warning INFINITI QX56 2011 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 1741 of 5598

AUTOMATIC BACK DOOR WARNING DOES NOT OPERATE

DLK-205

< SYMPTOM DIAGNOSIS >

C

D E

F

G H

I

J

L

M A

B

DLK

N

O P

Check hazard and horn reminder function.

Is the inspection result normal?

YES >> GO TO 5.

NO >> Refer to DLK-183, "

Diagnosis Procedure".

5.REPLACE AUTOMATIC BACK DOOR CONTROL MODULE

1. Replace automatic back door control module. Refer to DLK-262, "

Removal and Installation".

2. Confirm the operation after replacement.

Is the result normal?

YES >> INSPECTION END

NO >> Check intermittent incident. Refer to GI-40, "

Intermittent Incident".

Revision: 2010 May2011 QX56

Page 1751 of 5598

HOOD

DLK-215

< REMOVAL AND INSTALLATION >

C

D E

F

G H

I

J

L

M A

B

DLK

N

O P

REMOVAL AND INSTALLATION

HOOD

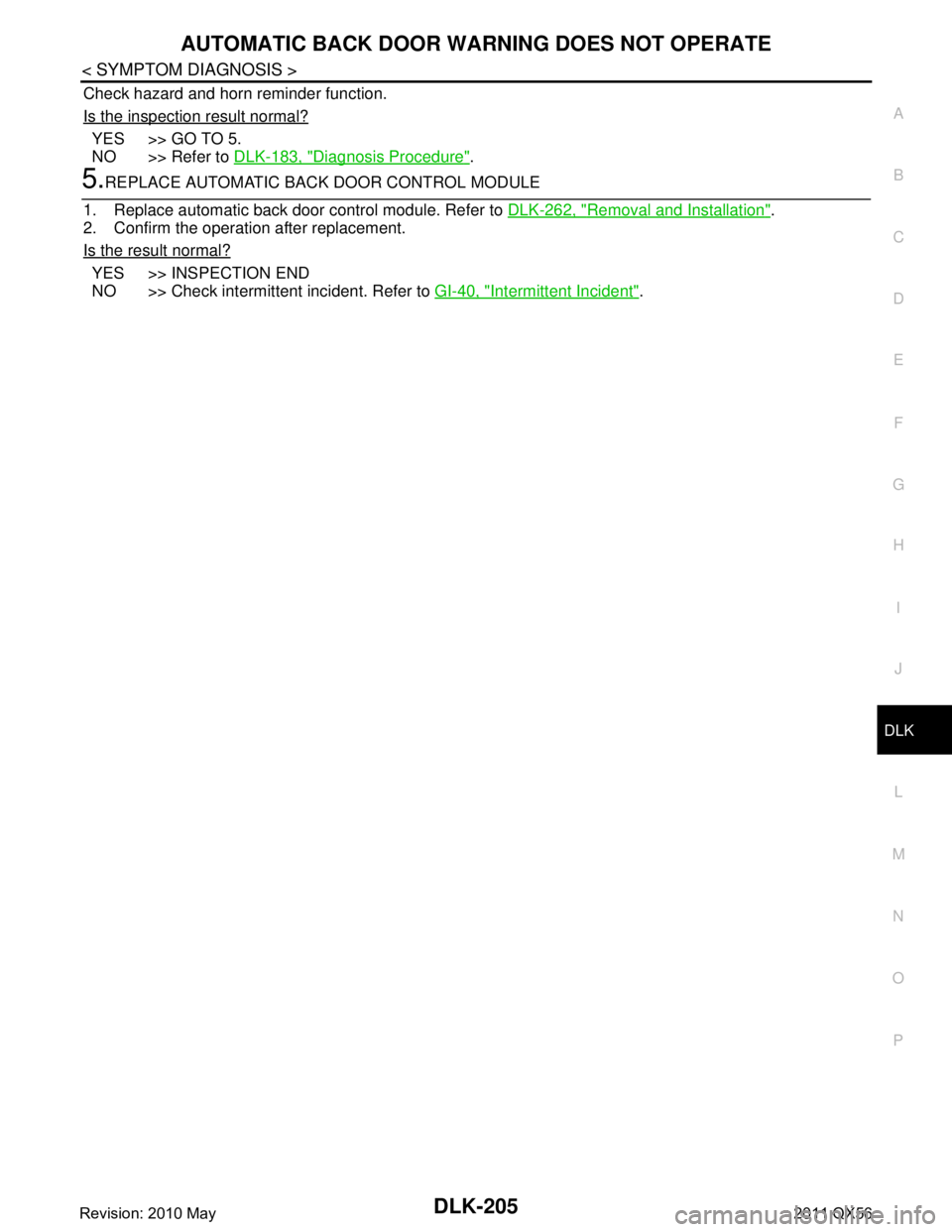

Exploded ViewINFOID:0000000006226062

HOOD ASSEMBLY

HOOD ASSEMBLY : Removal and InstallationINFOID:0000000006226063

CAUTION:

Operate with two workers, because of its heavy weight.

Use protective tape or shop cloth to protect from damage during removal and installation.

REMOVAL

1. Support hood assembly with the proper material to prevent it from falling.

WARNING:

