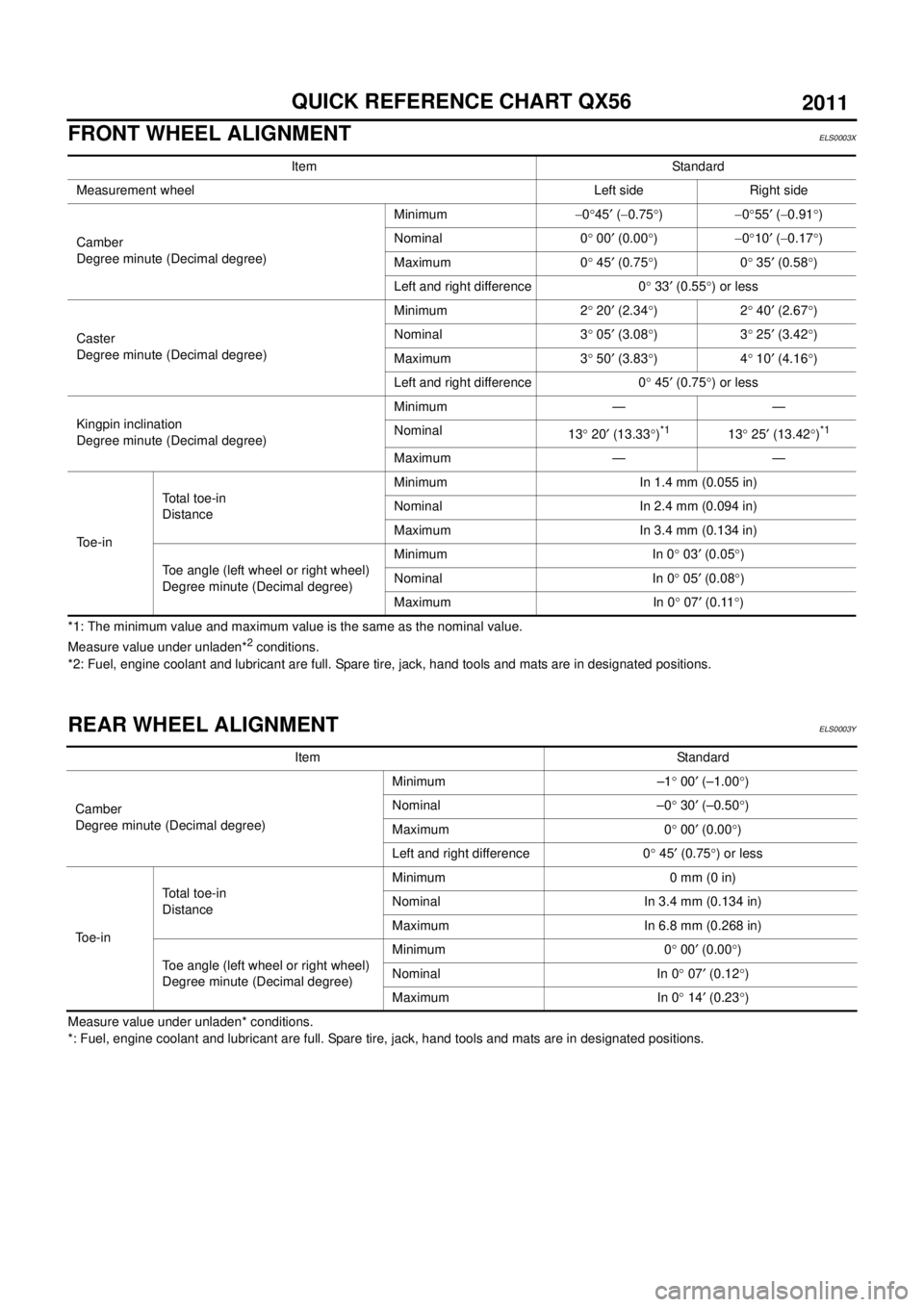

QUICK REFERENCE CHART QX56

FRONT WHEEL ALIGNMENT

ELS0003X

*1: The minimum value and maximum value is the same as the nominal value.

Measure value under unladen*2 conditions.

*2: Fuel, engine coolant and lubricant are full. Spare tire, jack, hand tools and mats are in designated positions.

REAR WHEEL ALIGNMENTELS0003Y

Measure value under unladen* conditions.