Bodily injury may occur if no proper material is holding hood open when removing hood stay.

1. Hood assembly 2. Hood front seal 3. Radiator core seal

4. Hood insulator 5. Hood side bumper 6. Clip

7. Hood stay 8. Stud ball 9. Hood bumper rubber

10. Hood hinge

: Clip

Refer to GI-4, "

Components" for symbols in the figure.

JMKIA5477GB

Revision: 2010 May2011 QX56

Page 1754 of 5598

DLK-218

< REMOVAL AND INSTALLATION >

HOOD

After installation, apply touch-up paint (the body color) onto the head of hood hinge mountingbolts and nuts.

HOOD HINGE

HOOD HINGE : Removal and InstallationINFOID:0000000006226065

REMOVAL

1. Remove hood assembly. Refer to DLK-215, "HOOD ASSEMBLY : Removal and Installation".

2. Remove front fender cover. Refer to EXT-21, "

Exploded View".

3. Remove front fender mounting bolt. DLK-222, "

Exploded View".

4. Remove hood hinge mounting bolts, and then remove hood hinge.

INSTALLATION

Note the following items, and install in the reverse order of removal.

CAUTION:

Before installation of hood hing e, apply anticorrosive agent onto the mounting surface of the vehicle

body.

After installation, apply touch-up paint (the body color) onto the head of the hinge mounting bolts

and nuts.

After installation, perform hood fitting adjustment. Refer to DLK-216, "

HOOD ASSEMBLY : Adjust-

ment".