*: Fuel, engine coolant and lubricant are full. Spare tire, jack, hand tools and mats are in designated positions. Item Standard

Measurement wheel Left side Right side

Camber

Degree minute (Decimal degree) Minimum

−0 °45 ′ ( −0.75 °) −0°55 ′ ( −0.91 °)

Nominal 0 ° 00 ′ (0.00 °) −0°10 ′ ( −0.17 °)

Maximum 0 ° 45 ′ (0.75 °)0 ° 35 ′ (0.58 °)

Left and right difference 0 ° 33 ′ (0.55 °) or less

Caster

Degree minute (Decimal degree) Minimum 2

° 20 ′ (2.34 °)2 ° 40 ′ (2.67 °)

Nominal 3 ° 05 ′ (3.08 °)3 ° 25 ′ (3.42 °)

Maximum 3 ° 50 ′ (3.83 °)4 ° 10 ′

(4.16 °)

Left and right difference 0 ° 45 ′ (0.75 °) or less

Kingpin inclination

Degree minute (Decimal degree) Minimum — —

Nominal

13° 20 ′ (13.33 °)

*113 ° 25 ′ (13.42 °)*1

Maximum — —

Toe-in Total toe-in

Distance

Minimum In 1.4 mm (0.055 in)

Nominal In 2.4 mm (0.094 in)

Maximum In 3.4 mm (0.134 in)

Toe angle (left wheel or right wheel)

Degree minute (Decimal degree) Minimum In 0

° 03 ′ (0.05 °)

Nominal In 0 ° 05 ′ (0.08 °)

Maximum In 0 ° 07 ′ (0.11 °)

Item Standard

Camber

Degree minute (Decimal degree) Minimum –1

° 00 ′ (–1.00 °)

Nominal –0 ° 30 ′ (–0.50 °)

Maximum 0 ° 00 ′ (0.00 °)

Left and right difference 0 ° 45 ′ (0.75 °) or less

To e - i n Total toe-in

Distance

Minimum 0 mm (0 in)

Nominal In 3.4 mm (0.134 in)

Maximum In 6.8 mm (0.268 in)

Toe angle (left wheel or right wheel)

Degree minute (Decimal degree) Minimum 0

° 00 ′ (0.00 °)

Nominal In 0 ° 07 ′ (0.12 °)

Maximum In 0 ° 14 ′ (0.23 °)

2011

Page 689 of 5598

BRM-14

< PREPARATION >

BODY COMPONENT PARTS

NOTE:

For the parts without a number described in the figure, it is supplied only with the assembly part that the part is included with.

Tensile strength column shows the largest strength value of a part in the component part.

CAUTION:

If the high strength steel (ultra high strength steel) of this is broken, replace by assembly for the supply part. No. Parts name

Tensile strength

(MPa) Both sided anti-corrosive

precoated steel sections

1. Frame assembly Refer to No.2−36

2. Front bumper crossmember assembly T=1.8 mm

(0.071 in)

980

caution—

3. 2nd crossmember assembly 440 —

4. 2nd crossmember reinforcement (RH & LH) 440 —

5. 1st cab mounting bracket (RH & LH) Under 440 —

6. Front side member assembly (RH & LH) 540 —

7. Front suspension bracket assembly (RH & LH) Under 440 —

8. Engine mounting bracket assembly (RH & LH) Under 440 —

9. 2nd cab mounting bracket assembly (RH & LH) Under 440 —

10. 3way connector bracket assembly (RH & LH) Under 440 —

11. Piping bracket assembly (RH & LH) Under 440 —

12. Front bound bumper bracket assembly (RH & LH) 540 —

13. Lower front link mounting bracket assembly (RH & LH) 440 —

14. Diagonal member complete (RH & LH) 540 —

15. Rear engine mounting gusset assembly Under 440 —

16. Rear engine mounting member complete Under 440 —

17. Front fuel tank protector (RH & LH) Under 440 —

18. 3rd cab mounting bracket assembly (RH & LH) Under 440 —

19. Center side member assembly (RH & LH) 540 —

20. 6th crossmember assembly Under 440 —

21. Exhaust bracket (Front) Under 440 —

22. Fuel tank protector (RH & LH Rear) Under 440 —

23. Heat insulator bracket Under 440 —

24. Fuel tank protector assembly (RH & LH) 540 —

25. Rear suspension mounting bracket assembly (RH & LH) 540 —

26. 4th cab body mounting bracket assembly (RH & LH) Under 440 —

27. Rear brake hose bracket (RH & LH) Under 440 —

28. Rear shock absorber bracket assembly (RH & LH) 540 —

29. Rear side member assembly (RH & LH) 540 —

30. 5th cab body bracket (RH & LH) Under 440 —

31. 7th crossmember assembly Under 440 —

32. Exhaust bracket (Rear) Under 440 —

33. Spare wheel crossmember assembly Under 440 —

34. Front under cover bracket assembly Under 440 —

35. Rear end gusset (RH & LH) 440 —

36. Rear end crossmember assembly 540 —

Revision: 2010 May2011 QX56

Page 1253 of 5598

![INFINITI QX56 2011 Factory Service Manual

DAS-288

< SYSTEM DESCRIPTION >[LDW & LDP]

HANDLING PRECAUTION

HANDLING PRECAUTION

Precautions for Lane Departure Wa

rning/Lane Departure PreventionINFOID:0000000006223714

LANE CAMERA UNIT HANDLING

To INFINITI QX56 2011 Factory Service Manual

DAS-288

< SYSTEM DESCRIPTION >[LDW & LDP]

HANDLING PRECAUTION

HANDLING PRECAUTION

Precautions for Lane Departure Wa

rning/Lane Departure PreventionINFOID:0000000006223714

LANE CAMERA UNIT HANDLING

To](/img/42/57033/w960_57033-1252.png)

DAS-288

< SYSTEM DESCRIPTION >[LDW & LDP]

HANDLING PRECAUTION

HANDLING PRECAUTION

Precautions for Lane Departure Wa

rning/Lane Departure PreventionINFOID:0000000006223714

LANE CAMERA UNIT HANDLING

To keep the proper operation of the LDW/LDP systems and prevent a system malfunction, be sure to observe

the following:

Always keep the windshield clean.

Do not attach a sticker (including transparent materi al) or install an accessory near the lane camera unit.

Do not place reflective materials, such as white paper or a mirror, on the instrument panel. The reflection of

sunlight may adversely affect the lane camera unit capability of detecting the lane markers.

Do not strike or damage the areas around the lane camera unit.

Do not touch the camera lens.

Do not remove the screw located on the lane camera unit.

LANE DEPARTURE WARNING (LDW)

LDW system is only a warning device to inform the dr iver of a potential unintended lane departure. It will not

steer the vehicle or prevent loss of cont rol. It is the driver’s responsibility to stay alert, drive safely, keep the

vehicle in the traveling lane, and be in control of the vehicle at all times.

LDW system will not operate at speeds below approximat ely 70 km/h (45 MPH) or if it cannot detect lane

markers.

Excessive noise will interfere with the warning chime sound, and the chime may not be heard.

LDW system may not function properly under the following conditions:

- On roads where there are multiple parallel lane marker s; lane markers that are faded or not painted clearly;

yellow painted lane markers; non-standard lane markers; or lane markers covered with water, dirt or snow,

etc.

- On roads where the discontinued lane markers are still detectable.

- On roads where there are sharp curves.

- On roads where there are sharply c ontrasting objects, such as shadows, snow, water, wheel ruts, seams or

lines remaining after road repairs. (The LDW syst em could detect these items as lane markers.)

- On roads where the traveling lane merges or separates.

- When the vehicle's traveling direction does not align with the lane marker.

- When traveling close to other vehicle in front of the vehicle, which obstructs the lane camera unit detection

range.

- When rain, snow or dirt adheres to the wi ndshield in front of the lane camera unit.

- When the headlights are not bright due to dirt on the lens or if the aiming is not adjusted properly.

- When strong light enters the lane camera uni t. (For example, the light directly shines on the front of the vehi-

cle at sunrise or sunset.)

- When a sudden change in brightness occurs. (For exampl e, when the vehicle enters or exits a tunnel or

under a bridge.)

LANE DEPARTURE PREVENTION (LDP)

LDP system will not steer the vehicle or prevent loss of control. It is the driver’s responsibility to stay alert,

drive safely, keep the vehicle in the traveling lane, and be in control of vehicle at all times.

LDP system is primarily intended for use on well-dev eloped freeways or highways. It may not detect the lane

markers in certain roads, weather or driving conditions.

Using the LDP system under some conditions of road, lane marker or weather, or when driver change lanes

without using the turn signal could lead to an unexpect ed system operation. In such conditions, driver needs

to correct the vehicle's direction with dr iver's steering operation to avoid accidents.

When the LDP system is operating, avoid excessive or sudden steering maneuvers. Otherwise, driver could

lose control of the vehicle.

The LDP system will not operate at speeds below approxim ately 70 km/h (45 MPH) or if it cannot detect lane

markers.

The LDP system may not function properly under the following conditions, and do not use the LDP system:

- During bad weather (rain, fog, snow, wind, etc.).

- When driving on slippery roads, such as on ice or snow, etc.

- When driving off-road such as on sand or rock, etc.

- When driving on winding or uneven roads.

- When there is a lane closure due to road repairs.

- When driving in a makeshift lane.

- When driving on roads where the lane width is too narrow.