HOOD STAY

HOOD STAY : Removal and InstallationINFOID:0000000006226066

REMOVAL

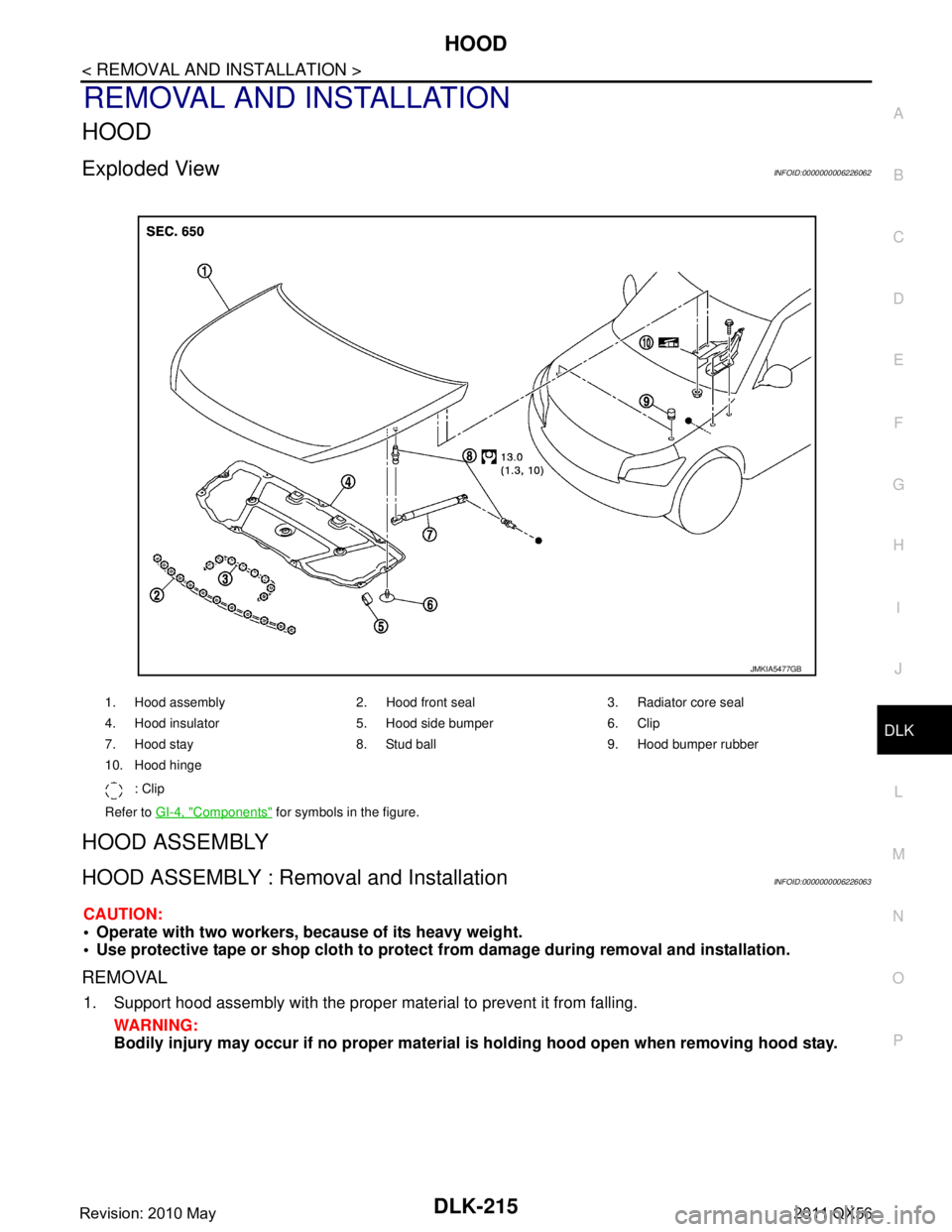

1. Support hood assembly with a proper material to prevent it from falling.

WARNING:

Bodily injury may occur if no proper material is holding the hood open when removing the hood

stay.

2. Remove the metal clip (3) located on the connection between the hood stay (1) and the stud ball (2) (hood side), by using a

flat-bladed screwdriver (A).

3. Disengage the stud ball from the hood stay (hood side).

4. Repeat the same operation to disengage the stud ball from the hood stay (body side), then remove the hood stay.

INSTALLATION

Install in the reverse order of removal.

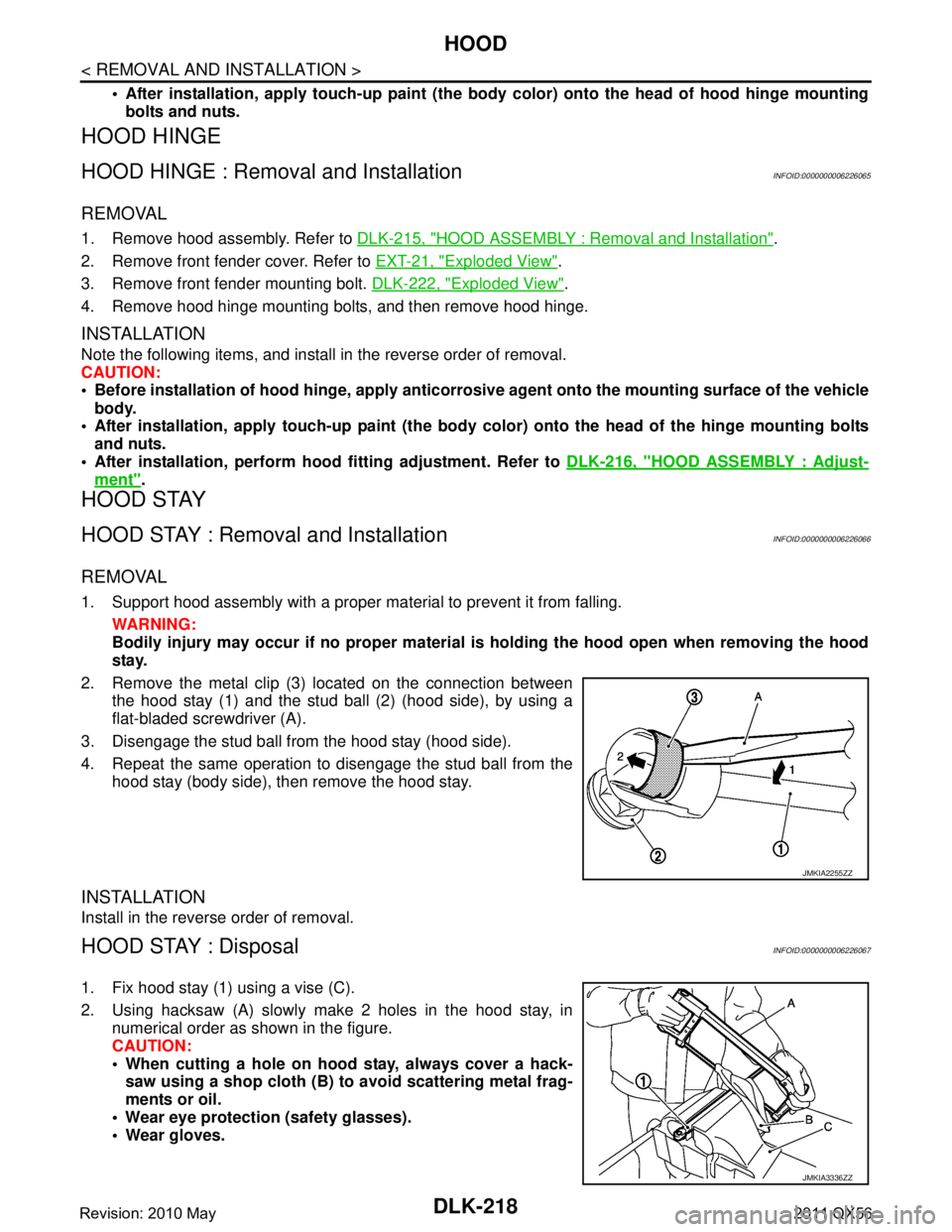

HOOD STAY : Disposal INFOID:0000000006226067

1. Fix hood stay (1) using a vise (C).

2. Using hacksaw (A) slowly make 2 holes in the hood stay, innumerical order as shown in the figure.

CAUTION:

When cutting a hole on hood stay, always cover a hack-saw using a shop cloth (B) to avoid scattering metal frag-

ments or oil.

Wear eye protection (safety glasses).

Wear gloves.