Revision: 2010 May2011 QX56

Page 1254 of 5598

![INFINITI QX56 2011 Factory Service Manual

DAS

HANDLING PRECAUTIONDAS-289

< SYSTEM DESCRIPTION > [LDW & LDP]

C

D

E

F

G H

I

J

K L

M B

N P A

- When driving without normal tire conditions (for example, tire wear, low tire pressure, installation INFINITI QX56 2011 Factory Service Manual

DAS

HANDLING PRECAUTIONDAS-289

< SYSTEM DESCRIPTION > [LDW & LDP]

C

D

E

F

G H

I

J

K L

M B

N P A

- When driving without normal tire conditions (for example, tire wear, low tire pressure, installation](/img/42/57033/w960_57033-1253.png)

DAS

HANDLING PRECAUTIONDAS-289

< SYSTEM DESCRIPTION > [LDW & LDP]

C

D

E

F

G H

I

J

K L

M B

N P A

- When driving without normal tire conditions (for example, tire wear, low tire pressure, installation of spare tire, tire chains, non-standard wheels).

- When the vehicle is equipped with non-origi nal brake parts or suspension parts.

- When towing a trailer or other vehicle.

Excessive noise will interfere with the warning chime sound, and the chime may not be heard.

The functions of the LDP system (warning and brake control assist) may or may not operate properly under

the following conditions:

- On roads where there are multiple parallel lane marker s; lane markers that are faded or not painted clearly;

yellow painted lane markers; non-standard lane markers or lane markers covered with water, dirt or snow,

etc.

- On roads where discontinued lane markers are still detectable.

- On roads where there are sharp curves.

- On roads where there are sharply contrasting objects, such as shadows, snow, water, wheel ruts, seams or

lines remaining after road repairs (The LDP syste m could detect these items as lane markers.).

- On roads where the traveling lane merges or separates.

- When the vehicle's traveling direction does not align with the lane marker.

- When traveling close to other vehicle in front of the vehicle, which obstructs the lane camera unit detection

range.

- When rain, snow or dirt adheres to the windshield in front of the lane camera unit.

- When the headlights are not bright due to dirt on the lens or if the aiming is not adjusted properly.

- When strong light enters the lane camera unit (For example, the light directly shines on the front of the vehi-

cle at sunrise or sunset.)

- When a sudden change in brightness occurs (For exampl e, when the vehicle enters or exits a tunnel or

under a bridge.)

While the LDP system is operating, driver may hear a sound of brake operation. This is normal and indicates

that the LDP system is operating properly.

Revision: 2010 May2011 QX56

Page 1366 of 5598

![INFINITI QX56 2011 Factory Service Manual

DAS

NORMAL OPERATING CONDITIONDAS-401

< SYMPTOM DIAGNOSIS > [LDW & LDP]

C

D

E

F

G H

I

J

K L

M B

N P A

NORMAL OPERATING CONDITION

DescriptionINFOID:0000000006223842

PRECAUTIONS FOR LANE DEPARTURE WARN INFINITI QX56 2011 Factory Service Manual

DAS

NORMAL OPERATING CONDITIONDAS-401

< SYMPTOM DIAGNOSIS > [LDW & LDP]

C

D

E

F

G H

I

J

K L

M B

N P A

NORMAL OPERATING CONDITION

DescriptionINFOID:0000000006223842

PRECAUTIONS FOR LANE DEPARTURE WARN](/img/42/57033/w960_57033-1365.png)

DAS

NORMAL OPERATING CONDITIONDAS-401

< SYMPTOM DIAGNOSIS > [LDW & LDP]

C

D

E

F

G H

I

J

K L

M B

N P A

NORMAL OPERATING CONDITION

DescriptionINFOID:0000000006223842

PRECAUTIONS FOR LANE DEPARTURE WARNING (LDW)

LDW system is only a warning devic e to inform the driver of a potential unintended lane departure. It will not

steer the vehicle or prevent loss of c ontrol. It is the driver’s responsibility to stay alert, drive safely, keep the

vehicle in the traveling lane, and be in control of the vehicle at all times.

LDW system will not operate at s peeds below approximately 70 km/h (45 MPH) or if it cannot detect lane

markers.

Excessive noise will interfere with the warning chime sound, and the chime may not be heard.

LDW system may not function properly under the following conditions:

- On roads where there are multiple parallel lane marker s; lane markers that are faded or not painted clearly;

yellow painted lane markers; non-standard lane markers; or lane markers covered with water, dirt or snow,

etc.

- On roads where the discontinued lane markers are still detectable.

- On roads where there are sharp curves.

- On roads where there are sharply contrasting objects, such as shadows, snow, water, wheel ruts, seams or

lines remaining after road repairs. (The LDW syst em could detect these items as lane markers.)