JMKIA2255ZZ

JMKIA3336ZZ

Revision: 2010 May2011 QX56

Page 1769 of 5598

BACK DOORDLK-233

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

L

M A

B

DLK

N

O P

3. Disconnect back door harness connectors (A) and remove back door harness clip (B).

4. Remove back door harness grommet, and then pull harness out of vehicle through roof panel hole.

5. Disconnect washer tube.

6. Remove washer tube grommet, and then pull was her tube out of vehicle through roof panel hole.

7. Support back door lock with the proper material to prevent it from falling. WARNING:

Body injury may occur if no sup porting rod is holding the back door open when removing the

back door stay.

8. Remove back door stay. Refer to DLK-236, "

BACK DOOR STAY : Removal and Installation".

9. Remove back door hinge mounting nuts on back door and remove back door assembly.

INSTALLATION

Note the following items, and then install in the reverse order of removal.

CAUTION:

Apply anticorrosive agen t onto the mounting surface.

Check back door open/close, lock/un lock operation after installation.

After installation, perform fitting adjustment. Refer to DLK-234, "

BACK DOOR ASSEMBLY : Adjust-

ment".

JMKIA5262ZZ

Revision: 2010 May2011 QX56

Page 1772 of 5598

DLK-236

< REMOVAL AND INSTALLATION >

BACK DOOR

BACK DOOR HINGE

BACK DOOR HINGE : Removal and InstallationINFOID:0000000006226090

CAUTION:

Operate with two workers, because of its heavy weight.

Use protective tape or cloth to protect fr om damage during remove and installation.

REMOVAL

1. Remove back door assembly. Refer to DLK-232, "BACK DOOR ASSEMBLY : Removal and Installation".

2. Remove back door hinge mounting nuts (body side), and then remove back door hinge.

INSTALLATION

Note the following items, and then install in the reverse order of removal.

CAUTION:

Apply anticorrosive agent onto the mounting surface.

Check back door open/close op eration after installation.

Check back door hinge ro tating part for poor lubricatio n. If necessary, apply body grease.

When removing and installing back door assembly, perform the fitting adjustment. Refer to DLK-234,

"BACK DOOR ASSEMBLY : Adjustment".

After installation, apply touch-up paint (the body color) onto the head of back door hinge mounting

nuts.

BACK DOOR STAY

BACK DOOR STAY : Removal and InstallationINFOID:0000000006226091

REMOVAL

1. Support back door lock with the proper material to prevent it from falling.

WARNING:

Body injury may occur if no su pporting rod is holding the back door op en when removing the

back door stay.

2. Remove the metal clip (3) located on the connection between the back door stay (1) and the stud ball (2) (back door side) by

using a flatted-blade screwdriver (A).

3. Remove back door stay (back door side).

4. In the same way, remove back door stay (body side).

INSTALLATION

Note the following item, and then install in the reverse order of removal.

CAUTION:

Check back door open/close ope ration after installation.

JMKIA2255ZZ

Revision: 2010 May2011 QX56

Page 1794 of 5598

DLK-258

< REMOVAL AND INSTALLATION >

INTELLIGENT KEY WARNING BUZZER

INTELLIGENT KEY WARNING BUZZER

Removal and InstallationINFOID:0000000006226125

REMOVAL

Remove the Intelligent Key warning buzzer mounting bolt, and then remove the Intelligent Key warning

buzzer.

INSTALLATION

Install in the reverse order of removal.

Revision: 2010 May2011 QX56

Page 1799 of 5598

AUTOMATIC BACK DOOR WARNING BUZZERDLK-263

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

L

M A

B

DLK

N

O P

AUTOMATIC BACK DOOR WARNING BUZZER

Removal and InstallationINFOID:0000000006226130

REMOVAL

1. Remove the back door finisher inner. Refer to INT-39, "Removal and Installation".

2. Remove the automatic back door warning buzzer mounting nut, and then remove the automatic back door

warning buzzer.

INSTALLATION

Install in the reverse order of removal.