- On roads where the traveling lane merges or separates.

- When the vehicle's traveling direction does not align with the lane marker.

- When traveling close to other vehicle in front of the vehicle, which obstructs the lane camera unit detection

range.

- When rain, snow or dirt adheres to the windshield in front of the lane camera unit.

- When the headlights are not bright due to dirt on the lens or if the aiming is not adjusted properly.

- When strong light enters the lane camera unit. (For example, the light directly shines on the front of the vehi-

cle at sunrise or sunset.)

- When a sudden change in brightness occurs. (For exampl e, when the vehicle enters or exits a tunnel or

under a bridge.)

PRECAUTIONS FOR LANE DEPARTURE PREVENTION (LDP)

LDP system will not steer the vehicle or prevent loss of control. It is the driver’s responsibility to stay alert,

drive safely, keep the vehicle in the traveling lane, and be in control of vehicle at all times.

LDP system is primarily intended for use on well-devel oped freeways or highways. It may not detect the lane

markers in certain roads, weather or driving conditions.

Using the LDP system under some conditions of road, lane marker or weather, or when driver change lanes

without using the turn signal could lead to an unexpect ed system operation. In such conditions, driver needs

to correct the vehicle's direction with dr iver's steering operation to avoid accidents.

When the LDP system is operating, avoid excessive or sudden steering maneuvers. Otherwise, driver could

lose control of the vehicle.

The LDP system will not operate at speeds below approximat ely 70 km/h (45 MPH) or if it cannot detect lane

markers.

The LDP system may not function properly under the following conditions, and do not use the LDP system:

- During bad weather (rain, fog, snow, wind, etc.).

- When driving on slippery roads, such as on ice or snow, etc.

- When driving on winding or uneven roads.

- When there is a lane closure due to road repairs.

- When driving in a makeshift lane.

- When driving on roads where the lane width is too narrow.

- When driving with a tire that is not within normal tire c onditions (for example, tire wear, low tire pressure,

installation of spare tire, tire chains, non-standard wheels).

- When the vehicle is equipped with non-origi nal brake parts or suspension parts.

Excessive noise will interfere with the warning chime sound, and the chime may not be heard.

The functions of the LDP system (warning and brake control assist) may or may not operate properly under

the following conditions:

- On roads where there are multiple parallel lane marker s; lane markers that are faded or not painted clearly;

yellow painted lane markers; non-standard lane markers or lane markers covered with water, dirt or snow,

etc.

- On roads where discontinued lane markers are still detectable.

- On roads where there are sharp curves.

Revision: 2010 May2011 QX56

Page 1788 of 5598

DLK-252

< REMOVAL AND INSTALLATION >

CAB MOUNTING INSULATOR

Drain brake fluid from brake line. Refer to BR-10, "Draining".

Release fuel pressure. Refer to EC-153, "

Work Procedure".

Disconnect both battery cables. Refer to PG-164, "

Removal and Installation".

Drain engine coolant from radiator. Refer to CO-8, "

Draining".

Discharge refrigerant from A/C circuit. Refer to HA-20, "

Recycle Refrigerant".

Drain power steering fluid from reservoir tank.

4. Remove parts relating to connection of body assembly and frame assembly. Tire and wheel: Refer to WT-64, "

Removal and Installation" (with TPMS).

Front fender protector (LH and RH): Refer to EXT-23, "

FENDER PROTECTOR : Removal and Installa-

tion".

Front bumper: Refer to EXT-13, "

Removal and Installation".

Radiator core support upper: Refer to DLK-220, "

Removal and Installation".

Fan shroud: Refer to CO-16, "

Removal and Installation".

Battery and battery case: Refer to PG-164, "

Removal and Installation".

Air cleaner case (upper and lower): Refer to EM-27, "

Removal and Installation".

Engine cover: Refer to EM-25, "

Removal and Installation".

Rear wheel house protector (LH and RH): EXT-24, "

REAR WHEEL HOUSE PROTECTOR : Removal

and Installation".

Rear bumper: Refer to EXT-17, "

Removal and Installation".

Fuel filler tube: Remove to FL-8, "

Exploded View".

Spare tire

Towing hook bracket.

5. Separate parts relating to connection of body assembly and frame assembly. Vehicle front

Disconnect ICC sensor connector. (models with ICC) Refer to CCS-176, "

Removal and Installation".

Remove radiator upper hose and radiator lower hose from radiator assembly. Refer to CO-13,

"Exploded View".

Remove A/T fluid cooler hose B and A/T fluid cooler hose E from A/T fluid cooler tubes. Refer to TM-

202, "Exploded View".

Remove power steering return hose from oil cooler, and then power steering return hose clamp bolt from frame assembly. Refer to ST-54, "

Exploded View".

Remove power steering suction hose from reservoir tank. Refer to ST-54, "

Exploded View".

CAUTION:

Never spill power steering fluid in engine room.

Remove A/C low-presser flexible hose from A/C low-presser pipe. Refer to HA-35, "

LOW-PRESSURE

FLEXIBLE HOSE : Removal and Installation".

Remove A/C hi-presser flexible hose from condenser. Refer to HA-34, "

HIGH-PRESSURE FLEXIBLE

HOSE : Removal and Installation".

Remove all engine Control Harness connectors, har ness clips and others that are connected to the

body assembly side of the engine room. (engine room LH and RH side). Refer to PG-148, "

Engine Con-

trol Harness".

NOTE:

Separate harness connectors from ECM (engine control module). Refer to EC-10, "

General Precau-

tions".

CAUTION:

When pulling out harnesses, never damage harnesses or connectors.

After temporarily securing connectors, cover th em with vinyl or similar material to protect

against adhesion of foreign materials.

Disconnect engine room harness connectors and remo ve harness clips from engine assembly (engine

RH side). Refer to PG-146, "

Engine Room Harness".

Remove heater hoses from front water outlet tube (engine room RH side). Refer to HA-33, "

Exploded

View".

Disconnect front wheel sensor connectors (LH and RH). Refer to BRC-134, "

FRONT WHEEL SENSOR

: Exploded View".

Disconnect fuel feed tube and EVAP hos e (front wheel well LH side).

Remove steering lower shaft from steering gear side assembly. Refer to ST-37, "

Removal and Installa-

tion"

CAUTION:

Spiral cable may be cut if steering wheel turns while separating steering column assembly and

steering gear assembly.

Revision: 2010 May2011 QX56

Page 2945 of 5598

PRECAUTIONSFSU-3

< PRECAUTION >

C

DF

G H

I

J

K L

M A

B

FSU

N

O P

5. When the repair work is completed, re-connect both battery cables. With the brake pedal released, turn

the push-button ignition switch from ACC position to ON position, then to LOCK position. (The steering

wheel will lock when the push-button ignition switch is turned to LOCK position.)

6. Perform self-diagnosis check of a ll control units using CONSULT-III.

Precaution for Procedure without Cowl Top CoverINFOID:0000000006271994

When performing the procedure after removing cowl top cover, cover

the lower end of windshield with urethane, etc.

Precautions for SuspensionINFOID:0000000006225635

When installing rubber bushings, the final tightening mu st be carried out under unladen conditions with tires

on ground. Spilled oil might shorten the life of rubb er bushings. Be sure to wipe off any spilled oil.

- Unladen conditions mean that fuel, engine coolant and l ubricant are full. Spare tire, jack, hand tools and

mats are in designated positions.

After servicing suspension parts, be sure to check wheel alignment.

Self-lock nuts are not reusable. Always use new ones w hen installing. Since new self-lock nuts are pre-oiled,

tighten as they are.

PIIB3706J

Revision: 2010 May2011 QX56

Page 2949 of 5598

WHEEL ALIGNMENTFSU-7

< PERIODIC MAINTENANCE >

C

DF

G H

I

J

K L

M A

B

FSU

N

O P

WHEEL ALIGNMENT

InspectionINFOID:0000000006225640

DESCRIPTION

Measure wheel alignment under unladen conditions.

NOTE:

“Unladen conditions” means that fuel, engine coolant, and lubricant are full. Spare tire, jack, hand tools and

mats are in designated positions.

PRELIMINARY CHECK

Check the following:

Tires for improper air pressure and wear

Road wheels for runout: Refer to WT-64, "

Inspection".

Wheel bearing axial end play: Refer to FA X - 7 , "

Inspection" (2WD), FAX-16, "Inspection" (4WD).

Lower link and upper link ball joint axial end play: Refer to FSU-15, "

Inspection" and FSU-18, "Inspection".

Shock absorber operation.

Each mounting part of axle and suspension for looseness and deformation

Lower link for cracks, deformation and other damage

Vehicle height (posture)

GENERAL INFORMATION AND RECOMMENDATIONS

A four-wheel thrust alignment should be performed.

- This type of alignment is recomm ended for any NISSAN/INFINITI vehicle.

- The four-wheel “thrust” process helps ensure that t he vehicle is properly aligned and the steering wheel is

centered.

- The alignment rack itself should be capable of accepting any NISSAN/INFINITI vehicle.

- The rack should be checked to ensure that it is level.

Make sure the machine is properly calibrated.

- Your alignment equipment should be regularly ca librated in order to give correct information.