Revision: 2010 May2011 QX56

Page 1805 of 5598

DLN-3

CEF

G H

I

J

K L

M A

B

DLN

N

O P

U1000 CAN COMM CIRCUIT ......................... ....91

Description .......................................................... ....91

DTC Logic ...............................................................91

Diagnosis Procedure ...............................................91

U1010 CONTROL UNIT (CAN) ..........................92

Description .......................................................... ....92

DTC Logic ...............................................................92

Diagnosis Procedure ...............................................92

POWER SUPPLY AND GROUND CIRCUIT ......93

Description .......................................................... ....93

Diagnosis Procedure ...............................................93

4WD WARNING LAMP ......................................97

Component Function Check ................................ ....97

Diagnosis Procedure ...............................................97

4WD INDICATOR LAMP ....................................98

Component Function Check ................................ ....98

Diagnosis Procedure ...............................................98

SYMPTOM DIAGNOSIS ..............................99

HEAVY TIGHT-CORNER BRAKING SYMP-

TOM OCCURS . .............................................. ....

99

Description .......................................................... ....99

Diagnosis Procedure ...............................................99

4WD MODE DOES NOT CHANGE ..................100

Description .......................................................... ..100

Diagnosis Procedure .............................................100

4WD MODE INDICATOR LAMP CONTINUES

BLINKING .........................................................

101

Description .......................................................... ..101

Diagnosis Procedure .............................................101

4WD WARNING LAMP BLINKS QUICKLY .....102

Description .......................................................... ..102

4WD WARNING LAMP BLINKS SLOWLY .....103

Description .......................................................... ..103

Diagnosis Procedure .............................................103

INFORMATION DISPLAY IS NOT DIS-

PLAYED ...........................................................

104

Description .......................................................... ..104

Diagnosis Procedure .............................................104

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING ..........................

105

NVH Troubleshooting Chart ................................ ..105

PERIODIC MAINTENANCE .......................106

TRANSFER FLUID ......................................... ..106

Inspection ............................................................ ..106

Draining .................................................................106

Refilling .................................................................106

REMOVAL AND INSTALLATION .............107

TRANSFER CONTROL UNIT .........................107

Removal and Installation ..................................... ..107

4WD MODE SWITCH ......................................108

Removal and Installation .......................................108

FRONT OIL SEAL ...........................................109

Exploded View .......................................................109

Removal and Installation .......................................109

REAR OIL SEAL .............................................111

Exploded View .......................................................111

Removal and Installation .......................................111

Adjustment .............................................................112

TRANSFER CONTROL ACTUATOR .............114

Exploded View .......................................................114

Removal and Installation .......................................114

Inspection ..............................................................114

TRANSFER HI-LO POSITION SENSOR ........116

Exploded View .......................................................116

Removal and Installation .......................................116

Inspection ..............................................................116

TRANSFER ROTARY POSITION SENSOR ...117

Exploded View .......................................................117

Removal and Installation .......................................117

Inspection ..............................................................118

TRANSFER LOCK POSITION SENSOR ........119

Exploded View .......................................................119

Removal and Installation .......................................119

Inspection ..............................................................119

TRANSFER FLUID TEMPERATURE SEN-

SOR .................................................................

120

Exploded View .......................................................120

Removal and Installation .......................................120

Inspection ..............................................................120

UNIT REMOVAL AND INSTALLATION ....121

TRANSFER ASSEMBLY ................................121

Exploded View ..................................................... ..121

Removal and Installation .......................................121

INPUT OIL SEAL ............................................123

Exploded View .......................................................123

Removal and Installation .......................................123

SERVICE DATA AND SPECIFICATIONS

(SDS) ............... ...........................................

124

SERVICE DATA AND SPECIFICATIONS

(SDS) ...............................................................

124

General Specifications ......................................... ..124

FRONT PROPELLER SHAFT: 2F P15

PREPARATION ........ .................................