- Check with the manufacturer of your specific equi pment for their recommended Service/Calibration Sched-

ule.

ALIGNMENT PROCESS

IMPORTANT:

Use only the alignment specificati ons listed in this Service Manual.

When displaying the alignment settings, many alignment machines use “indicators”: (Green/red, plus or

minus, Go/No Go). Never use these indicators.

- The alignment specifications programmed into your machine that operate these indicators may not be cor-

rect.

- This may result in an ERROR.

Some newer alignment machines are equipped with an optional “Rolling Compensation” method to “com-

pensate” the sensors (alignment targets or head units). Never use this “Rolling Compensation” method.

- Use the “Jacking Compensation Method”. After installi ng the alignment targets or head units, raise the vehi-

cle and rotate the wheels 1/2 turn both ways.

- See Instructions in the alignment machine you're using for more information on this.

AdjustmentINFOID:0000000006225641

CAMBER, CASTER

1. Adjust with the front/rear side adjusting bolts (1) on the lower link

(2).

2. See the following table for the amount of cam bolt scale move- ment and the variation of camber and caster.

CAUTION:

Align the adjusting bolt cutout with the stamp of lower link

bracket.

: Vehicle front

JPEIA0235ZZ

Revision: 2010 May2011 QX56

Page 2963 of 5598

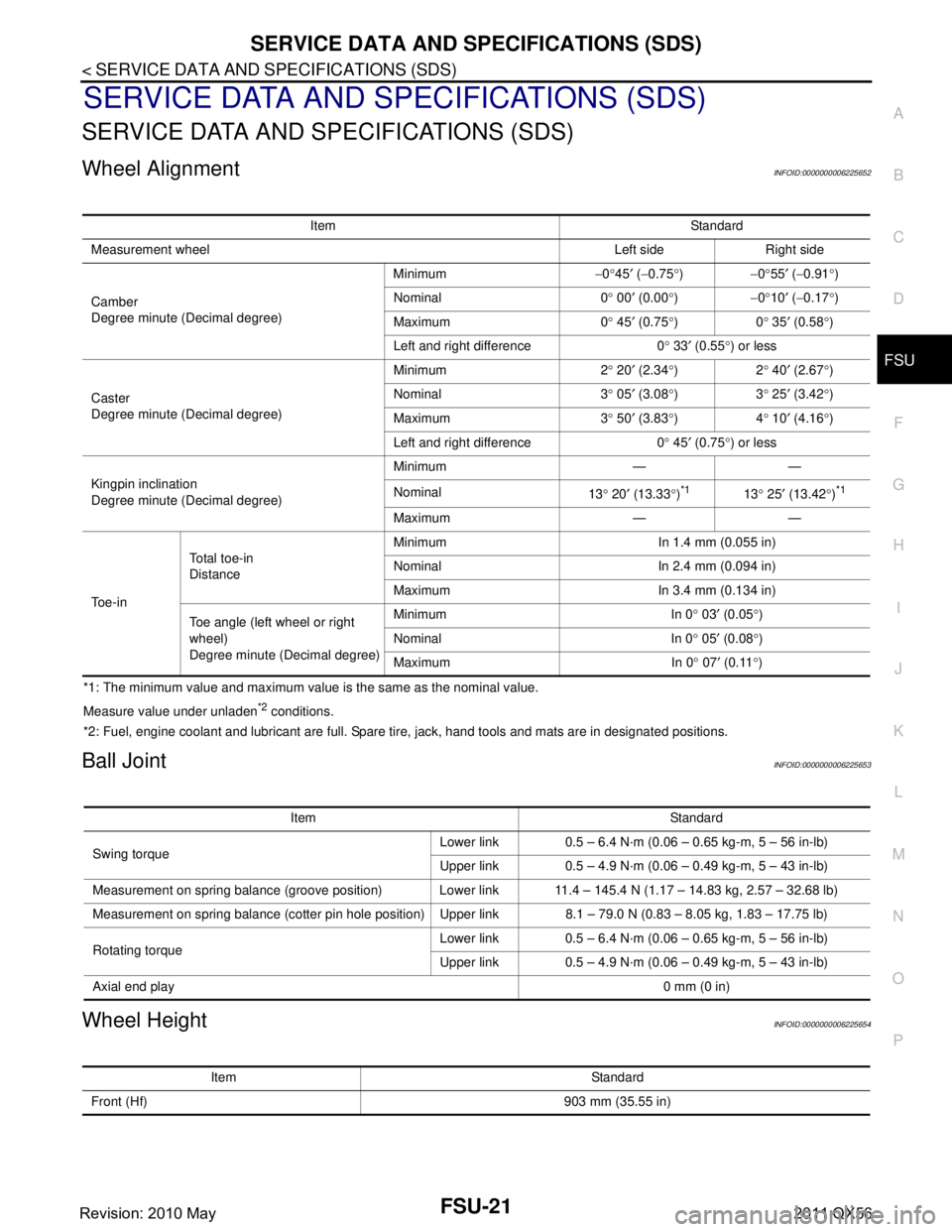

SERVICE DATA AND SPECIFICATIONS (SDS)

FSU-21

< SERVICE DATA AND SPECIFICATIONS (SDS)

C

D F

G H

I

J

K L

M A

B

FSU

N

O P

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

Wheel AlignmentINFOID:0000000006225652

*1: The minimum value and maximum value is the same as the nominal value.

Measure value under unladen

*2 conditions.

*2: Fuel, engine coolant and lubricant are full. Spare tire, jack, hand tools and mats are in designated positions.

Ball JointINFOID:0000000006225653

Wheel HeightINFOID:0000000006225654

Item Standard

Measurement wheel Left side Right side

Camber

Degree minute (Decimal degree) Minimum

−0 °45 ′ ( −0.75 °) −0°55 ′ ( −0.91 °)

Nominal 0 ° 00 ′ (0.00 °) −0°10 ′ ( −0.17 °)

Maximum 0 ° 45 ′ (0.75 °)0 ° 35 ′ (0.58 °)

Left and right difference 0 ° 33 ′ (0.55 °) or less

Caster

Degree minute (Decimal degree) Minimum 2

° 20 ′ (2.34 °)2 ° 40 ′ (2.67 °)

Nominal 3 ° 05 ′ (3.08 °)3 ° 25 ′ (3.42 °)

Maximum 3 ° 50 ′ (3.83 °)4 ° 10 ′ (4.16

° )

Left and right difference 0 ° 45 ′ (0.75 °) or less

Kingpin inclination

Degree minute (Decimal degree) Minimum — —

Nominal

13° 20 ′ (13.33 °)

*113 ° 25 ′ (13.42 °)*1

Maximum — —

To e - i n To t a l t o e - i n

Distance

Minimum In 1.4 mm (0.055 in)

Nominal In 2.4 mm (0.094 in)

Maximum In 3.4 mm (0.134 in)

Toe angle (left wheel or right

wheel)

Degree minute (Decimal degree) Minimum In 0

° 03 ′ (0.05 °)

Nominal In 0 ° 05 ′ (0.08 °)

Maximum In 0 ° 07 ′ (0.11 °)

Item Standard

Swing torque Lower link 0.5 – 6.4 N·m (0.06 – 0.65 kg-m, 5 – 56 in-lb)

Upper link 0.5 – 4.9 N·m (0.06 – 0.49 kg-m, 5 – 43 in-lb)

Measurement on spring balance (groove position) Lower link 11.4 – 145.4 N (1.17 – 14.83 kg, 2.57 – 32.68 lb)

Measurement on spring balance (cotter pin hole position) Upper link 8.1 – 79.0 N (0.83 – 8.05 kg, 1.83 – 17.75 lb)

Rotating torque Lower link 0.5 – 6.4 N·m (0.06 – 0.65 kg-m, 5 – 56 in-lb)

Upper link 0.5 – 4.9 N·m (0.06 – 0.49 kg-m, 5 – 43 in-lb)

Axial end play 0 mm (0 in)

Item Standard

Front (Hf) 903 mm (35.55 in)

Revision: 2010 May2011 QX56

Page 2989 of 5598

IDENTIFICATION INFORMATIONGI-25

< VEHICLE INFORMATION >

C

DE

F

G H

I

J

K L

M B

GI

N

O P

DimensionsINFOID:0000000006280863

Unit: mm (in)

Wheels & TiresINFOID:0000000006280864

: Vehicle front

JPAIA0770ZZ

Overall length 5,290 (208.3)

Overall width 2,030 (79.9)

Overall height 1,925 (75.8)

Front tread 1,715 (67.5)

Rear tread 1,725 (67.9)

Wheelbase 3,075 (121.1)

ConventionalTire

20 inch P275/60R20 114H

22 inch P275/50R22 111H

Road wheel 20 inch

(Aluminum)

Size 20

× 8J

Offset 30 mm (1.18 in)

22 inch

(Aluminum) Size 22

× 8J

Offset 30 mm (1.18 in)

Spare Tire

20 inch P275/60R20 114H

22 inch P275/50R22 111H

Road wheel 20 inch

(Aluminum)

Size 20

× 8J

Offset 30 mm (1.18 in)

22 inch

(Aluminum) Size 22

× 8J

Offset 30 mm (1.18 in)

Revision: 2010 May2011 QX56