125

PREPARATION ...............................................125

Revision: 2010 May2011 QX56

Page 1808 of 5598

![INFINITI QX56 2011 Factory Service Manual

DLN-6

< PRECAUTION >[TRANSFER: ATX90A]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint S

ystem (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000006222209

The Supp INFINITI QX56 2011 Factory Service Manual

DLN-6

< PRECAUTION >[TRANSFER: ATX90A]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint S

ystem (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000006222209

The Supp](/img/42/57033/w960_57033-1807.png)

DLN-6

< PRECAUTION >[TRANSFER: ATX90A]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint S

ystem (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000006222209

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the “SRS AIR BAG” and “SEAT BELT” of this

Service Manual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision that would result in air bag inflation, all maintenance must be performed by

an authorized NISS AN/INFINITI dealer.

Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the “SRS AIR BAG”.

Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

When working near the Air Bag Diagnosis Sensor Unit or other Air Bag System sensors with the ignition ON or engine running, DO NOT use air or electric power tools or strike near the sensor(s)

with a hammer. Heavy vibration could activate the sensor(s) and deploy the air bag(s), possibly

causing serious injury.

When using air or electric power tools or hammers , always switch the ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution Necessary for Steering W heel Rotation after Battery Disconnect

INFOID:0000000006222210

NOTE:

Before removing and installing any control units, first tu rn the push-button ignition switch to the LOCK posi-

tion, then disconnect bot h battery cables.

After finishing work, confirm that all control unit connectors are connected properly, then re-connect both

battery cables.

Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If a DTC is detected, perform trouble diagnos is according to self-diagnosis results.

For vehicle with steering lock unit, if the battery is disconnected or discharged, the steering wheel will lock and

cannot be turned.

If turning the steering wheel is required with the bat tery disconnected or discharged, follow the operation pro-

cedure below before starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Turn the push-button ignition switch to ACC position. (At this time, the steering lock will be released.)

3. Disconnect both battery cables. The steering lock wi ll remain released with both battery cables discon-

nected and the steering wheel can be turned.

4. Perform the necessary repair operation.

Revision: 2010 May2011 QX56

Page 1812 of 5598

![INFINITI QX56 2011 Factory Service Manual

DLN-10

< SYSTEM DESCRIPTION >[TRANSFER: ATX90A]

COMPONENT PARTS

SYSTEM DESCRIPTION

COMPONENT PARTS

Component Parts LocationINFOID:0000000006222214

1. ECM

Refer to EC-16, "

Component Parts

Location" INFINITI QX56 2011 Factory Service Manual

DLN-10

< SYSTEM DESCRIPTION >[TRANSFER: ATX90A]

COMPONENT PARTS

SYSTEM DESCRIPTION

COMPONENT PARTS

Component Parts LocationINFOID:0000000006222214

1. ECM

Refer to EC-16, "

Component Parts

Location"](/img/42/57033/w960_57033-1811.png)

DLN-10

< SYSTEM DESCRIPTION >[TRANSFER: ATX90A]

COMPONENT PARTS

SYSTEM DESCRIPTION

COMPONENT PARTS

Component Parts LocationINFOID:0000000006222214

1. ECM

Refer to EC-16, "

Component Parts

Location". 2. ABS actuator and electric unit (con-

trol unit)

Refer to BRC-10, "Component Parts

Location". 3. Steering angle sensor

Refer to BRC-10, "

Component Parts

Location".

4. Control valve & TCM Refer to TM-10, "

A/T CONTROL

SYSTEM : Compon ent Parts Loca-

tion". 5. Transfer control unit 6. 4WD switch assembly

7. Transfer lock position sensor 8. Transfer Hi-Lo position sensor 9. Transfer rotary position sensor

10. Transfer control actuator 11. Transfer fluid temperature sensor

A. Back of glove box assembly B. 4WD indicator lamp, 4WD warning lamp, ATP warning lamp (in combina-

tion meter)C. Console assembly

D. Transfer assembly upper side E. Transfer assembly under side

JPDIE0270GB

Revision: 2010 May2011 QX56